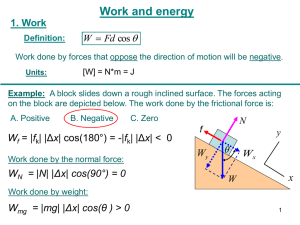

Chapter 8 C

advertisement

V12/ 2 + p1/ + gz1= V22/2 + p2/ + gz2 + hlT

H

E

A

D

L

O

S

S

hlT = hl + hm

Convenient to break up energy losses, hlT, in fully

developed pipe flow to major loses, hl, due to

frictional effects along the pipe and minor losses, hlm,

associated with entrances, fittings, changes in area,…

Minor losses not necessarily < Major loss , hl, due to pipe friction.

Minor losses traditionally calculated as:

hlm = KV2/2

(K for inlets, exits, enlargements and contractions)

where K is the loss coefficient or

hlm = (Cpi – Cp)V2/2

(Cpi & Cp for diffusers)

where Cp is the pressure recovery coefficient or

hlm = f(Le/D)V2/2

(Le for valves, fittings, pipe bends)

where Le is the equivalent length of pipe.

Both K and Le must be experimentally determined and will depend on

geometry and Re, uavgD/. At high flow rates weak dependence on Re.

V1avg2/ 2 + p1/ + gz1= V2avg2/2 + p2/ + gz2 + hlT

hlT = hl + hm; hlm = KV2/2

inlets, sudden enlargements & contractions; gradual contractions and exits

Minor losses due to inlets:

hlm= p/ = K(V2/2); V2 = mean velocity in pipe

If K=1, p = V2/2

V1avg2/ 2 + p1/ + gz1= V2avg2/2 + p2/ + gz2 + hlT

hlT = hl + hm

Head is lost because of viscous dissipation when

flow is slowed down (2-3) and in violent mixing in

the separated zones

For a sharp entrance ½ of the velocity head is lost at

the entrance!

vena contracta

K = 0.78

separation

unconfined mixing

as flow decelerates

r

K = 0.04

r/D > 0.15

D

V12/ 2 + p1/ + gz1= V22/2 + p2/ + gz2 + hlT

hlT = hl + hlm; hlm = KV2/2

inlets, sudden enlargements & contractions; gradual contractions and exits

Minor losses due to sudden area change:

hlm= p/ = K(V2/2); V2 = faster mean velocity pipe

• hlm head losses are primarily due to separation

• Energy is dissipated deceleration after separation

leading to violent mixing in the separated zones

NOTE SOME BOOKS (Munson at al.):

hlm = K V2/(2g) our Hlm!!!

AR < 1

V2

AR < 1

hlm = ½ KV2fastest

V1

AR < 1

Why is Kcontraction and Kexpansion = 0 at AR =1?

V1avg2/ 2 + p1/ + gz1= V2avg2/2 + p2/ + gz2 + hlT

hlT = hl + hlm; hlm = KV2/2

inlets, sudden enlargements & contractions; gradual contractions and exits

Entire K.E. of exiting fluid is

dissipated through viscous effects,

V of exiting fluid eventually = 0

so K = 1, regardless of

the exit geometry.

hlm = KV2/2

hydrogen bubbles

hydrogen bubbles

Only diffuser can help by

reducing V.

Water, velocity = 14 cm/s, width of opening = 30 mm, Re = 4300

V2 ~ 0

Which exit has smallest Kexpansion?

K =1.0

K =1.0

K =1.0

K =1.0

MYO

V1avg2/ 2 + p1/ + gz1= V2avg2/2 + p2/ + gz2 + hlT

hlT = hl + hlm; hlm = KV2/2

inlets, sudden enlargements & contractions; gradual contractions and exits

GRADUAL CONTRACTION

AR < 1

Where average velocity is fastest

breath

V1avg2/ 2 + p1/ + z1=V2avg2/2 + p2/ + gz2 + hlT

hlT = hl + hlm; hlm = p/ = (Cpi – Cp) 1/2V12

gentle expansions ~ diffusers

ugly

DIFFUSERS

3 cm/sec

good

20 cm/sec

bad

assume

fully developed

…..

?

>

P1

P2

<

=

Fully developed laminar flow, is:

P1 greater, less or equal to P2?

What if fully developed turbulent flow?

What if developing flow?

P1, V1

P2, V2

P1, V1

P3, V3

Is P2 greater, less than or equal to P1?

Is P2 greater, less than or equal to P1?

Is P likely to be greater, less than or equal to P?

DIFFUSERS

Diffuser data usually presented as a

pressure recovery coefficient, Cp,

Cp = (p2 – p1) / (1/2 V12 )

Cp indicates the fraction of inlet K.E.

that appears as pressure rise

[ hlm = p/ = (Cpi – Cp) 1/2V12]

The greatest that Cp can be is Cpi,

the case of zero friction.

DIFFUSERS

Diffuser data usually presented as a

pressure recovery coefficient, Cp,

Cp = (p2 – p1) / (1/2 V12 )

Cp indicates the fraction of inlet K.E.

that appears as pressure rise

[ hlm = p/ = (Cpi – Cp) 1/2V12]

Cp will get from empirical data charts.

It is not difficult to show that the ideal

(frictionless) pressure recovery coefficient is:

Cpi = 1 – 1/AR2, where AR = area ratio

Cp = (p2 – p1) / (1/2 V12 )

Cpideal = 1 – 1/AR2

AR = A2/A1

>1

p1 + ½ V12 = p2 + ½ V22 (BE - ideal)

p2/ – p1/ = ½ V12 - ½ V22

A1V1 = A2V2

(Continuity)

V2 = V1 (A1/A2)

p2/ – p1/ = ½ V12 - ½ [V1(A1/A2)]2

p2/ – p1/ = ½ V12 - ½ V12 (1/AR)2

(p2 – p1)/( ½ V12) = 1 – 1/AR2

Cpi = 1 – 1/AR2

Relating Cp to Cpi and hlm

p1 / + ½ V12 = p2/ + ½ V22 + hlm

(z1 = z2 = 0)

hlm = V12/2 - V22/2 – (p2 – p1)/

hlm = V12/2 {1 + V22/V12 – (p2 – p1)/ ( 1/2 V12)}

A1V1 = A2V2

Cp = (p2 – p1)/ ( 1/2 V12)

(Cp is positive & < Cpi)

hlm = V12/2 {1 - A12/A22 – Cp}

Cpi = 1 – 1/AR2

hlm = V12/2 {Cpi – Cp} Q.E.D.

(see Ex. 8.10)

hlm = (Cpi – Cp)V2/2; Cpi = 1 – 1/AR2

Cp

N/R1 = 0.45/(.15/2) = 6

AR ~ 2.7

*

Cp 0.62

Pressure drop fixed, want to max Cp

to get max V2; minimum hlm

If flow too fast or angle too big may get flow separation.

Cp for Re > 7.5 x 104, “essentially” independent of Re

V1avg2/ 2 + p1/ + z1=V2avg2/2 + p2/ + gz2 + hlT

hlT = hl + hlm; hlm = f(Le/D)V2/2

valves and fittings

hlm = f(Le/D)V2/2

Head loss of a bend is greater

than if pipe was straight (again due to separation).

Nozzle Problem

A

Neglecting friction, is flow faster at A or B or same?

V12/

2 + p1/ +

z1=V22/2

=0

+ p2/ + gz2 + hlT

VA2/ 2 + patm/ + d = VB2/ 2 + patm/ + d

A

If flow at B did not equal flow at

A then could connect and make

perpetual motion machine.

A

C

d

C

d

V12/ 2 + p1/ + z1=V22/2 + p2/ + gz2 + hlT

=0

0

=0

VT2/ 2 + patm/ + d = VC2/ 2 + patm/ + d

?

neglect friction

V12/ 2 + p1/ + z1=V22/2 + p2/ + gz2 + hlT

C

d

Nozzle

V12/ 2 + p1/ + z1=V22/2 + p2/ + gz2 + hlT

=0

0

=0

VT2/ 2 + patm/ + d = VC2/ 2 + patm/ + d

breath

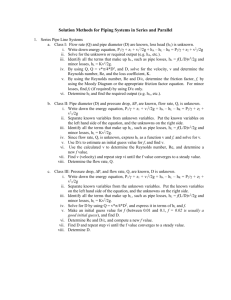

Pipe Flow Examples ~

Solving for pressure drop in horizontal pipe

V1avg2/2 + p1/ + gz1 – (V2avg2/2 + p2/ + gz2)

= hlT = hl + hlm

= f [L/D][V2/2] + f [Le/D][V2/2] + K[V2/2]

Laminar flow ~

f = 64/ReD

Turbulent flow ~

1/f0.5 = -2.0 log{(e/D)/3.7 + 2.51/(ReD f0.5)

(f = 0.316/ReD0.25 for Re < 105)

p2- p1 = ?; Know hlT , L, D, Q, e, , , z2, z1

p2- p1 = ?; Know L, D, Q, e, , , z2, z1

Compute the pressure drop in 200 ft of horizontal

6-in-diameter asphalted cast-iron pipe carrying

water with a mean velocity of 6 ft/s.*

V1avg2/2 + p1/ + gz1 - V2avg2/2 - p2/ - gz2

= f [L/D][V2/2] + f [Le/D][V2/2] + K[V2/2]

p1/ - p2/ = f [L/D][V2/2] = hlm

p2- p1 = ?; Know L, D, Q, e, , , z2, z1

p1/ - p2/ = f [L/D][V2/2] = hl

f(Re, e/D); ReD = 270,000 & e/D = 0.0008

1/f0.5 = -2.0 log{(e/D)/3.7 + 2.51/(ReD f0.5); f = 0.0197

f ~ 0.02

p2 – p1 = hl = f(Re, e/D) [L/D][V2/2] = 280 lbf/ft2

Pipe Flow Examples ~

Solving for pressure drop in non-horizontal pipe

p2- p1 = ?; Know L, D, Q, e, , , z2, z1

Oil with = 900 kg/m3 and = 0.00001 m2/s flows

at 0.2 m3/s through 500m of 200 mm-diameter cast

iron pipe. Determine pressure drop if pipe slopes

down at 10o in flow direction.

V1avg2/2 + p1/ + gz1 - V2avg2/2 - p2/ - gz2

= f [L/D][V2/2] + f [Le/D][V2/2] + K[V2/2]

p1/ + gz1 - p2/ - gz2= f [L/D][V2/2] = hlm

p2- p1 = ?; Know L, D, Q, e, , , z2, z1

p1/ + gz1 - p2/ - gz1= f [L/D][V2/2]

f(Re, e/D); ReD = 128,000 & e/D = 0.0013

1/f0.5 = -2.0 log{(e/D)/3.7 + 2.51/(ReD f0.5) f = 0.0227

f ~ 0.023

p2 – p1 = hl - g500(sin 10o) = 265,000 kg/m-s2

If know everything but pressure drop or L

then can use Moody Chart without iterations

Pipe Flow Examples ~

Solving for V in horizontal pipe

Q = ?; Know L, D, Q, e, , , z2, z1, p1, p2

Compute the average velocity in 200 ft of horizontal

6-in-diameter asphalted cast-iron pipe carrying

water with a pressure drop of 280 lbf/ft2.

V1avg2/2 + p1/ + gz1 - V2avg2/2 - p2/ - gz2

= f [L/D][V2/2] + f [Le/D][V2/2] + K[V2/2]

p1/ - p2/ = f [L/D][V2/2]

p1/ - p2/ = f [L/D][V2/2]

V = (0.7245/f)

f ~ 0.19

e/D = 0.0008

Guess fully

rough regime

f ~ 0.19

f1 = 0.19; V1 = (0.7245/f1)1/2 = 6.18 ft/s

ReD1 = 280,700

f2 = 0.198; V2 = (0.7245/f1)1/2 = 6.05 ft/s

Pipe Flow Examples ~

Solving for D in horizontal pipe

Q = ?; Know L, D, Q, e, , , z2, z1, p1, p2

Compute the diameter of a 200 m of horizontal pipe,

e = 0.0004 mm, carrying 1.18 ft3/s, = 0.000011ft2/s

and the head loss is 4.5 ft.

HlT = hl/g = [length] = 4.5 ft

V1avg2/2g + p1/g + z1 - V2avg2/2g - p2/g - z2

= f [L/D][V2/2g] + f [Le/D][V2/2g] + K[V2/2g]

p1/ - p2/ = f [L/D][V2/2]

f = function of ReD and e/D

ReD = VD/ = 4Q/(D)

or ReD = 136,600/D

f [L/D][V2/2] = hl

f = hl [D/L]2/[(4Q/D2)2]

f ={2/8}{hlD5/(LQ2)} = 0.642D

or D = 1.093 f 1/5

e/D = 0.0004/D

(1) ReD = 136,600/D

(2)

D = 1.093 f 1/5

(3) e/D = 0.0004/D

Guess f ~ 0.03; then from (2)

get D ~ 1.093(0.03)1/5 ~ 0.542 ft

From (1) get ReD ~ 136,600/0.542 ~ 252,000

From (3) get e/D = 0.0004/0.542 ~ 7.38 x 10-4

fnew ~ 0.0196 from plot;

ReDnew ~274,000;

fnewest ~ 0.0198 from plot

Dnew ~ 0.498;

e/D ~8.03 x 10-4

Dnewest~ 0.499

Solve for V in vertical pipe with minor losses, hlm

Assume D >> d;

turbulent flow;

Atm press. at top & bottom

f = 0.01

Find Ve as a function of g & d

V12/2 + p1/ + gz1 – (V22/2 + p2/ + gz2)

= hlT = hl + hlm

= f [L/D][V2/2] + f [Le/D][V2/2] + K[V2/2]

V12/2 + p1/ + gz1 – (V22/2 + p2/ + gz2)

= hlT = hl + hlm

= f [L/D][V2/2] + f [Le/D][V2/2] + K[V2/2]

V02/2 + patm/ + gz0

- V22/2 - patm/ - gz2

= f [L/D](V22/2)+(K1+K2+f[L/d])(V22/2)

V02/2 = 0; V22/2 = 1V22/2

gz0–gz2–V22/2={f [L/D]+K1+K2)}(V22/2)

V22 = 2g(z0-z2)/[1 + K1 + K2 + f(L/d)]

V22 =2g140d/(1+0.5+1.0+1.0+001x100)1/2

V2 = (80gd)1/2

laminar

transitional

turbulent

The END ~