Document

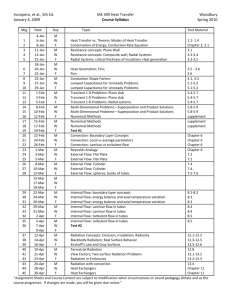

advertisement

2.3 Differential Energy-Balance Equation

2.3.1 Derivation

In materials processing, the kinetic and potential energy are negligible as

compared to the thermal energy, that is the total energy per unit mass et=CvT.

Furthermore, the pressure, viscosity, and shaft work are usually negligible.

According to Gauss’ divergence theorem, we have

A

and

CvTv ndA ( CvTv)d

q ndA qd

A

[2.3-1]

[2.3-2]

Substituting Eqs.[2.3-1] and [2.3-2] into Eq.[2.2-6]

CvTd ( CvTv)d qd sd 0

A

A

t

If the control volume Ω does not change with time, t in Eq.[2.3-3] can be

moved inside the integration sign:

{t ( CvT ( CvTv) q - s}d 0

19

The integrand, which is continuous, must be zero everywhere since the

equation must hold for any arbitrary region.

( CvT ) ( CvTv) q - s 0

t

[2.3-5]

The first two terms can be expanded and the equation becomes

CvT [( ) ( v)] 0

( CvT ) ( CvTv)

t

t

(CvT ) (CvT )

(CvT ) ( v) v (CvT )

t

t

(CvT ) v (CvT )

t

0

[2.3-6]

Note that q=-k▽T, substituting the Equation into Eq.[2.3-5], we have

(CvT ) v (CvT ) (kT ) s

t

[2.3-7]

20

Assuming constant Cv and k

T

Cv [ v T ] k 2T s

t

[2.3-8]

Eq. [2.3-8] is the differential energy-balance equation, or the equation of energy.

2.3.2 Dimensionless form

The equation of energy can be presented in the dimensionless form to

make the solutions more general. For forced convection the following

dimensionless variables can be defined:

Dimensionless temperature

T*

T T0

T1 T0

[2.3-9]

v

[2.3-11]

V

p - p o [2.3-12]

dimensionless pressure p

V 2

tV

x y z

Dimensionless timet

[2.3-10] dimensionless coordinates x , y , z , ,

L

L L L

Dimensionless velocity v

[2.3-13]

Dimensionless operator , *2 L, L2 2 [2.3-14]

21

In the absence of a heat source, the energy equation Eq.[2.3-8] reduces to

T

v T 2T

t

[2.3-15]

Substituting Eqs.[2.3-9] through [2.3-14] into Eq. [2.3-15]

V

1 2

1

T T1 T0 Vv T

T1 T0 2 T T1 T0

L t

L

L

[2.3-16]

Multiplying Eq.[2.3-16] by L/[V(T1-T0]

T

2

v

T

T

t

LV

[2.3-17]

By combining Eq. [2.3-17] with Eq.[1.5-25] through Eq.[1.5-28], the following

equations can be obtained for heat transfer in forced convection:

Continuity:

v 0

[2.3-18]

Motion:

v

1 2 1

v

v

p

v

eg

t

Re

Fr

[2.3-19]

Energy:

T

1

1 2

2

v

T

T

T

t

Re Pr

PeT

[2.3-20] 22

Where

LV

inertia force V 2 L [2.3-21]

Re

Reynold number =

v

viscous force V L2

[2.3-22]

V2

inertia force V 2 L

Fr

Froude number =

gL

gravity force g

v

viscous diffusivity v

[2.3-23]

Pr

Prandtl

number

=

thermal diffusivity

PeT Re Pr

LV

convection heat transport CvV T1 T0

thermal Peclet number

conduction

heat

transport

k

T

T

L

1

0

[2.3-24]

23

2.3.3 Boundary conditions

Heat flow boundary conditions in rectangular coordinates

24

25

Heat flow boundary conditions in cylindrical coordinates

26

2.3.4 Solution procedures

T

v T 2T

t

27

Example 2.3.1 Heat conduction in a resistance heated rod

0

Cv [

0

0

0

T

T v T

T

vr

vz

]

t

r

r

z

0

0

1 T

1 2T 2T

k[

(r

) 2

2 ] s

2

r r r

r

z

T

0

t

No convection inside the rod

Axisymmetry T 0

T

Neglect end effect

0

z

Steady state

Governing Eq.

B.Cs.

vr v vz 0

1 d dT

s

(r

)

r dr dr

k

dT

0 at r = 0

and

dr

dT

-k

h(T T f ) at r = R

28

(A)

Example 2.3.2 Heat conduction in a cooling fin

qz+dz

Given:

No temp. variation in thickness dir.

wall temp. Tw

dz

ambient temp. Ta

heat transfer coefficient h

w

q=hA(T-Ta)

f

qz

Find: T and Q under steady state

T

T

T

T

2T 2T 2T

Governing Eq. Cv [

vx

vy

vz

] k[ 2 2 2 ] s

t

x

y

z

x

y

z

0

Steady

state

0

No convection

0

T varies with z only

Consider the volume of a C.V. with the length of dz in the fin: f w dz, f : fin thickness

Arte of convection heat loss from the wall: 2w dz h (T-Ta) (heat sink loss heat)

2h

(T Ta )

dT

f

2

0 at z = L and

dT

2h

Governing Eq.

B.Cs. dz

a (T Ta ) where a=

2

dz

fk

T Tw at z = 0

f w dz s 2w dz h(T Ta )

s

29

Example 2.3.2 Heat conduction in a cooling fin

qz+dz

qz f w qz dz f w

w

q=hA(T-Ta)

dz

f

2h (w dz)(T-Ta )

qz

dqz

dz 2(h wdz )(T -Ta )

dz

d

dT

fw ( k

)dz 2(h wdz )(T -Ta )

dz

dz

d 2T

fk 2 (2h)(T -Ta )

dz

d 2T 2h

(T -Ta ) a (T Ta )

2

dz

fk

fw

qz f w qz dz f w 2h (w dz )(T -Ta )

dqz

dz

dz

dq

qz f w (qz z dz ) f w 2h (w dz )(T -Ta )

dz

qz dz qz

dT

0 at z = L and

B.Cs. dz

T Tw at z = 0

30

Example 2.3.3 Heat conduction into a semiinfinite solid

No source

term

T

T

T

T

2T 2T 2T

Cv [ v x

vy

vz

] k[ 2 2 2 ] s

t

x

y

z

x

y

z

0

No convection

0

0

T varies

with x only

T

d 2T

Governing Eq.

2

t

dx

T ( x, 0) Ti

B.Cs.:

T (0, t ) Ts

T (, t ) Ti

31

Example 2.3.4 Heat loss from a rising film

Given: Film thickness L

Belt velocity V

Temp. of liquid bath Ti

Temp. at infinite Tf

Find: T under steady state

No source

term

0

Governing Eq.

T

T

T

T

2T 2T 2T

Cv [ v x

vy

vz

] k[ 2 2 2 ] s

t

x

y

z

x

y

z

0

Steady

state

0

Flow in the z-dir.

only, Vx=vy=0

0

No Temp. variation

In the x-dir

0

No conduction,

Heat transfer mainly by

convection in the z-dir

Governing Eq. reduces to

T

2T

vz

2

z

y

32

T

2T

vz

2

z

y

Velocity distribution

vz ( y) V

g 2 2

( y L ) (Example 1.5-3)

2

The temp. drops significantly only near the free surface

(y<<L), especially for high-Pr liquid (heat conduction is slow)

v z ( y) v min V

g 2

L

2

Then governing Eq. reduces further to

B.Cs.:

T ( y, 0) Ti

T

2T

z v min y 2

T ( y, z ) Ti as y

k

T (0, z )

h(T (0, z ) T f )

y

Can the condition T(0,z)=Tf be used ?

33

Example 2.3.5 Heat transfer in laminar flow over a flat plate

Given: Steady state, laminar flow, incompressible,

Newtonian, uniform temp. Ts. Physical properties is

not a function of temp., no source term and viscous

dissipation

Governing Eq.

Steady

state

0

No source

term

0

0

T

T

T

T

2T 2T 2T

Cv [ v x

vy

vz

] k[ 2 2 2 ] s

t

x

y

z

x

y

z

0

No temp. gradient

in the x-dir.

0

0

No Temp. gradient

In the z-direction,

In the x-dir

heat transfer mainly due to

convection but not conduction

T

T

2T

vy

vz

2 (energy Eq.) (2.3-70)

y

z

y

v z

v z

2vz

vy

vz

(Eq. of motion)

2

y

z

y

v y v z

y

0 (Continuity Eq. ) v y v z dy (2.3-71)

0 z

y

z

34

Substituting (2.3-71) into (2.3-70) to give

(

y

0

vz

T

T

2T

dy)

+vz

= 2

z

y

z

y

(2.3-72)

Using the temp. profile of

T Ts 3 y

1 y 3

( ) ( ) (2.3-73)

T Ts 2 T

2 T

Subjective to the B.Cs.

T Ts at y = 0

(2.3-74)

T

T T and

0 at y = T

y

(2.3-75)

Take the derivation of

T

T

2T

(2.3-76) ,

(2.3-77), and

(2.3-78)

2

z

y

y

Substitute Eqs. (2.3-76) through (2.3-78) to Eq. (2.3-72) and substitute

Eq. (1.5-78) for vz and Eq. (1.5-81) for v z z

35

We have

8

T

5

1 T 2 d T 6 4 2 1 T 2 d

8 2

1

(

)

(

)

T (2.3-79)

T

7 dz 5 3 7 dz

v

According to Eq. (1.5-87)

vz

4.64

(2.3-80)

v

vz

280 v

2 (4.64) 2

and

2 d

dz (2.3-81)

v

13 v

Let T =a

(2.3-82)

where a is a constant depending only on the physical properties of the fluid.

Substituting Eqs. (2.3-80) and (2.3-82 into Eq. (2.3-79), we have

13

a -14a + =0

Pr

5

3

(2.3-83)

Let consider the case where a<1, that is

a 5 <<14a 3

Equation (2.3-83) reduces approximately to a=Pr (1/3)

That means

vz

T

(2.3-87)

=Pr ( 1/3) (2.3-86) and T 4.64 Pr (1/3)

v

36

Example 2.3.6 Heat transfer with laminar in a tube

Given: Steady state, laminar flow, incompressible,

Newtonian, uniform heat flux qR at the wall

T

qR h(TR Tav ) k

r

r R

Define average fluid temperature

R

Tav

2 rv zTdr

0

m

R

2 rv zTdr

0

(2.3-89)

Q(volume flow rate)

Fluid flow is significant enough that heat transfer in

the z-dir is dominated by convection

Find: h

According to B.Cs.

h(TR Tav ) k

In order to find h, we must first find

T

r

T

r

r R

r R

h

k

T

(TR Tav ) r

r R

and (TR Tav )

37

Governing Eq.

0

Cv [

0

0

0

T

T v T

T

vr

vz

]

t

r

r

z

0

0

1 T

1 2T 2T

k[

(r ) 2

2 ] s

2

r r r

r

z

Governing Eq. reduces to

vz

T

1 T

(r

)

z

r

r

r

From Eq. [1.5-54]

2Q

r 2

[1

(

) ] and thus

2

R

R

1 T

r 2

2Q T

(r )

1 ( )

2

r r r

R

R z

vz

(2.3-94)

B.Cs.

T

0 at r = 0 and T=TR (z) at r=R

r

38

T TR

T

4

2 2

4

(3

R

4

R

r

R

)

4

2 R z

Q

(2.3-99)

T

Q T

2

3

(

8

R

r

4

r

)

4

r

8 R z

and

T

r

rR

T

2 R z

Q

(2.3-101)

Substitution Eqs. (2.3-94) and (2.3-99) into Eq.(2.3-89), we have

Tav TR

11Q T

48 z

(2.3-102)

Substitution Eqs. (2.3-101) and (2.3-102) into Eq.(2.3-90),

we have

NuD

hD D

k

T

k

k (TR Tav ) r

r R

D

Q T

(TR Tav ) 2 R z

DQ T 48 T 1 48

( )

4.36

2 R z 11Q z

11

39

2.5 Turbulence

2.5.1 Time-smoothed variables

The velocity fluctuations arising in turbulent flow affect the local pressure. The

velocity fluctuations also affect the local temperature.

T T T '

1

T

t0

1

T

t0

'

t t0

t

t t 0

t

[2.5-1]

Tdt

T ' dt 0

[2.5-2]

[2.5-3]

40

2.5.2 Time-smoothed governing equations

Substituting

v v v'

[1.7-1] and T T T [2.5-1] into [2.3-7]

'

(CvT ) v (CvT ) (kT ) s

t

[2.3-7]

and taking the time average, we get the time-smoothed equation of energy

T

Cv v T q q ' s

t

where

q kT

[2.5-4]

and the turbulent heat flux

q ' Cv v x ' T ' v y ' T ' vz ' T '

[2.5-5]

Eq. [2.5-4] is the same as the equation of energy for laminar flow Eq.[2.3-7],

except that the time-smoothed velocity and temperature replace the instantaneous

velocity and temperature, and that one new terms q ' arises.

41

2.5.3 Turbulent heat flux

Several semiempirical relations have been proposed for the turbulent heat flux

To solve Eq. [2.5-4] for temperature distributions in turbulent flow.

2.5.3.1 Eddy thermal conductivity

By analogy with Eq. [2.1-1] Fourier’s law of conduction, one may write

dT

q y ' k '

dy

[2.5-6]

The coefficient K’ is a turbulent or eddy thermal conductivity and is usually

position-dependent.

2.5.3.2 Prandtl’s Mixing length

By analogy with Eq. [1.7-13]

2 dvz dT

q y ' Cvl

dy dy

[2.5-7]

And from Eq. [2.5-7]

dvz

k ' Cvl

dy

2

[2.5-8]

42

In the turbulent boundary-layer energy equation in time-averaged values

for small velocities

T

T

2T

(v 'T ' )

Cv (u

v

) k 2 Cv

x

y

y

y

This equation differs from the corresponding laminar equation for steady flow by

the last term on the right-hand side, which is an expressed for the turbulent

exchange of heat equivalent to the following Eq.

qt m ' C p (T T ')

Boussinesq introduced for this

turbulent heat flow the expression.

T

qt C p v T C p q

y

'

'

With q called the turbulent diffusivity for heat.

This expression, together with the turbulent diffusivity for momentum, has

become very useful for a calculation of heat transfer from flow information,

since even the simplest assumption for the ratio m/q, namely, that is a constant.

43

Heat and Mass Transfer, by Eckert & Drake, McGraw-Hill 1950, p.219

turbulent diffusivity for momentum

u

t u v m

y

' '

T

qt C p q

y

By dividing the equations for the turbulent heat flow and the turbulent shear

stress, The result is

q

T

Cp

t

m

u

qt

The ratio of m/q, which is called turbulent Prandtl number (Prt), has a value

of approximately 0.7 in boundary-layer flow and approximately 0.5 for wake

flow behind blunt objects and for vortex flow.

44

Heat and Mass Transfer, by Eckert & Drake, McGraw-Hill 1950, p.219

2.6 Heat transfer correlations

Convection heat transfer can be determined by solving the governing equation

for fluid flow and heat transfer. Correlations that are derived theoretically but verified

experimentally or are based on experimental data alone, are useful for studying

convection heat transfer.

2.6.1 External Flow

2.6.1.1 Forced convection over a flat plate

Flow over a flat plate is laminar for local Reynolds number Rez < 2 x 105. The

following correlation can be used for laminar flow of fluid with a bulk temperature

T∞ over a flat plate with a surface temperature Ts.

Nu z 0.332 Re z1 2 Pr1 3

0.6 < Pr < 50

Nu z (local Nusselt number)

hz

v

[2.6.2]

k

k

Nu z 0.332 Re1/ 2 Pr1/ 3

z

z

Re z (local Reynolds number)

Pr (Prandtl number)

hz z

k

[2.6.1]

Cv

k

zv z v

v

[2.6.3]

[2.6.4]

45

From these equations, the heat transfer coefficient averaged over a distance L

from the leading edge of the plate is

1 L

hL hz dz

L 0

[2.6.5]

Substituting Eq. [2.6-1] into Eq. [2.6-5]

1 L k

hz

0.332 Re1/ 2 Pr1/ 3 dz

L 0 z

or

1

2

k

1/ 3 v

hz 0.332( ) Pr ( ) z dz

z

0

L

NuL 0.664 Re L1 2 Pr1 3

(0.6<Pr<50)

[2.6.6]

[2.6.7]

where

hL L

NuL (average Nusselt number)

k

Re L (average Reynolds number)

Lv L v

v

[2.6.8]

[2.6.9] 46

The fluid properties in Eqs. [2.6-1] and [2.6-7] are evaluated at the film temperature

T Ts

Tf

2

For liquid metals and semiconductors Pr<<1 and Eqs. [2.6-1] and [2.6-2] cannot be

applied. For these materials the following theoretical correlation has been suggested:

Nu z 0.565 Re z Pr

12

0.565 Pez1 2

[2.6-11]

where

Pez (local Peclet number) Re z Pr

zv

[2.6-12]

For turbulent flow over a flat plate, the following theoretical correlation has

been suggested:

Nu z 0.0288 Re z 4 5 Pr1 3 (0.6<Pr<60)

[2.6-13]

and from Eq. [2.6-5]

Nu z 0.036 Re L 4 5 Pr1 3

(0.6<Pr<60)

[2.6-14]

47

2.6.1.2 Forced convection normal to a cylinder

For the flow of air normal to a cylinder of diameter D. An empirical correlation for

the forced convection heat transfer is

NuD a Re D b Pr1 3

0.1 Re

D

3 105 , Pr 0.7

where

hD

Dv D v

Re

[2.6-16]

D

k

v

The constants a and b are listed in Table 2.6-1

NuD

[2.6-15]

[2.6-17]

The following empirical correlation has also been suggested:

NuD 0.3

12

D

13

0.62 Re Pr

[1 (0.4 / Pr) 2 3 ]1 4

58

Re

D

1

282, 000

45

[2.6-18]

48

2.6.1.3 Forced convection past a sphere

For the flow of air past a sphere of diameter D, an empirical correlation for

the forced convection heat transfer is

14

12

23

0.4

NuD 2 0.4 Re D 0.06 Re D Pr

s

[2.6-19]

(0.71 < Pr < 380, 3.5 < ReD < 7.6 X 104, 1 < /s < 3.2)

All fluid properties are evaluated at bulk T∞ except for s, which is evaluated at

the surface temperature of the sphere. This correlation is accurate to within ±30%

for the range of parameter values specified.

A special case of convection heat transfer from sphere is that of a freely falling

drop. The following theoretical correlation has been proposed:

NuD 2 0.6 Re D1 2 Pr1 3

[2.6-20]

49

2.6.2 Internal flow

2.6.2.1 Forced convection inside a circular tube

For laminar fully developed flow inside a circular tube of diameter D and uniform

surface heat flux. The following theoretical correlation has been proposed:

NuD 4.36 Pr 0.6

[2.6-21]

For a uniform surface temperature rather than heat flux, the following theoretical

correlation has been proposed:

[2.6-22]

NuD 3.66 Pr 0.6

For turbulent fully developed flow inside a circular tube of diameter D and

length L, the following theoretical correlation has been suggested:

NuD 0.023Re D 4 5 Pr1 3

[2.6-23]

A slightly different and preferred correlation is as follows:

NuD 0.023Re D 4 5 Pr n

L

(0.6 Pr 160, Re D 10, 000, 10)

D

where n is 0.4 if the fluid is being heated and 0.3 if it is being cooled.

[2.6-24]

50

Eq.[2.6-24] is good for small to moderate temperature difference between the

wall and the bulk fluid. The following equation is preferred for flows characterized

by large property variations:

0.14

NuD 0.027 Re D 4 5 Pr1 3 b

w

[2.6-25]

L

(0.7 Pr 16, 700, Re D 10, 000, 10)

D

All fluid properties are evaluated at the bulk temperature except w, which is

evaluated at the wall temperature.

Equations [2.6-23] through [2.6-25] are ReD>104. The following correlation

can be used even if ReD is below 104.

f 8 Re D 1000 Pr

NuD

12

1 12.7 f 8 Pr 2 3 1

[2.6-26]

6

(0.5 Pr 2000, 2300 Re D 5 10 )

Where the friction factor f can be obtained from the Moody chart or, for smooth

pipes, from.

f 0.79 ln Re D 1.64

2

[2.6-27]

51

Example

Air at 200C and 1 atm flows over a flat plate at 35 m/s. The plate is 75 cm long

and is maintained at 600C. Assuming unit depth in the z direction, calculate the

heat transfer from the plate.

Given: P=1.0132x105 N/m2, R=287, =2.007x10-5kg/ms, Cp=1.007 kJ/kg0C

k=0.02723 W/m0C

Eq. for forced convection heat transfer

1

hL

0.8

Nu L

Pr 3 (0.037 Re L 850)

k

52