Radiation Protection:

advertisement

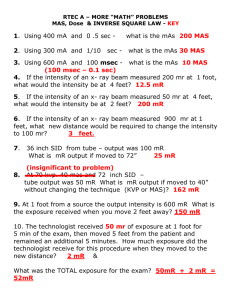

Radiographic Inspections Procedures for Digital and Conventional Radiographic Imaging Systems Lee W. Goldman Hartford Hospital Filling in the Gap Reasons for Rad or R/F Inspection State regulatory requirement 3rd party payer requirement Employer expectations (see following) Standards of good practice (see above) It is not uncommon that “inspections” include the minimum set of tests and evaluations needed to fulfill the expectation or legal requirement (perhaps due to time constraints and priorities) Philosophy of Inspections The goal of radiographic and fluoroscopic (R/F) inspections should be to provide value by evaluating and (if necessary) improving: radiation safety image quality image consistency This may entail going beyond commonly accepted standards to striving for stricter yet generally achievable performance levels Philosophy of Inspections Accomplishing this goal require thoroughness on the part of the inspecting physicist. Since “time is money”, emphasis must be placed on: efficiency of inspection methodology organization of work attention to frequent problem areas Sources of Requirements/Guidelines Radiographic and Fluoroscopic Units Visual Inspection/general Collimation: PBL (if so equiped) Grid alignment and focusing Light field illumination Half-value Layer Exposure timer accuracy Exposure reproducibility Exposure rates (mR/mAs): mA/mAs Linearity:# 0.1 kVp accuracy Focal spot size SID Indication Accuracy AEC (phototiming): Fluoro min source-skin distance Max fluoro entrance exposure rates (EER) Typical EER measurements Spot film exposures and rates Automatic brightness control function Fluoro resolution and sensitivity Fluoro/TV system lag, flare Criteria NCRP AAPM ACR ACMP CFR CFR CFR Annual Semiann Semiann Annual Annual Annual Annual Annual Annual Annual Annual New Annual Semiann Annual Semiann Semiann Semiann Semiann Semiann Semiann Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual New Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual --Annual Annual Annual Annual Annual Annual --Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual Annual --Annual Annual Annual Annual Annual Annual Annual Annual Annual CFR CFR CFR CFR CFR CFR CFR CFR Annual Annual Annual Annual Annual ---- Guidelines and Acceptance Limits Many items commonly evaluated physicists have performance levels specified by the Code of Federal Regulations (CFR) 21 Part 1020 For other items, recommendations from various organizations (AAPM, etc)are fairly consistent State law may impose stricter limits, require more frequent evaluations and include more test items If not legally mandated, acceptance criteria may depend on environment, equipment used, etc. Might recommend stricter criteria if reasonably achievable and provides appropriate benefits Efficiency of Methodology Combination of tests where appropriate Time saving tools Minimizing cassette/film usage (trips to the darkroom) Organization of Work Concise data forms: avoid multiple pages Sensible order: verify detents before AEC tests Effective reports: Clear summary, recommendations MODEL:____________________________________MAX mA:___________________ TUBE SER #:______________________________ CHAMBER:_________________ KVP ACCURACY AND EXPOSURE (mR/mAs): SELECTED TECHNIC kVp mA Sec mAs Focal-Chamber Distance: MEASURED KVP kV-1 SURVERYOR:_______________ CHAM CF:__________________ kV-2 kV-3 EXPOSURE (mR) AVG mR-1 mR-2 mR-3 CF: AVG CF mR/mAs 60 80 100 120 EXPOSURE LINEARITY, REPRODUCIBILITY AND TIMER ACCURACY: kVp:_________ Frequency of Radiographic Findings Year 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 Total: Total Collim kVp Reprod Linear Tim er SID Grid Fog 33 34 43 38 33 38 17 24 31 25 9% 18% 26% 26% 36% 39% 18% 33% 26% 28% 30% 21% 30% 24% 18% 11% 12% 29% 32% 28% 9% 6% 2% 5% 15% 3% 12% 0% 0% 8% 24% 21% 35% 32% 27% 13% 12% 17% 35% 28% 6% 3% 2% 5% 6% 3% 6% 0% 3% 4% 6% 12% 12% 5% 6% 3% 6% 0% 0% 4% 33% 35% 42% 42% 39% 29% 24% 33% 13% 8% 0% 6% 0% 0% 6% 11% 0% 8% 6% 8% 316 26% 24% 5.7% 25% 3.8% 5.7% 31% 4.4% Other: mR/mAs (1), HVL (1), Focal Spot (1), Artifacts (2) Inspection Factors for Digital Systems Many inspection components--no difference – kVp, mR/mAs, linearity, timer accuracy, HVL) For beam measurements (kVp, mR/Mas, etc) – Move tube off of digital receptor if possibile – If not, use lead blocker Some (may) require digital receptor to record – Collimation – Grid alignment – Focal spot size – SID Indication ---? Cardboard Cassettes or ReadyPack Radiographic Inspection Components Visual Inspection Beam Measurements (kVp, mR, HVL, etc) Receptor Tests: Grids, PBL, Coverage Tube Assembly Tests: Collim, Foc Spot, SID AEC (table and upright) Darkroom Tests (if applicable) Visual Inspection Visually evident deficiencies often ignored/worked around by staff Reporting deficiencies often leads to corrective actions Include: –Lights/LEDs working –Proper technique indication –Locks and interlocks work –No broken/loose dials, knobs –Any obvious electrical or mechanical defects X-ray Beam Measurements kVp accuracy AND reproducibility Exposure rates (mR/mAs) mA linearity – Adjacent station – Overall Exposure control – Timer accuracy – Timer and/or mAs linearity Reproducibility Half-Value Layer kVp Evaluation: Significance Total kVp Reprod Among 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 33 34 43 38 33 38 17 24 31 25 30% 21% 30% 24% 18% 11% 12% 29% 32% 28% 5% – Increase dose if kV’s too low 15% – Cause poor mA linearity, 3% 12%leading to possible repeats 0% Image contrast: affected, 0% but relatively minor effect 8% Total: 316 23.7% most common issue, even with HF 9% generators 6% 2% Poor kV calibration can: for ranges of miscalibration usually encountered 5.7% Causes of kV Miscalibration Inadequate provisions for kV adjustments – May have only one overall kV adjustments to raise or lower all kVps and one to adjust kV ramp – Result: difficult to properly calibration all stations Miscalibrated compensation circuits: – Initial sags or spikes as tube begins to energize – May significantly affect short exposure times Important to evaluate kV accuracy at several mA/kV combinations, and possibly all mA’s. Causes of HF kVp Miscalibration Pulse freq calibration: infrequent but seen on units invasively calibrated at generator rather than at tube Power line limitations: more common if powered by 1-phase line with inadequate power Units incorporating energy storage device helps Measuring kV: Yesterday Measuring kVp: Today kVp Measurements (Con’t) Invasive measurement: – still standard for many service personnel) Non-invasive kV meters (highly recommended): – Measurements at many settings practical--allows comprehensive eval of accuracy & reproducibility Understand characteristics of your kV meter – – – – – Minimum exposure time for accurate measurement Accuracy ~2%: beware of imposing tight limits Effect of mid- or HF (meters that sample waveform) Selection of waveform type Properly calibrated filtration range Effect of Filtration on kV Meters Measured kVp mm added Filtration Meter 1 Meter 2 MultiFunc 0 2 AL 0.1 Cu + 1 Al 0.2 Cu + 1 Al 79.2 79.8 81.1 83.8 80.1 82.5 84.8 82.2 79.1 79.2 79.2 79.3 kVp Waveforms Obtainable with meters having computer output Very useful to recognize cause of calibration problems(ramps, spikes, dropped cycles or phases) kV Waveform 70 60 50 kV 40 30 20 10 0 0 10 20 30 m illiseconds 40 50 60 kVp: Action Limits CFR: refers only to manufacturer’s specifications Manufacturer specs: often quite loose (eg, +/-7%) Common recommendations: 5% or 4-5 kV For consistency: differences between kV calibration at different mA stations may be more important than across-theboard errors: eg: 100 mA --> 80 kVp measured to be 84 200 mA --> 80 kVp measures to be 76 Both may yield similar intensities at receptor!! kVp Action Limits-Considerations Inconsistencies may be more important than across-the-board errors More important for multi-unit sites (technique consistency matters more) Older Generators: – Often difficult to accurately calibrate all mA/kV – Recalibrations may shift error to other ranges – More important to accurately calibrate limited but clinically important limited range May attempt improvements during next service or during servicing for other corrective actions X-ray Beam Measurements kVp accuracy AND reproducibility Exposure rates (mR/mAs) mA linearity Exposure control reproducibility Half-Value Layer Beam Exposure Measurements Year Total Repro Linear Timer 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 33 34 43 38 33 38 17 24 31 25 9% 6% 2% 5% 15% 3% 12% 0% 0% 8% 24% 21% 35% 32% 27% 13% 12% 17% 35% 28% 6% 3% 2% 5% 6% 3% 6% 0% 3% 4% Total: Other: 316 5.7% 25.3% mR/mAs (1), HVL (1) 3.8% PROBLEM FREQUENCIES Poor linearity (adjacent or a common problem Timer and Reproducibility issues occur less frequently Problems may appear only: – with certain mA settings – Under certain conditions – At certain kV ranges Important to evaluate many kV/mA settings!! Efficient Beam Measurements Valuable to make both kV and exposure measurements at many kV/mA settings. Appropriate to measure kV and exposure measurements simultaneously. May accomplish this via: – Appropriate (multipe) tools and test geometry – Multifunction meters Efficient Beam Measurements Multiple Meters Geometry with Multiple Detectors Scatter from kV meter (or other material) can significantly affect exposure measurement Procedures: – Tight collimation – Block scatter from dosimeter (air gap, foam spacer, lead blocker Efficient Beam Measurements Multifunction Meters X-ray Beam Measurements kVp accuracy AND reproducibility Exposure rates (mR/mAs) mA linearity Exposure control reproducibility Half-Value Layer Exposure Rates (mR/mAs) Measure at several mA/kV settings covering the commonly used clinical ranges – Can measure along with kVp (no add’l exposures) – Measure at relevant distance (eg, 30”) Normal ranges very broad: – Affected by filtration, age, kV and mA calibration – Common range (30”): 12 +/- 50% (3-phase, HF) – Narrow limits which have been published (6 mR/mAs +/- 1 at 100 cm) are not realistic Greatest value is for patient dose estimates X-ray Beam Measurements kVp accuracy AND reproducibility Exposure rates (mR/mAs) mA linearity Exposure control reproducibility Half-Value Layer Evaluating Linearity Both adjacent-station linearity as well as overall linearity (between any two mA stations) are important mA Linearity (con’t) Definition: L = (RmA-1 - RmA-2)/(RmA-1 + RmA-2) where R is mR/mAs at mA-1 and mA-2 Usual Requirement: L < 0.1 for any pair of adjacent mA stations Exposure rates may differ by ~20% yet pass Prob signif contributor to technique errors We recommend: L < 0.1 for any pair of mA L < 0.05 for adjacent pairs mA Linearity (con’t) For some HF and Falling Load Generators: Don’t allow selection of mA May allow selection of load: – 60%/80%/100% – Low/Half/Full, etc) May evaluate linearity for different load Note: For these (and some other HF) units, linearity of mAs rather than mA may be more pertinent X-ray Beam Measurements kVp accuracy AND reproducibility Exposure rates (mR/mAs) mA linearity Exposure control – Timer accuracy – Timer or mAs linearity reproducibility Half-Value Layer Timer Accuracy Exposure Control & Timer Accuracy Measure as part of linearity tests – Also at longer and shorter times if necessary For HF generators: – exposures terminated at desired mAs, not time. – More meaningful to evaluate exposure control via linearity of exposure versus mAs Timer Accuracy: Action Limits 1-Phase CFR AAPM1 ACMP 2 NCRP 3 Hendeei4 Manuf Not specif Not separately specif 1 pulse if >1/20 sec 0 pulses if < 1/20 sec 1 pulse if >1/10 sec 0 pulses if < 1/10 sec 3-phase >10 mSec < 10 mSec Manuf Manuf 5% 10% 5% 20% 5% 5% 5% 20% 1 - AAPM Report 74, July 2002 2 - ACMP Report #1, Jnauary 1986 3 - NCRP Report 99, December 1988 4 - HEW Publ (FDA) 79-8094 Recommend: – Greater attention to mAs and timer exposure linearity – Attention to accuracy of short exposure times – Awareness of non-invasive timer characteristics X-ray Beam Measurements kVp accuracy AND reproducibility Exposure rates (mR/mAs) mA linearity Exposure control reproducibility Half-Value Layer Reproducibility Usual Criteria: coeff of variaton < 0.05 Our experience: Rarely a problem per se Causes when found: – Abnormally terminated exposures (errors) – Tripped circuit breaker – Often occur only at certain technique settings CFR test: 10 exposures within 1 hour, checking line voltage prior to each exposure We recommend: limited test (3 exposures) at several settings, with followup if necessary X-ray Beam Measurements kVp accuracy AND reproducibility Exposure rates (mR/mAs) mA linearity Exposure control Half-Value Layer HVL Measurement Failures do occur Should test new tubes prior to clinical use Test procedure should allow easy setup, proper geometry (adequate space between dosimeter and aluminum sheets Measure at desired measured kVp Criteria from CFR Collimation X-ray/light field congruence and alignment Light field Illumination Anode cutoff Damaged off-focus radiation limiters Positive Beam Limitation Collimation: Congruence Collimation: Congruence Simple tools can suffice Relatively frequent issue, particularly for portables Some uncertainty in marking light field edges CFR Criteria: 2% of SID for L/X congruence and indicator accuracy (1.5” at 72” SID !!) Can usually do better: try for 1% of SID congruence Light Field Illumination/Contrast CFR Specifications: – Illum: >160 lux at 100 cm – Contrast: I1/I2 > 4 (I1,I2 are illuminations 3 mm in and out from light edge, respectively) Often never inspected Common problem on some collim designs Recommend: test if visually dim or edge definition is poor Anode Cutoff and Off-focus Limiters Evaluated from full-field exposures: – both lengthwise and crosswise orientations – May combine with PBL or grid alignment tests Anode Cutoff: failure to reach anode edge of film with adequate intensity Off-focus limiters: – Can become bent inward, blocking primary x-ray – Poorly delineated edge of x-ray field occuring before reaching each of image receptor Positive Beam Limitation No longer FDA-required Still available/common for non-digital systems Test for each cassette size Can often use single test cassette by overriding PBL or switching to manual mode Place angled cassette on table of in front of receptor to capture full field Limits: from CFR Common causes of Failure: – Mechanical failure of sensors – Calibrated for metric but english sizes used, etc Measurement: –OK to use star pattern test with digital image but –difficult to properly expose with NEMA kV, mA (need lowest mAs, 1 mm Cu) Results rarely useful Pinhole/slit tests: –Not clinically relevant –Needed to resolve failure Resolution-based test (as in MQSA) at appropriate distance/position could be useful (limits?) Focal Spot Size SID Accuracy Measurement: – Location of focal spot usually not marked or visible – Determine magnification of known-object size: convenient to combine with star pattern f.s. test – Digital displays: should check 2-3 distances Criteria: 2% of SID Causes of failure: New installations: – incorrectly located/mounted scale – miscalibrated digital display Causes of Failure: Existing installations – incorrect or mispositioned tape measure – Incorrectly used tape (tape handle ‘tip’ or ‘flat’) Grid Alignment/Appropriateness Common problem area due to: Incorrect grid: 72” upright grid for orthopedic office Angulation due to installation errors or sag (with age) Incorrect lateral detents (table and upright receptors) Stationary grid artifacts with CR (“corduroy” effect) Grid Cutoff vs Lateral Misalignment Grid cutoff (absorption of primary x-rays) versus amount of lateral decentering of x-ray tube focal spot from the grid focal line. Lateral decentering is relatively common due to misplacement or changes in detent positions (measurements are for a typical 10:1 grid, 103 lines/inch) Distance (in): % absorbed: 0 0% 0.5 12% 1 24% 1.5 41% 2 53% 2.5 71% 3 82% 3.5 92% Stationary Grid Artifacts with CR Problem if grid lines parallel to CR horizontal scan direction Need > 65-70 lines/cm for clinically acceptable images Testing Grids If exposure possible with tube off lat detent: – – – – – – – Load cassette crosswise in receptor Position x-ray at lateral detent and proper SID Expose (~3 mAs at 50 kVp) with full x-ray field Repeat with lateral shift of +/- 1” and +/-2” Can use one cassette, exposing narrow strips Maximum density of signal should be at detent Image density or signal should be rel uniform If cannot move off detent: – one exposure--should have relatively uniform signal or density across image Radiograpic Inspection: Summary 1) Visual inspection and recording of information 2) kVp and mR/mAs together at 4 kVs, 3 mA’s 3) mR at fixed mAs for all mA; also measure time, kVp 4) HVL measurement 5) Light/X-ray field alignment 6) Star pattern focal spot test with SID verification 7) PBL test with film 14x17” test inspected for coverage 8) Grid alignment (also inspected for coverage) 9) Table and upright receptor AEC tests (if applicable) 10) Darkroom fog evaluation (if applicable) 11) Vendor-specific digital receptor tests, if available Portable Radiography Inspection Battery-powered: – mR/mAs and kV formerly frequent problems; rare with modern versions Capacitor-discharge – More uncommon – Difficult to test Outlet-powered and all portable types: – Collimation most frequent problem Ports Total 2003 2002 2001 2000 1999 1998 1997 1996 1995 1994 7 5 8 9 9 10 4 3 4 4 HVL 13% Collim kVp 20% 13% 11% 56% 30% 100% 33% 50% 25% 20% Reprod 11% 33% 20% 50% 67% 25% 25% 11% 11% Total: 63 10% 32% 22% Other: mR/mAs (0), Reprod (0), SID (0) Linearity (NA), timer (0), Foc Spot (0) 3% 10% 50% 33% 25%