©2015 American Bureau of Shipping. All rights reserved.

Title of Powerpoint

Subhead

Operational Safety:

Tools for Incident Prevention

Date of Event

Location of Event

Name of Presenter

Title of Presenter, Company

Operational Safety

• Operational safety

involves effort and

expense

• Trend these days

among ABS clients:

• Getting tools for

incident prevention is

– “The Right Thing To Do”

– “Simply Good Business”

2

Examples of Tools to Reduce Incidents

• Jackup rig moves

– Methodology to define

operational limits

– Systems to monitor

motions and seastates

• DP systems and

operations

– ABS DP Guide

• MODU hull condition

management

– Process for systematic

inspection and

maintenance

3

Present Practice: Jackup Rig Moves

• Jackups are prone to damage during rig moves

• Overly-conservative approach

– Waiting on weather

– Non-productive time (NPT), lost revenue – CERTAIN

• Overly-aggressive approach

– Rolling the dice, downside

is incident with unplanned

repair project

– Costly repairs

– NPT, lost revenue

4

Present Practice: Operational Limits

• Documented in rig’s Marine

Operating Manual

• Limits are based on seastate

• Largely experience-based

• Typically don’t account for:

–

–

–

–

Wave period

Wave direction

Swell

Other effects

5

Updated Practice: Methodology & Monitoring

• Moving off location:

– Get allowable limits. Analyze potential for damaging legs

and pinions during leg extraction.

– Monitor seastates while elevated, get statistics

– Use statistics vs limits for go/no-go decision

• Moving on location:

– Get allowable limits. Analyze potential for damaging legs

and pinions during touchdown on seabed.

– Monitor hull motions during approach, get statistics

– Use statistics versus limits for go/no-go decision

• ABS Guide / Guidance Notes under development

6

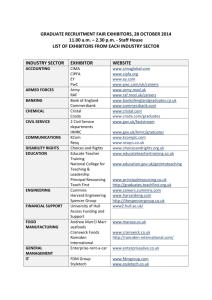

DP Drillships: Challenges of Expanding Fleet

• Pre–1995: 23 drillships exist – a few experts dealing with a few rigs

• 2015 and beyond: 170 drillships – not enough experts to go around

# of Drillships vs. Build Date (as of 4Q/14)

80

70

60

50

40

30

20

10

0

pre 1969

1970 1974-

1975 1979

1980 1984

1985 1989

1990 1994

1995 1999

2000 2004

2005 2009

2009 2014

2015-'19

So Far

7

DP Drillships: Risk Management Challenge

• Loss of station with

emergency disconnect of

riser:

– Safety

– Environmental event

– Costly downtime

• Who is controlling the risk?

– Operator A

– Contractor B

• Who owns the risk? All

industry stakeholders.

8

DP Drillships: Results of Standardization

• DP knowledge now resides in industry standards (e.g.,

ABS Guide for Dynamic Positioning Systems)

• Best practices for DP operations are available to all

stakeholders (ISO 13624-1, ISO 13624-2, API 16Q)

– Drift-off analysis techniques

– Watch circles in DP operations

– Emergency disconnect

sequences

– Riser recoil

– Drilling riser management

• This approach is:

– “The right thing to do”

– “Simply good business”

9

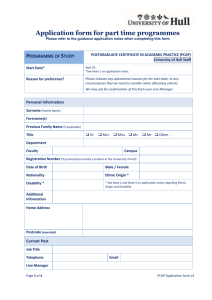

MODU Hull Condition Management: Ageing Fleet

• 50% of MODUs are over 30 years old (dominated by SEDUs)

# of MODUs vs. Build Dates

(Q4/14)

200

180

Drillships

CSDU

SEDU

160

140

120

100

80

60

40

20

0

pre - 1969

1970 1974-

1975 1979

1980 1984

1985 1989

1990 1994

1995 1999

2000 2004

2005 2009

2009 2014

10

MODU Hull Condition Management: Issues

• Safety and operational efficiency challenges:

– Safety issues (e.g., watertight integrity, structural failures)

– Cost of repairs; NPT; Time in repair yards

– Remaining life

• Inspection and maintenance

– Vital to the safe operation and longevity

– Time-consuming, difficult and expensive

• Preparation for periodic surveys

– Conducted on location – avoids lost revenue; avoids cost

of moving vessel to dry dock

11

MODU Hull Condition Management: Solution

• Systematic hull inspection and maintenance

• Employs the following tools:

–

–

–

–

Survey planning document

Computerized planning and inspection tools

Acceptance criteria

An eye toward repair and dry dock planning

• Minimizes chance of hull failures and reduces

costly repairs and NPT over the life of the vessel

• Inspection software used by on-board personnel

12

Operational Safety: Summary

• Operational safety involves effort and expense

• Tools for incident prevention are available

• Putting them to work is:

– “The Right Thing To Do”

– “Simply Good Business”

13

©2015 American Bureau of Shipping. All rights reserved.

14