Seed Fibers

advertisement

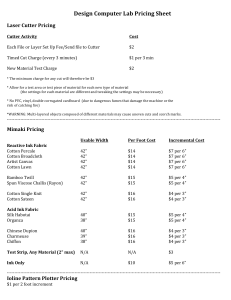

FASH 15 textiles natural cellulosic fibers—seed fibers natural cellulosic fibers all plants contain fibrous bundles that give • strength to the stem & root • pliability to the leaves • cushioning or protection to developing seeds natural cellulosic fibers classified according to plant component from which they are removed: • • • • seed stem (bast) leaf miscellaneous—root, bark, husk, moss natural cellulosic fibers Seed Fibers Cotton Kapok Coir Jute Bast Fibers Flax Ramie Hemp Milkweed Kenaf Hibiscus Nettle Bamboo Leaf Fibers Pina Abaca Sisal Henequen Miscellaneous Fibers Rush Sea grass Maize Palm fiber hundreds have been used—we’ll focus on the ones that are more globally significant or have potential for future growth natural cellulosic fibers properties common to all cellulosic fibers Properties Importance to Consumer Good absorbency Comfortable for warm weather; activewear; interiors. Good for towels, diapers & activewear Good conductor of heat Sheer fabrics cool for warmweather wear Ability to withstand high temp Fabrics can be sterilized; no special pressing precautions Low resiliency Fabrics wrinkle badly unless finish applied Low loft; good compressibility Dense, high-count fabrics possible; wind-resistant fabrics possible Good conductor of electricity No static build-up Properties Importance to Consumer Heavy fibers Fabrics are heavier than comparable fabrics of other fibers Harmed by mineral acids, minimal damage by organic acids Remove acid stains immediately Attacked by mildew Store clean items under dry conditions Resistant to moths, eaten by silverfish & crickets Store clean items under dry conditions Flammable Ignite quickly, burn freely with an afterglow and gray, feathery ash; loosely constructed garments should not be worn near an open flame; interior textiles should meet required codes Moderate resistance to sunlight Draperies should be lined seed fibers seed fibers develop in the seedpod of the plant to use the fiber it must be separated from the seed— seed is then used to produce oil & animal feed most important seed fiber? http://www.youtube. com/watch?v=_KZWe 0sYglc cotton cotton is an important cash crop in more than 80 countries the major producers in the world are: • China—32.0% • India—21.8% • USA—12.2% • Pakistan—7.8% • Brazil—5.7% in 2007 worldwide, 113 million bales (480 lbs/bale) cotton physical structure of cotton—length cotton fiber is a single cell—grows from the seed as a hollow tube over 1000 times as long as it is thick staple length is very important: • affects how fiber is handled during spinning • relates to fiber fineness & tensile strength longer cotton fibers are finer and make stronger yarns range from ½ - 2 inches long • • • upland cottons: 7/8 – 1 ¼ inches, Mexico/Central America (97% of US crop) long-staple cottons: 1 6/16 – 1 ½ inches, Egyptian/South American short-staple cottons: less than ¾ inch, Indian/Eastern Asian physical structure of cotton—length long staple fibers are considered to be higher quality— produce softer, smoother, stronger & more lustrous fabrics: • Pima • Supima • Egyptian • Sea Island physical structure of cotton—distinctive parts the cotton fiber is made up of: • cuticle—waxlike film covering primary wall • primary wall • secondary wall—cellulose layers • lumen—central canal that carries nourishment physical structure of cotton—convolutions convolutions are ribbon-like twists that characterize cotton twists form a natural texture that enables the fibers to cling to one another—thus despite short length spinning is easy convolutions may trap soil making cleaning more difficult physical structure of cotton—fineness cotton fibers vary from 16-20 micrometers in diameter cross-sectional shape varies with maturity: • immature tend to be u-shaped • mature nearly circular physical structure of cotton—color cotton is available in a range of colors—creamy white most desirable for dyeing purposes interest in naturally colored cottons is increasing due to less environmental impact—brown, rust, red, beige & green are available plant breeders continue to work to add blue, lavender & yellow classification of cotton describes the quality of cotton in terms of: • staple length—based on the length of a representative bundle; 19 staple lengths • grade—refers to color and absence of dirt, leaf matter, seed particles, motes/dead fibers, tangles (neps); 39 grades • character—includes aspects such as maturity, smoothness & fiber uniformity, fineness, strength and convolutions chemical composition of cotton cotton is when picked is 94% cellulose—finished cotton is 99% cellulose cotton can be altered using chemical treatments or finishes EXAMPLE: mercerization—treating yarns or fabrics with sodium hydroxide causes a permanent physical change: makes fibers more absorbent and improves dyeability properties of cotton—aesthetics cotton certainly has consumer acceptance matte appearance & low luster are standard drape, luster, texture & hand are affected by choice of yarn size & type, fabric structure, and finish cottons range from soft, sheer batiste to crisp, sheer voile to fine chintz & sturdy denim and corduroy properties of cotton—durability cotton is a medium-strength fiber—30% stronger wet can be handled roughly during laundering & in use abrasion resistance is good—heavy fabrics more so than thinner fabrics fiber elongation is low, with low elasticity properties of cotton—comfort cotton makes very comfortable fabrics for skin contact because of absorbency, soft hand & good heat and electrical conductivity static buildup is not a problem has no surface characteristics that irritate the skin good for use in hot, humid climates—moisture passes freely through fabric , thus aiding evaporation & cooling properties of cotton—appearance retention overall appearance retention for cotton is moderate with very low resiliency hydrogen bonds holding molecular chains together are weak so it wrinkles easily all-cotton fabrics shrink unless finished otherwise; untreated cottons shrink less in cool water with drip dry cotton stays stretched out in areas of stress—such as elbows or knees properties of cotton—care cotton can be washed with strong detergents and requires no special care during washing and drying white cottons can be washed in hot water—dyed cottons retain their color better if washed in warm water cotton releases most soils readily but soil-resistant finishes are desirable for some interior & apparel uses excessive bleaching weakens cellulosic fibers cotton fabrics respond best to steam pressing or ironing while damp—can be ironed safely at high temperatures properties of cotton—care cotton draperies should be dry-cleaned cotton upholstery may be steam-cleaned with caution cottons should be stored clean and dry cotton is harmed by acids—fruit & fruit juice stains should be treated promptly cotton oxidizes in sunlight which causes yellowing and degradation—some dyes are especially sensitive environmental concerns & sustainability • • • • agrichemicals—pest control, defoliants soil erosion water-intensive genetically-modified cotton ??? long-term environmental & health effects are unknown organic cotton—no synthetic commercial pesticides or fertilizers are used transition cotton—produced on land where organic farming is practiced but 3 year minimum has not been met green cotton— fabric that has not been bleached or treated with other chemicals conventional cotton—everything else environmental concerns & sustainability http://www.youtube.com/watch?v=O2Crnk9ZiZs identification of cotton microscopic identification of cotton is relatively easy— convolutions are easily seen along the fiber burn tests verify cellulose fiber length helps identify content cotton is soluble is sulfuric acid uses of cotton cotton is the single most important apparel fiber in the US also very important in interiors because of its versatility, natural comfort and ease of finishing and dyeing • • • • • • • sheets & pillowcases blankets & bedspreads draperies & curtains upholstery slipcovers rugs wall coverings uses of cotton medical, surgical & sanitary supplies frequently made of cotton—can be autoclaved for sanitization technical uses include book bindings, luggage, handbags, shoes, slippers, tobacco cloth, woven wiping cloths recycled denim? paper currency, insulation other seed fibers—coir coir comes from fibrous mass between outer shell and husk of the coconut http://www.youtube.com/watch?v=MM3uviXP0VU has good resistance to abrasion, water & weather used for indoor/outdoor mats, rugs, floor tiles, and brushes floor textiles are extremely durable and blend with many interior styles other seed fibers—kapok kapok is obtained from the seed of the Java kapok (silk cotton) tree or the Indian kapok tree fiber is lightweight, soft, hollow, very buoyant; breaks down quickly difficult to spin into yarns—used mainly as fiberfill researchers are studying ways to blend kapok with cotton for apparel uses other seed fibers—milkweed milkweed produces a soft, lustrous, hollow-floss seed fiber resembling kapok has been used as fiberfill in comforters, personal flotation devices and upholstery very difficult to spin into yarns because it is so weak, smooth and straight also known as silkweed fiber and asclepias cotton