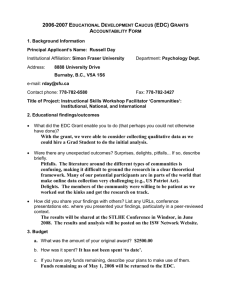

PLUS+1 Service Tool Training Presentation

advertisement

PLUS+1 Service Tool Training © Blue Graphics Concept Sauer-Danfoss © Blue Graphics Concept Sauer-Danfoss 1 1 Who is who? • • • • • • Name Company Position Programming skills Experience with PLUS+1 Projects 2 Agenda • • • • • • This is PLUS+1 Programming example Example system (what can we test?) Things to check, how and in what order CAN, Terminating resistor, CG150 Service Tool Overview – Safety – CG150 and connection – Checking the MC controller I/O • Deutch Pin crimping and disconnection 3 PLUS+1 Controls Platform © Blue Graphics Concept Sauer-Danfoss © Blue Graphics Concept Sauer-Danfoss Productivity and Performance 4 PLUS+1 Controls Platfrom Content • Introduction • Market Trends • Product and System Information • Unique Product Features and Benefits • Key Applications • Product Literature and Support • Summary 5 PLUS+1 Controls Platfrom Introduction • Introduced in 2004 • Growing family of microcontroller and software solutions • High power family of 12, 24, 38, 50 and 88 pin controllers and I/O modules • Graphical programming environment 6 PLUS+1 Controls Platfrom Introduction PLUS+1 Family Controllers 12-pin 24-pin 38-pin 50-pin MC012-010 MC024-010 MC038-010 MC050-010 MC024-020 MC050-020 MC050-055 I/O Modules IX012-010 IX024-010 OX012-010 OX024-010 IOX012-010 IOX024-020 7 88-pin MC088-015 PLUS+1 Controls Platfrom Market Trends - Productivity • Machine Productivity. Automation of functions to create more efficient vehicles – Work faster, longer – Less fuel consumption – Engine emission regulation driven advancements • Development Productivity – More work with smaller design teams – Faster time to market, shorter design cycles – Modularity to increase reuse of designs 8 PLUS+1 Controls Platfrom Market Trends - Performance • Machine Performance. Ability to differentiate operational functionality – Smooth, accurate controls – Maximize drive and work output – Comfortable working environment • Microcontroller Performance – – – – More processor capability required for complex applications Accurate current controlled outputs Ability to communicate with multiple subsystems Software becomes key to machine performance and differentiation 9 PLUS+1 Controls Platfrom Product and System Information 10 PLUS+1 Controls Platfrom Product and System Information • PLUS+1 microcontrollers offer a high performance, rugged platform for machine control – 150Mhz Texas Instruments DSP processor core – IP67 enclosure for dust and water ingress protection – 2 LEDs for visual diagnostics – Deutsch® electrical connectors – Multiple mounting configurations 11 PLUS+1 Controls Platfrom PLUS+1 Hardware Family Rugged Design for Mobile Off Highway Use • • • • • • • Temperature range: -40C to +70C Ingress protection: IP67 Shock: 100g, 6ms, 3 shocks in each of 6 directions Vibration: 5g RMS, 3 directions (x,y.z) EMC protection: to 100V/m Deutsch electrical connectors CE marked 12 PLUS+1 Controls Platfrom PLUS+1 Hardware Family • PLUS+1 Microcontroller Family Inputs* Optional Features Outputs* Rated Current Timing Digital Analog Rheostat PWM (3A max) PVG Digital (3A max) Application Keyed Other MC012-01x 8A 3 3 4 - 2 2 2 Yes High Temp MC024-01x 8A 5 11 8 2 3 3 3 Yes +Memory MC024-02x 24A 5 7 6 - 8 8 8 Yes +Memory MC038-01x 70A 3 14 13 - 8** - 13** Yes - MC050-01x 40A 6 12 12 4 6 6 12 Yes +Memory MC050-02x 40A 6 20 14 2 6 6 14 Yes +Memory MC050-05x 8A 4 33 36 - 2 2 3 Yes ISOBus MC088-01x 100A 6 32 24 8 32** 10 10 Yes - Product Family * Maximum number available through multi-function configurability ** High Current Outputs available 13 PLUS+1 Controls Platfrom PLUS+1 Hardware Family • Stand alone applications – PLUS+1 controller effective as stand alone control solution • Networked solutions – – – CAN communications facilitates distributed architecture Place control near I/O I/O modules easily extend control 14 PLUS+1 Controls Platfrom PLUS+1 Hardware Family • PLUS+1 Input/Output Modules – Expand the input and output capabilities of a PLUS+1 controller – Preconfigured CAN messaging makes it easy – Variants with • • • Inputs only Outputs only Combination of inputs and outputs 15 PLUS+1 Controls Platfrom PLUS+1 Hardware Family • PLUS+1 I/O modules Inputs* Outputs* Rated Current Timing Digital Analog Rheostat PWM (3A max) PVG Digital (3A max) IX012-010 - 3 3 6 2 - - - OX012-010 16A - - - - 6 6 6 IOX012-010 8A 3 3 4 - 2 2 2 IX024-010 - 7 13 12 4 - - - OX024-010 32A - - - - 10 10 16 IOX024-020 24A 5 7 6 - 8 8 8 Product Family * Maximum number available through multi-function configurability 16 PLUS+1 Controls Platfrom PLUS+1 Hardware Family • Summary: – Powerful controls for even the most complex applications – Large family of controllers and I/O modules to match the requirements of the machine – Rugged design for mobile off-highway use – Modular CAN based architecture is scaleable to the needs of the application 17 PLUS+1 Controls Platfrom GUIDE Development Environment • Program logic and signal flow is easily visualized in GUIDE • Drag, drop, and connect graphical modules on the programming workspace • Save, and then download your new application to a PLUS+1 controller or display 18 PLUS+1 Controls Platfrom GUIDE Development Environment • Modular software design for maximum flexibility • Manipulate data at bit level or combine high level functionalities 1. Boolean logic and math functions 2. Filters, PID controls, output drivers 3. Dual path control, automotive control • Graphical design environment reduces need for formal programming training 19 PLUS+1 Controls Platfrom GUIDE Development Environment • Description here 20 PLUS+1 Controls Platfrom GUIDE Development Environment • Sauer-Danfoss provides an extensive software library at each level of programming • Leverage SD’s application knowledge to create best in class solutions • Add additional features to create differentiated solutions • Flexible enough to interface with most any vehicle subsystem or secondary component 21 PLUS+1 Controls Platfrom Application Software Solutions Multiple projects, CAN connections Pump actuators, Sensors 2 Function Blocks (GUIDE) PID, Ramp, Filter, PWM Drivers, FNR Switches 1 Components (GUIDE) Math, Logical, Limit, Compare, CAN, E2 Included in GUIDE Keyed Applications 22 Block Dual Path EDC Joystick Ramp Ramp AND Custom Product Easier Control System Development PVE, Joystick, Motors and Core Dual Path Valves Compliance Blocks (GUIDE) EDC 3 Core Block Sub-system software EDC Core and Plug-ins for Dual Path, Automotive, Hitch, etc. Sensors 4 Application Blocks Steering Dual Path EDC Dual Path, Automotive, Fan Drive, Transit mixer Steering Sub-system EDC Core Block Joystick Subsystem Applications EDC 5 Vehicle Solutions Joystick 6 Propel Sub-system Integrated, CANDual Path Path connected Sub-systems Dual PLUS+1 Controls Platfrom Application Software Solutions Components - Basic logical building blocks • Fundamental elements for creative graphical programming • Build your own objects, and create CAN messages 23 PLUS+1 Controls Platfrom Application Software Solutions Function blocks – Higher level controls • Library of pre-engineered, generic control objects • User configurable for maximum versatility 24 24 PLUS+1 Controls Platfrom Application Software Solutions Application blocks – Core “application level” control • Library of pre-engineered, application solutions • Result of years of Sauer-Danfoss control experience 25 25 PLUS+1 Controls Platfrom Application Software Solutions “Core” Application Blocks and Plug-ins • Application Blocks – Contain proprietary Sauer-Danfoss control logic for programmable GUIDE applications – These blocks are keyed to Application Hardware (keyed blocks can only be downloaded to Application Hardware) – Content is locked from view Application Block (.SCS file format) Plug In Keyed Blocks (.SCS) Inside the Plug In Application (.SCS) Block Plug In (.SCS) • Plug-ins – Plug-ins can be added to core Application Blocks by developers – They provide optional functionality or performance – Plug-ins are also keyed to Application Hardware Plug In (.SCS) 26 PLUS+1 Controls Platfrom Application Software Solutions Keyed software blocks can only be loaded onto keyed Application Hardware Subsystem Application for PLUS+1 Application Hardware programming template (.P1P file format) Subsystem Application portable to other PLUS+1 controllers, applications (.SCS file format) Input Application Block Map Conditioning (.SCS file format) Output Output Blink Drivers Map Code Plug In Plug In Inside the (.SCS) Application Plug In Block (.SCS) Plug In (.SCS) (GUIDE Programmable) (GUIDE Programmable) (GUIDE Programmable) (GUIDE Programmable) Keyed Blocks Keyed Application Hardware Block (.SCS) (GUIDE Programmable) Input Fault Handler, Calibration, other supporting functions (GUIDE Programmable) STOP If the application software key matches the Sauer-Danfoss hardware key, installation to Application Hardware is allowed. If software keys are not detected, the application may be installed in standard priced hardware. 27 Standard priced hardware PLUS+1 Controls Platfrom Application Software Solutions Subsystem Applications • • • • Complete application software solution Facilitates rapid development of machine controls Tested solutions manage development risk GUIDE is used to tailor the application for vehicle requirements 28 PLUS+1 Controls Platfrom PLUS+1 Compliance Compliance Blocks - Software blocks for PLUS+1 products PLUS+1 Pressure Sensor PLUS+1 Joystick, CAN output • Specific PLUS+1 products, characterized by Compliance Blocks • Tested, fast and convenient to use, documentation included 29 PLUS+1 Controls Platfrom PLUS+1 Compliance Over 40 PLUS+1 Compliance Blocks: Pumps, motors, valves, sensors, displays and HMI products are represented in software, tested and optimized by Sauer-Danfoss Example: Optimized Pump Tuning Swashplate Angle Non-optimized tuning parameters Optimized tuning parameters stored in Compliance Block 0.00 0.05 0.10 0.15 0.20 0.25 Time (mS) 30 0.30 0.35 0.40 0.45 PLUS+1 Controls Platfrom PLUS+1 Compliance • PLUS+1 Compliance Blocks: – Shorten development time – Provide a tested solution – Ease start-up issues – Provide optimized performance 31 PLUS+1 Controls Platfrom Service Tools • Use Service Tool to download your GUIDE application to the PLUS+1 controller • Monitor, view and adjust parameters • Use Designer Service Tool to build custom screens PC to CANbus Gateway 32 PLUS+1 Controls Platfrom Service Tools • Fully customizable service solutions – Add ‘check points’ at any place in the application – Design PC screens to meet the need of the user (developer, service technician, etc.) – Password access capabilities – CAN bus interface provides access to all controllers in a system – .dll option for OEM service tool integration 33 PLUS+1 Controls Platfrom PC Communications • PC based service tool uses USB to CAN communication – – CG150 USB – CAN gateway USB ports on DP210, DP250 or DP600 displays 34 PLUS+1 Controls Platfrom Key Applications • Ideally suited for mobile off-highway equipment • Flexible enough for many control system needs • Stand alone control or CAN based distributed controls 35 PLUS+1 Controls Platfrom Product Literature • Technical Information • Data Sheets • Family Brochure 36 PLUS+1 Controls Platfrom Product Support Multiple projects, automated CAN connections AND R&D R&DProject Project Easier Control System Development Ramp Ramp EDC 11 Components Components(part (partof ofGUIDE) GUIDE) Math, Logical, Limit, Compare, CAN, E2 EDC Valves 22 Function FunctionBlocks Blocks(Library) (Library) PLUS+1 Tools 37 EDC Joystick PID, Ramp, Filter, PWM Drivers, FNR Switches In InDevelopment Development EDC PVE, Joystick, ED Motors, H1 Pump, Sensors • eLearning • Helpdesk telephone support Sensors Dual Path 33 Compliance ComplianceBlocks Blocks(Library) (Library) • Documentation • Email support & web site FAQ Dual Path Steering Core Block Dual Path Core Block Core and Plug-ins for Dual Path, Automotive, Hitch, etc. 44 Application ApplicationBlocks Blocks Released Released • Classroom training Steering Sub-system Sub-system software Joystick Dual Path, Automotive, Fan Drive, Transit mixer Dual Path Dual Path Core Block EDC 55 Sub-system Sub-systemApplications Applications Propel Sub-system EDC • PLUS+1 Compliance Integrated, auto CANconnected Sub-systems Joystick • Application software Library 66 Vehicle VehicleSolutions Solutions(R&D) (R&D) PLUS+1 Controls Platfrom Product Support – On-line Training • Self-paced GUIDE programming training, always available on line • E-learning supplements, or substitutes for available classroom training • Develop and save virtual applications on line without a GUIDE license 38 38 PLUS+1 Controls Platfrom Summary • High power family of 12, 24, 38, 50 and 88-pin controllers and I/O modules Scalable for any application • GUIDE graphical programming environment Customizable software solutions • Extensive Sauer-Danfoss application software library For best in class performance and fast time to market • Full array of product support options Your strongest partner for machine controls 39 PLUS+1 GUIDE Training • • • • Set up Software and Hardware Prepare and make a new program Set up Service Tool Set up a diagnostic file 40 Software • Download from www.sauer-danfoss.com • Run “PLUS+1 GUIDE……setup.exe” • Starting at V4.0 you can now have multiple versions of GUIDE installed 41 License • Go to: Tools>License Manager • Use Help • License types: – Full license – Service Tool Design license – Service Tool built in license (for download and debugging) • Each user can use the license on a desktop and a laptop. 42 Side panels and compiling messages Enable/disable panels here. Select pop-up or fixed panels by clicking here. 43 Setup a new project (program) • Create a new project • Select hardware • Load the template – An “empty” program that compiles – All inputs and outputs available 44 New project • Go to: File>New Type in a name for your project. Create a new unique folder for each project created. 45 Install Hardware Files • Go to: Setup>Install Hardware • Categories of Hardware files (.hwd): – Programmable • Controllers • Displays • Inverters – Non programmable • I/O modules • Compliance blocks • Install all for a category with a .PAC-file. 46 Install Function Libraries • Go to: Setup>Install Function Library 47 Select hardware Right click 48 Load template • All graphical files has got .SCS as extension Right click 49 Setting the backup interval • Go to: Setup>Options 50 Options, Shortcuts 51 Bus and page A bus. Contains many signals (wires) A page. Usually made with blue lines 52 Top view pages in the template Joystick, pressure sensor etc The program 53 Valves, lamps etc Node number for Service Tool Node number for Service Tool 54 Components • The smallest part of a program • To get help 1. Highlight the component 2. Press F1 55 Where can I get help? • Help Contents and User Manual has got the same info Pdf-format Opens Help Contents 56 Documents in the Hardware file • Data sheet • Application Programming Interface Specification (API Specification) 57 Data sheet 58 Input types Type Range Max input Value in GUIDE Digital in 5 – 36 Volt read as True 36 Volt False/True Multifunctional in 0 – 5 Volt 36 Volt 0 – 36 Volt 0 – 10000 Hz 2ch encoder (2 inputs) Digital 0 – 5000 mV 0 – 36000 mV 0 – 10000 Hz 0 – 4000 Hz False/True Analog in 0 – 5 Volt 0 – 10000 Ohm 36 Volt 0 – 5000 mV 0 – 10000 Ohm Analog in 5 Volt 0 – 5 Volt 25 Volt 0 – 5000 mV 59 Output types Type Range Max current Digital out 0 or supply voltage 3A False/True MC88 6A Multifunctional 0 – 100% duty cycle 3 A out 0–3A 0 or supply voltage 60 Value in GUIDE 0 – 10000 x 0.01% 0 – 30000 x 0.1 mA False/True Multiple Supply or Ground pins • Maximum current for a pin is 8 Amps. • If the total output load is more than 8 Amps, then you need to use more power pins in parallel. 61 API Specification • Example: C1p06.DigIn 62 Zooming and change view • Mouse operations – – – – Scroll wheel - Zoom In/Zoom Out Hold right key + move up to the right – Zoom in Hold right key + move down to the left – Zoom out Right click – That position will be the new center of the drawing without changing the zoom level • Keyboard operations – Page Up/Page Down - Zoom In/Zoom Out – Home – Zoom to fit drawing 63 Enter and leaving a page • PLUS+1 GUIDE has got a “Top-Down” structure • Moving down one level in the structure is called Enter – Press E and click on a page • Moving up one level in the structure is called Leave – Press L • The program is split into pages Top Level Unit_Config 1 level down 2 levels down Inputs OS OS …………………… …………………… 64 Application C2p12_MFOut C2p12 Outputs Page Navigator • Enter a page by double-clicking 65 Inputs page 1 level down in Inputs page Top Level Bus connection between levels 66 Digital input 67 Pull up/Pull down 5 Volts > 5 Volts Inside the Plus 1 Controller There must always be a connection to the input pin. 0. No Pull Up or Pull Down 5 Volts Inside the Plus 1 Controller Bias to 5 Volts, so switch must switch to ground. 1. Pull Up 5 Volts > 5 Volts Inside the Plus 1 Controller Bias to Ground, so switch must switch to a voltage more than 5 volts, typically supply. 2. Pull Down Digital Input Biasing 68 Multifunctional input 69 Settings for digital reading on MF in Volts Input Signal DigInConfigHigh DigInConfigLow Status ON Status OFF Time Digital Input Hystersis 70 Analog input 71 Signals from operating system 72 Outputs 73 Multifunctional output 74 Duty cycle 10% duty cycle Supply voltage 0V 50% duty cycle 90% duty cycle PWM frequency • Example: 24V supply, 90% duty cycle = 21.6V 75 How to connect to a Multifunctional output Constants connected to outputs to be able to compile To use DigOut, disconnect the False component To use OutputValue, disconnect the Typed Constant 76 Feedback from outputs 77 Drawing commands • R (Route) - Make a bus or wire connection – K – Change between red and green (bus or wire) – F9 – Drop a bus or wire without connecting • • • • • • • V (View Logical Net) – Cross reference. Trace a wire or a bus through pages S (Stretch) – Extend or compress a part of a drawing M (Move) – Almost the same as Stretch C (Copy) – Copy within the same page Ctrl C/Ctrl V – Copy and Paste. Copy between pages or projects Q (Query) – Edit (text, data types etc.) Delete key – Delete 78 Drawing commands • Spend some minutes trying out the drawing commands • After that, replace the Template to start from scratch 79 Functional description Give an alarm if pressure is higher than 150 bar Range: 0 – 300 bar Output range: 0 – 5 Volt Pressure sensor Program: Check if input signal is higher than 2500 mV Alarm lamp MC24-10 C2p05 > 2500 80 C2p09 Application 81 PLUS+1 Hitch Control Example 82 LEDs on the I/O-module • I/O-module LEDs 83 LEDs of IX module LEDs of IX module Potential for IX modules to not go online. If voltage is applied to an IX module input pin prior to the module being powered on, there is a possibility that the module CPU will not power up. The module is not damaged and will power up and operate normally once power is removed from the input pins. It is recommended that either the IX module’s 5 Vdc sensor power be used to power sensors or that power is removed from the input pins until the module is powered up. 520L0719 • Rev JA • Aug 2010 84 84 Checking the “Grounding” of the System With the volt meter 85 Safety and the Service Tool • When using the Service Tool connected to a running machine one may have the potential to control the outputs of the PLUS+1 which could mean moving the machine or machine parts. • When using the Service Tool connected to a running machine, make sure the machine is in a safe state. This could mean the machine be put up on blocks before testing so that if the wheels move unexpectedly no one would be hurt. • Make sure people are not close to or working on parts that could move when using the Service Tool on a running machine. 86 CG 150 • • • • • Interface the CAN bus with 9-pin D-SUB connector Designed for USB 2.0, backward compliant with USB 1.1 Microsoft Windows XP, Windows 2000, Vista & Windows 7 Plug and Play installation Part Number 10104136 87 Things to check, how and in what order NON-invasive checks from beginning of signal path to end – LEDs • MC controllers and Displays, user configurable but normally: green=powered on, Red flashing=can bus error) (power up, flash red/green then green) • RED and GREEN LED go off right after power up… may need ECU recovery • I/O expanders (flickering green and flickering red = ok, can bus communication) • PVEs (Green=ok, Solid RED=internal fault, flashing red=signal is out of range) – – – – – – – – Re-calibrate machine recent update to the PLUS+1 program Two displays with different contrasts (SETTINGS) Checking input and output signals with the Service tool Checking “open” output pins of the MC controller, may read voltage when the output pin is off if the load is not connected, this is normal Checking for Connectivity in Electrical System Analog sensors and Joysticks “Hot Plugging” Machine power should be off when connecting PLUS+1 modules to mating connectors. Proper grounding of system 88 MC Controller connection to CG 150 89 Service Tool Over View • COMMUNICATION – – – – ON LINE / OFF LINE MODE GREEN LIGHT AT BOTTOM OF SCREEN GATEWAY = DISPLAY / SAUER DANFOSS CG150 BAUD RATE DOWNLOAD 250K DEFAULT • WILL NEED MORE THAN THE FREE LICENSE TO CHECK SYSTEMS WITHOUT A DEDICATED SERVICE TOOL PROGRAM • DESIGN LOG • Power controller off/on and power computer off/on 90 PLUS+1 MC CONTROLLER I/O – – – – “Name” of devices on CAN Bus Obtain the pin number and configuration ECU recovery … RED and GREEN LED go off right after power up PLUS+1 Inputs Digital Input (active = 1 = True) Analog Input (0 – 32767) Volts (mV) (ranges: 0-368 mV, 0-5250 mV, 0-36000 mV) Rheostat Input (Ohm) Frequency Input (Hz) – PLUS+1 OUTPUTS: Digital Output Proportional Output 91 Checking the “Grounding” of the System With the Service Tool • logging the MF output pin feed back current on start up • If the power is on to the system you start logging and cycle power. The Service Tool will go back to logging quick enough to see the "Null Offset" work. 92 92 PLUS+1 Controls Platform PLUS+1 hardware products • Growing family of microcontrollers, displays, and joysticks • High power family of 12, 24, 38, 50 and 88 pin controllers and I/O modules • http://www.sauerdanfoss.com/Products/MobileElectronics/Microcontroller/PL US1Microcontrollers/index.htm 93 PLUS+1 Controls Platform PLUS+1 hardware products PLUS+1 Family Controllers 12-pin 24-pin 38-pin 50-pin MC012-010 MC024-010 MC038-010 MC050-010 MC024-020 MC050-020 MC050-055 I/O Modules IX012-010 IX024-010 OX012-010 OX024-010 IOX012-010 IOX024-020 94 88-pin MC088-015 Service Tool • • • • Download program Read signals in the system Set parameters in the system Create diagnostic files (.P1D) 95 Set up the Service tool • Connect appropriate Gateway (CG150, DP600) • Make sure the CAN bus terminating resistors are in place (2 x 120 ohm). • Open Service tool. • Check communications parameters • Scan system • Design a Log file to view the checkpoint signals 96 SauerDanfoss CG150 Gateway USB CAN bus connection 97 Install CG150 Gateway • Insert USB connector • Drivers come with PLUS+1 GUIDE installation 98 Open Service Tool • How to open Service Tool from GUIDE This or this 99 Select Gateway Physical Gateway, select this! 100 Select File Download or 101 Select controller 102 Select file and Start Download 103 Trainer Break Out Box Pot 0 – 5V C1p06 C2p06 C2p05 C2p07 104 Service tool screen Scan system Requested Log period setting Log to a file Play a saved Log file Actual Log period Connection status Requested Log period 105 Gateway and channel Baud rate setting Make a new Log Function Right click Give the Log Function a name 106 Open Design Screen When highlighted press Enter to go to Design Screen 107 Design Screen 108 Recover ECU • Used if a controller has become inaccessible 109 ECU status • The warning icon is used when the ECU is: – – – – Not scanned In boot loader mode Error during System Scan Created with a HWD or GUIDE that is not officially released 110 Decimal values range Data Type Min Max U8 0 255 S8 -128 127 U16 0 65,535 S16 -32,768 32,767 U32 0 4,294,967,295 S32 -2,147,483,648 2,147,483,647 BOOL False True 111 Comment Most common