Document

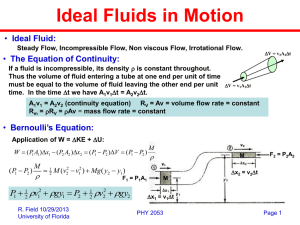

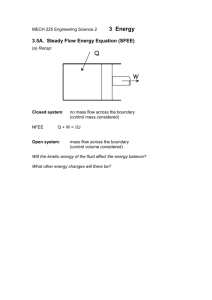

advertisement

Quiz 2 – 2013.11.27 Questions 1. What is the Reynolds number? 2. Differentiate the flow patterns observed in laminar flow from those in turbulent flow. 3. How does temperature affect the dynamic viscosity of a fluid? TIME IS UP!!! Overall Balances Outline 1.Mass Balance 2.Energy Balance 3.Momentum Balance Mass Balance For an overall mass balance, no mass is being generated. Why? rate of mass output rate of mass input from control volume to control volume rate of accumulation 0 of mass within control volume Mass Balance Imagine the control volume as having infinitesimal surfaces dA. We need to find the net outflow of mass across the control surface. Mass Balance For every dA element, a streamline of velocity vector v passes through it. Mass Balance For every dA element, a unit normal vector n exists. Mass Balance The component of velocity vector v in the direction of the unit normal vector n is given by: v n v n cos Mass Balance The rate of mass efflux through dA: (v n)d A v n cos dA Mass Balance What do we get when we integrate over the entire control surface? v n d A Mass Balance v n d A POSITIVE: net outflow of mass NEGATIVE: net inflow of mass ZERO: ? Mass Balance Rate of mass outflow across control surface (and control volume): v n d A Rate of mass accumulation in control volume: dV t Mass Balance rate of mass output rate of mass input from control volume to control volume rate of accumulation 0 of mass within control volume v n d A d V 0 t Overall Mass Balance v n d A d V 0 t dM m 0 dt Overall Mass Balance A well-stirred storage vessel contains 10000 kg of dilute methanol solution (xMetOH = 0.05). A constant flow of 500 kg/min of pure water is suddenly introduced into the tank and a constant rate of withdrawal of 500 kg/min of solution is started. These two flows are continued and remain constant. Assuming that the densities of the solutions are the same and that the total contents of the tank remain constant at 10,000 kg of solution, calculate the time for the alcohol content to drop to 1.0 wt.%. Outline 1.Mass Balance 2.Energy Balance 3.Momentum Balance Forms of Energy • Possessed/Carried by fluid – Internal Energy – Potential Energy – Kinetic Energy – PV-work • Transferred between system and surroundings – Heat – Shaft work Internal Energy (U) • Intrinsic property of the fluid • Molecules in random motion Potential Energy (mgz) • Position of the fluid with respect to an arbitrary reference plane g z gc Kinetic Energy (mv2/2α) • Due to fluid motion • Correction factor, a – To account for velocity distribution – Ranges from 0.5 (laminar) to 1.0 (turbulent) PV Work (PV) • Work done by surroundings to push the fluid into the system P S d WPV V Fd PS PV S Heat (Q) • Net heat passing through the boundary of the system – Positive if heat is transferred to the system from the surroundings – Negative if system to the surroundings • Excludes heat generated by friction Shaft Work (Ws) • Net work done on the system by the surroundings • Convention (IUPAC) – Positive if work done on the system – Negative if work done by the system Total Energy Balance Energy balance from point 1 to point 2: v12 gz1 P1V1 m U1 2a Q Ws U1, v1, P1, V1, S1 Q z1 Ws U2, v2, P2, V2, S2 z2 Datum/reference plane v22 gz2 P2V2 m U2 2a d(mU) dt Total Energy Balance Energy balance from point 1 to point 2: d(mU) v12 v22 m U1 gz1 P1V1 Q Ws m U2 gz2 P2V2 2a 2a dt d(mU) v2 m U gz PV Q Ws dt 2a d(mU) v2 m H gz Q Ws dt 2a Total Energy Balance Water at 93.3°C is being pumped from a large storage tank at 1 atm abs at a rate of 0.189 m3/min by a pump. The motor that drives the pump supplies energy at the rate of 1.49 kW. The water is pumped through a heat exchanger, where it gives up 704 kW of heat and is then delivered to a large open storage tank 15.24 m above the first tank. What is the final temperature of the water to the second tank? Mechanical Energy Balance A modification of the total energy balance - shaft work - kinetic energy - potential energy - flow work (PV) Does not include heat and internal energy. - Why? Energy converted to heat is lost work - loss of mechanical energy by friction Ideal Fluids No shear stress; zero viscosity For isothermal flow and Q=WS=0, v12 v22 P1V1 gz1 P2V2 gz2 2a 2a P1 v12 P2 v22 z1 z2 1 g 2 ga 2 g 2 ga Bernoulli Equation Bernoulli Equation Restrictions: P1 v12 P2 v22 z1 gz2 1 g 2 ga 2 g 2 ga 1. Valid only for incompressible fluids 2. No devices that add/remove energy should be between points 1 and 2 3. No heat transfer occurring in the system 4. No loss of energy due to friction Real Fluids • Friction losses: SF (energy dissipation) • Total heat absorbed by the fluid Q Q F • Total work done by fluid, -W = -WS + SF – Additional work must be done by the fluid to overcome fluid friction Real Fluids Q Ws v2 U gz PV 2a m m Q Q F Q Q F v 2 Q SF WS U (PV ) gz m m 2a • Note: energy per mass units • kJ/kg or ft-lbf/lbm • For incompressible flow: v 2 P g z SF WS 2a