LAB 3: Heat Treatment & Tensile Strength Aileen Johnsrud

advertisement

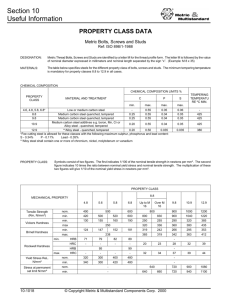

LAB 3: HEAT TREATMENT & TENSILE STRENGTH AILEEN JOHNSRUD 3/19/2015 Abstract Figure 1 Metal alloys behave differently to thermal treatments 4 trials of; 1018 steel C3600 brass are compared with as received specimens. Specimens are cooled by; quenched in water, oil, and air cooled. Differences occur in the heat treatment and cooling methods of 1018 steel higher carbon content contributes to the strength of a steel alloy, due to the carbon atoms preventing atomic dislocations that occur during plastic deformation. C3600 brass after heating remains soft no matter the quenching technique. LAB 3: Heat Treatment & Tensile Strength Aileen Johnsrud INTRODUCTION|one Two primary reasons for plastically deforming engineering metals and alloys are to change their shape for some particular purpose or to change their properties. Often times the deformation process alters the mechanical strength of the material. Cold worked material is harder and stronger than material deformed at other temperatures. These harder materials are advantageous for applications such as machine parts and mechanical supports. The temperature at which the deformation takes place is an important determinant of the final properties. If the temperature is relatively low with respect to the melting point of the material the deformation process is termed "cold working". A material that is plastically deformed at temperatures near or at the melting point is said to be hot worked. There are significant differences between the effects of cold and hot working on the properties and structure of materials. While cold-working a metal will tend to increase its strength, other properties such as ductility or corrosion resistance may be negatively affected. Therefore, to remove internal stresses of cold work, it is sometimes desirable to heat treat the metal after cold working. If this heat treatment, or annealing, is conducted at a sufficiently high temperature, a reduction of the stress necessary to further deform the material may be achieved as recrystallization occurs. This experiment introduces us to the relationship between cold work and recrystallization processes and their associated properties. During cold-working, it may take a considerable amount of energy to affect the change in size and shape. Some of the energy expended will appear in the form of heat. A considerable amount of the energy will also be stored in the material. This stored energy is associated with the defects created during the deformation. The free energy of the worked metal will be increased by approximately the amount represented by the stored energy. The most important result of cold working, which accompanies this increase in the number of defects, is strain hardening. Strain hardening is the increase in the yield stress of the metal after it has been deformed. This makes it more difficult to further deform the material. The increase in yield stress comes from the fact that deformation results in a higher density of dislocations. The strain fields around the dislocations most often repel one another, limiting dislocation movement. C36000 Free cutting Brass * 1018 cold rolled steel These 2 metals will be tested within 3 temperature zones, & then tensile tested with the MTS Load frame Ambient room 68oF * steel 1550o F * brass 900o F Heat treating and cooling methods may result in brittle failure of an alloy, which might otherwise react as ductile under other heat treating circumstances. A comparison of the results of temperature, hardness, and tensile strength amongst these two engineering alloys will be made. Page 1 LAB 3: Heat Treatment & Tensile Strength Aileen Johnsrud PROCEDURE|two This is an outline of the steps taken in the heat treatment & tensile strength experiment as a function of testing hardness by tempering or annealing. (Fig.2) Steel & brass specimens are 3/8” stock, cut to 1” pieces 1. One each of C3600 brass and 1018 steel are Rockwell tested at room temperature as a baseline or control for the experiment are summarized in Table T-1:. Alloy Rockwell Measurements at room temperature Average Rockwell Table T-1 Measurement C3600 brass 73.5, 75.5, 74.5, 74, 74, 69, 72.5, 73, 74, 73.5 73.35 0.240”ᴓ 1018 cold steel 90, 90, 90, 89.5, 89, 91, 86, 90, 89, 90 89.85 0.246”ᴓ 2. Specimens are Rockwell tested at the following temperatures after being held at temperature for a period of time; 3 specimens of 1018 cold steel at 1550o, held for 30 minutes 3 specimens of C3600 brass at 900o, held for 45 minutes in order to anneal them 3. After specimens are held at temperature for the designated times. One sample of each alloy will be cooled in the following ways to determine the effects of hardening or annealing due to cooling rate; Page 2 QUENCHED IN WATER, THEY MUST BE REMOVED FROM FURNACE AND PLACED IN THE WATER VERY QUICKLY QUENCHED IN OIL (SAE 30), THEY MUST BE REMOVED FROM FURNACE AND PLACED IN THE OIL VERY QUICKLY AIR COOLED ON FIRE BRICK, UNTIL COOL TO TOUCH LAB 3: Heat Treatment & Tensile Strength 4. Aileen Johnsrud Samples are then Rockwell hardness tested 10 times. Brass testing went no further to due to limited class time. It was understood that all further measurements of brass samples would be equivalent to the air cooled sample. Since brass lacks carbon, softening of the metal regardless of cooling technique occurs under heat treating, making the brass more ductile. The results of these tests are summarized in Table T-2: Table T-2 Rockwell B scale Rockwell B scale Rockwell B scale Alloy Oil Quenched SAE30 Water Quenched Air cooled 1018 cold Steel 78,80,78.5,78.5,79,79,78,79,8 0,80: Average =79 0.247”ᴓ 96,94.5,93,92,96.5,86,92,93,90.5,9 0.5: Average=92.4 0.246”IDᴓ 68,69,66,70,69,70,69,67,69, 69: Average= 68.6 C3600 Brass 10,11,11.5,11.5,12,11,12.5, 12,12.5,12: Average=11.7 5. After Rockwell testing, specimens are then loaded into the Instron tensile test machine to determine yield strength, tensile strength, & percent elongation. 6. A sample of a material between two fixtures called “grips” which clamp the material. The material has known dimensions, like length and cross-sectional area.. 7. An extensometer is mounted to specimen for data logging. Machine grips are placed around the grip sections of specimen (see below). 8. MTS load frame is then zeroed out, data for class & specimen type, diameters, length, thickness are imputed. 9. We then begin to apply weight to the material gripped at one end while the other end is fixed. We keep increasing the weight (often called the load or force) while at the same time measuring the change in length of the sample 10. Brass is not tensile tested in this lab Page 3 LAB 3: Heat Treatment & Tensile Strength Aileen Johnsrud RESULTS|three We observed how the properties of 1018 steel and C3600 brass vary with the heat treatment condition. 250 1018 Cold rolled Steel Stress Mpa (N/mm^2) 200 150 1018 CF Steel - Control 1018 Oil Quenched 100 1018 Water Quenched 1018 Air Annealed 50 0 -10 0 -50 Page 4 10 20 Strain 30 40 LAB 3: Heat Treatment & Tensile Strength Aileen Johnsrud DISCUSSION & CONCLUSION|four Heat treatment has a tremendous impact on some of the properties of materials used by engineers, and the effects of heat treatment should always be considered. We studied three different heat treatment configurations; as-received, fully annealed, quenched and tempered. Pearlite is formed as steel is cooled. Quenching is used to quickly reduce the temperature of the steel, preventing the pearlite from forming. The fully annealed condition is reached by heating the steel enough to turn into austenite (Fig.2), an FCC phase of steel, and then slow cooling it to room temperature. The elastic modulus for three sample types (control, air, oil) was Figure2 approximately the same. Heat treating and quenching lowered the strength of the steel in all trials except that of water quenched steel. Using Rockwell hardness testing machines, we determined that heat treatment roughly halves a steel sample’s yield strength during oil quenching and air cooling. As the yield strength was decreased the plastic deformation hump Figure3 seemed to double. Water quenching raised the steel alloys strength tremendously, only to fail catastrophically and loudly under the tensile test. If steel is forced to take a very steep cooling path a brittle, needlelike structure known as martensite (Fig.3) is formed Metallic alloys vary greatly in their material properties depending on their temperature history. This behavior is both composition-dependent and time-dependent. REFERENCES|five Figure 1 http://www.alliedmineral.com/industries/heat-treat-forging/heat-treating.html Figure2 http://www.pacmet.com/index.php?h=basicheattreat Figure3 http://en.wikipedia.org/wiki/Martensite Page 5 LAB 3: Heat Treatment & Tensile Strength Aileen Johnsrud Figure2 +3 http://www.scielo.br/scielo.php?pid=S1516-14392002000300020&script=sci_arttext Page 6