Casting

advertisement

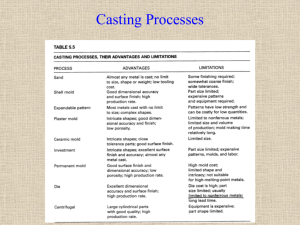

Casting By: Jackie Ho Casting The process of which a material is introduced into a mold in liquid state, and is allowed to solidify inside the mold, creating a fabricated part Sand Casting Cavity formed by pattern made by wood or metal Require a riser since molten metal shrinks as it solidify Material used in sand casting: low temperature steel, Al, Mg, and Ni alloy Riser is used to account for the shrinkage of the molten metal when it solidifies. The function of riser is just to feed molten metal into the void where shrinkage occurs. Permanent mold casting Mold: Takes weeks to prepare is made out of cast iron is preheated to 200°C before pouring expand during the pour cavity is bigger than desired dimensions Material used in permanent mold casting: Fe, Al, Mg, Cu based alloys Die casting Similar to permanent mold casting (difference is high pressure is used in this type of casting) Mold cavity can be very precise Very technical and a great deal of skill is required to create the die Metal used in die casting: non-Fe, Al, Mg, Zn, Cu based alloys Centrifugal casting Has a spinning chamber at 300-3000rpm Spinning while molten metal is poured in Molten metal is thrown to the side where it solidifies Parts produced have fine grained outer surface and impurities in the inner diameter Material used in centrifugal casting: Fe, steel, stainless steel, and alloys of Al, Cu, Ni Advantages Sand casting Produce large part Can be recycled Preparation time for sand mold is fast Permanent mold casting Fast production rate Lower cost production per unit Advantages (cont.) Die casting Good for mass production Lifetime production of up to 500,000 castings Very fast production rate Centrifugal casting Very fine-grained outer surface Resistance to atmospheric corrosion Disadvantages Sand Casting Limited quantities can be produced Metal wasted in the riser Permanent mold casting Molds take up storage space Die casting Require a long time to prepare the die Centrifugal casting Is only good for producing cylindrical parts