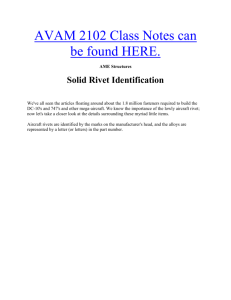

Rivet Identification Code

advertisement

Rivet Identification Code The rivet codes shown in figure 2-1 are sufficient to identify rivets only by head shape. To be meaningful and precisely identify a rivet, certain other information is encoded and added to the basic code. Figure 2-1.—Rivet head shapes and code numbers. A letter or letters following the head-shaped code identify the material or alloy from which the rivet was made. Table 2-1 includes a listing of the most common of these codes. The alloy code is followed by two numbers separated by a dash. The first number is the numerator of a fraction, which specifies the shank diameter in thirty-seconds of an inch. The second number is the numerator of a fraction in sixteenths of an inch, and identifies the length of the rivet. The rivet code is shown in figure 2-2. Rivet Composition Most of the rivets used in aircraft construction are made of aluminum alloy. A few special-purpose rivets are made of mild steel, Monel, titanium, and copper. Those aluminum alloy rivets made of 1100, 2117, 2017,2024, and 5056 are considered standard. ALLOY 1100 RIVETS.— Alloy 1100 rivets are supplied as fabricated (F) temper, and are driven in this condition. No further treatment of the rivet is required before use, and the rivet’s properties do not change with prolonged periods of storage. They are relatively soft and easy to drive. The cold work resulting from driving increases their strength slightly. The 1100-F rivets are used only for riveting nonstructural parts. These rivets are identified by their plain head, as shown in table 2-1. ALLOY 2117 RIVETS.— Like the 1100-F rivets, these rivets need no further treatment before use and can be stored indefinitely. They are furnished in the solution-heat-treated (T4) temper, but change to the Figure 2-2.—Rivet coding example. solution-heat-treated and cold-worked (T3) temper after driving. The 2117-T4 rivet is in general use throughout aircraft structures, and is by far the most widely used rivet, especially in repair work. In most cases the 2117-T4 rivet may be substituted for 2017-T4 and 2024-T4 rivets for repair work by using a rivet with the next larger diameter. This is desirable since both the 2017-T4 and 2024-T4 rivets must be heat treated before they are used or kept in cold storage. The 2117-T4 rivets are identified by a dimple in the head. Solid shank rivets are the most commonly used fastener in aviation today. When a solid shank rivet is “driven” (aka: installed) in a hole, several things change: ◦ The diameter of the rivet’s shank increases ◦ The bearing strength increases ◦ The shear strength increases 3. Different types of solid shank rivets are used for different applications. To help identify the type of rivet you are working with, rivets are given codes to identify their size, head style, and alloy material. 4. The rivet codes break down like this: ◦ Example: AN470AD4-5 AN 470 AD 4 - 5 Numbering system 5. There are several common systems used to identify hardware: ◦ AMS Aeronautical Material Specifications ◦ AN Air Force-Navy ◦ AND Air Force-Navy Design ◦ AS Aeronautical Standard ◦ ASA American Standards Assoc. ◦ ASTM American Society for Testing & Materials ◦ MS Military Standards ◦ NAF Naval Aircraft Factory ◦ NAS National Aerospace Standard ◦ SAE Society of Automotive Engineers The red systems are the ones you need to know. 6. The rivet codes break down like this: ◦ Example: AN470AD4-5 AN 470 AD 4 - 5 Numbering system Style of Rivet Head 7. The rivet head code will always be three numbers. The most common rivet head styles (which you need to know) are the: 8. Countersunk rivets: ◦ Are flush with the aircraft skin ◦ Are aerodynamic and reduce drag 9. Universal head rivets: ◦ Are not flush with the aircraft skin so will cause drag ◦ Are usually used on slower aircraft ◦ Replace all other head styles (round, flat, etc.) ◦ Sometimes called “button head” rivets 10. The rivet codes break down like this: ◦ Example: AN470AD4-5 AN 470 AD 4 - 5 Numbering system Style of Rivet Head Alloy Material 11. The alloy code tells you the type of metal the rivet is made from. # Name Code Head Marking 1100 Pure Aluminum A - 2117 Aluminum Alloy AD dimple 5056 Aluminum Alloy B raised cross 2017 Aluminum Alloy D raised dot 2024 Aluminum Alloy DD 2 raised dashes 7050T73 Aluminum Alloy E raised circle - Corrosion Resistant Steel F - - Monel M 2 recessed dimples 12. The AD rivet is the most commonly used. It is sometimes called the “field rivet”. # Name Code Head Marking 1100 Pure Aluminum A - 2117 Aluminum Alloy AD dimple 5056 Aluminum Alloy B raised cross 2017 Aluminum Alloy D raised dot 2024 Aluminum Alloy DD 2 raised dashes 7050T73 Aluminum Alloy E raised circle - Corrosion Resistant Steel F - - Monel M 2 recessed dimples 13. The D and DD rivets are called “icebox rivets” because they are stored in freezers after annealing to prevent them from becoming to hard to drive. # Name Code Head Marking 1100 Pure Aluminum A - 2117 Aluminum Alloy AD dimple 5056 Aluminum Alloy B raised cross 2017 Aluminum Alloy D raised dot 2024 Aluminum Alloy DD 2 raised dashes 7050T73 Aluminum Alloy E raised circle - Corrosion Resistant Steel F - - Monel M 2 recessed dimples 14. The rivet codes break down like this: ◦ Example: AN470AD4-5 AN 470 AD 4 - 5 Numbering system Style of Rivet Head Alloy Material Shank Diameter (1/32” increments) 15. The diameter of the shank is measured in 1/32 of an inch. For example: AN470AD6-8 has a diameter of 6/32” or 3/16” 16. The rivet codes break down like this: ◦ Example: AN470AD4-5 AN 470 AD 4 - 5 Numbering system Style of Rivet Head Alloy Material Shank Diameter (1/32” increments) Shank Length (1/16” increments) 17. The length of the shank is measured in 1/16 of an inch. For example: AN470AD6-8 has a length of 8/32” or 1/4” 18. So a rivet with code of AN426DD6-10 would be a: ◦ Countersunk head ◦ 2024 Aluminum Alloy “icebox” rivet ◦ 6/32” (3/16”) in diameter ◦ 10/32” (5/16”) in length Rivet Head Styles and Standard Head Markings http://www.rivetsinstock.com/ We carry a commercial equivalent line of Military Standard rivets and Army Navy Specifications rivets for all standard rivet head styles and markings. For more information, use the chart below, or call us today! AN470 rivet Supersedes AN430 rivet, AN442 rivet, AN-455 rivet & AN456 rivet In Most Applications. AN425 rivet Inactive - Example: AN-470-AD-4-8 rivet AN - When these two letters precede numbers, they indicate Army and Navy Specifications. MS - When these two letters precede numbers, they indicate Military Standard Specifications. 470 - The first three numbers indicate they type of head 470=universal head, 430= round head, etc. AD - Letters following head type code indicate material: A=1100(2S) Aluminum, AD=2117-T4(A17ST), etc. 4 - First numbers after material code indicate diameter of rivet in 32nds of an inch. 4=4/32" or 1/8", 12=12/32" or 3/8", etc. 8 - Last numbers indicate length of rivet in 16ths of an inch: 8=8/16" or 1/2", 10=10/16" or 5/8", etc.