CH2_PLCProgramming_v1 1090KB Feb 01 2012 07:07:58 AM

advertisement

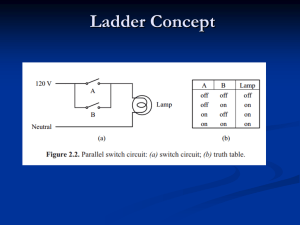

LADDER DIAGRAM A ladder diagram is a means of graphically representing the logic required in a relay logic system. Rail start PB1 emergency stop PB2 R1 Rung R1 R1 A PLC WIRING DIAGRAM A Input 01 B 02 Output PLC 01 02 20 11 12 20 03 20 11 External switches Stored program C SCAN A PLC resolves the logic of a ladder diagram (program) rung by rung, from the top to the bottom. Usually, all the outputs are updated based on the status of the internal registers. Then the input states are checked and the corresponding input registers are updated. Only after the I/Os have been resolved, is the program then executed. This process is run in a endless cycle. The time it takes to finish one cycle is called the scan time. In some controllers the idle state is eliminated. In this case, the scan time varies depends on the program length. PLC Scan Output Input begin Idle Scan cycle Resolve logic PLC Ladder Diagram INSTRUCTIONS 1) Relay, 2) Timer and counter, 3) Program control, 4) Arithmetic, 5) Data manipulation, 6) Data transfer, and 7) Others, such as sequencers. LOGIC STATES ON : TRUE, contact closure, energize, etc. OFF: FALSE, contact open , de-energize, etc. Do not confuse the internal relay and program with the external switch and relay. Internal symbols are used for programming. External devices provide actual interface. (In the notes we use the symbol "~" to represent negation. AND and OR are logic operators. ) PROGRAMMING Normally Open (NO) Normally Closed (NC) Power flows through these contacts when they are closed. The normally open (NO) is true when the input or output status bit controlling the contact is 1. The normally closed (NC) is true when the input or output status bit controlling the contact is 0. 7 Coils Coils represent relays that are energized when power flows to them. When a coil is energized it causes a corresponding output to turn on by changing the state of the status bit controlling the output to 1. That same output status bit maybe used to control normally open or normally closed contact anywhere in the program. 8 Boxes Boxes represent various instructions or functions that are Executed when power flows to the box. Some of these Functions are timers, counters and math operations. 9 AND OPERATION A B C Rung Each rung or network on a ladder program represents a logic operation. In the rung above, both inputs A and B must be true (1) in order for the output C to be true (1). 10 OR OPERATION A C Rung B In the rung above, it can be seen that either input A or B is be true (1), or both are true, then the output C is true (1). 11 NOT OPERATION A C Rung In the rung above, it can be seen that if input A is be true (1), then the output C is true (0) or when A is (0), output C is 1. AND and OR LOGIC PB1 PB2 R1 R1 = PB1.AND.PB2 AND PB3 PB4 R2 R2 = PB2.AND.~PB4 PB1 R1 R1 = PB1 .OR. PB2 OR PB2 COMBINED AND & OR R1 = PB1 .OR. (PB2 .AND. PB3) R1 PB1 PB2 PB3 PROGRAMMING EXAMPLE 1 Bar code reader microswitch Stopper Conveyor Part Robot Machine Operation id MSI R1 C1 R2 R3 C2 R4 C3 C4 description microswitch output to bar code reader input from bar code reader output robot output robot input from robot output to stopper input from machine input from machine state 1 1 1 1 1 1 1 1 1 explanation part arrive scan the part right part loading cycle unloading cycle robot busy stopper up machine busy task complete PLC WIRING DIAGRAM Input MS1 C1 C2 C3 C4 01 02 03 04 05 Programmable Controller PLC Output 11 12 13 14 15 R1 R2 R3 R4 Operation Rung 1. If part arrives and no part is stopped, trigger the bar code reader. Rung 2. If it is a right part, activate the stopper. Rung 3. If the stopper is up, the machine is not busy and the robot is not busy, load the part onto the machine. Rung 4. If the task is completed and the robot is not busy, unload the machine. PLC Ladder 01 11 14 14 02 14 04 05 03 03 12 13 Sequential Function Chart Action Qualifiers: N non-stored, executes while the step is active R resets a store action S sets an action active L time limited action, terminates after a given period D time delayed action. P a pulse action, executes once in a step SD stored and time delayed DS time delayed and stored SL stored and time limited Sequential Function Chart A Detailed Design Process A Detailed Design Process 1. Understand the process 2. Hardware/software selection 3. Develop ladder logic 4. Determine scan times and memory requirements Specifications OUTPUT-PORT POWER RATINGS Each output port should be capable of supplying sufficient voltage and current to drive the output peripheral connected to it. SCAN TIME This is the speed at which the controller executes the relay-ladder logic program. This variable is usually specified as the scan time per 1000 logic nodes and typically ranges from 1 to 200 milliseconds. MEMORY CAPACITY The amount of memory required for a particular application is related to the length of the program and the complexity of the control system. Simple applications having just a few relays do not require significant amount of memory. Program length tend to expand after the system have been used for a while. It is advantageous to a acquire a controller that has more memory than is presently needed. PLC Status Indicators • Power On • Run Mode • Programming Mode • Fault Troubleshooting 1. Look at the process 2. PLC status lights HALT - something has stopped the CPU RUN - the PLC thinks it is OK (and probably is) ERROR - a physical problem has occurred with the PLC 3. Indicator lights on I/O cards and sensors 4. Consult the manuals, or use software if available. 5. Use programming terminal / laptop. List of items required when working with PLCs: 1. Programming Terminal - laptop or desktop PC. 2. PLC Software. PLC manufacturers have their own specific software and license key. 3. Communication cable for connection from Laptop to PLC. 4. Backup copy of the ladder program (on diskette, CDROM, hard disk, flash memory). If none, upload it from the PLC. 5. Documentation- (PLC manual, Software manual, drawings, ladder program printout, and Seq. of Operations manual.) Examples of PLC Programming Software: 1. Allen-Bradley – Rockwell Software RSLogix500 2. Modicon - Modsoft 3. Omron - Syswin 4. GE-Fanuc Series 6 – LogicMaster6 5. Square D- PowerLogic 6. Texas Instruments – Simatic 7. Telemecanique – Modicon TSX Micro 8. Mitshibishi – MelSoft (GX Developer) Outputs & Power Supply Communication Ports (RS-485) PLC Inputs PLC Internal Architecture PLC Input/Output PLC Input Devices Push buttons Switches (limit switches, level switches, etc.) Sensors ... PLC Output Devices Relay contacts Solenoid valves Signal devices (such as lamps, alarms, etc.) Motors ... Programming terminal Programming terminal Programming is done through programming terminal Programming terminal translates engineering language (logic control) to machine language (binary code) Programming through standard computer Most PLC manufacturers offer software packages that allow a standard computer to be used as a programming terminal Programming through standard computer Relating the program to inputs and outputs SWITCHES Non-locking Locking Normally Ope n Normally Clos e d DPST P1 SPDT P2 Multiple Throw Multiple Pole Bre ak-before -make Make -be fore -bre ak TERMS Throw - number of states Pole - number of connecting moving parts (number of individual circuits). SPDT A serial switch box (A-B box) has two 25 pin serial ports to switch from. A B Output DPST Input Knob How is this switch classified? TYPES OF SWITCHES RATING: Selector switches Pushbutton switches •24 Volts AC/DC •48 Volts AC/DC Photoelectric •120 Volts AC/DC •230 Volts AC/DC switches •TTL level (Transistor-to-transistor Limit Switches ±5V) Proximity switches •Isolated Input Level switches Thumbwheel switches Slide switches RELAYS A switch whose operation is activated by an electromagnet is called a "relay" contact coil input Relay coil R1 Output contact R1 RELAY Ladder Logic Example 1: For a process control, it is desired to have the process start (by turning on a motor) five seconds after a part touched a limit switch. The process is terminated automatically when the finished part touches a second limit switch. An emergency switch will stop the process any time when it is pushed. L1 PB1 LS1 LS2 R1 R1 TIMER R1 R2 PR=5 PB1 LS1 LS2 TIMER 5 R1 Motor R2 Example 2: One motor with two pushbuttons: start and stop State variables: PB1(for start), PB2(for stop), M (for motor) Logic PB1 is on -> CR1 energized, normally open contact 1 is closed -> M=1 PB2 is on -> CR2 energized, normally close contact 2 is open -> M=0 Rung 1: CR1=(PB1+CR1) CR2 Rung 2: CR2=(PB2) Rung 3: M=CR1 CR2 Cylinder Pneumatic Also called Actuator ElectroPneumatic Valve Directional Control Valve which acts as a ‘switch’ to direct compressed air to each side of pneumatic actuator. 5-Port 2 Way Valve Also called Double Acting Pneumatic Actuator and 5/2 way solenoid operated directional control valve. Two ports to allow air in, one for outstroke (extend) and one for in-stroke (retract). Cylinder & Valve Assembly TIMER TIMER A timer consists of an internal clock, a count value register, and an accumulator. It is used for or some timing purpose. Clock Accumulator reset Register contact Contact output Clock Reset Output Count 0 1 2 3 4 Time 5 seconds. 5 ON-DELAY TIMER (TON) For this example the timer has been set for 5 seconds. When S1 is closed, TR1 begins timing. When 5 seconds have elapsed, TR1 will close its associated normally open TR1 contacts, illuminating pilot light PL1. When S1 is open, de-energizing TR1, the TR1 contacts open, immediately extinguishing PL1. This type of timer is referred to as ON delay.. TON Example When the switch is closed input 4 becomes a logic 1, which is loaded into timer T37. T37 has a time base of 100 ms (.100 seconds). The preset time (PT) value has been set to 150. This is equivalent to 15 seconds (.100 x 150 ). The light will turn on 15 seconds after the input switch is closed. Retentive On-Delay (TONR) The Retentive On-Delay timer (TONR) functions in a similar manner to the On-Delay timer (TON). There is one difference. The Retentive On-Delay timer times as long as the enabling input is on, but does not reset when the input goes off. The timer must be reset with a RESET (R) instruction. TONR Example TONR Example Cont. The same example used with the On-Delay timer will be used with the Retentive On-Delay timer. When the switch is closed at input I0.3, timer T5 (Retentive timer) begins timing. If, for example, after 10 seconds input I0.3 is opened the timer stops. When input I0.3 is closed the timer will begin timing at 10 seconds. A RESET (R) instruction can be added. Here a pushbutton is connected to input I0.2. If after 10 seconds input I0.3 were opened, T5 can be reset by momentarily closing input I0.2. T5 will be reset to 0 and begin timing from 0 when input I0.3 is closed again. OFF-DELAY (TOFF) The Off-Delay timer is used to delay an output off for a fixed period of time after the input turns off. When the enabling bit turns on the timer bit turns on immediately and the value is set to 0. When the input turns off, the timer counts until the preset time has elapsed before the timer bit turns off. TIMER MAX VALUES TIMER EXAMPLE Start PB Pressed >> Pump1 ON (5 sec) >> Pump2 ON (3 sec) >> Mixer ON (60 sec) >> Drain Valve ON >> Pump 3 (8 sec) Counter COUNTER Digital counters output in the form of a relay contact when a preassigned count value is reached. input Register 5 Accumulator reset contact output Input Reset Output Count 0 12 3 4 5 0 1 CTU, CTD, and CTUD UP COUNTER (CTU) Down Counter (CTD) UP/DOWN COUNTER (CTUD) COUNTER EXAMPLE Example Example (cont.)