PESTICIDE CALCULATIONS

advertisement

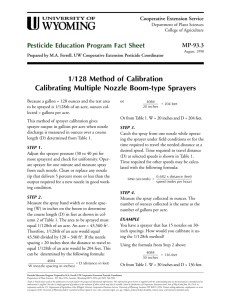

INAG 106 Pesticide Use & Safety Course Lecture 12: Pesticide Application & Calibration David Myers Extension Educator, Agriculture myersrd@umd.edu PESTICIDE CALCULATIONS Determine the amount of product needed Formulated Product vs Active Ingredient Formulations and Active Ingredient Dry formulations will report their active ingredient as a % by weight For example the label for Thalonil states that it is a 90 DF product Therefore the active ingredient is 90% by weight of the container If the container weighs 5 lbs then .9 x 5 = 4.5 lbs of active ingredient Formulations and Active Ingredient Liquid formulations will report their active ingredient in lbs active ingredient per gallon and as % by weight For example the label for Illoxan states that it is a 3 EC formulation This means that there is 3 lbs of active ingredient per gallon If the container size is 5 gallons then one would have 5 x 3 = 15 lbs of active ingredient Formulations and Active Ingredient For example Diuron 4L is a liquid formulation Its % active ingredient is 40%. To get the amount of active ingredient in a gallon one would have to multiply .40 by the weight of 1 gallon of this material Since weight may not be given refer to the lbs A.I. / gallon statement FORMULATED PRODUCT The Label Contains Information On The Amount of Product Needed Under the “Directions For Use” Section How much Aliette would you need to make up 450 gallons if you plan to use the lowest possible rate? ANSWER Set up a proportion as follows and solve for x 2.5 lbs 100 gallons = x____ 450 gallons Label Rate (100) x (X) = (2.5) x (450) X = (2.5) x (450) 100 X = 1125 100 X = 11.3 lbs of Aliette ACTIVE INGREDIENT If you want to solve for the amount of active ingredient (A.I.) or if you are given the application rate in lbs A.I. then use one of the following formulas. DRY MATERIAL (% A.I. As a Decimal) (Form. Product) = lbs of A.I. LIQUID MATERIAL lbs A.I = lbs A.I. Needed gallon formulated prod. PRACTICE PROBLEM If a 7.5 G insecticide is recommended at a rate of 4.5 lbs A.I./A, determine how much of the formulated product is needed to treat 4 acres? Use this formula: (% A.I.) x (lbs of Formulated Product) = lbs of A.I. (.075) x (X) = 4.5 lbs A.I. X= 4.5 % A.I. needs to be .075 expressed as a decimal X = 60 lbs of product per acre Remember you have to treat 4 acres therefore multiply 60 x 4 to get 240 lbs of insecticide for the 4 acre area. PRACTICE PROBLEM A 13,300 sq. ft. area needs to be treated with Daconil 4F. How much Daconil 4F will be needed if you want to apply 3.5 lbs A.I.per acre. Use the following formula for a liquid formulation: 4 lbs A.I. 1 gallon = 3.5 lbs A.I. X Solve for X : (4) x (X) = (1) (3.5) X = 3.5 4 X = .88 gallons of Daconil 4F is needed per acre You need to treat a 13,300 sq. ft. area 13,300 43,560 = .305 of an acre (.88 gallons) X (.305 acre) = .27 gallons of Daconil 4F will be needed. ACTIVE INGREDIENT If you want to make up a % spray solution then the following formulas can be used. One is for a dry formulation and the other is for a liquid formulation PERCENT CALCULATIONS DRY (Gallons Spray) (% Spray) (8.3) % A.I. of Pesticide LIQUID (Gallons Spray) (% Spray) (8.3) (lbs A.I. /Gallon) (100) 8.3 is a constant and represents the weight of 1 gallon of water PRACTICE PROBLEM You want to make up a 1.7% spray of Roundup 4 L. You have a 250 gallon sprayer which you plan to fill. How much Roundup will be needed? How much water will be needed? Use this formula to solve the problem : ( % Spray ) ( Spray Volume) ( 8.3) ( lbs A.I./gallon) ( 100 ) ( 1.7 ) ( 250 ) ( 8.3) ( 4 ) ( 100 ) 3527.5 400 = Amount of water needed = = [250 - 8.82] = 241.18 gallons of water and 8.82 gallons of Roundup will be added to give 250 gallons of spray 8.82 gallons of Roundup 4 L will be needed PRACTICE PROBLEM You want to make up a .75% spray solution of Dursban 50 WP. How much Dursban will be needed if you want to make up a 30 gallons? Use This Formula : ( % Spray) ( Gallons of Spray ) ( 8.3 ) (% A.I.) = (.75 ) ( 30 ) ( 8.3 ) 50 = 186.75 50 = 3.7 lbs of Dursban 50 WP Note: When using the percent mix formulas the % spray and % A.I. Values are not entered as decimals PRACTICE PROBLEMS 1. If a 2.5G insecticide is applied at the rate of 3 lbs. A.I./A, how much of the formulated product is needed to treat 5 acres? Answer: 120 lbs/A and 600 lbs for 5 acres. 2. A 26,500 sq. ft area needs to be treated. The recommended application much of the formulated rate is 1.8 lbs A.I./A. The pesticide is formulated as a 2 EC. How much of the formulated material will be needed to treat this site? Answer: .55 gallon or 70 oz PRACTICE PROBLEMS 3. A 1.7% spray of Weedbgone 4L is required for excellent weed control. How much Weedbgone will be needed to treat a 2 acre field? Assume that you want to mix the product in water and apply the mixture at 1 gallon per 1,000 sq. ft. Answer: 3.1 gallons 4.A fungicide, Nopatho 50 WP, is recommended at a 2 oz per 1,000 sq. ft. rate on the label. How much Nopatho fungicide is needed to treat 1.75 acres? Answer: 9.5 lbs CALIBRATION EXERCISES APRIL 25, 2005 CALIBRATION The process by which one determines the application rate (gallons per acre or pounds per acre) of equipment under a given set of conditions. APPLICATION EQUIPMENT Multipurpose Sprayers : Hand Held Units, Airblast Sprayers, and Spray Booms Broadcast Applicators for Granular Formulations Band or Row Applicators for Granular Formulations Soil Fumigation Equipment Injection and Implantation Equipment for Trees Greenhouse Applicators Can Range From Mists, Dusters, Drenches, to Foliar Spray Applicators APPLICATION EQUIPMENT Each Commodity Has a Separate Write Up in the Commodity Manuals Agricultural Manual : 10-15 Ornamental and Turf Manual: Nursery and Landscape: 24-32 Turf : 40-43 Greenhouse: 51 WHY IS IT IMPORTANT TO CALIBRATE? Damage was due to poor nozzle distribution. Sprayer nozzles set too low thus causing a streaking effect. SPRAYER CALIBRATION FOUR VARIABLES THAT ONE CAN ADJUST TO GOVERN SPRAY OUTPUT ARE : 1) NOZZLE TYPE 2) NOZZLE SPACING 3) SPRAYER SPEED 4) SPRAYER PRESSURE CONSIDERATIONS IN NOZZLE SELECTION Spray Product Catalogs Will Provide Important Information In Nozzle Selection Nozzle Construction Nozzle Pattern Nozzle Spacing And Height Above Ground Nozzle Screen Which Is Placed Before Nozzle to Prevent Plugging of Nozzle Example of Catalog Information on Nozzle Selection CATALOG INFORMATION & INTERPRETATION 65 Degree Nozzle 80 Degree Nozzle 110 Degree Nozzle Screen Mesh Size Table Interpretation: For nozzle model 650067-SS it has the following characteristics : It is a 65 degree nozzle and can be used between 30 and 60 psi. If used at 50 psi it’s output would be .07 gallons per minute (GPM). Also at a 20 inch spacing and traveling at 5 MPH the application rate would be 4.5 gallons per acre (GPA). PRODUCT CATALOG INTERPRETATION Based on the previous slide answer the following questions: 1. What would be the GPM of nozzle model 8001-SS if used at 40 psi? Answer: .1 GPM 2. If this nozzle is placed at a 20 inch spacing and a sprayer travels at 6 MPH what will its GPA be? Answer : 5.0 GPA CATALOG INFORMATION The height of the nozzle above the spray boom is important so as to ensure uniform application. The table below shows the recommended height for different spray nozzles spaced at 20” to 40”. NOZZLE HEIGHT NOZZLE TYPE SPRAY 20” ANGLE Spacing 30” Spacing 40” Spacing NOZZLE CONSTRUCTION Brass Polymer Stainless Steel Hardened Stainless Steel Ceramic Nozzles will wear differently based on their construction . Refer to the following slide on wear differences. Ceramic H. St. Steel St. Steel Polymer Brass 0 2 4 6 8 10 12 % INCREASE IN FLOW RATE AFTER 40 HOURS Brass nozzles wear much quicker than other types of nozzles. The ceramic nozzle wears the least. This Sprayer Distribution Pattern Shows Good Coverage Across The Boom This Spray Pattern Shows Worn Nozzles ; Greater Spray Under Each Tip Will Occur NOZZLE PATTERN Not every nozzle is created equal ! ! MAJOR TYPES 1)Standard Flat Fan 2)Extended-Range Flat Fan 3)Even Flat Fan 4)Twin Flat Fan 5)Flooding Fan Nozzles 6)Full Cone FLAT FAN NOZZLE Jack of all trades Operating Pressure : 30 - 60 psi Available in 65 , 80, and 110 degree angles Overlapping is required for uniform application A preferred nozzle for herbicide EXTENDED-RANGE FLAT FAN NOZZLE Similar to Flat Fan but with wider pressure range. 15-60 psi. EVEN - FLAT FAN NOZZLE Applies uniform amount across its spray width Used in band applications Pressure requirement of 2040 psi and available in 40 or 60 degree spray TWIN-FLAT FAN NOZZLE Nozzle will have two openings ; 60 degree separation Increases penetration into crop canopy 30 to 60 psi FULL CONE NOZZLE Best for pre-plant incorporated herbicides at the 15-25 psi range. Low pressure and large droplet size will reduce drift This cone nozzle is used for high volume applications 40 inch spacing and nozzles need to be angled at 30 to 45 degrees from vertical to increase uniformity HOLLOW CONE NOZZLE Best suited for Postemergence herbicides. Can also do well for placement of insecticides, etc. Fits well into low volume applications Drop nozzle applications / 40-60 psi FLOODING FAN NOZZLE “FLOODJET” Create a wide deflector type flat spray pattern Larger orifice reduces clogging 10-40 psi range / 40” spacing SPRAYER SPEED Inverse relationship between speed and application rate As speed increases application rate decreases To determine mph use the following formula : MPH = Distance Traveled (ft) x 60 Time (sec.) x 88 SAMPLE PROBLEM Determine the mph if a sprayer travels 130 ft. in 40 seconds. MPH = 130 x 60 40 x 88 MPH = 7800/3520 = 2.2 mph CALIBRATION TECHNIQUES There are numerous methods used in calibrating sprayers. Several different techniques and formulas will be discussed in class Calibration Tools CALIBRATION: Method 1 •Measure off known area Fill sprayer with water to set level Spray known area noting pressure and speed settings Determine volume used Set up an equality to solve for your application rate CALIBRATION: Method 1 Assume area measured off is 50 feet by 60 feet 50 x 60 = 3000 sq ft. The volume used was 4 gallons then the equality is as follows … 4 gallons = x gallons 3,000 sq. ft 43,560 sq. ft X = 58 gallons per acre (GPA) CALIBRATION FORMULAS : Method 2 GPA = 5940 x GPM ( of nozzle) MPH x NW (nozzle spacing in inches) GPA = 495 x GPM ( of sprayer) MPH x BW ( boom width in feet) Conversion Factors CALIBRATION While the sprayer is running determine the nozzle output or boom output by collecting the spray and measuring the volume. SAMPLE PROBLEM Determine the GPA of a sprayer if given the following information. The nozzle out put averages .25 GPM and they are spaced at 30 inches. The sprayer will travel at 6 MPH. Using this formula one can solve for GPA : GPA = 5940 x GPM MPH x NW GPA = 5940 x .25 6 x 30 GPA = 8.25 SAMPLE PROBLEM Determine the GPA of a sprayer given the following information : The sprayer has 8 nozzles and each nozzle averages .5 GPM. The boom width is 12 feet and will be traveling at 4 MPH. GPA = 495 x GPM MPH x BW GPA = 495 x 4 4 x 12 GPM is for the entire sprayer (8 nozzles). Therefore multiply 8 times .5 to get the sprayer out put of 4 GPM GPA = 41.3 or round off to 41 Farmer Calibration On-Line at: http://annearundel.umd.edu/files/SprayerCalibration.doc Farmer Calibration Farmer Calibration DRY BROADCAST APPLICATION Measure a Known Area Weigh Product Before One Treats the Area and Note Spreader Setting Reweigh After Application Setup Equality DRY BROADCAST APPLICATION How much Insecto 5G will be applied per acre based on the following information Spreader Setting L Area for calibration is 50 ft by 80 ft : 80x50 = 4,000 sq. ft. Amount of Insecto 5G placed in spreader was 90 lbs Area is treated and Insecto 5G is reweighed at 85 lbs. Difference = 5 lbs Set equality : 5 lbs = x 4,000 43,560 Solve for x : (4000) (x) = (5) x (43560) X = 54.5 lbs will be applied per acre COMPUTERIZATION Sprayer Control Systems Adjust Pressure and Speed to Deliver Desirable GPA Rates Pictures From Teejet Web Page