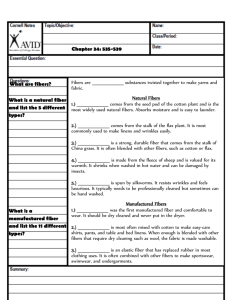

Textile Vocab

advertisement

FABRIC • Fabric- a general term referring to any material that is woven, knitted or somehow made into cloth. 8/16 Yarn 8/17 • Yarn- a general term referring to any material that is woven, knitted or somehow made into cloth. Warp • Warp- in weaving, the yarns placed on the loom first. They run lengthwise on the fabric. • Weft or filling yarns are woven over and under the warp yarns. 8/18 WEFT • Weft- The crosswise filling yarns that are interwoven with the lengthwise warp yarns to make a fabric. 8/19 Warp and Weft Selvage 8/20 • Selvage- the woven edge of fabric, running parallel to the warp. The selvage keeps the textile from fraying. It is often used to identify the manufacturer or provide a color check. Selvage PLAIN WEAVE • Plain Weave- The most used basic weave. Each filling yarn alternates crossing over and under each warp yarn. Like a window screen or a tennis racket. 8/23 TWILLWEAVE • Twill Weave- One of three basic weaves. Recognized by the diagonal “twill line” or “rib” visible in the finished fabric. 8/24 SATIN WEAVE • Satin Weave- A weave in which each yarn crosses over four to twelve other yarns before going under another. The distance the yarn covers is called a “float.” Because of these long “floats” the satin weave is flat, smooth, and lustrous. Usually made of silk or manmade fibers that give a lustrous, shiny appearance. 8/25 Basket Weave 8/26 • Similar to Plain Weave, but 2 weft threads are interlaced with two warp threads. Terry cloth 8/27 • A slack-tension, warpyarn pile fabric with loops on one of both sides of the fabric. Two sets of warps and one set of filling yarns are used. It may have a jacquard pattern. Un-Cut Pile Weave 8/30 • Produced by additional threads in the weft and warp that form loops or tufts of yarn that stand out form the surface of the fabric. These loops may be cut, uncut or a combination. Terry cloth corduroy Cut-Pile Weave 8/31 • 3 dimensional structure made by weaving an extra set of warp or filling yarns with the ground yarns so that cut yarn loops create a pile Velvet Leno Weave • a locking type weave in which two or more warp yarns cross over each other and interlace with one or more filling yarns. • used primarily to prevent shifting of yarns in open fabrics. • Sheers, semi sheers, and casements (coarsely woven sheers 9-1 Jacquard Weave 9/2 • Requires an intricate series of hole-punched cards that tell the machine which threads to raise and which threads to drop. • produce patterned fabrics. • costly because it involves more time and skill in making the Jacquard cards to produce new pattern • Damask , brocades tapestries Grain in Fabric • effects the way fabric will hang and drape • refers to the way threads are arranged in a piece of fabric • Lengthwise grain runs parallel to the selvagestrongest and most stable • Crosswise grain runs perpendicular to the selvedge of the fabric or the cut edge of the fabric as it comes off the bolt. • Bias grain runs on a 45 degree angle to the selvage 9/3 9/7 Microban® • antimicrobial protection (microbes can double in number every 20 minutes) • built-in to products during the manufacturing process to provide continuous antimicrobial protection • fights the growth of odor causing bacteria, mold and mildew to keep fabrics cleaner and fresher for the useful life of the fabric 9/8 VELCRO® • brand name of fabric hook-and-loop fasteners which have been used for 50 years • consists of two layers: a "hook" side, which is a piece of fabric covered with tiny hooks, and a "loop" side, which is covered with even smaller and "hairier" loops. X 20 magnification 9/9 Natural Fibers • Found in nature and require little or no processing to be used. • Made from plant and animal sources • Cellulosic - plant • Protein- animal • mineral 9/10 cellulosic Plant fibers include stems, leaves, and seed hairs found in plant Cotton Flax -Linen Jute Ramie flax Jute Protein 9/13 • Wool • silk Mineral Fibers 9/14 • Asbestos • Comes from deep in the earth’s crust • Found in veins or cracks of solid rock • Fibers are resistant to fire, heat, and acid • Nonconductor of electricity – was used in insulation • Is now banned in US because it was found to cause cancer Cotton 9/15 • Believed to have been grown in India during the 4th century B.C. • Used in early Rome • Most plentiful of natural fibers Cotton boll seeds Cotton Gin 9/16 • designed and constructed by Eli Whitney (Yale) in 1793 • machine that automated the separation of cottonseed from the short-staple cotton fiber (50 lbs. daily) Cotton 9/17 Advantages • Takes and holds color well • Washes easily, easy care, comfortable • Can be woven into sheer or heavy weight fabric • Flexibility • Not damaged by sunlight and most chemicals Disadvantages • Not as durable as other fibers • Wrinkles easily • Can mildew and fade • Absorbs moisture easily • Cost varies according to quality of fiber, weave, ad finish Quality of Cotton Fiber • Determined by 3 factors • Color of ginned cotton (cotton fibers separated from cottonseed 1. Color ranges from white to yellow white 2. White, Light Spotted, Spotted Tinged, Yellow Stained 9-27 • Purity(absence of foreign matter) and quality of ginning process • Length of fibers (inherited genetic characteristic of the seed variety) weather ,nutrient deficiencies and excessive cleaning may affect fiber length • USDA rates cotton Organic Cotton 9/29 • grown using methods and • Twice as expensive as materials that have a low conventional cotton impact on the environment • Additional costs related to • Produced following statelower fiber yield per acre, fiber-certification standards requirements for where organic farming processing in facilities practices have been used free of harmful chemicals for at least 3 years and smaller quantities of • No synthetic commercial fibers processed pesticides or fertilizers are • represents 0.76 percent used of global cotton production. (2009) ORGANIC COTTONSEED 9/28 • used for animal feed • Organic cottonseed oil is used in a variety of food products, including cookies and chips. EGYPTAIN COTTON • comes ONLY from Egypt where the humid conditions and rich soil along the Nile River Valley create the perfect conditions to grow long cotton fibers • falls under the classification of an ELS (extra-long staple) cotton • Fiber staples can range from 1 1/2 inches to 2 1/4 inches. (about twice the size of other cotton fibers which allows fibers to be spun into very fine yarns 9/29 • Highest quality is a fabric count of 1000 to 1200 • Softer and more durable than other cotton • American version of Egyptian cotton is known as Pima cotton. (Pima Indian Reservation in Arizona in early 1900’s to meet demand for quality long staple cotton Egyptian cotton logo was trademark ed in 2001 LINEN 9/30 • Made from flax fibers (found in the stem of the flax plant) • oldest of all fabric • evidence has been found in Swiss lake dwellings dating from 8000 B.C. • ancient Greece-evidence of a linen industry is shown on 4,000 year-old tablets • lightweight and breathable fabric • More expensive than cotton • since 1970, linen fabric production for apparel has increased from 5% to 70%. • Today, Western Europe, Ireland in particular, dominates flax and linen production in both quantity and quality. LINEN 10/1 • • • • • • Advantages Strong, especially when wet Comfortable, pliable, lustrous Not damaged by sunlight and chemicals Washable Takes and holds color Absorbent Disadvantages • Wrinkles easily if not chemically treated • Fades • stiff • Difficult to clean • Absorbs moisture easily RAMIE 10/4 • Also known as rhea, grasscloth, and China grass • Been used for several thousand years in China • A tall perennial plant that requires a hot, humid climate • Fast growing and can be harvested every 60 days • Has to be cut, not pulled • Has been grown in the Everglades and Gulf Coast regions of US, but not currently • Produced in China, Philippines and Brazil Ramie • bast fiber – part of a plant stem • one of oldest textile fibers –used in mummy cloths in ancient Egypt during the period 5000-3000B.C. • Very durable • long, fine fibers are naturally white and lustrous with an almost silky appearance. October 6 • requires chemical processing to de-gum the fiber. • Blends are more common than pure ramie - most typical is 55 %ramie/45 % cotton • Blends - available in woven and sweater knit form. (Cotton and wool) RAMIE 10/7 Advantages • High absorbency • Greater strength when wet • hold shape well , • introduce a silky luster to the fabric appearance Disadvantages • possesses little elasticity and is somewhat brittle and stiff which causes fiber breakage where creased or folded repeatedly • Wrinkles easily • Will not dye as well as cotton • Very brittle and fibers will break if folded repeatedly JUTE • Used in Biblical times • 61% cellulose • One of cheapest fibers • Grown throughout Asia-chiefly India and Bangladesh 10/8 • Primary fibers are short and brittle • One of weakest of the cellulosic fibers • Creamy white to brown in color • Used to produce coffee bags carpet backing, rope and twine Manufactured/ Synthetic Fibers 10/11 • Originally designed to improve the quality, durability, and ease of care of fibers • Designed to resist soil, mildew, and insects • Made from substances such as wood pulp, petroleum, and coal • Produced in labs through chemical processes • Mimic natural fibers because they look, feel, and act like them • Have many desirable characteristics: generally strong, have ability to spring back to their original shape, don’t wrinkle and are easy to care for Protein Fibers 10/12 • Are of animal origin • Wool and specialty wools are the hair and fur of animals • Silk is the secretion of the silk caterpillar • Are luxury fibers today Protein Fibers 10/13 Wool Silk • Animal hair fibers – sheep’s • Fiber formed from wool extruded filaments • Alpaca, camel, cashmere goat, • According to legend – llama, vicuna, guanaco, and discovered about 2540 the angora goat (mohair), B.C. quivit (hair from musk ox), angora rabbit hair • Produced from the larvae • Used since 4th century BC of silkworms • Used for clothing and some • Known as sericulture-was household articles in early kept secret for manyyears Egypt, Greece, Asia, an Middle East. Wool ADVANTAGES • Resilient • Flame retardant • Resists abrasion good insulator • Can be woven into a variety of textures • Dyes well • Cleans well, resists dirt\ • Absorbs up to 20% of its weight in moisture without feeling damp • Doesn’t wrinkle easily 10/14 Disadvantages • Yellows with age • Shrinks • Can be damaged by moths • Expensive • Requires professional cleaning • Can cause allergies • Weak, especially when wet Manufactured/Synthetic Fibers 10/19 • During the past 5 decades, production and consumption has steadily increased • Today over 80% of fibers used • Comprise 75% of U.S. textile market • • • • • • Used for: Apparel Furnishings Medical applications Construction Transportation Aerospace applications • Environmental applications Manufactured regenerated fibers 10/20 • Produced from naturally occurring polymers (very large molecule made by connecting many small molecules) • Polymers do not occur naturally as fibers and processing is needed to convert them into fiber form • Starting material is cellulose and protein • 3 regenerated cellulosic fibers : rayon, lyocell and acetate Rayon 10/21 • First commercially successful manufactured regenerated fiber • Cellulose fiber regenerated from wood pulp • Production began around the beginning of 20th Century • Referred to as “Artificial Silk” • Name RAYON was not officially adopted until 1924 • Called VISCOSE IN Europe • Used in apparel- from lingerie to suits, dresses, and sportswear • Often blended with polyester Acetate 10/22 • Originated in Europe • Dreyfus brothers experimented with acetate in Switzerland • Brothers moved to England during WWI – acetate was used as a coating for the fabric wings of WWI airplanes • After war-they perfected the process of making acetate fibers • 1924 became the 2nd manufactured derivative cellulose fiber in U.S. • Dry spun methodpolymers are dissolved in a solvent of acetate to be formed into fibers • First thermoplastic (heatsensitive fiber) • Fabric melts under a hot iron Lyocell • Developed by Courtlands, a European fiber manufacturer • Introduced in early 1990’s as a type of Rayon • Development was prompted by a concern about Rayon’s negative impact on the environment • First produced under brand name Tencel 10/25 • Solvent spinning – cellulosic starting material (wood pulp) is directly dissolved in an organic solvent- fiber is regenerated from that solvent • Produced in both Europe and U.S. • Properties are more like cotton than any other regenerated fiber Synthetic Fiber Production 10/26 • Made from chemicals synthesized from petroleum by-products and other chemicals • Chemists discovered that when a glass rod was pulled away from a chemical compound, it formed a fine filament that was strong, elastic, and flexible • Are produced in similar way • Thick syrupy liquid is forced through tiny holes in a spinneret • Each tiny hole produces a fiber • A spinneret can produce a few dozen fibers or as many as several thousands at a time Synthetic Fiber Production 10/27 • Shape of spinneret holes can be altered so that fibers of different cross – sectional shapes can be produced – round, octagonal, hollow, threesided, or other shapes • The shape of the fiber gives certain qualities like luster, sparkle, and ability to hide soil, or hold heat to the body • Can be solution dyed –color is added to the syrup before fiber is made – the color is more permanent • Most fibers a ARE NOT solution dyed because the process makes the fibers more expensive and less responsive to changes in fashion colors • Solution dyed fibers cannot be dyed another color later Manufactured and Synthetic Fibers10/28 Can be engineered to enhance performance like: • Fire resistance • Soil resistance • Bacterial resistance • Heat resistance Examples: • Fibers for swimwear can be produced so that they resist fading from sunlight, salt water or swimming pool water • Fibers for bath towels can be produced to provide continuous antimicrobial protection ACRYLIC • Synthetic fiber • Developed in the 1940’s • Both dry and wet spinning methods are used • Have been called the “warmth without weight” • Wet spun fibers can have cross-sections varying from round to bean shape • Dry spun methods have a dogbone shape • Fibers are soft, warm, lightweight and resilient 10/29 • Fabricated into woven and knitted fabric construction • Often blended with other fibers especially wool • Good fiber for sweaters, suits, coats, and socks • Superior to wool in their easycare properties and are nonallergenic • Declined from 15% to 5% of world fiber production • Manufacturing has moved from U.S and Europe to China, Taiwan, and India ACRYLIC • • • • Advantages Resist wrinkling during use and care Mildew, microorganisms, and moths will not harm acrylic Lower cost competitor for wool Resistant to sunlight – superior to polyester and nylon Nov. 1 • • • • Disadvantages Shrink when exposed to high temperatures Will “pill” Low moisture absorbency Generate static electricity Nylon • First synthetic fiber and first fiber developed in U.S. • Inventor was Wallace Carothers –chemist working for Dupont Company in 1928 (research program) • Generic name NYLON was proposed in 1938 by Dupont • First nylon product a nylon bristle toothbrush which went on sale on Feb. 24, 1938 • Women’s stockings went on sale on May 15, 1940 Nov. 3 • became unavailable to civilian consumers, because nylon was used extensively during WW II (1939-1945) • During WW II Nylon replaced Asian silk in parachutes • Also used to make tires, tents, ropes, ponchos and other military supplies • Could be heat-set and permanent pleats became a reality NYLON Nov. 4 • • • • • • ADVANTAGES Strong and Elastic Easy to launder Dries quickly Retains its shape Resilient and responsive to heat setting Resistant to damage from oils DISADVANTAGES • Extensive washing and drying in a dryer can lead to piling • White Nylon should be washed separately to avoid it turning gray • Has a tendency to “Scavenge” colors picking up surface color easily from other fabrics POLYESTER 11/9 • English researchers experimented and manufactured polyester fibers called Terylene • Introduced to U.S. in 1951 under name of Dacron • Dupont bought the English patent and started manufactured polyester in March 1953 • Often referred to as the workhorse fiber of the industry • most widely used synthetic fiber in U.S. • Used alone or blended with other fibers • Used for apparel and furnishings • First use of polyester filament fibers was in knit shirts for men and boluses for women POLYESTER 10/10 Advantages • • • • Good strength Wrinkle resistant Mildew resistant Retains heat-set pleats and crease • Resistant to stretching and shrinking • Easily washed –quick drying • Polyester is extensively recycled-products made from recycled polyester include apparel and carpeting Disadvantages • Lack absorption • Consumers like recycled polyester, but the cost is usually higher OLEFIN 11/11 • In the 1920’s attempts were made to polymerize ethylene (a byproduct of natural gas) • Ethylene was polymerized (formation of polymers) and used as an important plastic during WW II, but filaments made from it did not have sufficiently consistent properties for use in textiles • In 1954 in Germany, Karl Ziegler developed a process that raised the melting point of polymerized ethylene filaments – but it was still too low for many uses • In Italy Giulio Natta successfully made linear polypropylene polymers of polypropylene polymers suitable for most textile applications • By 1957, Italy was producing olefin fibers • U.S. production of olefin started in 1960 • Fibers are often called polyolefins, but the FTC(Federal Trade Commission) specifies the generic name olefin Olefin Fiber Uses 11/12 • APPAREL activewear and sportswear socks, thermal underwear, lining fabrics OLEFIN 11/12 • AUTOMOTIVE Interior fabricsused in or on kick panel seat construction, truck liners OLEFIN 11/12 • Home Furnishings Indoor/outdoor carpet; carpet backing, upholstery and wall coverings, furniture and bedding construction fabrics OLEFIN 11/12 • INDUSTRIAL Carpets, disposable, durable nonwoven fabrics; ropes, OLEFIN 11/15 Advantages • • • • • Colorfast Quick drying Stain and soil resistant Sunlight resistant Very lightweight –(olefin fibers have the LOWEST specific gravity of all fibers • Dry hand (the way a fiber feels to the sense of touch) • wicks (ability of a fiber to transfer moisture along its surface) body moisture from the skin Environmental Impact • Easier fiber to recycle than most other fibers • Olefin is seldom dyed, so the environmental problems related to dyeing are minimal • Can be engineered for specific end uses, so the problems related to recycling or disposing of finishing chemicals is of little concern SPANDEX 11/16 • First manufactured elastic fiber was introduced in 1958 and called Lycra • Known as elastane in many other parts of the world • Superior to rubber in strength and durability • Name was coined by shifting the syllables of the word expand Uses of Spandex 11/17 • used to support, shape, or mold the body or to keep textiles from stretching out of shape during use • Used primarily in knit foundation garments, action wear, intimate apparel, shape wear, hosiery, furnishings and narrow fabrics • Medical uses-surgical an d support hose, bandages, and surgical wraps • Blends of 2% to 40% spandex with other fibers are common • Spandex yarns are woven or knitted SPANDEX Advantages • Spandex is resistant to the body oils, perspiration, lotions and cosmetics that degrade rubber. • Has a good shelf life and does not deteriorate with age as quickly as rubber 11/18 Disadvantages • Extended exposure to light may cause discoloration of some types of white spandex but does not deteriorate the fiber seriously • Should not be subjected to very hot water or excessive heat from ironing CARDING 9/28 • Carding- a process in which raw fibers (cotton, wool, etc.) are untangled and partially straightened by drawing them through a series of sharp points. After carding, fibers are combed. 8/27