Warp Knitted Fabrics

advertisement

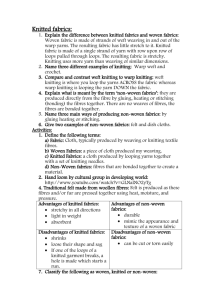

Knitted Fabrics Knitted fabrics are made from interlocking loops of yarn. There are two main types of knitting: •WEFT KNITS •WARP KNITS In weft knitting the loops of yarn are linked across the width of the fabric. Warp knitting machine In warp knitting the loops are linked in a vertical direction. Weft Knitting Weft knitting is made using a single yarn. It can be made by hand knitting or by machines. Characteristics of weft knits: • The fabric has high elasticity and stretch. • The loops of yarn trap air which retains body heat to keep us warm. • The right and wrong sides of the fabric look different. • the fabrics can lose shape easily. • Creases fall out easily. • The fabric can unravel and ladder easily. • Weft knitted fabrics curl up at the edges when they are cut. Weft Knitting Weft knitting machines being used in industry: http://www.youtube.com/watch?v=B4qzdAdhKIo What this looks like in slow motion: http://www.youtube.com/watch?v=SUXkEHKD_c&feature=related How to knit by hand: http://www.youtube.com/watch?v=4ViZRI6oPPg&f eature=related Warp Knitted Fabrics In warp knitting the yarn loops vertically up the fabric and the process uses many yarns rather than one. The fabric does not unravel or ladder. It is an industrial process only. Characteristics of warp knits: • The production system is fast so the fabrics are quick to make. • The fabric is elastic but it can keep its shape. • It can be cut and sewn easily as it lies flat when cut. • It is mainly used with synthetic filament yarns. Warp Knitting A warp knitting machine http://www.youtube.com /watch?v=xrSU2XfkA dg&feature=related Making a narrow lace trim http://www.youtube.com /watch?v=Wpx5Cubq 7oo&feature=related Uses of Knitted Fabrics • • • • • • • • • Weft Knits T-shirts Jumpers Cardigans Sweatshirt fabrics Warp Knits Net curtains Swimwear Terry towelling fabrics Patterned tights Lace fabrics Exam questions Manufactured Synthetic Fibres Learning Objectives: •Understand the sources, properties and uses of manufactured synthetic fibres. • Identify the advantages and disadvantages of manufactured synthetic fibres. Manufactured Synthetic Fibres – Polyamide (Nylon) Properties: • Very strong • Hard-wearing • Does not decompose (rot) • Melts as it burns • Not very absorbent so it dries quickly • Crease resistant • Resists alkalis but can be damaged by acids. • Versatile - can be made into many types of products. Advantages: • Strong when wet Disadvantages: • Inexpensive • Can be damaged by sunlight which discolours it and makes it weak. • Resists bacteria • Low absorbency • Durable and long lasting • Not always comfortable to wear. Uses: • Clothing • Ropes • Carpets & rugs • Seat belts Fabric Names: • Nylon • Tactel • Tactel Micro Manufactured Synthetic FibresPolyester Fabric Names: Properties: • Very strong • Can be made flame resistant • Thermoplastic – can be heat set into pleats and shapes. • Does not decompose • Resists most alkalis but can be damaged by acids. • Versatile as it can be made into many types of products. Uses: Terylene •Sportswear Polar Fleece •Ties Trevira •Sewing threads Finesse •Medical textiles Miratec Dacron •Net curtains •Carpets Advantages: • Strong when wet • Dries quickly • Crease resistant • Cheap • Resists bacteria Disadvantages: • Poor absorbency so it is difficult to dye. Manufactured Synthetic Fibres Acrylic Properties: • Strong when it is dry but weaker when wet. • Shrinks away from heat. • Thermoplastic • Burns slowly then melts. • Soft • Warm • Easy to wash and dry. Uses: Knitwear Upholstery fabrics Fake fur Sportswear Toys Advantages: • Warm Disadvantages: • Poor absorbency • Soft • Insulating • Inexpensive • Dries quickly Fabric Names: Courtelle Amicor Manufactured Synthetic Fibres Elastane Properties: • Very elastic • Lightweight • Very strong • Resists chemicals • Not damaged by perspiration • Aids crease resistance Advantages: Disadvantages: • Very stretchy • Very poor absorbency • Keeps its shape • Always needs to be blended with other fibres. It is too stretchy and elastic to be used on its own. • Resistant to damage by sun and seawater • Lightweight • Strong • Makes garments comfortable to wear Uses: • Swimwear • Sportswear • Jeans Fabric names: Lycra Regenerated Cellulose Fibres Regenerated cellulose fibres are made from wood pulp and chemicals. They are similar to cotton. Names of regenerated fibres: Viscose Rayon Acetate Triacetate Modal Tencel Lyocell Uses: Properties of Regenerated Cellulose Fibres: • Highly absorbent These are environmentally friendly fibres because they reuse waste chemicals in the production process. •Lyocell is used as a non woven fabric for medical wipes and swabs. •Fashion clothing • Washable •Lingerie • Soft •Ribbons • Smooth •Protective clothing • Comfortable to wear • Drape well • High strength when wet Exam questions Natural Fibres Learning Objectives: • Understand the sources, properties and uses of natural fibres. • Identify the advantages and disadvantages of natural fibres. Natural Plant Fibres - Cotton Properties: • Strong • Absorbent • Cool to wear • Hard- wearing • Creases easily • Smooth • Versatile • Easy to care for • Breathable Fabric Names: Calico Drill Corduroy Poplin Denim Velvet Advantages: Disadvantages: • Strong when wet • Creases easily Uses: • Durable & long lasting • Burns easily •Soft furnishings such as cushions and curtains • Not expensive • Shrinks when washed •Clothing such as jeans and T-shirts • Comfortable to wear •Knitting yarns • Environmentally sustainable Natural Plant Fibres - Linen Properties: • Very hard-wearing • Cool next to the skin • Strong • Absorbent • Creases easily • Dull lustre • Breathable Uses: •Light weight summer clothing •Tea towels Fabric Names: Duck Huckabuck Mattress Ticking Holland Advantages: Disadvantages: •Strong when wet • Creases easily •Very hard-wearing • Expensive • Sheets •Highly absorbent so dyes easily • Table cloths •Comfortable to wear Natural Animal Fibres - Wool Properties: • Warm • Absorbent • Low flammability • Good elasticity so creases drop out easily • Comfortable to wear Fabric Names: Lambswool Merino Superwash Felt Harris Tweed Gaberdine Uses: • Warm outer wear such as coats Advantages: Disadvantages: • Jumpers and cardigans • Warm and insulating • Blankets • Comfortable • Carpets • Takes a long time to dry as it is very absorbent • Can be produced in a wide range of weights of fabric. • Some types can be itchy next to the skin • Does not crease easily • Can shrink & felt when washed Natural Animal Fibres - Silk Properties: • Absorbent • Soft and comfortable • Cool but also warm and insulating when worn in layers • Natural sheen and lustre • Strong when dry Uses: • Luxury clothing such as lingerie, evening and bridal wear. • Knitwear • Soft furnishings Fabric Names: Chiffon Duchess Advantages: • Soft, smooth and lustrous • Drapes well • Comfortable to wear next to the skin Crepe Organza Dupion Taffeta Disadvantages: • Expensive •Can be weak when wet so it needs careful washing or dry cleaning. • May crease easily Exam questions Definition: Regenerated fibres are made from wood pulp (cellulose). They are partly natural and partly synthetic as a chemical is needed to extract the fibres. They way the fibres are produced differs from fibre to fibre. It can be done through wet spinning and dry spinning or even melt spinning. All cellulose fibres are either wet or dry spun or a combination of both. 1.Cellul ose sheets are placed in a bath of causti Wet spin 1.The fibre ning solution is pressed through the spinneret 2.It enters the Pollution acid bath Viscose currently which is becoming less causes the Prop 1.Viscose drapes ertie and s swings beautifully and the material is Uses: softer than Jersey, cottonsuits, and more dress fabric springy than and lining. silk. 2. It is Viscose is a solution made Which spinning from woodchips process is used Which liquid is to produce the spinneret Viscose pollutes Viscose? placed into? the environment Give anthe by due to example Give an of products of the viscose fabric False. It is a solution made Wet spinning from cellulose Acid sheets dipped Carbon into caustic disulfide soda. It drapes well, is soft & It’s a filament, comfortable 1.Lyocell is produced from wood pulp cellulose. It is marketed under the brand name Tencel. It is the modern Rayon! 2.It that it is soft, Making process: 1.Dissolve the wood pulp in a coagulation bath chemical which Dry/we creates a t solution spinni Uses: Staple fibres are used in apparel items such as denim, chino, underwear and Fibres blends: other1.Look casualfor wear clothing, Tencel® lyocell even in bath Propertie s of cellulose acetate: 1.Good toughne Natural and Renewable 1.It is Viscose is a solution made Which spinning from woodchips process is used Which liquid is to produce the spinneret Viscose pollutes Viscose? placed into? the environment Give anthe by due to example Give an of products of the viscose fabric False. It is a solution made Wet spinning from cellulose Acid sheets dipped Carbon into caustic disulfide soda. It drapes well, is soft & It’s a filament, comfortable 1.The production of cellulose acetate fibres is clean and meets all environmental regulations. Also, acetone is Dry spinn ing Uses: Ties, lingerie, and bathing suits, lining, dress fabric. What are What do you need regenerated fibres to make the wood Which two made out off? pulp into methods a fibre? spinning Which products Which products are there to make are made from Which is the least are made from a generated fibre? Acetate? environmentally Viscose? Which friendly regenerated fibres Which R.F. have regenerated have poor good acrease Cellulose A Dry/wet chemical spinning Lining, Lining, dress Viscose dress fabric & fabric ties & Viscose jersey & Acetate Tencel & Lyocell