CAN 4

advertisement

EC312 CANopen mbed Intrusion

E. Zivi April 26, 2015

References:

1.

2.

3.

4.

5.

6.

7.

8.

A CAN Physical Layer Discussion Microchip Application Note AN00228a

Controller Area Network (CAN) Implementation Guide Analog Devices Application Note AN-1123

Controller Area Network, CANPRES Version 2.0 , Siemens Microelectronics, Inc., October 98

http://www.kvaser.com/en/about-can/the-can-protocol.html

CAN physical layer ref: http://www.can-cia.org/index.php?id=systemdesign-can-physicallayer

Controller Area Network Physical Layer Requirements, TI SLLA270–January 2008

CAN Tutorial, http://www.computer-solutions.co.uk/download/Peak/CAN-Tutorial.pdf

CANopen Introduction,

ref: http://www.canopensolutions.com/english/about_canopen/about_canopen.shtml

1. Embedded Networking with CAN and CANopen, by Pfeiffer, Ayre and Keydel

2. CANopen Implementation: Applications to Industrial Networks, by Farsi and Barbosa

3. CAN in Automation, http://www.can-cia.org/

Recall CAN & ISO/OSI

Reference Model

2

CAN in Automation (CiA) CANopen &

ISO / OSI Reference Models

CiA 401

Generic I/O

Profile

CiA 402

Motion Control

Profile

IEC 61131-3

Programmable

Devices Profile

CiA 4xx Device Profiles

CiA 302 CANopen Framework for CANopen

Managers & Programmable Devices

Application

CiA 301 CANopen Application Layer &

Communication Profile

Not Implemented by CAN or CANopen

ISO 11898 CAN Data Link Layer

ISO 11898 CAN Physical Layer

High level CAN Protocols implement Application layer and skip the four intervening layers

3

CANopen Device Model

All node, network, configuration and process data is

stored in the object dictionary in pre-defined locations

CAN Lab #4 Functional Block Diagram

mbed CAN Transceiver Circuit

CAN Physical Vulnerabilities

1. Damage to CAN physical network

termination, signal integrity or continuity can

bring down network.

2. Short circuits will kill the network (MIL-STD1553 avoids this by using coupling

transformers)

3. Nodes must stay bit synchronized; one node

with the wrong bit rate will kill the system.

CAN Logical Link Vulnerabilities

1. Any node can assert an error condition at

any time

2. Highest priority messages can prevent lower

priority messages

3. At the CAN Logical Link layers, there are no

rules regarding how nodes should interact

4. All nodes are assumed to conform to the

specified rules.

CANopen Vulnerabilities

1. It is assumed that all nodes conform to the CANopen rules

and conventions.

2. Since CANopen specifies an upper level protocol based on

CAN, any CAN node (such as the mbed) can abuse the

CANopen rules.

3. There are no CANopen “hall monitors” to “police” the

system. Systems integration engineers should ensure that

all nodes are compliant with the CANopen standards.

(There are standard compliance tests).

4. All nodes are assumed to conform to the CANopen

network management specified rules.

Mbed Intrusion Lab

1. mbed controls motor, CANopen Magic monitors

experiment.

2. mbed intercepts CANopen messages and

immediately sends false messages.

a. Duty cycle command reversed (25% becomes 75%)

b. Motor speed data reversed (fast reported as slow)

3. Mbed implements PI feedback control over CAN

network. CANopen Magic sends motor speed

commands to mbed.

mbed_Maxon_steps.cpp Code Snippets

mbed CAN Initialization:

can1.frequency(500000); // set CAN bit rate to 500kbps

msg_tx.len = 8; // set data packet length (8 is default)

msg_tx.type = CANData; // CAN data messages (default)

msg_tx.format = CANStandard; // CAN 11 bit message ID )

// PWM duty cycle command to MicroMod

msg_tx.id = NODE_micromod+RPDO_2;

mbed CAN Message Transmission:

// Send PWM duty cycle sequence as MicroMod RPDO 2

...

if (can1.write(msg_tx)) // send CAN PWM command to MicroMod

led3 = 0; // clear transient CAN write error indicator

else {

led3 = 1; // set transient CAN write error indicator

led4 = 1; // set sticky CAN write error indicator

}

mbed_in_the_middle.cpp Code Snippets

if(can1.read(msg_rx)) // watch for transmitted msg

// MicroMod RPDO 2 PWM duty cycle command?

if (msg_rx.id == NODE_micromod+RPDO_2) {

// reverse duty cycle

msg_rx.data[0] = 0xff-msg_rx.data[0];

if (!can1.write(msg_rx)) // send reversed cmd

...

// MicroMod TPDO 3 tachometer motor speed?

} else if (msg_rx.id == NODE_micromod+TPDO_3) {

bad_tach = Ain4_max-(msg_rx.data[0]

+256*msg_rx.data[1]);

if (bad_tach < 0) bad_tach = 0; // lower bound

msg_rx.data[0] = 0xff&bad_tach; // load LSB

msg_rx.data[1] = bad_tach>>8;

// load MSB

if (!can1.write(msg_rx)) // send reversed speed

...

mbed_Maxon_PI.cpp Code Snippets

// Configure interrupt for RPDO2 transmission to MicroMod

ticker.attach(PI_controller,DELTA_T); // send every DELTA_T

...

void PI_controller() { // calculate & send PI command

U = (K*Omega_error+KI*I_error);

DUTY = (int)(U*1023.0/5.0); // MicroMod 8-bit duty cycle

if (DUTY > 0x00FF) // check upper bound

DUTY = 0x00FF;

// if necessary, bound

else if (DUTY < 0) // check lower bound

DUTY = 0;

// if necessary, bound

else // Calculate integral error if control is not limited

I_error = I_error + Omega_error*DELTA_T;

...

// Construct and send RPDO2 MicroMod PWM command

msg_tx_MM.data[0] = (char)(DUTY&0xFF); // unsigned 8-bit

if(can1.write(msg_tx_MM)) { // send to MicroMod

...

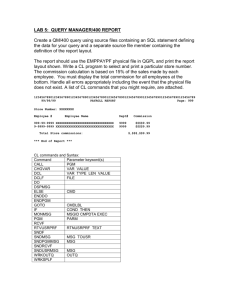

CANopen Magic Sample Trace Windows Part 1:

All CAN Messages:

Only Process Data Objects (PDOs) CAN Messages:

CANopen Magic Sample Trace Windows Par 2:

MicroMod Node 2 TPDO 3 (Ain4 – Ain7) Messages Only:

Mbed Node 3 TPDO 1 CAN Messages to CANopen Magic only:

Lab #4 CANopen Magic Graphical User Interface

New Closed Loop Motor Speed Command CAN Messages

Performance Expiated

Process Data Visual Display

New mbed TPDO 1 Trace Window: Messages to CANopen Magic

CAN Lab #4 Functional Block Diagram