Project Control

advertisement

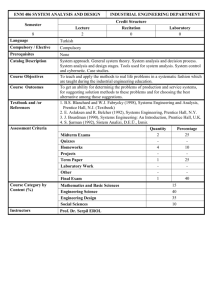

1.040/1.401/ESD.018 Project Management, Spring 2007 Lecture 15 Project Control Samuel Labi and Fred Moavenzadeh Department of Civil and Environmental Engineering Massachusetts Institute of Technology Project Control Recall: The 5 Phases of Project Management FEASIBILITY Finance Evaluation DESIGN, PLANNING Organization Estimation Planning CLOSEOUT DEVELOPMENT CLOSEOUT Monitoring & Control Changes & Claims Quality & Reviews Actual Start of Project OPERATIONS Project Control Monitoring & Control: A Feedback Process Detect deviations Monitoring Control 1. Measurement 2. Performance Analysis) 1. Actions 2. Revised Plans, Cash Flows, Schedules, etc. Correct Deviations Project Control Project Control: The Big Picture … Given Project is Off-track Project Control Project Control: The Big Picture … Given Project is Off-track Monitoring indicates that: - Project is behind time-schedule, and/or - Project has exceeded budget, and/or - Quality of materials or finished work is below standard, and/or - Productivity is lower than as planned, etc. Project Control Project Control: The Big Picture … Given Project is Off-track Resources for PC (the 4-M’s) Project Control Project Control: The Big Picture … Given Resources for PC (the 4-M’s) Project is Off-track Resources available to the Project Manager for Project Control: - Money - Manpower (labor) - Materials - Machinery (Equipment) Project Control Project Control: The Big Picture … Given Project is Off-track Resources for PC (the 4-M’s) Mechanism and Elements of PC Adjust the resources Adjust the project characteristics: size, scope, etc Project Control Project Control: The Big Picture … Given Resources for PC (the 4-M’s) Project is Off-track Mechanism and Elements of PC Adjust the resources resources project More labor? Better labor? Better supervision? More materials? Better materials? More equipment? Better equipment? More money? Reduce project size? Reduce project scope? Terminate project? Adjust the project characteristics: size, scope, etc Project Control Project Control: The Big Picture … Given Project is Off-track Resources for PC (the 4-M’s) Mechanism and Elements of PC Adjust the resources Adjust the project characteristics: size, scope, etc Was the Project Control successful? How can we tell? output Project brought back on-track Project Control Project Control: The Big Picture … Given Project is Off-track Resources for PC (the 4-M’s) Elements and Mechanism of PC Adjust the resources Adjust the project characteristics: size, scope, etc output Project brought back on-track Project Control Outline of this Lecture: 1. How can we tell when PC is needed? 2. What resources are available for PC? 3. What are the elements of PC? 4. What is the mechanism of PC? 5. Some important issues in Project Control Part 1 How can we tell when Project Control is needed? Is Project Control is needed now? How can we tell? General Clues Performance and Quality Cost Time Specific Clues “Primitive” Indicators Other Indicators How can we tell when Project Control is needed? GENERAL CLUES (Meredith and Mantel, 2006) Performance - Unexpected technical problems arise - Insufficient resources are unavailable when needed - Quality or reliability problems occur - Owner/Client requires changes in technical specifications - Inter-functional complications and conflicts arise - Market changes that increase/decrease the project’s value How can we tell when Project Control is needed? GENERAL CLUES (Meredith and Mantel, 2006) Cost - Technical difficulties that require more resources - Scope of work increases - Bid amount (accepted for the contract award) is too low - Reporting of the monitoring results are poor/late - Project budgeting for contractor cash flows not done right - Changes in market prices of the inputs How can we tell when Project Control is needed? GENERAL CLUES (Meredith and Mantel, 2006) Time - Technical difficulties require more time to solve - Scope of work increases - Unexpected utilities needing relocation - Task sequencing not done right - Required material, labor/equipment unavailable when needed - Key preceding tasks were not completed on time. 1. How can we tell when PC is needed? SPECIFIC CLUES “Primitive” indicators: – More resources or less resources haven been used than planned – Activities are taking long than planned – Cost of activity (or of project to date) is higher than expected planned actual Equipment-hours planned Total Man-hours actual planned actual Amt of concrete used (tons) 0 500 1000 1500 2000 Amount input to date 1. How can we tell when PC is needed? SPECIFIC CLUES “Primitive” indicators: – More resources or less resources haven been used than planned – Activities are taking long than planned – Cost of activity (or of project to date) is higher than expected planned actual Equipment-hours planned actual Total Man-hours planned actual Amt of concrete used (tons) 0 500 1000 1500 2000 Amount input to date 1. How can we tell when PC is needed? SPECIFIC CLUES JAN “Primitive” indicators: – More resources or less resources haven been used than planned FEB MAR planned Activity 1 APR MAY actual Activity 2 – Activities are taking long than planned Activity 3 NOW – Cost of activity (or of project to date) is higher than expected Legend planned actual JUN 1. How can we tell when PC is needed? SPECIFIC CLUES “Primitive” indicators: – More resources or less resources haven been used than planned – Activities are taking long than planned – Cost of activity (or of project to date) is higher than expected Program (schedule) Progress (actual) $ 70% 50% Program (schedule) Progress (actual) now time 1. How can we tell when PC is needed? SPECIFIC CLUES Why are they “primitive”? - May be biased. - Do not consider that progress may be overestimated or underestimated due to: - execution of unscheduled work done, or execution of more work of low value and less work of high value 1. How can we tell when PC is needed? SPECIFIC CLUES Used for plotting the Program S-curve Work Schedule (WS) Work Performed (WP) Budgeted Cost (BC) BCWS BCWP Actual Cost (AC) ACWS ACWP Used for plotting the EVA S-curve Used for plotting the Progress S-curve 1. How can we tell when PC is needed? SPECIFIC CLUES $max TIME VARIANCE BCWS ACWPt BCWSt BCWPt RESOURCE FLOW VARIANCE COST VARIANCE SCHEDULE VARIANCE ACWP BCWP t-p t now tmax Time 1. How can we tell when PC is needed? So we know Project Control is needed (at time t) particularly when: - RVt is –ve, - RIt < 1 - CVt is –ve - CIt <1 - SVt is –ve - SIt is < 1 - TVt is –ve - TIt is < 1 Part 2 Resources for Project Control 2. Resources for Project Control Money Machinery (Equipment) Materials and Supplies Manpower (Labor and Supervision) Money as a PC Resource Not a direct resource Rather, used to influence the amounts or quality of the other resources Using Equipment for PC Often used to augment labor in order to speed up project Can be expensive May involve renting or purchasing Materials and Supplies as a PC Resource Increase in quality or quantity may be necessary to enhance project control Improved inventory systems for materials Manpower as a PC Resource Project problems (time delays, excess costs, poor performance, etc.) are partly due to the human element (action or inaction) In using Manpower as a tool for project control, PM encounters human emotions (anger, fear, frustration, etc.) Part 3 Elements of Project Control Elements of Project Control Resources-related Project-related 3. Elements of Project Control 3A. Resource-related Re-allocate resources Manpower-related control Machinery-related control Money-related control Material-related control Elements of Project Control 3A. Resource-related Re-allocate resources Manpower Also referred to as ”Human Resource Control” - Lay-off/fire any under-performing staff Machinery - Hire staff with needed skills - Assign staff with specific skills to specific activities Money Issues: Materials -PM may be seen as a “stern disciplinarian” - PM must avoid heavy handed actions, - Fix problems without blaming people Elements of Project Control 3A. Resource-related Re-allocate resources Manpower Also referred to as ”Physical Asset Control” Machinery - Re-assign specific equipment to specific activities Money Materials - Decommission any under-performing equipment - Bring in equipment with appropriate capabilities Elements of Project Control 3A. Resource-related Re-allocate resources Manpower Also referred to as ”Physical Asset Control” Machinery - Re-assign specific equipment to specific activities Money Materials - Decommission any under-performing equipment - Bring in equipment with appropriate capabilities Issues: - Equipment decisions may involve some economic analysis - Equipment-based control easier than manpowerbased control - Some trade-off may exist between manpower and equipment utilization. Elements of Project Control 3A. Resource-related Re-allocate resources Manpower Machinery Money Also referred to as ”Financial Resource Control” - How much money should be spent? - How should it be spent? - PM assisted by: Materials - Project accountant - Project Finance Manager Elements of Project Control 3A. Resource-related Re-allocate resources Manpower Machinery Money Materials - Discontinue use of sub-standard material - Seek new sources of superior material Elements of Project Control 3B. Project-related Options: - Reduce project size? - Reduce project scope? - Terminate project? Part 4 Mechanisms of Project Control Mechanisms of Project Control Types of Mechanisms: - Cybernetic - Go/No-go - Post-control Types of Control Mechanisms Cybernetic - “Cyber” means “Steer” or helmsman (Greek language) - May be First-, Second-, or Third-order Cybernetic control mechanisms Monitoring mechanism (e.g. sensor) Inputs Process Effector and Decisionmaker Comparator Standards Outputs Mechanism: - System output monitored by sensor - Sensor measurements transmitted to Comparator - Measurements compared with predetermined standards -- Deviation from standard sent to decision-maker -If deviation from standard is too large, signal sent to Effector Cybernetic control mechanisms Monitoring mechanism (e.g. sensor) Inputs Process Effector and Decisionmaker Outputs Comparator Standards This is a First-order cybernetic control system. (Standards are fixed) Example: Thermostat that keeps room temperature to 70F all year round. Mechanism: - System output monitored by sensor - Sensor measurements transmitted to Comparator - Measurements compared with predetermined standards -- Deviation from standard sent to decision-maker -If deviation from standard is too large, signal sent to Effector Cybernetic control mechanisms Monitoring mechanism (e.g. sensor) Inputs Process Effector and Decisionmaker Outputs Comparator Standards Mechanism: - Same as described for Firstorder Cybernetic systems, but: - Standards are not fixed, but the manner they change is fixed. Memory Pre-programmed Responses This is a Second-order cybernetic control system (standards vary according to a fixed set of rules) Examples: Thermostat that keeps room temperature to 70F in winter and 65F in summer, Robot installations, Automated inventory systems, Automated record keeping systems Cybernetic control mechanisms Monitoring mechanism (e.g. sensor) Inputs Process Effector and Decisionmaker Outputs Comparator Standards Mechanism: - Same as described for Firstorder Cybernetic systems, but: - Standards are not fixed but are variable. Also, the manner they change is variable because there is a consciousness (human element) involved. Consciousness Memory, Selection This is a Third-order cybernetic control system (standards vary according to a variable set of rules) Examples: Most Project management systems. Cybernetic control in Project Management 1. PM must clearly define “outputs” in terms of relevant project characteristics 2. PM must establish standards for each characteristic 3. Monitoring mechanisms (sensors) must be established to measure the characteristics at regular intervals 4. For each characteristic, the trigger point or maximum deviation (difference between “attained level” and “standard level”) should be established. 5. If triggered, appropriate action should be taken to minimize the deviation between Attained Level and Standard Level of performance. “Go/No-go” Mechanisms of Project Control Testing to see if some specific precondition has been achieved Yes/No (discrete) Control in most PM fall into this category (Cooper, 1994; Meredith and Mantel, 2006) Example: Was Activity X completed within 6 months? Did Activity Y cost exceed its budget of $1.5 million? Some engineering judgment is necessary in exercising these types of controls. Post-Control Types of Project Control Also called: Post-performance control, Post-performance review Is done after the activity or project is over Like a post-mortem or report card Is it “Locking the barn door after the horse has escaped”? Or is it “We need to learn from the past to avoid future mistakes”? Generates lessons from current projects so that future projects can be controlled better. Desired characteristics of a project control mechanism Flexible – PC should be able to react to changes in system performance Cost-effective – Value of PC should exceed cost of PC Useful – Must really satisfy the needs of project, not the whims of the PM Timely – Be able to react quickly before the problem overwhelms the project Simple –Easy to understand and operate Adjustable – Capable of being adjusted to reflect changing priorities Documented – so that training is possible Some Interesting Issues in Project Control Flexibility Trade-offs Some things to watch out for Impediments to Project acceleration Cost-only and time-only actions to control projects Some Interesting Issues in Project Control Value of Flexibility in Project Planning Flexibility is primary defense against risk Planning too tightly may highly complicate control Flexibility in construction is key during control Want adequate float and contingency to change plans if needed Be careful on value engineering that limits flexibility! Some Interesting Issues in Project Control Trade-offs between Performance Measures during Project Control Can sometimes only correct for one performance measure at a time – Time – Cost – Quality Need to understand tradeoffs and triage – Pick where to make tradeoffs (e.g. non-critical activities) Some Interesting Issues in Project Control Tradeoffs Acceleration $ Need for rework imposes (Overtime, shift work, high expenses Rework, higher-end High quality needs can lead equipment, better crews etc.) to costly miscalculations Slow progress $ on labor time Delayed occupation, Higher interest on Less $ Low progress Trying to save $ const. loan Resource reduction Can lead to substitution, Loss of tenants Selection of poor quality workers lower quality Opportunity cost Default of contractor/subs workmanship $ Time Quality level impacts speed of work, Level of rework Quality problems result from overtime, shift work, new hires Quality Some Interesting Issues in Project Control Trade-offs: The Time-Quality-Money Triage In many cases, the best we can do is to pick the areas where tradeoffs do the least harm e.g. – Move resources from non-critical activities – Accelerate only critical activities – Sacrifice quality on non-critical items that can be remedied after substantial completion Some Interesting Issues in Project Control Some things to watch out for: Overreacting/Improvisation, etc.) When trying to correct, often bump up against other limiting factors – Space constraints/Hiring time/Morale/Coordination difficulties Improvisation dangerous (working w/o planning) – Often can lead to “Snowballing” (increased problems at a rapidly accelerating rate) – Confusion, discoordination, cascading unanticipated effects, suboptimal work efficiency, lack of morale – Breaking “Job rhythm” and learning curves can really inhibit productivity! Some Interesting Issues in Project Control Controlling the Time Schedule – Project Crashing – Adding new project resources – Changing the “production function” (Change the technology) – Change operation conditions by altering the precedence, sequence, or timing of work Fast-track, activity overlapping Overtime Shift work – Changes in the tools, methods, operating conditions – Work in more sheltered location Some Interesting Issues in Project Control Impediments to Project Acceleration Human resources – Multiple-shift work Environmental/safety issues, High cost, Neighborhood objections – Overtime/extended workdays Fatigue, Lower morale, Rework – Increasing # of workers Training (takes time of most experienced!), Space constraints, Hiring time Technology – Using more, larger or more efficient equipment Training/learning curve, Procurement time, Space constraints – Using faster-installing materials Procurement, Submittals for owner approval – Alternate construction methods Skill set, Learning curve, Unknown side-effects Some Interesting Issues in Project Control Impediments to Project Acceleration Human resources – Multiple-shift work Environmental/safety issues, High cost, Neighborhood objections – Overtime/extended workdays Fatigue, Lower morale, Rework – Increasing # of workers Training (takes time of most experienced!), Space constraints, Hiring time Technology – Using more, larger or more efficient equipment Training/learning curve, Procurement time, Space constraints – Using faster-installing materials Procurement, Submittals for owner approval – Alternate construction methods Skill set, Learning curve, Unknown side-effects