IB Design Technology Sample SOW

advertisement

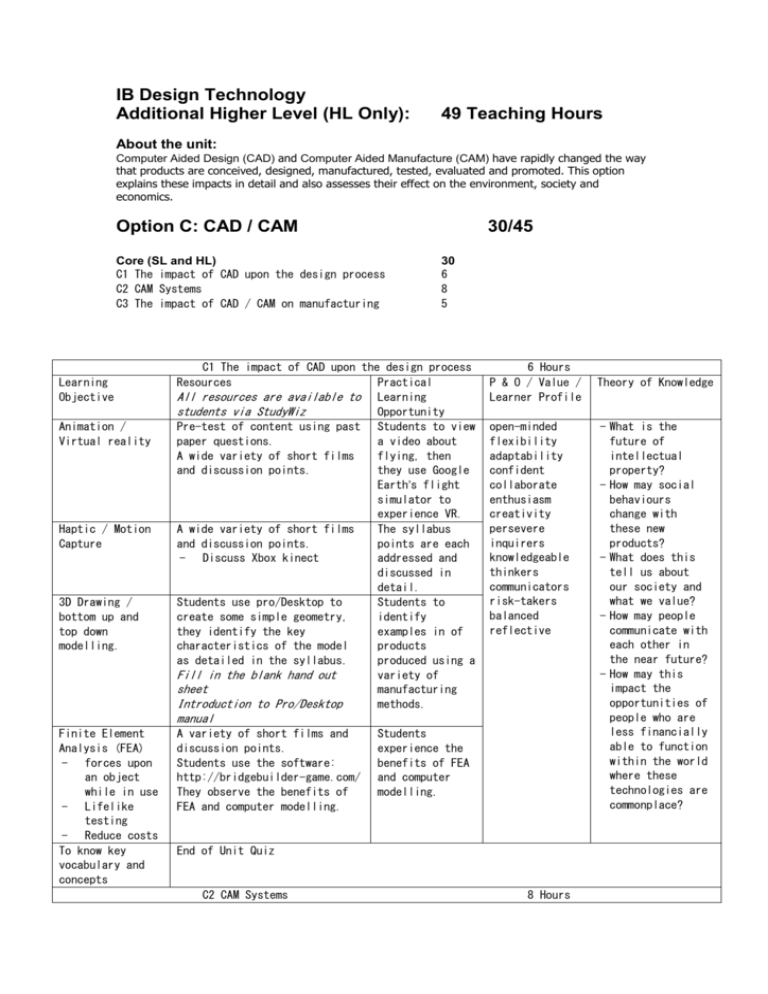

IB Design Technology Additional Higher Level (HL Only): 49 Teaching Hours About the unit: Computer Aided Design (CAD) and Computer Aided Manufacture (CAM) have rapidly changed the way that products are conceived, designed, manufactured, tested, evaluated and promoted. This option explains these impacts in detail and also assesses their effect on the environment, society and economics. Option C: CAD / CAM 30/45 Core (SL and HL) C1 The impact of CAD upon the design process C2 CAM Systems C3 The impact of CAD / CAM on manufacturing Learning Objective Animation / Virtual reality Haptic / Motion Capture 3D Drawing / bottom up and top down modelling. 30 6 8 5 C1 The impact of CAD upon the design process Resources Practical All resources are available to Learning students via StudyWiz Opportunity Pre-test of content using past Students to view paper questions. a video about A wide variety of short films flying, then and discussion points. they use Google Earth’s flight simulator to experience VR. A wide variety of short films The syllabus and discussion points. points are each - Discuss Xbox kinect addressed and discussed in detail. Students use pro/Desktop to Students to create some simple geometry, identify they identify the key examples in of characteristics of the model products as detailed in the syllabus. produced using a Fill in the blank hand out variety of sheet manufacturing Introduction to Pro/Desktop methods. 6 Hours P & O / Value / Learner Profile open-minded flexibility adaptability confident collaborate enthusiasm creativity persevere inquirers knowledgeable thinkers communicators risk-takers balanced reflective manual Finite Element Analysis (FEA) - forces upon an object while in use - Lifelike testing - Reduce costs To know key vocabulary and concepts A variety of short films and discussion points. Students use the software: http://bridgebuilder-game.com/ They observe the benefits of FEA and computer modelling. Students experience the benefits of FEA and computer modelling. End of Unit Quiz C2 CAM Systems 8 Hours Theory of Knowledge - What is the future of intellectual property? - How may social behaviours change with these new products? - What does this tell us about our society and what we value? - How may people communicate with each other in the near future? - How may this impact the opportunities of people who are less financially able to function within the world where these technologies are commonplace? Learning Objective Resources Additive vs. Subtractive Manufacturing Student made geometry is them rapid prototyped using the 3D printer (FDM) to demonstrate additive. Subtractive is demonstrated when students make their own vinyl decals. G-Code and STL files are created and explained. All resources are available to students via StudyWiz C.2.7, C.2.8 & C.2.9 A variety of outcomes from various technologies are examined. Variety of tools, feed speed, machine tool step variable, cutting paths, quality of finish and limitations of 3 axis machines. A wide variety of short films and discussion points. Students to identify examples in of products produced using a variety of manufacturing methods. To know key vocabulary and concepts End of Unit Quiz Students use pro/Desktop to create some simple geometry. They use Modella Virtual Machining software to adjust variables and to ‘see’ the cutting process virtually. Students complete supporting worksheet. A sample work is also cut using the 3-Axis CNC Router machine to demonstrate the actual process. Practical Learning Opportunity Students to design and make their choice of CAD/CAM product. (3 Hours) The simple geometry is processed into Gcode with Replicator G software. The syllabus points are each addressed and discussed in detail. Modella Virtual Machining software is used to complete a supporting worksheet. With a variety of materials, tool size, quality of cut, etc. P & O / Value / Learner Profile Theory of Knowledge open-minded flexibility adaptability confident collaborate creativity persevere inquirers knowledgeable thinkers communicators reflective - What is the future of our relationship to our products? - Will we begin to value the uniqueness of products more or less and how does this reflect our relationship with the environment? Learning Objective Definitions introduced in the previous section are further defined. Numerical Control, NC, CNC, 2, 3, 4 and 5 axis machining. Interfacing of Milling machines and CAD / CAM systems. The CNC Lathe and its products Define Computer integrated manufacture (CIM). How CAD / Cam is integrated into CIM and outline an example of CIM / discuss advantages and disadvantages. To know key vocabulary and concepts C3 The impact of CAD / CAM on manufacturing Resources Practical All resources are available to Learning students via StudyWiz Opportunity A wide variety of short films Students to make and discussion points. a 3 axis etched Students to identify examples image of their in of products produced using choice using the a variety of manufacturing 3 axis CNC methods. routers A wide variety of short films and discussion points. Students to identify examples in of products produced using a variety of manufacturing methods. Short Videos: a variety of Computer Integrated Manufacture (CIM), Discussion and group work in making a flowchart, then a story. Example Story: http://storybird.com/books/com puter-integratedmanufacture/?token=pp74hxrqxn End of Unit Quiz The syllabus points are each addressed and discussed in detail. Students create a storybird.com story for a new company and their product, tracking a product from order to delivery and explaining the advantages and disadvantages along the process. 5 Hours P & O / Value / Learner Profile open-minded flexibility adaptability confident collaborate enthusiasm creativity persevere inquirers knowledgeable thinkers communicators risk-takers balanced reflective Theory of Knowledge - What may the impact upon traditional businesses be? - How could this technology and working practice impact other products and industries? i.e food: meat and dairy? - What is the potential for the workers and the workplace of the future?