RAMSES: Rule-Based Asset Management

for Space Exploration Systems:

Automatic IMS Self-Reporting

Prof. Olivier de Weck

deweck@mit.edu

MIT Department of Aeronautics and Astronautics

(RAMSES Principal Investigator)

Joe C. Parrish

jparrish@aurora.aero

Aurora Flight Sciences Inc.

(RAMSES Project Manager)

Abe Grindle

grindle@mit.edu

MIT Department of Aeronautics and Astronautics

(Graduate Research Assistant)

End of NASA STTR NNC07AB25C Phase 2 System Demonstration

NASA Johnson Space Center

August 14, 2009

The Team

• Massachusetts Institute of Technology

–

–

–

–

Olivier de Weck, Ph.D., Associate Professor (RAMSES PI)

Abe Grindle, Graduate Student, AA and TPP

Sydney Do, Graduate Student AA

Howard Yue, Graduate Student AA

• Aurora Flight Sciences Inc.

–

–

–

–

Joe Parrish, VP (RAMSES PM)

James Francis, Software Engineer

Joe Zapetis, Software Engineer

Joanne Vining, Senior Technician

• NASA

– Nathan Sovik, NASA SSC Stennis, COTR (Phase 1)

– Ray Bryant , NASA SSC Stennis , COTR (Phase 2)

– Sarah Shull, NASA JSC DO5

2

Agenda

• Motivation for Real-Time Automated Asset Management

• Overview of RAMSES STTR Phase 1/2 Project

– Project Heritage

– High-Level System Architecture

– Smart Container (CTB)

– Location-based Asset Tracking Software (RAILS v2)

– Microgravity Testing Results

– Cost-Benefit Analysis

• RAMSES Demo (in Lunar Habitat Mockup)

• Discussion and Suggestions for Phase 3

3

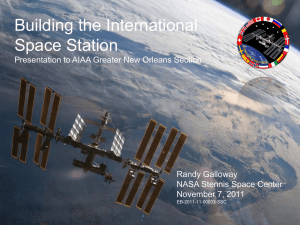

Motivation for Real-Time

Automated Asset Management

4

Evans W., de Weck O., Laufer D., Shull S., “Logistics Lessons

Learned in NASA Space Flight”, NASA/TP-2006-214203, May 2006

Supply

Items

M02

Bags

MPLM

Racks

•

•

•

•

•

•

•

•

•

•

•

•

Nested Complexity

Pocket

Container

Carrier

Module

Segment

Compartment

Element

Pallet

Assembly

Facility*

Node

Vehicle

MPLM

Cargo

Integration

•

•

•

•

•

•

•

•

•

•

•

Item

Drawer

Kit

Locker

Unit

Rack

Lab

Platform

MPLM

Payload Bay

Fairing

•

•

Component

Subsystem

• System

• SRU

• LRU

• ORU

• CTB

• M-01

• M-02

• M-03

*In-Space Facility

(e.g., the European Technology

Exposure Facility (EuTEF)

Need to track items

across dynamic

parent-child

relationships

MPLM

In Shuttle

5

Current ISS Inventory Architecture

• Barcodes

• CTBs (Cargo Transfer Bags) and other bags/kits

– 1/2, Standard, Double, Triple

– Concentration of Inventory Transactions

• IMS (Inventory Management System)

– Copies in Houston, Moscow, Baikanour, and ISS

– Delta files

• ISO (Integration Stowage Officer)

– Mission Control; assist crew with IMS

– Write stowage notes for all procedures

6

Inventory Tracking on ISS

SSC/NGL

Client

Multiple

SSC/NGL

Clients

D

B

Relatively accurate

system (~ 3% lost)

SSC/NGL File Server

Bar Code R eader

Manual bar-code

based system

Communication occurs

via Radio Frequency

(RF) and is relayed

through the RF Access

Point located in the LAB

OCA Router

OCA

OCA Down

Up

RSA/NASA

Inventory

Management

System (IMS)

Requires substantial

manual labor

(>20min/day/astronaut)

7

ISS Lessons Learned

International Space Station Multilateral Coordination Board

Consolidated Lessons Learned For Exploration, report issued July 22, 2009

10-Lesson: Micromanage Consumables

Resupply, logistics and onboard stowage have proven to be critical issues for

the ISS. Out of necessity, the program carefully re-evaluated the usage rates for

critical consumables and found innovative ways to reduce resupply

requirements. Micromanagement of consumables was found to be

essential to ensure adequate supply inventories. Reliability and

maintenance strategies are critical.

Application to Exploration: Consumables will be even more critical for extended

lunar or Mars expeditions because of the more limited resupply opportunities.

Micromanagement of consumables and inventory will be critical and should be

thoroughly addressed during the systems design phase.

8

ISS Lessons Learned

International Space Station Multilateral Coordination Board

Consolidated Lessons Learned For Exploration, report issued July 22, 2009

NASA ISS Lessons Learned – Logistics, Resupply, and Stowage

Based on the ISS experience, careful management of consumables and

inventory will be critical and should be thoroughly addressed during the systems

design phase. The Exploration Programs should utilize technologies that were

not readily available at the beginning of the ISS Program to help minimize

resupply requirements and track inventory. For example, Radio-Frequency

Identification Devices (RFID) might help to simplify inventory tracking.

9

Functions of a State-of-the-Art IMS

• Automated inventory tracking and management

• Automated mass and C.G. calculations for vehicle

management before launch and during flight operations

• Automatic reports of % full levels (by mass or volume) by

module/vehicle/node for precise stowage planning

• Alerts when critical consumables are about to run low (can

establish dynamic warning thresholds)

• Alerts when incompatible/hazardous items are stored

together or in the wrong place

• Save temperature/pressure history with the item

• Real time assistance in searching for items

• …

10

Implications of Automated ISS Inventory Process

@ ISS Assembly Complete:

• 600 Cargo Transfer Bags

(CTBs) on-orbit

• 730 Crew Hours / Year spent

updating IMS ~ 4 ½ personmonths (40 hrs/wk)

11

RAMSES Project Heritage

12

MIT Space Logistics Planning & Analysis

MIT and Aurora Flight Sciences (formerly Payload Systems Inc.)

have been collaborating on a series of projects relating to space

logistics and automated inventory tracking/management

•Interplanetary Supply Chain Management & Logistics Analysis

(ISCM&LA)

–

–

Funded through NASA Exploration Systems technology BAA 2005-2007,

$4M over 2 years

Multi-faceted project, resulting in SpaceNet software for LEO/Lunar/Mars

supply chain modeling and analysis

Haughton-Mars

Research Station

•Haughton-Mars Research Station Expedition 2005

–

–

Field campaign, applying principles from SpaceNet

RFID-based portals enabled tracking of vehicular traffic in/out of base

camp; personnel and equipment in/out of habitat and lab areas

•Rule-Based Analytic Asset Management for Space Exploration Systems

(RAMSES)

–

–

–

STTR Phase 1 and 2, from NASA Stennis Space Center 2006-2009

Focus on hardware-agnostic architecture for tracking diverse assets on

ground and in space

Several generations of smart containers

13

Smart CTB

Prototype

Introduction to SpaceNet

•

•

SpaceNet is an interplanetary supply chain modeling

and simulation tool

Goal: Support short and long-term architecture and

operational decisions such as:

– What effect will vehicle (element) design decisions have

on future NASA operations and lifecycle costs?

– Are in-space refueling and ISRU helpful in improving

performance?

– Is it better to have cargo vehicles that carry small resupply loads or a few large pre-deploy or resupply flights?

•

Staging Location

Diverse user base

–

–

–

–

Mission/system architects

Mission planners and logisticians

Operations personnel

Etc…

In-Space Refueling

14

SpaceNet – Network View

SpaceNet 1.3

15

Interplanetary Supply Chain

Management and Logistics

15

Architectures

SpaceNet – Manifest View

16

RFID at the Haughton-Mars Project

Research Station

17

HMP Expedition 2005: Objectives

1.

Inventory classes of supply on base

•

2.

Analyze analogy to lunar/Mars base

Model HMP supply chain

•

3.

Quantitative transportation network model

Test and evaluate RFID technology

•

•

4.

Field experiments during normal HMP operations

Test autonomous tracking of supplies, vehicles,

people

Study EVA logistics requirements

•

Short traverses and overnight stays

18

HMP: Inventory

HMP Actuals: Total Mass inventoried at HMP: 20,717 [kg]

Total Mass Inventoried [kg]

Goals: Understand, Categorize Supplies on Base

- Classification of inventory

- Quantify inventory (total imported mass)

- Compare with prediction for a lunar base

- What would it take to ‘create’ an HMP-like base?

102

4153

9305

2934

Comparison by Supply Class

(Full Data Set)

Lunar Long

Lunar Short

470

286

.HMP Est

1723

HMP Actuals

1022

176

547

1. Propellants and Fuels

2. Crew Provisions

3. Crew Operations

1. Propellants and Fuels

2. Crew Provisions

3. Crew Operations

4. Maintenance and Upkeep

5. Stowage and Restraint

6. Exploration and Research

7. Waste and Waste Disposal

8. Habitation and Infrastructure

9. Transportation and Carriers

10. Miscellaneous

4. Maintenance and Upkeep

•

5. Stowage and Restraint

6. Exploration and Research

7. Waste and Waste Disposal

•

8. Habitation and Infrastructure

9. Transportation and Carriers

10. Miscellaneous

0

1

2

3

4

5

6

7

8

9

10

Thousands

Total [kg]

19

•

•

Inventoried 2300 items

(20,717 kg)

Developed inventory

procedures

Validated supply classes

Maintained inventory over

time (for use next season)

19

HMP: Transportation Analysis

Transportation Network Analysis for HMP

• Mass inflow per season ~ 20 mt

• Analysis highlights room for improvement:

Personnel Profile

45

40

35

Plan for reverse logistics

Reduce asymmetric flight usage

Smooth personnel profile

• “Robustness” more important than optimality

–

30-Jun

30

# of People

–

–

–

Number of People Staying in Devon

10-Jul

25

21-Jul

20

31-Jul

7-Aug

15

BOXCAR

10

due to weather, emergencies, aircraft availability

5

34

32

30

28

26

24

22

20

18

16

14

12

8

10

6

4

2

0

0

Days from 8 July

4. M

6. F

Cumulative Cargo Flow HMP 2005

Cargo

Mass Flow

0.D

0.D

6. F

7.

I

60000

7. C

50000

5. H

cum at HMP

20000

10000

27

25

23

21

19

18

16

14

12

8

10

0

6

Normal Trans.

Emergency Trans.

cum out

4

2. E

cum in

30000

0

7. Y

0. D

6. F

0. Dep. Point for Each Team

1. Ottawa

2. Edmonton

3. Resolute

4. Moffet USMC St.

5. HMP Base

6. HMP Field

7. Cambridge Bay

Iqaluit

Yellowknife

40000

2

1.O

Cargo/Crew Mass [lbs]

3. R

Flight Num ber (according to log)

20

20

HMP: Agent & Asset Tracking

(RFID)

Goal: “Smart Base” for Micro-Logistics

– Technology demonstrations

– Observation/Insight for further implementation

Selected Conclusions

– RFID has potential for remote bases

• dramatically improve asset management

• reduce crew time spent in inventory

• increase ground knowledge of base requirements

– Technical hurdles

• reliability, interference, packaging

– STTR to further investigate

Bar Code

RFID

Camp

Activity

07/17 to 07/19

Asset

Flow

ATV Tracking

Number of Triggers

200

180

160

140

120

100

80

60

40

20

0

160

140

120

100

80

60

40

20

0

9:

00

11

:0

0

13

:0

0

15

:0

0

17

:0

0

19

:0

0

21

:0

0

23

:0

0

1:

00

3:

00

5:

00

7:

00

Seconds

Mean Time

Formal Experiments

Exp 20-4

Exp 10-4

Time of Day

Exp 10-2

21

21

Overview of RAMSES

Phase 1/2 STTR Project

22

RAMSES Project Overview

•

NASA STTR Phase 2 (Research Institution partner: MIT)

– Contract number NNS07AB25C (NASA Stennis Space Center)

•

Objective: Provide asset tracking and management for all of NASA’s assets

– Document in office at NASA center…supply item on International Space

Station…pressurized rover on surface of Moon/Mars

•

Hierarchical to accommodate diverse styles of assets

– Room level…outdoors…orbits and planetary surfaces

•

Device-agnostic to accommodate diverse styles on locating/tracking systems

– RFID…WiFi…Cellular…GPS

•

Emphasis on open source software

– E.g., Google Maps API

•

Strong potential for terrestrial applications

–

–

–

–

Military theater operations

Humanitarian aid

Entertainment industry

Consumer products

23

NASA Applications

LN

R

Local Node

RFID Reader

Applications

RFID RFID Tag

Real-Time Data Capture

Platform

Integrate real-time RFID; Barcode; GPS;

Interplanetary

Network

Connection

Internet

TDRSS

Earth Ground

LN

R

Planetary Surface

In-Space

R

R ISS

CEV

Ground

Processing

LN

LN

Launch

vehicle

Spaceport

R

Lunar

Base

RFID

RFID

RFID

RFID

RFID

24

R

R

Mars

RFID

RAMSES Architecture

Informational Architecture

Physical Architecture

events

Rule-Based

Analytics

Outdoor Tracking

transactions

Indoor Tracking

Container

Tracking

raw data

(e.g. triggers)

system

state

Relational

Database

Messaging

System

Relational

Google

Maps

Database

802.11

interrogate

Tracked

Items

Web

Browser

(RAILS)

Other

Devices

external

information

User

25

Email, SMS

RAILS

• RDF-based Asset Information and Location Software

– Web-based real-time interface

Facility-level Tracking

Item Locator

Container Inventory

Supported Web Browsers: Internet Explorer, Firefox

26

Smart Container Concept

8:41a.m.

www

interface

wireless router

passive

tag

802.11

item

x

PC/laptop

wireless

radio

802.11

switch

RFID

Antennas

(1-4)

RF opaque

“liner”

RFID

Reader (915 MHz)

5V DC

Battery (30Ah)

27

Prototype:

Instrumented

CTB

database

container 1

item x 8:41am

MySQL

Relational

database

….

Smart Container Evolution

Generation 1

Cooler

Proof-of-concept for RF-insulated container and

automated/wireless inventory function

Generation 2

Hard Container

Hard-case with integrated display,

modular electronics

Generation 3

Soft Bag

Generation 4

CTB Retrofit Kit

CTB proxy with RF-shielding insert,

integrated electronics and antennae

CTB-specific prototype, ready to transition to

flight implementation

28

Testing Results (2007 MIT Undergraduate Design Project)

Mean Time vs No. of Items

• 6 Test Subjects

– 3 male, 3 female

• 24 Experiments each

• Time Savings: RFID

versus Bar-coding can be

> factor of 2 time savings

– Benefit increases as

more items have to be

managed in the system

• Accuracy: Above 95% is

feasible if:

– use 3 RFID antennas

– ~20 items

– 2 tags per item helps

90

Barcode

80

RFID

70

60

50

Time (sec)

40

30

20

10

0

6

24

15

33

Number of Items

Mean Accuracy vs No. of Items

100

95

90

% Accuracy

85

80

75

6

15

24

No. of Items

Source: Teresa Pontillo, Alice Fan, 16.622 Final Report, MIT

29

33

Microgravity Testing of

Smart CTB

August 11-12, 2009

Play Movie

Clip X48p test

condition

30

Motivation for Microgravity Testing

• Hypothesis that microgravity environment could actually

improve RFID tag read accuracy

– Tags in free-float will move around in container and present

themselves in randomized orientations to antennae

• Vice laying on top of each other in bottom of container

• MIT and Aurora proposed parabolic flight experiment to

NASA FAST program, and were approved for two sorties

– Sorties took place earlier this week, using Zero-G Corp. B727 from Ellington Field

– Collected data during 68 parabolas, with emphasis on

measuring read rates for different numbers and types of

tagged materials and different tags

31

W=Water Bottles

T=Tissues

M=Metal Cans

X=miXed Items

Parabola 15

X36 ___

v

W30 ___

M30 ___

W30 ___

M30 ___

W24 ___

T24 ___

M24 ___

T24 ___

M18 ___

W18 ___

W6 ___

v

X24 ___

X24 ___

X18 ___

T18 ___

X12 ___

T12 ___

M12 ___

W12 ___

X30 ___

T30 ___

M24 ___

W24 ___

X30 ___

T30 ___

T6 ___

M6 ___

X6 ___

X60 ___

Parabolas 1-7

Parabolas 16-22

Parabolas 8-14

X54 ___

RAMSES System 0-g Test Flights

TEST PLAN – FAST Program

August 10-14, 2009

X48 ___

0g

1.8g

0g

1.8g

X42 ___

MIT-Aurora Flight Sciences

Parabolas 23-34

Flight Day One Results with Alien Tags

Read Rate Tissues Comparison

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

One-G

Zero-G

0

6

12

18

24

30

Number of Items Detected

Number of Items Detected

Read Rate Water Comparison

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

Number of Items Detected

Number of Items Detected

Zero-G

12

18

24

30

Number of Items in CTB

12

18

24

30

Read Rate Mixed Items Comparison

One-G

6

6

Number of Items in CTB

Read Rate Metals Comparison

0

Zero-G

0

Number of Items in CTB

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

One-G

33

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

One-G

Zero-G

0 6 12 18 24 30 36 42 48 54 60

Number of Items in CTB

Results of Microgravity Testing

• Flight data collected for three materials (water, metal,

paper) and two types of tags (Alien, Omni-D)

• Baseline data collected in 1-G for comparison

• For all materials and tags, microgravity read rates were

equal or better than those from 1-G

• From a performance standpoint, we believe that there are

no fundamental reasons why RFID in 0-G would be

inferior to 1-G

• Caveats:

– Small statistical samples for 0-G cases

– Tag read rates are still not perfect – but we generally saw

90-100% read rates during 20 seconds of reader integration

34

Cost-Benefit Analysis

35

Net Present Value Analysis

• Are the benefits of this RFID application worth the

costs? How likely is this system to result in net

present value?

• Key Equation:

N

NPV

i 1

Bi Ci

1 r i

B = Benefits

C = Costs

r = Discount Rate (Set to 7%, per OMB guidelines [1])

N = Number of Years of Study (FY 2009 – FY 2016, N=8)

36

Two Implementation Strategies Modeled

• “Phase-In” Implementation

– Existing CTBs currently on Station are gradually replaced by

new, “wired” CTBs according to the existing launch schedule

– Contents transferred to new bags by Crew; most-used bags first

– CTB launch rate perhaps too low, especially post-Shuttle

Retirement

• Modification Kits Implementation

– Instead of launching new CTBs, just launch RAMSES hardware

in mod-kits that the Crew can install on-orbit to retrofit existing

CTBs

– Assumes all mod-kits launched & installed in FY 2009

37

Costs Considered

• NASA Engineer Time for:

– Flight Certification & Approval

– Operational Support & Maintenance

• Cost for Vendor to Modify CTBs or Cost to Build Mod-Kits

• Cost of RFID Hardware

• “Opportunity Cost” of:

– Launching the System Mass

– Launching the System Volume

– Crew Time to Transfer Items to Wired Bags or Install Mod

Kits

38

Benefits Considered

• Value of Crew Time Saved on:

– Bi-annual Inventory Audits

– Missing Item Searches

– Daily Inventory Management System Updates

• Reduced workload for JSC Inventory Stowage Officers (ISOs)

– Less need to assist Crew with Inventory updates/searches

• Only Partial Savings realized, per “System Effectiveness” (β)

parameter:

β = (% of Inventory Transactions ‘Automate-able’) x (System

Accuracy)

39

Quantifying Value (“Opportunity Cost”) of Cargo

Launch Volume & Mass

• Value of Cargo Launch Volume =

[Annual Net Variable Recurring Cost (all Cargo Missions)]

[Annual Net Dry Cargo Launch Volume Available (habitable)]

= ~ $20.3 million / m^3 (‘09-’10), ~ $31.6 million / m^3 (‘10’16)

• Value of Cargo Launch Mass =

[Annual Net Variable Recurring Cost (all Cargo Missions)]

[Annual Net Cargo Launch Mass Available]

= ~ $25,500 / lb (‘09-’10), ~ $35,700 / lb (‘10-’16)

40

Quantifying Value of On-Orbit Crew Time

• Value of 1 Hour of On-Orbit Crew Time =

[Average Annual ISS Ops Budget (Common Systems Operations Cost)]

[# Crew] x [# “Active” Hours per day / Crew Member] x [365 days/yr]

•

= ~ $185K / hr (’09)

# Crew = 3, Each active 16 hrs/day

= ~ $ 100K / hr (’10-’16)

# Crew = 6, Each active 16 hrs/day

Notes:

– Common Systems Operations (CSO) Cost is defined as “the cost to operate the ISS”,

including “the cost to transport crew and common supplies” and “ground operations

costs” [9]

– International Partners’ negotiated shares of CSO Costs [10]:

NASA = 76.6%; JAXA = 12.8%; ESA = 8.3%; CSA = 2.3% || RSA = Russian Segment & Crew Ops

Costs

41

Key Variables

• 7 “High-Impact”, Uncertain Variables identified via Sensitivity Analysis

of Discrete Calculation results (“best-available” input values):

– Average ISS Ops Budget

– # of “Active” Crew Hours

Value of Crew Time

– % of IMS Transactions that could be Automated

“System Effectiveness”

– System Accuracy

– Volume Required for 1 RAMSES Unit

– “Opportunity Cost” of Cargo Launch Volume

“Cost” of System Volume

– # of CTBs that are to be “Wired”

•

All but “# of CTBs” are randomly varied within reasonable ranges for

probabilistic Monte Carlo simulations; “# of CTBs” is varied between Monte

Carlo simulations

42

Results

• NPV = +$14.8 Million for Discrete Calculation, Mod-Kit Scenario

• NPV = -$ 63.0 Million for Discrete Calculation, Phase-In Scenario

• Monte Carlo general results:

– Mod-Kit Scenario performs better than gradual Phase-In

– Simulations w/ Normally-Distributed Variables perform slightly better

than those w/ Uniformly-Distributed Variables

– Both scenarios less than 50% likely to result in NPV > 0 if inventory

transactions are evenly distributed among all CTBs

– If transactions are somewhat concentrated in subset of CTBs, and

RAMSES installation can be targeted to those CTBs, both

scenarios are likely (to very likely) to result in NPV > 0. Magnitude

and Likelihood of NPV vary with degree of transaction concentration.

43

Results

If the transactions are evenly distributed throughout all CTBs and we wire 100% of the total CTBs:

If 50%

If 75%

of of

allall

transactions

transactions

occur

occur

in in

25%

50%

of of

thethe

total

total

CTBs:

CTBs:

• 43%

probability

of NPV

> NPV

0 > 0> 0

• 95%

• 84%

probability

probability

of ofNPV

• Mean

= $(13.2)

Million

• Mean

•NPV

Mean

NPV

NPV

= $49.4

= $46.8

Million

Million

• NPV

Std.

Dev.

= Dev.

$77.4

• NPV

• NPV

Std.

Std.

Dev.

= $30.6

= Million

$48.7

Million

Million

• Modification Kits Scenario: Normally-Distributed Variables

25%

Mean NPV

NPV Std. Dev.

25%

Actual % 33%

CTBs

Wired

50%

100%

$

$

(6,028,603.41)

19,313,461.96

x

x

x

x

x

x

% NPV

>0

37%

x

x

x

$

$

$

$

Launch Mod Kits (Best Ops Guess); Normally-Distributed Simulations

Effective % of CTBs Wired (As determined by concentration of transactions)

33%

50%

75%

100%

Mean NPV

Mean NPV

Mean NPV

Mean NPV

% NPV

% NPV

% NPV

% NPV

NPV Std. Dev.

NPV Std. Dev.

NPV Std. Dev.

NPV Std. Dev.

>0

>0

>0

>0

12,484,645.27

$ 49,435,199.17

$ 103,185,422.47

x

71%

95%

100%

x

23,066,435.14

$ 30,550,819.73

$

44,754,456.13

x

(6,035,666.20)

$ 29,780,636.00

$

85,406,626.04

x

41%

82%

98%

x

25,918,469.55

$ 32,852,633.72

$

46,558,196.89

x

x

$ (7,233,783.26)

$

46,835,438.82

x

x

43%

84%

x

x

$ 38,902,427.71

$

48,677,956.52

x

x

x

x

$

(13,223,978.27)

x

x

x

43%

x

x

x

$

77,414,934.03

Aurora Flight Sciences / Payload Systems Division

Grindle

44

Page 44

2008

September 9,

Conclusions

•

If inventory transactions are concentrated in some subset of CTBs, and

part or all of that subset can be targeted for RAMSES installation, this

application of RAMSES is quite likely to result in positive Net Present

Value.

– Such concentration has been reported by JSC ISOs, but not quantified. Intuitively,

it makes sense - some desk drawers get almost all the use.

•

•

•

Cost drivers: System Volume, Mass, & Crew Time required to install.

Key Benefit: Saving part of 20 min/day each Crew Member spends

updating IMS (total = 730 hours/yr) . System Effectiveness (β) parameter is

critical.

As with any Cost/Benefit Analysis, results are limited – can provide

guidance, but not absolute truth. Assumptions and unknowns are important.

45

RAMSES Demo

46

Demo Flow

1. Login to RAILS with web browser

2. Smart Container Inventory (what is in it?)

•

•

Inventory database

Real-time updating

3. Supply Item Hierarchical Tracking (where is it moving (item)?)

•

•

Removal of item

Return item

Login Information

4. Supply Item Addition

5. Item Search (where can I find …?)

6. Rule-based Analytics

•

•

•

Low Inventory Warning

Mass Properties, Shelf Life

Supply Class Incompatibility Rule

7. Automatic Messaging (email)

8. Logging out

47

http://projects.payload.com/RailsV2

user: ramses

password: rfid1

Discussion

Suggestions for Phase 3

48

Interest/Contact Points at NASA

• NASA Stennis Space Center

– T9.02 Integrated Life-Cycle Asset Mapping,

Management, and Tracking Lead Center: SSC

• NASA Wireless & RFID Working Group

– Lead Center: JSC

– Asset Management on ISS

– Lunar Surface Micro-Logistics (e.g. in Habitat)

• NASA Glenn (and NASA JSC CHeCS)

– Crew Medical Supply Inventory

• NASA Astronaut Office

– Greg Chamitoff

– ISS Operations Branch

49

Recommendations for Phase 3

• Establish “Permanent” Test Implementation at JSC

– Bldg. 9 ISS Mockup

– Bldg. 14 Lunar Habitat Mockup

• On-Orbit DTO Demonstration in 2010-2011 timeframe

with “a few” retrofitted CTBs

–

–

–

–

How many? What items?

Integration with IMS

Medical supply tracking

STS-134 and E25/E26 are potential targets of opportunity

• Continue/Evolve Database and Rule-Base Development

– Critical Inventory Levels with Crew Size 6

– Extended ISS Operations (2016-2020)

• Possible recommendation by Augustine Commission today

50

Thank you!

Questions?

Backup Slides

52

T9.02 Integrated Life-Cycle Asset Mapping,

Management, and Tracking Lead Center: SSC

STTR Topic Recap

To support NASA’s need for reliable and low-cost asset management in all of its

programs including Earth-based activities, robotic and human lunar exploration, and

planning for later expeditions to Mars and beyond, the Earth Science Applications

Directorate at Stennis Space Center seeks proposals supporting NASA’s

requirements for asset management. With proper physical infrastructure and

information systems, identification tags should allow any item to be tracked

throughout its life cycle. When combined with Earth and lunar GIS, and related

supporting documentation, any significant asset should be located, through

time and space, as well as organization. Starting with programmatic requirements

and design data, assets would be tracked through manufacture, testing, possible

launch, use, maintenance, and eventual disposal. Innovative technology and

information architectures should integrate and visually map infrastructure,

assets, and associated documentation with the ability to link to program structure,

budget, and workflow. …. A simple operator interface would provide “finger-tip

knowledge” about the asset. …

The innovation may eventually interoperate with a holistic information system, and may

not preclude other uses for a terrestrial and lunar GIS such as:

•

•

•

Operational infrastructure support AM/FM (automated mapping / facilities

management);

Asset and resource management, including waste disposal;

2005/6 SBIR Solicitation

Lunar landing and facility site selection, and optimization …..other

53

Commercial RFID vs NASA

• NASA/Exploration

• Commercial RFID Technology

–

–

–

–

–

–

–

–

– complex supply class

structure

– high value items

– dynamic environment, items

are repackaged, moved

frequently changing

parent/child relationships

– need high read rates

(reliability) > 95%

– routing less predictable

– extreme environments

– less cost sensitive in terms

of $/tag

pushed by Wal-Mart

some industry leaders (Gillette)

mainly “slap and ship”

good for stable supply and

demand situations

items remain in their packaging

throughout the supply chain

predictable routing

tagging at the box or pallet level,

rarely below at the item level

very cost sensitive ($/tag must

be very low)

54

Frequency and Range

Frequency

Range

Tag cost

Applications

Low-frequency

125 - 148 KHz

3 feet

$1+

Pet and ranch animal

identification;

car keylocks

High-frequency

13.56 MHz

3 feet

$0.50

library book identification;

clothing identification; smart

cards

Ultra-high freq

915 MHz

25 feet

$2+

Supply chain tracking:

Box, pallet, container, trailer

tracking

Microwave:

2.45GHz

100 feet

$25+

Highway toll collection;

vehicle fleet identification

55

Flight Day One Results with Alien Tags

Tissues Comparison

30

Number of Items Detected

Number of Items Detected

Water Comparison

24

18

Baseline

12

ZeroG

6

Jan Test Data

0

0

6

12

18

24

30

Number of Items in CTB

30

24

18

Baseline

12

ZeroG

6

Jan Test Data

0

0

6

12

18

24

30

Number of Items in CTB

Metals Comparison

Number of Items Detected

Number of Items Detected

Mixed Items Comparison

30

24

18

Baseline

12

ZeroG

6

Jan Test Data

0

0

6

12

18

24

30

Number of Items in CTB

56

60

54

48

42

36

30

24

18

12

6

0

Baseline

ZeroG

Jan Test Data

0 6 12 18 24 30 36 42 48 54 60

Number of Items in CTB

Flight Day One Results with Alien Tags

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

Read Rate Tissues Comparison

Number of Items Detected

Number of Items Detected

Read Rate Water Comparison

Baseline

ZeroG

Jan Test Data

0

6

12

18

24

30

Number of Items in CTB

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

Baseline

ZeroG

Jan Test Data

0

6

12

18

24

30

Number of Items in CTB

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

Read Rate Mixed Items Comparison

Number of Items Detected

Number of Items Detected

Read Rate Metals Comparison

Baseline

ZeroG

Jan Test Data

0

6

12

18

24

30

Number of Items in CTB

57

100.0%

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

Baseline

ZeroG

Jan Test Data

0 6 12 18 24 30 36 42 48 54 60

Number of Items in CTB

Flight Day Two Results with Omni Tags

Tissues Comparison

30

Number of Items Detected

Number of Items Detected

Water Comparison

24

18

Baseline

12

ZeroG

6

0

0

6

12

18

24

30

Number of Items in CTB

30

24

18

0

0

Number of Items Detected

Number of Items Detected

24

18

Baseline

ZeroG

0

0

6

12

18

24

6

12

18

24

30

Number of Items in CTB

Mixed Items Comparison

30

6

ZeroG

6

Metals Comparison

12

Baseline

12

30

Number of Items in CTB

58

60

54

48

42

36

30

24

18

12

6

0

Baseline

ZeroG

0 6 12 18 24 30 36 42 48 54 60

Number of Items in CTB

ZeroG with

Plastic Cover

Flight Day Two Results with Omni Tags

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

Tissues Read Rate Comparison

Read Rate

Read Rate

Water Read Rate Comparison

Baseline

ZeroG

0

6

12

18

24

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

30

ZeroG

24

Number of Items in CTB

18

24

30

Mixed Items Read Rate Comparison

Baseline

18

12

30

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

Read Rate

Read Rate

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

12

6

Number of Items in CTB

Metals Read Rate Comparison

6

ZeroG

0

Number of Items in CTB

0

Baseline

59

Baseline

ZeroG

ZeroG with

Plastic Cover

0

6 12 18 24 30 36 42 48 54 60

Number of Items in CTB

Analysis Flowchart

60

Monte Carlo Results: CDF

• Modification Kits Implementation

• 100% of CTBs wired

61

Monte Carlo Results: Histogram

• Modification Kits Implementation

• 100% of CTBs wired

62

Quantifying Value (“Opportunity Cost”) of

Cargo Launch Volume & Mass

Cost Per Mission (Variable

Recurring Cost)

Shuttle MPLM

Progress M1

ATV

HTV

$

$

$

$

400,000,000

89,423,000

500,000,000

500,000,000

Max Cargo Max Dry Cargo

Capacity (kg)

Mass (kg)

9400

2230

7667

6000

9400

1800

5500

5500

Available Dry

Cargo Volume

(m^3)

31

6.6

13.8

14

Cost Per Cubic Meter

of Dry Cargo Volume

$

$

$

$

12,903,225.81

13,548,939.39

36,231,884.06

35,714,285.71

Notes:

- Assumed for Shuttle MPLM missions that all cargo capacity is located in MPLM.

- All “Cost Per Mission” values should be regarded as rough approximations, and do not include program costs.

- Dry Cargo Volume is vehicle’s “habitable” volume; this is larger than actual dry cargo volume, but only consistent

value available

References:

- Cost Per Mission [2].

- Max Cargo - Shuttle MPLM [5], Progress M1 [3], ATV [4], HTV [6].

- Max Dry Cargo Mass - Shuttle MPLM [5], Progress M1 [3], ATV [4], HTV [5].

- Available Dry Cargo Volume – Shuttle MPLM [5], Progress M1 [7], ATV [8], HTV [5].

63

Quantifying Value (“Opportunity Cost”) of

Cargo Launch Volume & Mass

64

Quantifying Value of On-Orbit Crew Time

ISS Ops Budget:

US

RSA

JAXA

ESA

CSA

Total:

•

$

$

$

$

$

$

2010-2016

2,261,175,000

550,000,000

377,846,475

245,009,824

67,894,289

3,501,925,587

Sample Calculations:

–

–

–

–

–

•

$

$

$

$

$

$

2009

2,060,200,000

550,000,000

344,263,185

223,233,159

61,859,791

3,239,556,136

US = $2,060,200,000

from NASA FY 2009 Budget Proposal

[11]

Common Systems Operations Costs = (1/.766) * US = $2,689,556,136 [10]

JAXA = (.128)*Common Systems Operations Costs = $344,263,185

[10]

ESA = (.083)*Common Systems Operations Costs =$223,233,159

[10]

CSA = (.023)*Common Systems Operations Costs = $61,859,791

[10]

Note:

– Value of $550 million for RSA is an educated guess; no data available

65

General Inputs (Discrete Calc, Mod-Kits

Implementation Scenario)

Year:

# Crew:

Avg. ISS Budget: $

# "Active" Crew Hours in a Day:

$ / 'Active' Crew Hr: $

2009

3

3,239,556,135.77 $

16

184,906.17 $

2010-2016

6

3,501,925,587.47

16

99,940.80

RFID System Weight (lbs):

Launch Cost ($ / lb): $

$ / System: $

4

25,511.96 $

102,047.85 $

4

35,715.01

142,860.02

Discount Rate:

Volume of Standard CTB (m^3):

Percent of Standard CTB volume required for RFID System:

Volume Cost ($ / m^3): $

$ / System: $

7%

0.053

12%

20,272,793.47 $

128,717.97 $

7%

0.053

12%

31,598,719.79

200,629.63

Note:

•“Launch Cost ($/lb)” and “Volume Cost ($/m^3)” both have different values for Pre- and Post-Shuttle Retirement. For

convenience, these values are listed under “2009” and “2010-2016” respectively, even though the Shuttle will not

retire until the end of 2010. All calculations are performed using the correct retirement date.

66

General Inputs (Discrete Calc, Mod-Kits

Implementation Scenario)

Cost to Build & Prepare Modification Kit to Install RFID System: $

Cost of Hardware Components for 1 RFID System: $

Time Required for Astronauts to Transfer CTB Contents to new CTB (hr):

Number of CTBs upgraded by On-Orbit Crew:

3,000.00

3,000.00

1/3

600

Cost of 1 NASA Engineer Person-Year (Salary + Overhead): $

# NASA Engineer Person-Years for Flight Certification Testing & Review:

# NASA Engineer Person-Years for Operational Maintenance (per year):

# ISOs Employed to Cover 1 Console Shift / Day, 365 Days / Yr:

200,000.00

7

2

12

# of CTBs On-Orbit that are to be wired:

600

First Year to Realize Benefits:

Final Year of ISS Operations:

2010

2016

% On-orbit IMS Entries that could be Automated by Wired CTBs:

% of CTB Transactions Accurately Detected by System:

SYSTEM EFFECTIVENESS (%) for those CTBs that are Wired:

50%

95%

48%

67

Costs (Discrete Calc, Mod-Kits)

Name

Cost to Build & Prepare Modification Kit to Install RFID System

RAMSES Hardware System (parts & labor)

NASA Engineer Time for Flight Certification testing & approval (Person-Yr)

Opportunity Cost of additional mass launched ('09)

Opportunity Cost of cargo displaced due to volume of RFID systems ('09)

Opportunity Cost for On-Orbit Crew to Upgrade CTBs ('09)

Name

NASA Engineer Time for RAMSES operational maintenance (Person-Yr)

Total Capital Costs

One-Time (FY 2009)

Cost ($) Per Unit

Quantity

$

3,000.00

600

$

3,000.00

600

$

200,000.00

7

$

102,047.85

600

$

128,717.97

600

$

61,635.39

600

TOTAL One-Time:

2009

Total ($)

$

1,800,000.00

$

1,800,000.00

$

1,400,000.00

$

61,228,712.53

$

77,230,779.89

$

36,981,234.43

$ 180,440,726.84

Comment

estimate; new bag = $3-5k

estimate; parts ~$3k

estimate; 1 FTE @ GS 12 Step 5 (Hou, TX) + overhead

estimate; 4lb per system

estimate; 0.12 of std CTB volume. required per sys

estimate; 1/3 crew hr per bag, all bags

Spent in FY 2009; No Discount

Recurring Costs during Operations (Per Year)

Cost ($)

Quantity Total ($)

Comment

$

200,000.00

2 $

400,000.00 Cost = salary + overhead

% of CTBs Launched Fiscal Yr TOTAL Recurring:

100%

2009 $

400,000.00

100%

2010 $

373,831.78

100%

2011 $

349,375.49

100%

2012 $

326,519.15

100%

2013 $

305,158.08

100%

2014 $

285,194.47

100%

2015 $

266,536.89

100%

2016 $

249,099.90

Lifetime TOTAL Costs:

$

Present value; No Discount (Crew = 3)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

182,996,442.60

Aurora Flight Sciences / Payload Systems Division

Grindle

68

Page 68

2008

September 9,

Benefits (Discrete Calc, Mod-Kits)

Name

Astronaut On-Orbit Hours for Inventory Audits / yr (2009)

Astronaut On-Orbit Hours for Inventory Audits / yr (2010-2016)

Astronaut On-Orbit Hours for Missing Items Searches / yr (2009)

Astronaut On-Orbit Hours for Missing Items Searches / yr (2010-2016)

Astronaut On-Orbit Hours for Updating IMS (offical timeline) (2009)

Astronaut On-Orbit Hours for Updating IMS (offical timeline) (2010-2016)

Flight Controller (ISO) Time to help crew update IMS (Person-Yr)

Potential Value Added (Crew Time Freed) & Cost Savings Per Year

Cost ($)

Quantity Total ($)

$

184,906.17

24 $

4,437,748.13

$

99,940.80

24 $

2,398,579.17

$

184,906.17

10 $

1,849,061.72

$

99,940.80

10 $

999,407.99

$

184,906.17

365 $

67,490,752.83

$

99,940.80

730 $

72,956,783.07

$

150,000.00

6 $

900,000.00

% of CTBs Wired

Fiscal Yr TOTAL Recurring:

0%

2009 $

100%

2010 $

34,295,341.92

100%

2011 $

32,051,721.42

100%

2012 $

29,954,879.84

100%

2013 $

27,995,214.80

100%

2014 $

26,163,752.15

100%

2015 $

24,452,104.81

100%

2016 $

22,852,434.40

ISS Ops currently projected for NASA funding through end of FY 2016;

if RAMSES was installed and operational by end of FY 2010, potential valued-added &

cost-savings over ISS lifetime =

Lifetime TOTAL Savings = $

Net Present Value = $

Comment

4 hrs/yr/crew member; source = Ursula Stockdale

4 hrs/yr/crew member; source = Ursula Stockdale

estimate; ~10 hrs / yr source = Ursula Stockdale

estimate; ~10 hrs / yr source = Ursula Stockdale

official NASA policy (20 min / day / crew member); 3 crew

official NASA policy (20 min / day / crew member); 6 crew

estimated # of ISOs to support 1 console shift /day, 365 days / yr;

assumed 1 FTE @ GS 11 Step 5 (Hou, TX) + overhead

Present value; No Discount (Crew = 3)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

197,765,449.35

14,769,006.75 Lifetime Total Savings - Lifetime Total Costs

Aurora Flight Sciences / Payload Systems Division

Grindle

69

Page 69

2008

September 9,

General Inputs (Discrete Calc, Phase-In

Implementation Scenario)

Year:

# Crew:

Avg. ISS Budget: $

# "Active" Crew Hours in a Day:

$ / 'Active' Crew Hr: $

2009

3

3,239,556,135.77 $

16

184,906.17 $

2010-2016

6

3,501,925,587.47

16

99,940.80

RFID System Weight (lbs):

Launch Cost ($ / lb): $

$ / System: $

4

25,511.96 $

102,047.85 $

4

35,715.01

142,860.02

Discount Rate:

Volume of Standard CTB (m^3):

Percent of Standard CTB volume required for RFID System:

Volume Cost ($ / m^3): $

$ / System: $

7%

0.053

12%

20,272,793.47 $

128,717.97 $

7%

0.053

12%

31,598,719.79

200,629.63

Note:

•“Launch Cost ($/lb)” and “Volume Cost ($/m^3)” both have different values for Pre- and Post-Shuttle Retirement. For

convenience, these values are listed under “2009” and “2010-2016” respectively, even though the Shuttle will not

retire until the end of 2010. All calculations are performed using the correct retirement date.

70

General Inputs (Discrete Calc, Phase-In

Implementation Scenario)

Year:

Cost to Modify 1 CTB for RFID System (add pockets, insulation, install electronics): $

2009

3,000.00

Cost of Hardware Components for 1 RFID System: $

Time Required for Astronauts to Transfer CTB Contents to new CTB (hr):

Number of CTBs Contents Transferred to Wired CTB On-Orbit:

3,000.00

1/3

80

Cost of 1 NASA Engineer Person-Year (Salary + Overhead): $

# NASA Engineer Person-Years for Flight Certification Testing & Review:

# NASA Engineer Person-Years for Operational Maintenance (per year):

# ISOs Employed to Cover 1 Console Shift / Day, 365 Days / Yr

200,000.00

7

2

6

# of CTBs On-Orbit:

Wired CTB Launch Rate (% of Total ISS Population):

First Year to Realize Benefits:

Final Year of ISS Operations:

600

13%

2010

2016

% On-orbit IMS Entries that could be Automated by Wired CTBs:

% of CTB Transactions Accurately Detected by System:

SYSTEM EFFECTIVENESS (%) for those CTBs that are Wired:

50%

95%

48%

71

2010-2016

520

Costs (Discrete Calc, Phase-In)

Name

NASA Engineer Time for Flight Certification testing & approval (Person-Yr)

Total Capital Costs

One-Time (FY 2009)

Cost ($)

Quantity Total ($)

Comment

$

200,000.00

7 $

1,400,000.00 estimate; 1 FTE @ GS 12 Step 5 (Hou, TX) + overhead

TOTAL One-Time:

Name

Modify Standard Cargo Transfer Bag for RAMSES (add pockets, insulation)

RAMSES Hardware System (parts & labor)

NASA Engineer Time for RAMSES operational maintenance (Person-Yr)

Opportunity cost of additional mass launched ('09-'10)

Opportunity cost of additional mass launched ('11-'16)

Opportunity Cost of cargo displaced due to volume of RFID systems ('09-'10)

Opportunity Cost of cargo displaced due to volume of RFID systems ('11-16)

Opportunity Cost for On-Orbit Crew to Upgrade CTBs (2009)

Opportunity Cost for On-Orbit Crew to Upgrade CTBs (2010-2016)

2009 $

1,400,000.00 Spent in FY 2009; No Discount

Recurring Costs during Ramp-Up (Per Year)

Cost ($)

Quantity Total ($)

$

3,000.00

80 $

239,400.00

$

3,000.00

80 $

239,400.00

$

200,000.00

2 $

400,000.00

$

102,047.85

80 $

8,143,418.77

$

142,860.02

80 $

11,400,229.67

$

128,717.97

80 $

10,271,693.73

$

200,629.63

80 $

16,010,244.09

$

61,635.39

80 $

4,918,504.18

$

33,313.60

80 $

2,658,425.25

% of CTBs Launched Fiscal Yr TOTAL Recurring:

13%

2009 $

24,212,416.67

27%

2010 $

20,516,203.49

40%

2011 $

24,186,294.09

53%

2012 $

22,604,013.17

67%

2013 $

21,125,245.95

80%

2014 $

19,743,220.51

93%

2015 $

18,451,607.96

100%

2016 $

8,946,391.32

Lifetime TOTAL Costs:

72

$

161,185,393.16

Comment

estimate; new bag = $3-5k

estimate; parts ~$2k

cost = salary + overhead

estimate; 4lb per system

estimate; 4lb per system

estimate; 0.12 of std CTB volume. required per sys

estimate; 0.12 of std CTB volume. required per sys

estimate; 1/3 crew hr per bag, all bags

estimate; 1/3 crew hr per bag, all bags

Present value; No Discount (Crew = 3)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Benefits (Discrete Calc, Phase-In)

Name

Astronaut On-Orbit Hours for Inventory Audits / yr (2009)

Astronaut On-Orbit Hours for Inventory Audits / yr (2010-2016)

Astronaut On-Orbit Hours for Missing Items Searches / yr (2009)

Astronaut On-Orbit Hours for Missing Items Searches / yr (2010-2016)

Astronaut On-Orbit Hours for Updating IMS (offical timeline) (2009)

Astronaut On-Orbit Hours for Updating IMS (offical timeline) (2010-2016)

Flight Controller (ISO) Time to help crew update IMS (Person-Yr)

Potential Value Added (Crew Time Freed) & Cost Savings Per Year

Cost ($)

Quantity Total ($)

$

184,906.17

24 $

4,437,748.13

$

99,940.80

24 $

2,398,579.17

$

184,906.17

10 $

1,849,061.72

$

99,940.80

10 $

999,407.99

$

184,906.17

365 $

67,490,752.83

$

99,940.80

730 $

72,956,783.07

$

150,000.00

6 $

900,000.00

% of CTBs Wired

Fiscal Yr TOTAL Recurring:

0%

2009 $

13%

2010 $

4,561,280.48

27%

2011 $

8,525,757.90

40%

2012 $

11,951,997.05

53%

2013 $

14,893,454.27

67%

2014 $

17,398,895.18

80%

2015 $

19,512,779.64

93%

2016 $

21,275,616.43

ISS Ops currently projected for NASA funding through end of FY 2016;

if RAMSES was installed and operational by end of FY 2010, potential valued-added &

cost-savings over ISS lifetime =

Lifetime TOTAL

Savings

$

NPV =

$

73

Comment

4 hrs/yr/crew member; source = Ursula Stockdale

4 hrs/yr/crew member; source = Ursula Stockdale

estimate; ~10 hrs / yr source = Ursula Stockdale

estimate; ~10 hrs / yr source = Ursula Stockdale

official NASA policy (20 min / day / crew member); 3 crew

official NASA policy (20 min / day / crew member); 6 cew

estimated # of ISOs to support 1 console shift /day, 365 days / yr;

assumed 1 FTE @ GS 11 Step 5 (Hou, TX) + overhead

Present value; No Discount (Crew = 3)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

Assumes Discount Rate; (Crew = 6)

98,119,780.95

(63,065,612.21) Lifetime Total Savings - Lifetime Total Costs

Normally-Distributed Random Variables

Mod-Kits

Phase-In

Lower 95%

Upper 95%

Mean

Std Dev

2009-2010

Bound

Bound

Avg. Total ISS Budget: $3,100,000,000 $3,650,000,000 $ 3,375,000,000 $ 137,500,000 $ 3,168,583,748

# "Active" Crew Hours in a Day:

10

18

14

2

12

% On-orbit IMS Entries that could be

30%

70%

50%

10%

45%

Automated by Wired CTBs:

% of CTB Transactions Accurately

80%

100%

90%

5%

92%

Detected by System:

$ / m^3 of Cargo Up-Volume: $ 10,000,000

$50,000,000 $

30,000,000 $ 10,000,000 $

35,979,362

Percent of Standard CTB volume

4%

20%

12%

4%

8%

required for RFID System:

Lower 95%

Upper 95%

Mean

Std Dev

2009-2010

Bound

Bound

Avg. Total ISS Budget: $3,100,000,000 $3,650,000,000 $3,375,000,000 $137,500,000 $3,188,222,430

13

# "Active" Crew Hours in a Day:

10

18

14

2

% On-orbit IMS Entries that could be

30%

70%

50%

10%

48%

Automated by Wired CTBs:

% of CTB Transactions Accurately

80%

100%

90%

5%

96%

Detected by System:

$50,000,000 $ 30,000,000 $ 10,000,000 $ 39,046,734

$ / m^3 of Cargo Up-Volume: $ 10,000,000

Percent of Standard CTB volume required

4%

20%

12.0%

4.0%

14%

for RFID System:

Wired CTB Launch Rate (% of Total ISS

5%

15%

10.0%

2.5%

11%

Population):

74

2011-2016

$ 3,365,681,107

$

28,675,797

2011-2016

$3,524,480,947

$

41,051,962

Uniformly-Distributed Random Variables

Mod-Kits

Avg. Total ISS Budget:

# "Active" Crew Hours in a Day:

% On-orbit IMS Entries that could be Automated by Wired CTBs:

% of CTB Transactions Accurately Detected by System:

$ / m^3 of Cargo Up-Volume:

Percent of Standard CTB volume required for RFID System:

Lower Bound

Upper Bound

2009-2010

$ 3,100,000,000 $ 3,650,000,000 $ 3,145,265,355

10

18

10

30%

70%

41%

80%

100%

97%

$

10,000,000

$50,000,000 $

11,549,377

4%

20%

4%

2011-2016

$ 3,363,132,171

$

49,555,001

Phase-In

Lower Bound

Upper Bound

2009-2010

Avg. Total ISS Budget: $ 3,100,000,000 $ 3,650,000,000 $ 3,357,339,623

13

# "Active" Crew Hours in a Day:

10

18

50%

% On-orbit IMS Entries that could be Automated by Wired CTBs:

30%

70%

85%

% of CTB Transactions Accurately Detected by System:

80%

100%

$ / m^3 of Cargo Up-Volume: $

10,000,000

$50,000,000 $ 15,565,849

4%

20%

13%

Percent of Standard CTB volume required for RFID System:

5%

15%

6%

Wired CTB Launch Rate (% of Total ISS Population):

75

2011-2016

$ 3,490,240,955

$

43,202,514

Future Work – Cost/Benefit Analysis

• Common Systems Operations Costs

– Likely to be larger than currently calculated (baseline uses Proposed NASA FY

2009 ISS Ops Budget as reference, but this does not include launch costs)

Would increase likelihood & magnitude of NPV (increase value of Crew Time)

– Russian Ops Costs unknown; likely to be larger as well? Same impact.

•

Dry Cargo Volume Capacity of Launch Vehicles

– Only “habitable volume” is consistently available; overestimates cargo space.

Would decrease likelihood & magnitude of NPV (increase cost of cargo volume)

•

Benefits of Enhanced Safety and Mission Assurance are not included in this

analysis

•

Cost of integrating RAMSES with existing IMS not included (technical &

political)

76

Contacts

Principal Investigator (MIT):

Prof. Olivier de Weck

MIT Dept of Aeronautics and Astronautics

MIT Room E40-261

77 Massachusetts Avenue

Cambridge, MA 02139

deweck@mit.edu

(617) 715-5195

Project Manager (Aurora Flight Sciences):

Joe C. Parrish

Aurora Flight Sciences

One Broadway, 12th Floor

Cambridge, MA 02142

jparrish@aurora.aero

(617) 500-0248

77

0

0

advertisement

Download

advertisement

Add this document to collection(s)

You can add this document to your study collection(s)

Sign in Available only to authorized usersAdd this document to saved

You can add this document to your saved list

Sign in Available only to authorized users