Standards of Evidence

advertisement

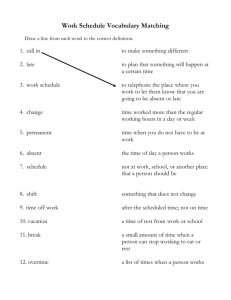

Quality Requirements for Finished Natural Health Products Natural Health Products Directorate Mandate of NHPD • Consumers need to know: –Is this product safe? –Does it do what it says it will do on the label? –Is it of good quality? 2 Assessing Product Quality • All finished Natural Health Products must meet the minimum specification requirements for identity, purity, quantity, and potency (if applicable) • Details are provided in the “Evidence for Quality of Finished Natural Health Products Guidance Document” at URL: http://www.hc-sc.gc.ca/hpfbdgpsa/nhpddpsn/evidence_for_quality_nhp_e.html 3 Relevant Sections of NHP Regulations • Should be read in conjunction with Part 3 of the NHP Regulations, i.e., Good Manufacturing Practices (GMP), and the GMP guidance document • S. 5 (i) states that a copy of the NHP specifications must be submitted when applying for a product licence 4 Relevant Sections of NHP Regulations • S. 44 states that the specifications shall contain the following information: (a) Purity & its tolerances (b) Identity, quantity & their tolerances (c) Potency (if applicable) & its tolerances (d) Description of test methods used 5 Relevant Sections of NHP Regulations • S. 98 deals with labelling & advertising of an NHP in oral dosage form with respect to the site, rate, extent of release or availability of the medicinal ingredient • S. 103 deals with disintegration times of an uncoated, plain coated tablet, enteric coating or similar coating and other related information including labelling & advertising 6 Quality Summary Report To be submitted with Product Licence Application: • Description of manufacturing process • Sterilization or irradiation of NHP if applicable • Analytical procedures • Justification of specifications including exceptions to testing • Summary template for specifications 7 Identity: Plant, Plant Material, Alga, Bacterium, Fungus, NonHuman Animal Material • Macroscopic, e.g. comparison with text book and herbarium specimens • Microscopic, e.g. special glandular hairs • Chemical fingerprinting, e.g. high performance liquid chromatography (HPLC) 8 Identity: Extract or Isolate of Plant, Plant Material, Alga, Bacterium, Fungus, Non-Human Animal Material • Chemical fingerprinting of extracts and/or other chemical analytical methods for extract marker constituents and pure isolates – e.g. HPLC, gas chromatography with mass spectrometry 9 Identity: Vitamins, Amino Acids, Essential Fatty Acids, Synthetic Duplicates & Minerals • Tests appropriate to the substance, that may include: – Physical description, molecular weight, infrared absorption – Specific rotation (isomers) – Refractive index (liquid) 10 Identity: Vitamins, Amino Acids, Essential Fatty Acids, Synthetic Duplicates & Minerals – Pharmacopoeial methods e.g., United States Pharmacopeia (USP) – Other verified methods, e.g. by the Association of Analytical Communities (AOAC) International 11 Identity: Probiotics & Enzymes • Probiotics: microscopic, phenotypic and genotypic methods • Enzymes: gel electrophoresis, enzyme activity or substrate specificity assays, other verified methods 12 Purity: Microbial Contaminants • • • • • • • Yeast and mould contaminants Total aerobic count Escherichia coli Salmonella spp. Staphylococcus aureus Enterobacter spp. Pseudomonas aeruginosa (only in liquid products with water or less than 50% ethanol) 13 Tolerances for Microbial Contaminants Schedule 1 List Item Yeast and Mould Contamin. Total Aerobic Count E. coli Salmonella spp. S. aureus Enterobacter spp. P. aeruginosa Plant, alga, fungus, bacterium and nonhuman animal materials < 1 x 104 for infusion, decoction, topical forms <1 x 103 for other internal use < 1 x 107 for infusion, decoction, topical forms <1 x 105 for other internal use < 1 x 102 for infusion, decoction, topical dosage forms Absent for other internal use Absent < 1 x 104 for infusion, decoction, topical forms <1 x 102 for other internal use < 1 x 102 Applicable only to bacterial products e.g. cyanobacteria N/A Extracts or isolates < 1 x 103 < 1 x 105 Absent Absent Absent < 1 x 102 Applicable only to bacteria-derived enzymes Absent Vitamins < 3 x 102 < 3 x 103 Absent Absent Absent N/A Absent Amino Acids < 1 x 103 < 1 x 105 Absent Absent Absent N/A Absent Essential Fatty Acids < 1 x 103 < 1 x 105 Absent Absent Absent N/A Absent Synthetic duplicates < 3 x 102 < 3 x 103 Absent Absent Absent N/A Absent Minerals < 3 x 102 < 3 x 103 Absent Absent Absent N/A Absent Probiotics < 1 x 104 N/A Absent Absent Absent < 1 x 102 N/A 14 1 Units are in Colony Forming Units per gram or per milliliter; 2 Absent means < 1 x 101 CFU/g or 1 x 101 CFU/ml Microbial Reduction or Sterilization • Irradiation may be used for microbial reduction or sterilizing procedure except for vitamins and probiotics • Sterility test must be included in the specifications for all ophthalmic products and other sterile products 15 Purity: Chemical Contaminants • • • • Arsenic, cadmium, lead, total mercury PCBs, PCDDs, PCDFs (e.g., fish oils) Toxins (e.g., cyanobacterial) Mycotoxins (e.g., aflatoxins), where necessary • Pesticides (not for certified organic NHP) • Other impurities e.g., solvent residues, radioactivity (if suspected) 16 Tolerancess for Chemical Contaminants Contaminants Tolerance Limits Arsenic < 0.14 g / kg b.w./day Cadmium < 0.09 g / kg b.w./day Lead < 0.29 g / kg b.w./day Total mercury < 0.29 g / kg b.w./day Mycotoxins (when applicable) Aflatoxins: < 0.02 g/kg of substance Solvent residues (when applicable) ICH limits Impurities (when applicable) No undeclared impurity Pesticides (when applicable) Pharmacopoeial limits (USP, BP, Eur. Ph) Specific toxins (when applicable) Dioxins < 2 pg/kg/b.w./day PCBs < 0.13 g/kg/b.w./day Radioactivity (if suspected) 600 Becquerels / kg of substance Antibacterial activity (for microbial derived enzymes) Absent 17 Quantity & Potency • Quantitative tests: apply to all NHPs – Amount of each medicinal ingredient per dosage unit, e.g. 500 mg vitamin C per tablet • Potency tests: apply to standardized NHPs, e.g. herbs, extracts, isolates, enzymes, essential fatty acids, vitamins – Percentage of an identity marker compound, e.g. 1.5% echinacoside in Echinacea angustifolia root – Percentage of an active ingredient in extract, e.g. 7% GLA in evening primrose oil – Units of activity of vitamin, e.g. 200 mg of d-alphatocopheryl acetate providing 272 IU Vitamin E 18 Tolerances for Quantity/Potency • • • • 80 to 120% of label claim for most NHPs 80 to 150% of label claim for enzymes 80 to 300% of label claim for probiotics Established standards for vitamins, minerals, amino acids & synthetic duplicates e.g. USP 19 Standardization • The preparation of a consistent product from batch to batch using a master formula that specifies standard operating procedures, materials and manufacturing steps such the extraction ratio and solvent composition. 20 Standardization • Acceptable methods include mixing batches of raw material (best practice), normalization by adjusting the extraction process or amount of excipients, and pharmacological standardization with a bioassay • Spiking with an isolate or synthetic substance gives a product that is fortified/enriched but not standardized • Provide rationale with respect to standardization and methods used 21 Manufacturing Information • Required for all non-compendial applications except: – Traditional methods of preparation (e.g. powdered herb, tea, tincture) – Vitamins & minerals – Item 1 of Schedule 1: plant or plant material, alga, bacterium, fungus or non-human animal material 22 Type of Manufacturing Information • A flow diagram including a description of: – Raw materials, solvents, catalysts, reagents – Yield ranges • The description should reflect: – Representative batch scale for commercial production – Critical steps, process controls, equipment and operating conditions such as temperature, pressure, pH and time 23 Other Tests • Disintegration time test is required • Tests below are not required but recommended for certain NHPs: – Dissolution – Leak rate and leachability – Uniformity of dosage units – Water (moisture) content 24 Summary and Conclusions • • • • Relevant sections of NHP Regulations Safety Summary Report Evidence Summary Report Quality Summary Report 25 QUESTIONS AND ANSWERS Please send further questions to the following: nhpd_dpsn@hc-sc.gc.ca Tel: 1-888-774-5555 26