Australian Maritime Safety Authority submission (DOC 310kb)

advertisement

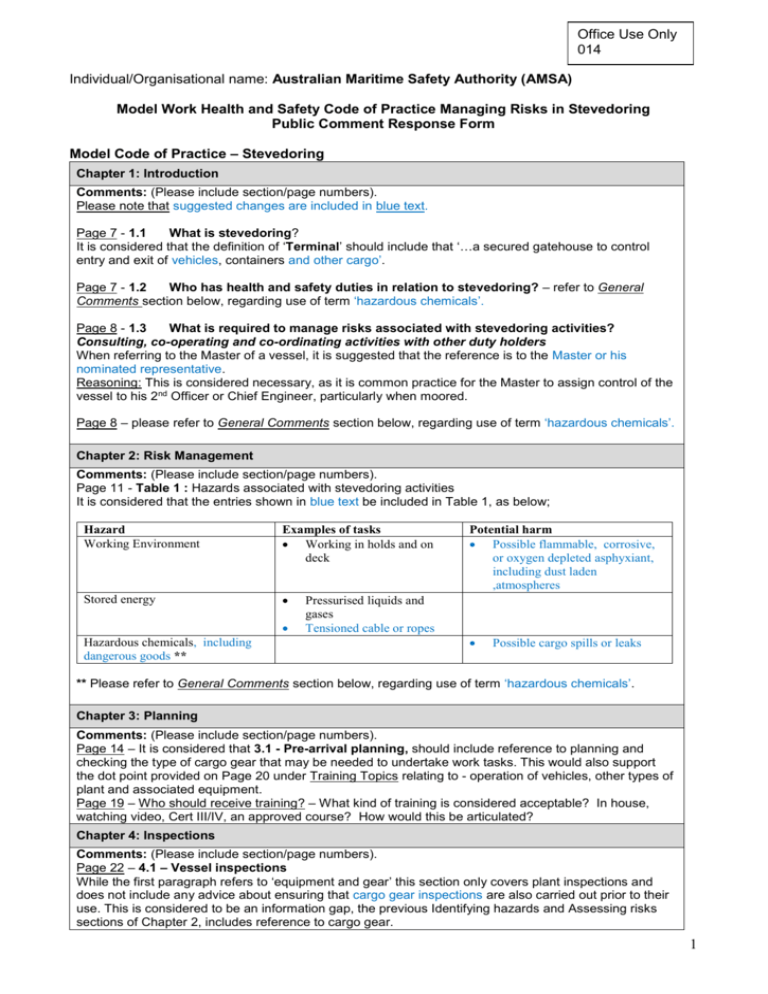

Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) Model Work Health and Safety Code of Practice Managing Risks in Stevedoring Public Comment Response Form Model Code of Practice – Stevedoring Chapter 1: Introduction Comments: (Please include section/page numbers). Please note that suggested changes are included in blue text. Page 7 - 1.1 What is stevedoring? It is considered that the definition of ‘Terminal’ should include that ‘…a secured gatehouse to control entry and exit of vehicles, containers and other cargo’. Page 7 - 1.2 Who has health and safety duties in relation to stevedoring? – refer to General Comments section below, regarding use of term ‘hazardous chemicals’. Page 8 - 1.3 What is required to manage risks associated with stevedoring activities? Consulting, co-operating and co-ordinating activities with other duty holders When referring to the Master of a vessel, it is suggested that the reference is to the Master or his nominated representative. Reasoning: This is considered necessary, as it is common practice for the Master to assign control of the vessel to his 2nd Officer or Chief Engineer, particularly when moored. Page 8 – please refer to General Comments section below, regarding use of term ‘hazardous chemicals’. Chapter 2: Risk Management Comments: (Please include section/page numbers). Page 11 - Table 1 : Hazards associated with stevedoring activities It is considered that the entries shown in blue text be included in Table 1, as below; Hazard Working Environment Examples of tasks Working in holds and on deck Stored energy Hazardous chemicals, including dangerous goods ** Potential harm Possible flammable, corrosive, or oxygen depleted asphyxiant, including dust laden ,atmospheres Pressurised liquids and gases Tensioned cable or ropes Possible cargo spills or leaks ** Please refer to General Comments section below, regarding use of term ‘hazardous chemicals’. Chapter 3: Planning Comments: (Please include section/page numbers). Page 14 – It is considered that 3.1 - Pre-arrival planning, should include reference to planning and checking the type of cargo gear that may be needed to undertake work tasks. This would also support the dot point provided on Page 20 under Training Topics relating to - operation of vehicles, other types of plant and associated equipment. Page 19 – Who should receive training? – What kind of training is considered acceptable? In house, watching video, Cert III/IV, an approved course? How would this be articulated? Chapter 4: Inspections Comments: (Please include section/page numbers). Page 22 – 4.1 – Vessel inspections While the first paragraph refers to ‘equipment and gear’ this section only covers plant inspections and does not include any advice about ensuring that cargo gear inspections are also carried out prior to their use. This is considered to be an information gap, the previous Identifying hazards and Assessing risks sections of Chapter 2, includes reference to cargo gear. 1 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) 4.1 – Vessel inspections While it is understood that contemporary WHS legislation uses the term ‘person in charge’, this section includes the terms: ‘person in charge’ and ‘designated responsible person’; with no definition or guidance explaining the meaning of these terms. These terms are also inconsistent with the terminology in common use in the stevedoring industry and in MO 32. MO 32 includes the terms ‘competent person’ and ‘responsible person’ and defines what those terms mean for the purposes of the order. To avoid confusion, it is considered that this code should include how the terms ‘person in charge’ and ‘designated responsible person’ relate to the terms, ‘competent person’ and ‘responsible person’, defined in MO 32. If the code does not include definitions or guidance explaining the meaning of the terms ‘person in charge’ and ‘designated responsible person’, AMSA considers that the code would need to define or provide further guidance on the expectations of the delegated person, relevant to the assigned task or tasks. Without such clarity, the person in charge has no guidance as to the scope, qualifications or suitability to be considered of the person they delegate responsibilities to. Chapter 5: Working Environment Comments: (Please include section/page numbers). Page 23 – With regard to the footnote 2: in section 5.1, as below; 5.1 Access and egress 5th dot-point…safe access and egress…where work is in a cargo compartment, that there are two means of access.2 Editorial change required - the text needs to be amended so that the 2 is shown as superscript to reflect the reference included at the bottom of the page The 5th dot-point also includes the term ‘cargo compartment’ whereas MO 32 uses the term ‘cargo space’. It is considered this inconsistency would create confusion for readers/users. **Please refer to General Comments section below, regarding references to specific provisions of MO 32. Chapter 6: Handling Loads and Cargo Comments: (Please include section/page numbers). Page 27 – Pre Slung Loads - third dot point, includes the term ‘qualified personnel’ ; whereas Page 28 – During lashing and unlashing - under Control measures for lashing and unlashing activities may include:…first dot point, includes the term ‘qualified person’; It is considered these terms need to be consistent and either defined, or guidance included, to explain the meaning of the selected term. Page 30 – 6.3 Working in ship’s holds Hatches and openings For hatches and openings that provide access to holds, ensure: (third dot point) means of access include a ladder which is clear of the hatchway through which cargo is loaded or unloaded3 3 Note Marine Order 32, issue 3 - Cargo handling equipment (Schedule 2 Clause 7) sets out the requirement for two means of access for each cargo compartment in ships built on or after 1 August 1998 (except ships used exclusively as bulk carriers or as cellular container ships). With regard to the footnote 3, please note that quoting specific references in MO 32 may not be advisable as these could be subject to change. Then, under the subheading Ladders; The dot-points included in the section commencing - When using portable ladders in holds ensure:.. It is considered that these dot-points need to be consistent with the same requirements set out in MO 32. 2 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) Page 32 – The first line includes references to Marine Orders, but there is also a reference to Marine Orders 35, which appears to be a misprint and should possibly be a reference to Marine Order 32? Please also note: the change to singular form of ‘Marine Order’ since 1 July 2013. 6.5 Storage and stowage It is considered this section should include ‘securing’ of cargo, so should be headed; Storage, stowage and securing, with additional mention of securing, where applicable. Also, the second dot-point: whether goods are classified as hazardous chemicals ** Please refer to General Comments section below, regarding use of term ‘hazardous chemicals’. Chapter 7: Plant and Equipment Comments: (Please include section/page numbers). Page 34 – 7.2 Cranes and workboxes It is considered that some reference needs to be made to the practice of ‘duel’ or ‘twin lifts' by cranes, particularly with regard to hazard identification and risk management, even if it refers to another document for guidance. For example, a reference could also be made to Section 6.4 of the Safe Work Australia, Code of Practice – Cranes. Reasoning: This opinion is formed on the basis that AMSA has responded to many queries about twin or dual lifts; and the same requirements need to be applied whether the cranes are mounted on ships or on the shore. Page 34 – Ship-based cranes The pre-operational inspection should be carried out for ship based cranes to check:… It is considered that an additional dot-point should be included, to check: that ‘emergency escape’ provisions are provided and suitable Also, in relation to the last paragraph on this page - Please refer to General Comments section below, regarding references to specific provisions of MO 32. Page 38 - last sentence re PPE; should a list of standard PPE be provided here?, or possibly as an Appendix? (i.e. provision of PPE may also require the inclusion of hearing protection) Chapter 8: Mooring and Unmooring Comments: (Please include section/page numbers). Pages 39 and 40 – While AMSA considers the inclusion of Mooring Guidance in this Code to be worthwhile, further AMSA comment has been provided below in the Comments on specific issues section below. APPENDIX B: Example checklist – Vessel inspection – Container operations Page 43 – AMSA notes that the only reference to a specific physical distance for provision of a clear space between and at the ends of cargo transport units, occurs on this page as part of: 1. Access / Egress (9th line down in table ) Working space is clear of all obstructions over a width of at least 550mm. Comment: It is considered that this reference is fairly obscure, as the only other reference appears to be on page 23 at 5.1 Access and egress - (4th dot point) and the physical distance is not included there, so AMSA believes the 550mm should be included in the body of the code, with page 23 considered the most appropriate place. Reasoning: This opinion is formed on the basis that AMSA has responded to many queries about such requirements and it is considered to be a critical part of ensuring a safe workspace/workplace. General Comments Comment sought Comment is sought on whether the guidance in this Code: requires additional examples to provide clarification. If so, please provide relevant examples that you think should be included. 3 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) AMSA comments It is considered that this Code of practice would benefit from inclusion of a ‘glossary of terms’ or ‘definitions’ section, as there are a number of terms which require clarification to provide certainty for readers/users of this code. For example, the Code includes many references to a ‘competent person’, and as included in AMSA’s comments relating to pages 27 and 28 above, the terms ‘qualified personnel’ and ‘qualified person’ are also included. Even though on page 38 for ‘qualified person’ the code includes; ‘for example a rigger’, these terms are not defined anywhere else in the code. AMSA is seeking clarification as to whether such terms used in this Code, will align with the definitions for ‘competent person’, and /or ‘responsible person’, as included in MO 32? AMSA considers that this Code of practice could also include a statement that: ‘relevant additional information and examples can be found in the International Labour Organisation publication: ILO Code of practice - ‘Safety and health in ports’. References to Marine Order 32 (MO 32) Please note; that it is AMSA’s intention to update MO 32 and any quoted specific references to the current version of MO 32, Issue 3, could be subject to change. Use of the term ‘hazardous chemicals’ AMSA considers that this term should be amended to: ‘hazardous chemicals including dangerous goods’. Reasoning: AMSA recognises that Safe Work Australia primarily references the GHS and that there are many hazardous chemicals that are not classifiable as dangerous goods. However, it should be noted that dangerous goods can present additional hazards and includes a broader scope than just chemicals, encompassing dangerous goods articles, which the term hazardous chemicals does not cover. Comments on specific issues – specific questions can be found in the draft model Code. Code of Practice or Guide: AMSA considers that a Model Code of Practice would provide a more robust legal document to support safe outcomes for managing risks in the stevedoring industry. Interaction with Marine Orders: The Safe Work Australia Model Code of Practice, Managing Risks in Stevedoring, will need to be applied to operate concurrently, but separately to, Marine Orders. This is necessary, as Marine Orders are not intended to apply Occupational or Workplace Health and Safety (OHS/WHS) provisions for Australian workers. However, Marine Orders may need to include comparable provisions to apply to ships officers and crew, including the Master or Captain of the vessel. For example, provision of adequate lighting to a prescribed safe level. There should also be no impediment to the replication of the same provisions in both regulatory documents, as complying with one law should also ensure compliance with the other. For example, where cargo gear such as cranes or slings are required to bear markings to show evidence of their capacity and certification, such evidence should ensure compliance with any prescribed requirement. Additionally, if such requirements are set out in the relevant legislative instrument, in this case the Model Code of Practice, Managing Risks in Stevedoring, without cross reference to another legislative instrument not administered by Safe Work Australia i.e. Marine Orders; then any modification to a Marine Order would not inadvertently affect a provision of the Stevedoring Code of Practice. It is for these reasons that AMSA has repeatedly included in the specific comments above, that direct reference to provisions in Marine Orders is not a desirable outcome for ensuring compliance with the Safe Work Australia Model Code of Practice, Managing Risks in Stevedoring. Reference to AMSA legislation in the Safe Work Australia Model Code of Practice, Managing Risks in Stevedoring: As of 1 July 2013, AMSA’s overarching maritime legislative instrument the Navigation Act was updated from the 1912 version to the Navigation Act 2012, a copy of which is available at: http://www.amsa.gov.au/vessels/standards-regulations/nav-act-2012/ 4 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) As a result, please note that: Marine Orders were amended to reflect all references to the new Act and to incorporate contemporary drafting practices. For instance; inclusion of penalty units relating to offences, references to provisions are now references to Divisions, Sections, paragraphs and subparagraphs; while Appendices are now included as Schedules. An AMSA Fact Sheet explaining the changes is available at: http://www.amsa.gov.au/forms-and-publications/Fact-Sheets/MOFactSheet.pdf Most importantly however, the titles of the orders have been amended to the singular form and the application dates of the orders have been updated. So on that basis, the Safe Work Australia Model Code of Practice, Managing Risks in Stevedoring will need to amend references to AMSA marine orders e.g. Marine Order 32 - (Cargo handling equipment) 2011. Guidance on mooring and unmooring: As advised above, while AMSA considers the inclusion of Mooring Guidance in this Code to be worthwhile, it is AMSA’s considered opinion that, Safe Work Australia should undertake a survey to determine whether stevedores regularly carry out mooring/unmooring duties, or whether those duties are usually carried out by specialist mooring/unmooring workers. The results of such a survey should then inform Safe Work Australia’s decision as to whether to include mooring/unmooring provisions in the Model Stevedoring Code, or to develop separate guidance material. Regardless of how the requirements are published by Safe Work Australia, it is again AMSA’s considered opinion that they should reflect the relevant information included in the ILO Code of Practice – Safety and health in ports, including the provisions for specific training of workers carrying out mooring/unmooring duties. 5 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) SAFE WORK AUSTRALIA – CONSULTATION REGULATORY IMPACT STATEMENT for the DRAFT MODEL CODE OF PRACTICE: MANAGING RISKS IN STEVEDORING Foreword - Page ii – no AMSA comment Executive Summary - Pages iii and iv – no AMSA comment Section 1 – Introduction - Page 1 – no AMSA comment Section 2 – Industry Overview - Page 2 Refers to ‘bulk’ imports and exports but should include reference to packaged cargoes, as the proposed Model Code of Practice: Managing Risks in Stevedoring, will predominantly address loading and unloading of packaged cargoes and package units, as well as bulk cargoes. AMSA notes that on Page 4 under Codes of Practice, it advises that; ‘There are currently no approved codes of practice specific to stevedoring under Australian WHS laws’; and under Guidance material, it advises that; ‘This material was developed prior to harmonisation of WHS laws, and has been adopted or referenced by only three of the nine jurisdictions’. 2.1.2 Other marine safety laws - Page 4 Although Marine Orders have a role in ensuring safety, they were never intended to include Occupational Health and Safety(OHS)/Workplace Health and Safety(WHS) provisions (see further comment in Section 2.1.3 and Section 3.1 below). Occupational Health and Safety (Maritime Industry) Act 1993 (the OHS (MI) Act) Page 5 It is considered that this RIS document does not fully explain that while the OHS (MI) Act has an objective of Occupational Health and Safety, the Act has limited application in so far as protecting all persons involved in loading and unloading of all ships at Australian ports. This is because it only applies to certain vessels (‘prescribed ships’, ‘prescribed units’) and the operators of those ships or units. 2.1.3 Relationship between WHS laws and Marine Orders Part 32 - Pages 5 and 6 As previously advised, although Marine Orders have a role in ensuring safety, they were never intended to include OHS/WHS provisions. It should be noted however, that certain aspects of such safety have been included in MO 32, primarily with the aim of preventing incidents/accidents. As advised in AMSA’s comments relating to the Model Code, AMSA has already notified Safe Work Australia and members of the Stevedoring Temporary Advisory Group (TAG) established by Safe Work Australia, that once mainstream OHS/WHS legislation is in place for stevedores, AMSA intends reviewing MO 32, with the intention of removing any apparent WHS provisions. MO 32 is intended to apply only to cargo handling equipment and associated gear, fitted or located on-board, and for use on-board, when loading or unloading a ship (further comment is included against Section 3.1 below). 6 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) Section 3 – Statement of the Problem - Page 8 While this section seeks to identify problems resulting in poor safety performance in the stevedoring industry, and the RIS elsewhere identifies there is a lack of specific codes of practice (refer 2.1.1 Work Health and Safety laws – Page 4 Codes of Practice) and poor uptake by jurisdictions of existing guidance for the stevedoring industry (refer Page 4 Guidance material), it neglects to identify there is a lack of legislation specifically aimed at addressing workplace safety in the stevedoring industry. So while some limited guidance material is available, there is no specific legislative regime in place to ensure use of this guidance material. 3.1 - Confusion between the application of WHS laws and Marine Orders - Page 8 It is AMSA’s opinion that confusion amongst industry stakeholders is as a result of the fact that Marine Orders were never designed to apply to Occupational/Workplace Safety. (refer to previous comments against Section 2.1.3 above). AMSA wishes to reiterate that it has advised Safe Work Australia, including industry and union representatives participating in the TAG, that once mainstream OHS/WHS legislation is in place for stevedores, AMSA intends reviewing MO 32 with the intention of removing any apparent WHS provisions. 3.2 - Quality of existing guidance material – Pages 8 and 9 (refer to AMSA comments above noting statements on page 4 of the RIS relating to Guidance Material) Question for Public Comment - Page 9 Are there any other issues with the quality of existing guidance which are an impediment to its application in the stevedoring industry? AMSA considers that the existing guidance material is fragmented (three separate publications) and the introduction sections of each document do not advise reading in conjunction with the other two documents to provide readers with the most extensive knowledge. It is not clear why three separate guidance documents were initially developed and published. AMSA also considers that the ILO publication, Safety and Health in Ports, is a quality guidance document providing consolidated and comprehensive information. 3.3 – Uptake by jurisdictions - Page 9 Questions for Public Comment - Page 9 Are there any other issues which may affect jurisdictional adoption of existing guidance material? How does jurisdictional adoption of guidance affect compliance with safety requirements in the stevedoring industry? AMSA considers that to be fully effective, guidance material would need some form of legislative application and this would need to be provided in a consistent manner across all jurisdictions. 3.4 – Duty holder compliance - Pages 9 and 10 As explained in this section of the RIS, compliance is currently voluntary and the extent of business compliance is unknown. On that basis, AMSA would support the opinion expressed by some other members of the TAG, that a mandatory code of practice would have better application and uptake than guidance material. 7 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) Section 4 – Objectives of the proposed reform - Page 10 AMSA supports the outlined objectives. Section 5 – Options to achieve the reform - Pages 11 and 12 Option 1: Retain the status quo This discussion paper does not identify whether any existing legislative instruments currently obligate use of the guidance material released in 2009. Option 2: Updating guidance material on stevedoring There does not appear to be any real cost saving or additional benefit supporting this option over option 3. Option 3: Develop a model Code of Practice Safe Work Australia has already invested considerable time and effort in developing a draft model code of practice. With some minor amendment, adoption of this code would appear to provide the greatest benefits to the stevedoring industry, for the most reasonable cost outcomes to both industry and the government. General comment - While section 5.2.3 of the RIS intimates that the shipping industry is already highly regulated, it neglects to identify that currently, very little regulation actually targets OHS/WHS safety in the stevedoring industry. Option 4: Include industry specific provisions in the model WHS Regulations While this section identifies a current overlap between WHS and maritime regulation, the remainder if the RIS document does not elaborate on the extent of any overlap or how this overlap has come into existence. It is acknowledged that currently Marine Order 32 includes some apparent OHS/WHS provisions, mainly owing to the absence of other existing provisions under alternative legislation. From the outset of this process, AMSA has advised Safe Work Australia and the other industry and union TAG participants, that once suitable WHS safety legislation is enacted, it will review with an intention of removing any apparent WHS provisions from its Marine Orders. Again, reference here to the OHS (MI) Act should include its limited application. Section 6 – Analysis of expected changes from the reform 6.1 - Overview AMSA wishes to again emphasise that Marine Orders were never intended to include OHS/WHS provisions, but were designed to ensure the physical structure of ships and attached or related cargo handling equipment, e.g. ship-board cranes, hoists, chains, slings, and other associated gear, are fitted and maintained in a safe condition for use in cargo loading/unloading operations. 6.2 - Comparison of the draft model Code with existing requirements Question for Public Comment – Page14 For each of the key components of the draft model Code (listed in Appendix B), what are the costs and benefits of implementation for you and/or your business? **Please note, AMSA has included specific comment against the topics included in the table in Appendix B of the RIS document which has been incorporated below. 8 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) 6.2.1 - Training needs analysis and training delivery plans AMSA can agree that whatever approach to training is finally agreed and adopted as part of the proposed Model Code of Practice, it should preferably be systematic rather than ad hoc. Any requisite training should provide a consistent framework, to ensure industry has a clear basis for developing, delivering, and meeting their training outcomes. Such a framework will also facilitate compliance auditing by the regulator. 6.2.2 - Use of hatchmen/cargo space lookouts Currently, MO 32 includes and will retain provisions requiring use of hatchmen in the prescribed circumstances. AMSA considers that if the Model Code provisions for hatchmen are not inconsistent then there should not be any issues. **AMSA specific comments against the table in Appendix B of the RIS document. Key provisions in the draft model Code and AMSA comments AMSA comments on expected impacts. 1. Introduction Appears to be consistent with current WHS provisions. 1. - No expected impact for AMSA 2. Risk Management Model CoP should provide more clarity for employers and stevedores. Appears to be consistent with risk management provisions of MO 32. 2. - No expected impact for AMSA. 3. Planning Model CoP should provide more clarity for employers and stevedores, particularly with regard to shore based planning requirements. Appears to be consistent with Marine Order load planning provisions. 3. - AMSA expects that land based traffic management procedures will be clearer and may result in safer loading and unloading operations. (Noting the RIS document includes statistics relating to stevedores being struck by moving vehicles or other objects). 4. Inspections The Model CoP inspection provisions appear to be consistent with current Marine Order provisions’ particularly with regard to ‘plant’ and ancillary cargo gear. 5. The working environment 5.1, 5.2, 5.3, 5.4 - It would appear the Model CoP requirements will not impact on access 4. - No expected impact for AMSA. General Comment Should now ensure that shore based ‘plant’ and ancillary equipment is inspected and certified in a consistent manner to ship based lifting machinery and material handling equipment. 5.1, 5.2, 5.3, 5.4 - No expected impact for AMSA. 9 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) **AMSA specific comments against the table in Appendix B of the RIS document. Key provisions in the draft model Code and AMSA comments AMSA comments on expected impacts. arrangements, lighting provisions or atmospheres in working spaces as prescribed in MO 32. 5.5 - The Model CoP will introduce requirements for considering adverse weather conditions. While AMSA is aware that such conditions have been considered for loading/unloading operations in the past, these provisions will now be formalised. 5.6 - The Model CoP includes requirements for consideration of ‘falls’ and ‘falling objects’, including reference to the separate Safe Work Australia Falls CoP. MO 32 also includes specific ‘falls’ provisions. 5.7 - The Model CoP will include requirements for considering noise management. 5.8 - The Model CoP will introduce requirements for considering fatigue management. 5.5 - AMSA does not expect formal provisions for consideration of adverse weather conditions to impact on existing practices, so again, no expected impact for AMSA. 5.6 - No expected impact for AMSA. 5.7 - The Model CoP noise provisions will cover more circumstances than current provisions in MO 32, so will enhance safety in regard to noise exposure. 5.8 - The Maritime industry already strictly monitors working hours under Standards of Training Certification and Watchkeeping (STCW), so no impact is expected for ship-board workers. 6. Handling loads and cargo 6.1 - Suspended loads The Model CoP requirements appear to be consistent with current MO 32 provisions. 6.1 - No expected impact for AMSA. 6.2 - Lashing and unlashing containers 6.2 - No expected impact for The Model CoP does not appear to include AMSA. any specific requirements in relation to lashing and unlashing containers, as this work is carried out on-board a ship, so it would be expected that MO 32 provisions would prevail. 6.3 - Working in ships’ holds: Hatches and openings 6.3 - No expected impact for AMSA. General comments 10 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) **AMSA specific comments against the table in Appendix B of the RIS document. Key provisions in the draft model Code and AMSA comments AMSA comments on expected impacts. AMSA is aware that Safe Work Australia is working with industry to resolve issues with regard to a perceived need for provisions of hatchman (lookout), additional to those specified in MO 32. Ladders Monitoring cargo operations The Model CoP requirements appear to be consistent with current Marine Order provisions. Although the risk of falls into holds needs to be considered, the reference here to WHS regulation 78 with regard to managing falls has been addressed in AMSA’s response to 5.6 above. 6.4 - Types of cargo: General Dry bulk Liquid bulk Containers Roll-on/roll-off activities Livestock 6.4 - No expected impact for AMSA. General comment The Marine Order references in the RIS document are not consistent with the Marine Order references in the Model CoP. References to MO 42 - Cargo Stowage and Securing, and MO 44 - Safe Containers, are not referenced in the RIS document. 6.5 - Storage and stowage for goods not in containers 6.5 - No expected impact for AMSA. General comment This column in the RIS document omits reference to other Marine Orders covering such work activities, such as; MO 44 - Safe Containers, and MO 42 - Cargo Stowage and Securing, which contains specific provisions for RoRo vessels which are also included in the Model CoP. 7. Plant and equipment 7.1 - Powered mobile plant 7.1 - No expected impact for AMSA. General comment Again, this column in the RIS document omits reference to other relevant Marine Orders considering 11 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) **AMSA specific comments against the table in Appendix B of the RIS document. Key provisions in the draft model Code and AMSA comments 7.2 - Cranes and work boxes Ship-based cranes Shore-based cranes Adverse weather conditions Emergency procedures Crane work boxes References Marine Orders for requirements relating to cranes on ships and the model Code of Practice Cranes for shore-based cranes. 7.3 - Other lifting equipment Loose gear 7.4 - Personal protective equipment (PPE) 8. Mooring and unmooring 8.1 - Prior to mooring 8.2 - Mooring 8.3 - Unmooring AMSA comments on expected impacts. such work activities, in particular MO 42 - Cargo Stowage and Securing, which contains specific provisions for Ro-Ro vessels which are also included in the Model CoP. 7.2 - No expected impact for AMSA. (also refer to AMSA comments against 5.5 above) General comment AMSA notes that the Stevedoring Model CoP will refer to a separate Safe Work Australia, Cranes Code of Practice, which will apply to shore-based cranes. 7.3 - No expected impact for AMSA. General comment Again, this column in the RIS document omits reference to a separate Safe Work Australia, Cranes Code of Practice, which will include provisions for material handling equipment associated with shore-based cranes. 7.3 - No expected impact for AMSA. 8. AMSA does not anticipate any conflicting impact. General Comment Currently each vessel includes specific mooring and unmooring procedures in the ship’s documented Safety Management System (SMS), required under International Safety Management (ISM) provisions of the Safety of Life at Sea (SOLAS) Convention. AMSA considers that Safe Work Australia should provide specific 12 Office Use Only 014 Individual/Organisational name: Australian Maritime Safety Authority (AMSA) **AMSA specific comments against the table in Appendix B of the RIS document. Key provisions in the draft model Code and AMSA comments AMSA comments on expected impacts. requirements for planning and carrying out safe mooring and unmooring procedures, when undertaken by shore-based personnel. Whether this is included in this Model Stevedoring CoP, or as a separate document, is a matter for Safe Work Australia to decide. Section 7 – Anticipated costs and benefits AMSA is unable to comment on anticipated costs, but anticipates that Safe Work Australia’s cost benefit analysis will provide an accurate reflection of implementing the proposed Model Code of Practice. AMSA would expect that introduction of clear duty based requirements will provide the stevedoring industry with the following benefits: a raised awareness of the risks involved in undertaking stevedoring work; consistent mechanisms for meeting their regulatory obligations; and result in improved safety outcomes for the industry. Safe Work Australia has also advised that the proposed code should provide nationally consistent regulation that will compliment Marine Order provisions administered by AMSA. It is anticipated that the introduction of consistent WHS regulation in all jurisdictions, will also assist industry and regulators in delineating the areas of coverage for land based and ship based stevedoring operations. Overall general comment - Clarifying AMSA’s intentions with regard to proposed review and modification of Marine Orders. In providing comment on the Safe Work Australia, Consultation RIS and Draft Model Code of Practice, AMSA has reiterated its proposal to review, with an intention of removing any apparent WHS provisions from its Marine Orders. However, there will always be a need for inclusion in Marine Orders, of provisions to allow AMSA to ensure that safety is paramount to the operation of the Navigation Act and Marine Orders. Provided there is no conflict between the requirements of the proposed mandatory Model Code of Practice – Managing Risks in Stevedoring and the provisions of AMSA Marine Orders, they should be able to operate concurrently with no unintended impacts. 13