UNIT-4

advertisement

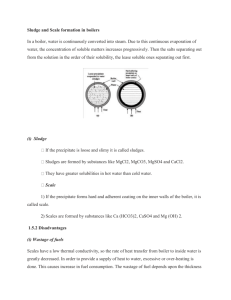

Page |1 WATER Hard water: Water which does not produce lather with water is known as hard water. It is due to some of the salts dissolved into the water. When we treat the water with soap, it gets precipitated in the form of insoluble salts of calcium and magnesium. CaCl2 + 2C17 H35 COONa → (Soap) (C17 H35 COO)2 Ca +2NaCl (Insoluble precipitate) Types of Hardness: 1. Temporary Hardness: It is due to the presence of bicarbonates of calcium and magnesium. It can be easily removed by boiling Heating Ca (HCO3)2 → CaCO3 + H2 O + CO2 Heating Mg (HCO3)2 → Ma (OH)2 + 2CO2 2. Permanent Hardness: This type of hardness can not be removed by boiling. This is due to the presence of chlorides and sulphates of calcium and magnesium. The hardness can be removed by the addition of some agents. Units of Hardness: 1. Parts per million (ppm) 2. Milligrams per litre (mg/L) 3. Degree French (°Fr) 4. Degree Clark (°Cl) Relationship: 1ppm = 1mg/L = 0.1 ºFr = 0.07 ºCl Page |2 Determination of Water Hardness Hard water is due to metal ions (minerals) that are dissolved in the ground water. These minerals includeCa2+, Mg2+, Fe3+, SO42-, and HCO3-. Rain water moving through the vast amount of limestone, CaCO3 and rocks, due to these the water becomes hard. This is why we measure hardness in terms of CaCO3. The determination of water hardness is a useful test that provides a measure of quality of water. When hard water is heated, CaCO3 precipitates out, which then clogs pipes and industrial boilers. The degree of hardness of the water is classified in terms of its calcium carbonate concentration as follows: Hardness rating Concentration of Calcium Carbonate (mg/L) Concentration of Calcium Carbonate (grains/US gallon) Soft 0 to <75 0 to <5.2 Medium hard 75 to <150 5.2 to <10.5 Hard 150 to <300 10.5 to <21 Very hard 300 and greater 21 and greater Determination of Water Hardness a) Complexometric Titration: EDTA Method : Permanent hardness is usually determined by titrating it with a standard solution of ethylene diamine tetra acetic acid (EDTA). The EDTA is a complexing or chelating agent used to capture the metal ions. This causes the water to become softened, but the metal ions are not removed from the water. EDTA simply binds the metal ions to it very tightly. It is frequently used in soaps and detergents because it forms complexes with calcium and magnesium ions. These ions which are in hard water are bound to the EDTA and cannot Page |3 interfere with the cleaning action of the soap or detergent. EDTA grabs all the metal ions in the water, not just the Ca2+ ions. This gives us a value that is not truly the concentration of Ca2+ ions. This causes an experimental error of about 1% which is acceptable in this type of titration. 1) Indicator : Eri-chrome Black – T 2) 3) 4) 5) TITRE : Hard Water Sample Titrant : Ethylene Diamine Tetra Acetic Acid (EDTA) Buffer : Mixing of NH4OH and NH4Cl Preparation of Reagents : a) Hard Water : Weigh out 0.5 gms of Magnesium Sulphate (MgSO4.7H2O) ,Transfer it into 100 ml Volumetric Flask and make up the flask with distilled Water up to the mark. Shake the solution vigorously to get homogeneous solution. b) EDTA : Weigh out 3.723 gms of Ethylene Diamine Tetra Acetic Acid ,Transfer it into 1000 ml Volumetric Flask and make up the flask with distilled Water up to the mark. Shake the solution vigorously to get homogeneous solution. c) EBT : Weigh out 0.5 gms of Eri-chrome Black – T ,Transfer it into 100ml Volumetric Flask and make up the flask with Ethyl/methyl alcohol up to the mark. Shake the solution vigorously to get homogeneous solution. d) Buffer : Weigh out 62.7 gms of NH4Cl and Transfer it into 570 ml NH4OH ,Shake the Solution vigorously to get homogeneous solution. Procedure : Take 20ml of Hard water sample In a conical flask , to this add 3 drops of EBT and 2 ml of Buffer it turns into Wine red colour solution. Page |4 ( Blue ) this red color solution is titrated against EDTA which is in Burette with continuous stirring , at a some stage the wine red is converts to blue color and that is taken as an end point of the titration. Repeat the titration until we get concurrent values. From then values we calculate the amount of Hardness of Water (Write the Calculation Part from Lab observation book). Boiler Troubles: The dissolved salts causing effects for steam boilers. The following are the troubles. 1) Priming and foaming 2) Scale and sludge’s 3) Caustic embrittlement 4) Boiler corrosion 1) Priming and foaming a) Priming: It is the carryover of varying amounts of droplets of water in the steam (foam and mist), which lowers the energy efficiency of the steam and leads to the deposit of salt crystals on the super heaters and in the turbines. Priming may be caused by improper construction of boiler, excessive ratings, or sudden fluctuations in steam demand. Priming is sometimes aggravated by impurities in the boiler-water. Page |5 b) Foaming: It is the contamination of the steam with boiler-water solids. Bubbles or froth actually build up on the surface of the boiler water and pass out with the steam. This is called foaming and it is caused by high concentration of any solids in the boiler water. It is generally believed, however, that specific substances such as alkalis, oils, fats, greases, certain types of organic matter and suspended solids are particularly conducive to foaming. In theory suspended solids collect in the surface film surrounding a steam bubble and make it tougher. The steam bubble therefore resists breaking and builds up foam. It is believed that the finer the suspended particles the greater their collection in the bubble Prevention : a) The most common measure to prevent foaming and priming is to maintain the concentration of solids in the boiler water at reasonably low levels. b) Avoiding high water levels, excessive boiler loads, and sudden load changes also helps. Very often contaminated condensate returned to the boiler system causes carry-over problems. In these cases the condensate should be temporarily wasted until the source of contamination is found and eliminated. c) The use of chemical anti-foaming and anti-priming agents, mixtures of surface-active agents that modify the surface tension of a liquid, remove foam and prevent the carryover of fine water particles in the stream, can be very effective in preventing carry-over due to high concentrations of impurities in the boiler-water. d) Hardness salts are the cause of scale inside a boiler; if they are not prevented or removed regularly they will cause localised overheating. This can lead to tube failure (explosion risk) and/or a reduction in the heat transfer properties of the transfer surfaces. 2) Boiler Scale & Sludge a) Sludge’s : sludges are soft ,loose,non-sticky precipitates produced due to higher concentration of dissolved salts. b) Scales : These are hard,stickly deposites formed on the inner walls of the boiler. Boiler scale is caused by impurities being precipitated out of the water directly on heat transfer surfaces or by suspended matter in water settling out on the metal and becoming hard and adherent. The evaporation in the boiler causes impurities to concentrate. In untreated boiler water, the formation of scale is like a "back to nature" movement. As Page |6 minerals are deposited out from water they from many types of crystalline and rock-like structures. The most common scale in boilers is due to carbonate deposits caused by hardness. Carbonate scale is usually granular and sometimes very porous. A carbonate scale can be easily identified by dropping it in a solution of hydrochloric acid. Bubbles of carbon dioxide will effervesce from the scale.Sulphates scales are harder and more dense. A sulphate deposit is brittle and does not effervesce when dropped in acid. Silica scales resemble porcelain. This scale is very brittle, is not soluble in acid, and dissolves slowly in alkali.Iron deposits are very dark colored. The are either due to corrosion or iron contamination in the water. They are soluble in hot acid giving a dark brown solution. Problems Caused by Scale The biggest problem caused by scale is overheating and failure of boiler tubes. The thermal conductivity of porous boiler scale is similar to insulating brick. The scale acts as an insulating layer and prevents an efficient transfer of heat through the tubes to the circulating water. The reduction in thermal conductivity means lower boiler efficiency which in turn leads to hot acid giving a dark brown solution. overheating and may result in the softening, bulging or even fracturing of the boiler tubes. Boiler scale can also cause plugging or partial obstruction of circulating tubes in a water tube boiler, which again causes starvation and overheating of the tubes. Another important aspect is that corrosion may occur under the boiler scale. In general, boiler scale causes a. b. c. d. e. increased fuel bill by decreasing the operating efficiency thermal damage unscheduled down-time increased cleaning time and cleaning costs reduced working life of a boiler. 3) Caustic embrittlement : It is the appearance of cracks inside the boilers particularly at joints and bends due to high concentration of alkali’s leading to the failure of the boiler. The boiler water containing Carbonates and bicarbonates of alkali metals Purified by limesoda process. During the process lime reacts with dissolved salts and soda is remains same in water. The lime reacts with water and form as caustic soda (NaOH) Page |7 Na2CO3 + H2O -------→ 2NaOH + CO2 The water in which NaOH is present is flows through Small pits and hair cracks present on the inner walls of the boilers. This soda forms concentration cells as ( + )Metal at bends / Conc.NaOH // Dil.NaOH / Metal at Plane Surface ( - ) ( Anode) (cathode) The metal at plane surfaces surrounded by dil.NaOH becomes anodic, where as the metal at bends surrounded by Conc.NaOH becomes cathodic which consequently corroded. Due to this inbalance in the same metal cracks will be developed , that cracks will be appeared as brittle nature. This is called as Caustic Embrittlement. Preventions : By using Sodium Phosphate, disodium hydrogen phosphate as softening reagents, they forms Complexes with Ca+2,Mg+2 . By using sodiumsulphate( Na2SO4 ) and sodium hydroxide ( NaOH ) in 1:1 ratio with boiled water. 4) Boiler Corrosion : The decay of boiler material by the attack of chemical or electrochemical environment is called as Boiler Corrosion. The reasons for the boiler corrosion is mainly due to a) Dissolved Oxygen b) Dissolved Carbon di Oxide c) Dissolved Acids Dissolved Oxygen : O2 is the most corroding environment .At 300c water contains 8cc of O2 per litre and the Moisture Contains 8mg/l of O2. Source : It is Naturally present Damages : At high temperatures oxygen attack the boilers creating serious corrosion 2 Fe +2 H2O + O2 2 Fe (OH)2 + O2 ----- 2 Fe (OH)2 ----------- > 2 Fe2 O3 .3 H2O (rust) Page |8 Removal Methods : a) Addition of sodium sulphide removes O2 by converting it into sodium sulphate. Na2S + O2 --- Na2SO4 b) Addition of sodium sulphite removes O2 by converting it into sodium sulphate. Na2SO3 + O2 --- Na2SO4 c) Addition of Hydrazene removes O2 by converting it into Nitrogen NH2-NH2 + O2 --- N2 + 2 H2O Disslved CO2 : Dissolved CO2 has a slow corrosive effect on boiler metals. Source : The bicarbonaes present in water ,at high pressure & Temperature decomposes in to CO2 . Ca(HCO3)2 ----- CaCO3 + CO2 ↑ + H2O Mg(HCO3)2 ----- Mg (OH)2 + 2 CO2 ↑ Damages : It react with water and Producing Carbonic Acid CO2 + H2O --- H2CO3 Removal Methode : By the addition of Calculated amount of Ammonia NH4OH + CO2 - (NH4)2 CO3 Dissolved Acids : Source : The dissolved Magnesium salts which undergo hydrolysis to produce Acids MgCl2 + 2 H2O -- Mg (OH)2 + HCl Damages : Acids reacts with metal of the Boilers produce the decay of the Page |9 Metal. Fe + 2 HCl --- 2 FeCl2 + H2 ↑ FeCl2 + H2 O 2 Fe (OH)2 + O2 ---- Fe (OH)2 + 2 HCl ----------- > 2 Fe2 O3 .3 H2O (rust) Removal Methodes : a) Softening of of the boiler water to remove MgCl2 from water. b) By frequent blow down operation i.e., removal of water , concentrated with dissolved salts and feeding the boiler with fresh water. Purifications Methods : 1)To remove temporary hardness (a) Lime-soda process : In this method, the soluble calcium and magnesium in water are chemically converted into insoluble compounds, by adding calculated and specific amounts of lime [Ca(OH)2] and soda [Na2CO3]. Calcium carbonate [CaCO3] and magnesium hydroxide [Mg(OH)2], these are precipitated and then filtered off. This lime soda process is of two types namely Cold lime soda and Hot lime soda : (i) Cold lime soda process: In this method, calculated quantity of chemical (lime and soda) is mixed with water at room temperature. P a g e | 10 At room temperature, the precipitates formed are finely divided, so they do not settle down easily and cannot be filtered easily. Consequently, it is essential to add small amounts of coagulanfs (like alum, aluminium sulphate, sodium aluminates, etc.), which hydrolyze to flocculent, gelatinous precipitate of aluminum hydroxide, and it then entraps the fine precipitates. Use of sodium aluminate as coagulant also helps the removal of silica as well as oil, if present in water. Cold L-S process provides water, containing a residual hardness of 50 to 60 ppm. NaAlO2 + 2H2O ---> Na0H + Al(0H)3 Al2(S04)3 + 3Ca(HC03)2 ---> 2Al(0H)3 + 3CaS04 + 6C02 The procedure for Cold Lime soda is as follows : Raw water and calculated quantities of chemicals (lime + soda + coagulant) are fed from the top into the inner vertical circular chamber, fitted with a vertical rotating shaft carrying a number of paddles. As the raw water and chemicals flow down, there is a vigorously stirring and continuous mixing, whereby softening of water takes place. As the softened water comes into the outer co-axial chamber, it rises upwards. The heavy sludge P a g e | 11 (or precipitated floc) settles down in the outer chamber by the time the softened water reaches up. The softened water then passes through a filtering media that's usually made of wood fibres to ensure complete removal of sludge. Filtered soft water finally flows out continuously through the outlet at the top. Sludge settling at the bottom of the outer chamber is drawn off occasionally. (ii) Hot lime-soda process : It involves treating the water with softening chemicals at a temperature of 80 - 150 C. Since hot process is operated at a temperature close to the boiling point of the solution, so following things takes place : (a) The reaction proceeds faster. (b) The softening capacity of hot process is increased to many fold. (c) The precipitate and sludge formed settle down rapidly and hence, no coagulants are needed. (d) Much of the dissolved gases like C02 and Air driven out of the water. (e) Viscosity of softened water is lower, so filtration of water becomes much easier. This in turn increases the filtering capacity of filters. (f) Hot lime-soda process produces water of comparatively lower residual hardness of 15 to 30 ppm. Hot lime-soda plant consists essentially three parts : (a) A 'reaction tank' in which raw water, chemicals and steam are thoroughly mixed (b) A 'conical sedimentation vessel' in which sludge settles down. (c) A 'sand filter' which ensures complete removal of sludge from the softened water. P a g e | 12 To Remove Permanent Hardness (a) Zeolite or permutit procees : Chemical structure of sodium zeolite may be represented as: Na2O.Al2O3.xSiO2.yH2O or Na2Al2O3.xH2O. where x = 2 - 10 and y = l - 5. Zeolite is hydrated sodium alumino silicate, capable of exchanging reversibly its sodium ions for hardness-producing ions in water. Zeolites are also known as pemutits. Zeolites arc of two types : (i) Natural Zeolites are non-porous. For example, natrolite, Na2O.Al203.4Si02.2H2O. (ii) Synthetic zeolites are porous and possess gel structure.They are prepared by heating together china clay, feldspar and soda ash. Such zeolites possess higher exchange capacity per unit weight than natural zeolites. figure (3) The proces is as follows : For softening of water by zeolite process, hard water is percolated at a specified rate through a bed of zeolite, kept in a cylinder . The hardness-causing ions like Ca+2, Mg+2 etc. are retained by the zeolite as CaZe and MgZe while the outgoing water contains sodium salts. Reactions taking place during the softerring process are : Na2Ze + Ca(HCO3)2 ---> CaZe + 2NaHCO3 Na2Ze + Mg( HCO3)2 ---> MgZe + 2NaHCO3 P a g e | 13 Na2Ze + CaCl2 (or) CaSO4 ---> CaZe + 2NaCl ( or Na2SO4) Na2Ze + MgC l2 (or MgS04) ---> MgZe + 2NaCl ( or Na2SO4) (Zeolite)................(Hardness) Regeneration : After some time, the zeolite is completely converted into calcium and magnesium zeolites and it ceases to soften water, it means it tets exhausted. At this stage, the supply of hard water is stopped and the exhausted zeolite is reclaimed by treating the bed with a concentrated (10%) brine (NaCl) solution. CaZe (or MgZe) + 2NaCl ---> Na2Ze + CaCl2 or MgCl2 (Exhausted zeolite)...........(Brine)....(Reclaimed Zeolite)...........(Washings) The washings that containing CaCl2 and MgCl2 are led to drain and the regenerated zeolite bed thus obtained is used again for softening Purpose. (b) Ion Exchange (de-ionization or de-mineralization) : The ion exchange resins are insoluble, cross-linked, long chain organic polymers with a microporous structute, and the "functional groups" attached to the chains are responsible for the ion-exchanging. Resins containing acidic functional groups (COOH, -SO3H, etc.) are capable of exchanging their H+ ions with other cations, which comes in their contact whereas containing basic functional groups ( -NH2 = NH as hydrochloride) are capable of their anions with other anions, which comes in their contact. The ion-resins may be classified as: (i) Cation exchange resins (RH ) are mainly styrene-diainyl benzene co polymers, which ion or carboxylation, become capable to exchange their hydrogen ions within the water. (ii) Anion exchange resins (R'OH ) are stytene-divinyl benzene or amine formaldehyde copolymers, which contains amino or quaternary ammonium or quaternary phosphonium or tertiary sulphonium groups as an integral part of the resin matrix. These, after treatment with dil. P a g e | 14 NaOH solution, become capable to exchange their OH anions with anions in water. Process : The hard water is passed first through cation exchange column, which removes all the cations (like Ca , Mg , etc.) from it, and equivalent amount of H ions are released from this column to water. Thus: 2RH+ + Ca+2 -----> R2Ca+2 + 2H+ 2RH+ + Mg+2 ------> R2Mg+2 + 2H+ After cation exchange column, the hard water is passed through anion exchange column, which removes all the anions like S042-, Cl , etc. present in the water and equivalent amount of OH- ions are released from this column to water. Thus : R'OH + Cl -----> R'Cl + OH 2R'OH + SO42- -----> R2' S042- + 20H 2R'OH + CO42- -----> R2' CO32- + 2OH P a g e | 15 H and OH ions that are released from cation exchange and anion exchange columns respectively together get combined to produce water molecule. H+ + OH -----> H2O Thus, the water coming out from the exchanger is free from cations as well as anions. Ion free water, is known as deionized or demineralised water. Treatment of municipal water (Drinking Water) and its treatment: Municipal water is that water that should be portable to supply to humans thus should be fit for drinking purposes. And it should be Treated as follows : 1. Screning process 2. Aeration 3. Sedimentation. 4. Fitration 5. sterelisation & Disinfactantion 6. Storage & supply Purification : 1. Screening : The raw water is passed through screens, having large number of holes, when floating matters are retained by them. 2. Aeration : 2. Sedimentation : It is a process of allowing water to stand undisturbed in big tanks, about 5 m deep, when most of the suspended particles settle down at the bottom, due to the force of gravity. The clear supernatant water is then drawn from tank with the help of pumps. The retention period in a sedimentation tank ranges from 2-6 hours. P a g e | 16 When water contains fine clay particles and colloidal matter, it becomes necessary to apply sedimentation with coagulation for removing such impurities. Sedimentation with coagulation is the process of removing fine suspended and colloidal impurities by the addition of requisite amount of chemicals called coagunlants to water before sedimentation. Just 4 Idea (don’t draw as it is ) Next, the water flows to a tank called a sedimentation basin where gravity causes the flocs to settle to the bottom. Large particles settle more rapidly than small particles. It would take a very long time for ALL of the particles to settle out and that would mean we would need a VERY large sedimentation basin. So the clarified water, with most of the particles removed, moves on to the filtration step where the finer particles are removed. (3) Filtration : It is the process of removing colloidal matter and most of the bacterias, micro organisms, etc. just by passing water through a bed of fine sand and other proper sized granular materials. Filtration is carried out by using sand filter. (a) The sand filter consists of a thick top layer of finely placed over coarse sand layer and gravels. It is provided with an inlet for water and an under drain channel at the bottom for exit of filter water. (b)Sedimented water entering the sand filter is uniformly distributed over the entire fine sand bed. P a g e | 17 During filtration, the sand pores get clogged, due to retention of impurities in the pores. When the rate of filtration becomes slow, the working of filter is stopped and about 2cm - 3cm of the top fine sand layer is scrapped of and replaced with clean fine sand and the filter is put back into use again. The scrapped sand is washed with water, dried and stored for reuse at the time of next scrapping operation. (c) Micro organisms : Water after passing through sedimentation, coagulation and filtration, operations still contains a small percentage of pathogenic bacteria which is disease producing. Consequently, water used, particularly for drinking or municipal purposes, must be freed from these disease producing bacteria, micro-organisms, etc. The process of destroying or killing the disease producing bacteria, micro-organisms, etc., from the water and making it safe for use, is called disinfection. The clemicals or substances which are added to water for killlng the bacteria, etc. are known as disinfectants. The disinfection of water can be carried out by following methods : (1) By boiling water for 10-15 minutes, all the disease producing bacterias are killed and water becomes safe for use. (2) By adding bleacing powder : In small water works about 1kg of bleaching powder per 1,000 kilolitres of water is mixed and water allowed to stand undisturbed for several hours. The chemical action produces hyypochlorous acid which is a powerful germicide. (3) By Chlorination : Chlorine produces hypochlorous acid. Cl2 + H2O - HOCl + HCl HCl + Bacterias ----> Bacterias killed. It was earlier believed that the disinfecting action of chlorine was due to the nascent oxygen liberated which oxidised harmful bacteris etc. After long experimentation it was reported that the death of micro organisms bacteria, etc., results from chemical reaction af hypochlorus acid (HOCl) with the enzymes in the cells of the organisms, etc. Since enzyme is essential for the metabolic proceses of the micro organisms so death of micro organisms results due to inactivation of enzyme (in th cells of organisms) by hypochlorous acid. (4) By Chloramine (CINH2) : When chlorine and ammonia are mixed in the ratio 2 : 1 by volume a compound chloramine is formed. Cl2 + NH3 - NH2Cl + HCl P a g e | 18 Chloramine is much more lasting than chlorine alone and consequently it's a better bactericidal than chlorine. NH2Cl + H2 O -- HOCl + NH3 Electro Dialysis : Electro Dialysis (ED) is a membrane process, during which ions are transported through semi permeable membrane, under the influence of an electric potential. The membranes are cation- or anion-selective, which basically means that either positive ions or negative ions will flow through. Cation-selective membranes are polyelectrolytes with negatively charged matter, which rejects negatively charged ions and allows positively charged ions to flow through. By placing multiple membranes in a row, which alternately allow positively or negatively charged ions to flow through, the ions can be removed from wastewater. In some columns concentration of ions will take place and in other columns ions will be removed. The concentrated saltwater flow is circulated until it has reached a value that enables precipitation. At this point the flow is discharged. This technique can be applied to remove ions from water. Particles that do not carry an electrical charge are not removed. Cation-selective membranes consist of sulphonated polystyrene, while anion-selective membranes consist of polystyrene with quaternary ammonia. Sometimes pre-treatment is necessary before the electro dialysis can take place. Suspended solids with a diameter that exceeds 10 µm need to be removed, or else they will plug the membrane pores. There are also substances that are able to neutralize a membrane, such as large organic anions, colloids, iron oxides and manganese oxide. These disturb the selective effect of the membrane. Pre-treatment methods, which aid the prevention of these effects are active carbon filtration (for organic matter), flocculation (for colloids) and filtration techniques. P a g e | 19 Reverse osmosis system Reverse osmosis (RO) is a filtration method that removes many types of large molecules and ions from solutions by applying pressure to the solution when it is on one side of a selective membrane. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be "selective," this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as the solvent) to pass freely.Reverse osmosis is most commonly known for its use in drinking water purification from seawater, removing the salt and other substances from the water molecules. This is the reverse of the normal osmosis process, in which the solvent naturally moves from an area of low solute concentration, through a membrane, to an area of high solute concentration. The movement of a pure solvent to equalize solute concentrations on each side of a membrane generates a pressure and this is the "osmotic pressure." Applying an external pressure to reverse the natural flow of pure solvent, thus, is reverse osmosis. P a g e | 20