Executive Summary - Brightwater Aquaculture

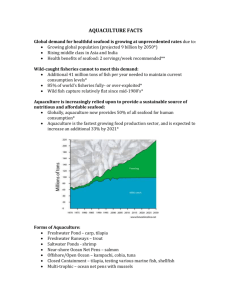

advertisement