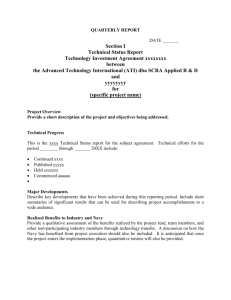

Technology Road Map

advertisement

Green Aviation Research & Development Network Hany Moustapha Directeur, Programme de technologies Pratt & Whitney Canada Executive Director, GARDN May 2009 OUTLINE • Road Map • Objectives • Research Themes • Governance • Projects • Growth GARDN Technology & Funding Road Map 2006 2007 2008 2009 (TRM) CAETRM Canadian Aviation Environmental Technology Road Map CAEWG Technology Road Map Projects Canadian Aviation Environmental Working Group BL-NCE Business-Led Network of Centres of Excellence Funding GARDN Green Aviation Research & Development Network (2009-2013) Execution IATA Warning ICAO Environmental Goals for Aviation The Aviation Industry is Committed to Action on Climate Change CAETRM – Committed Participants Bombardier Aerospace NRC - CNRC Air Canada OAC AQA Pratt & Whitney Canada Bell Helicopter Textron Canada Inc. Rolls-Royce Ltd. CRIAQ Standard Aero Aero Montreal Industry Canada AIAC Messier-Dowty Transport Canada CAETRM Structure Thrust Teams Steering Committee (21 Members) Aircraft Systems and ATM (13) Airframe Concepts (10) Fuels and Lubricants (14) Manufacturing and MRO (23) Materials and Coatings (15) Eco Design (6) Engine Concepts (13) Ground Operations (2) Rotary Wing A/C Concepts (4) Secretariat (4) Airframe Concepts Airframe Concepts TRL or Mid-TRL if range provided 0 1 2 3 4 5 6 7 0 1 Years to required maturity level 2 3 4 Actuation Technologies System Technology Aerodynamics / flight physics Aircraft Configuration Development 5 6 Multi-Disciplinary Optimization Aero-Structural Interaction 7 Structural Technology 8 9 10 11 12 Test Facilities Noise Reduction Technologies cost estimates not provided 8 Engine Concepts Engine Concepts TRL or Mid-TRL if range provided 0 1 2 3 4 5 0 Advanced Air/Oil System Technologies 1 Years to required maturity level 2 3 Advanced Compressor and Fan Technologies Aggressive Inter-turbine Transition Ducts 4 5 Engine acoustics 6 7 8 Advanced Combustion Systems Installations Advanced Modelling 9 10 11 12 Advanced Engine Cycle Technologies 6 7 8 GARDN Objectives • Fostering the development of technologies that will reduce aircraft noise and emissions in the vicinity of airports • Considering environmental impacts throughout the product life cycle • Investing in the talents of our universities and encouraging creativity in the development of aviation environmental technologies • Reducing the production of greenhouse gases by the aviation sector, and in so doing reducing the carbon footprint of the Canadian aviation sector GARDN Eight Research Themes Emission s Noise Icing Performance Aircraft Operations Alternative Fuels Product Life Cycle Management Icing Materials & Manufacturing Processes Noise Reduction Technologies: Geared Turbofan for Bombardier C-Series Munich International Airport Noise Footprints Simulated microphone location X Today’s Aircraft Source: Wyle Labs Simulated microphone location X Geared Turbofan Powered Airplane Green Engine Technologies: Materials and Manufacturing Non-chlorinated solvents Cadmium plate alternative Lead-free antigallants Non-chromium anodizing & conversion coatings Chromium plate alternative New technologies partnered with Canadian industry and universities Alternate Fuel Technologies Corn Sugar cane Switchgrass Cellulose Ethanol Synthetic Jet Fuel Butanol Biodiesel Bio-Jet Willow Microalgae Others Liquid methane Methanol P&WC-SDTC (2007-2011) Low Emission Demonstrator ($22M) Objectives Compact Diffuser Heat Exchanger 1. GHG & NOx reduction 2. Demo focus: TRL6+ Benefits Talon 3+ • • • • • • Lower SFC Lower emission Durability Low cost Weight reduction Thermal management New technologies Partners Demo Schematic using PW307 • NRC, Inco and UTIAS • UTRC and HS Sherbrooke Univ. and P&WC-BA-Bell Acoustics NSERC Chair (2009-2013, $3.3M) GARDN Research Themes and First Round Nine Projects ($23M) P&WC Themes CMC Project 1 Project 2 Project 3 Project 4 Project 5 Project 1 Project 2 Project 3 Project 1 x Noise Emissions Materials & Manufacturing Processes Performance Icing Aicraft Operations Alternative Fuels Product Lifecycle Management BA x x x x x x x x x x x x P&WC Project 1 (M. Bissinger) Project 2 (G. Girard) Project 3 (S-A. Meslioui) Project 4 (F. Lefebvre) Project 5 (Q-P. Zheng) Life-cycle improvement - Materials of concern (Poly, Integran, StandardAero) Forced mixer and nozzle noise reduction (McGill, Sherbrooke) Noise reduction for transonic fans (McGill, Poly) Engine core technologies to reduce emissions (Poly, Concordia, Waterloo, Ryerson) Altitude emissions control for aviation (Waterloo, Warsaw Polytechnic) BA Project 1 (S. Banerjee) Project 2 (S. Banerjee) Project 3 (M. Huising) Environmentally-focused regional aircraft (UTIAS, P&WC) Environmentally-focused long-range business jet (UTIAS, P&WC) Airframe noise reduction (Waterloo, Messier-Dowty, Aercoustics) CMC Project 1 (R. Hygate) Continuous descent arrivals research (ETS) Engine Core Technologies Compressor Demonstrator Durability Items Performance Items Nickel impeller Swept axial airfoils Surge load predictions Tip effect de-sensitization Enhanced compressor surge line V H IBR rotors D hybrid diffuser Weight Items V H Compact centrifugal stage Centrifugal Compressor Technology Demo Compact Centrifugal Compressor Stage Same compression with reduced overall length and casing radius Maintains aerodynamic efficiency State-of-the-Art optimization methods and CFD utilized Significant improvement in thrust-toweight ratio Conventional Impeller/Diffuser Low RadiusRadius-Ratio Diffuser Low AspectAspect-Ratio Impeller Compact Reduced Length + Diameter = Weight & Cost Reduction Compact Centrifugal Concept Baseline Reduced Radius Diffuser Reduced Length Impeller Centrifugal Compressor Technology Demo Advanced Diffuser Technology New patented “D-Hybrid” diffuser technology developed at P&WC to replace pipe diffuser Reduced cost – simpler construction Pipe Diffuser and Fishtail Improved Aerodynamic incidence at diffuser entry Improved operability range with state-ofthe-art efficiency Inner 1d Outer 1b Blades 1c Diffuser Assy. 1 Diffuser Ring 1a Two Pieces Assy. 2 Cover D-Hybrid Diffuser Noise Reduction for Transonic Fan Demo Objectives Improved fan performance No impact on noise Aerodynamic and Aeroacoustic modeling Advance 3D shapes Fan-Stator interaction Selection of fan-stator configurations for wind tunnel testing Separate Stator Arrangement Wind tunnel testing Anechoic chamber Far field noise measurement Flexible fan rig Variable spacing Many stator configurations Fan case acoustic treatment optimization Full-Span Stator Arrangement CFD analysis Extract acoustic content from CFD analyses Modeling validation Test results to calibrate and validate the models Incorporate the tools into standard design practices Feed acoustic data into noise propagation tool Verify analysis results vs. far field noise test data Forced Mixer and Nozzle Noise Reduction Objective: 1-2 dB reduction Characterization of the dominant noise features CFD analyses Develop a CAA methodology for far field noise prediction from turbulent subsonic jet Choose 10-15 promising mixer configurations Wind tunnel testing 10-15 scale models Phased array microphones (isolate mixer noise and shear layer noise) Jet flight effects on propagation Performance characterization Full scale static testing 3-4 full scale models Outdoor noise test with a full engine Far field noise signature Database for flight simulation Flight testing (2nd phase of project) Managing GARDN Management Structure Guiding Principles • Respecting NCE guidelines • Benchmarking other NCE (e.g. AUTO21) • Building on existing consortia know-how and strengths (CRIAQ, SDTC, ISTC, etc.) • Using industry’s best practices in technology management • Adopting a lean structure • Ensuring industry leadership • Leveraging the know-how and networks of CRIAQ and AIAC GARDN Management Structure Executive Directors: F. Kafyeke (BA) H. Moustapha (P&WC) Board of Directors (14) Industry-Academic-Government 3 Meetings / year Chairman: C. Lajeunesse (AIAC) Executive Committee (5) 6 Meetings / year Research Committee Network Manager GARDN Secretariat CAEWG CRIAQ (C. Trindade) AIAC Scientific Director P&WC (S. Sampath) Scientific Director BA (B. Pang) Scientific Director CMC (R. Hygate) Scientific Director TBD Project 1 Project 4 Project 1 Project 2 Project 5 Project 2 Total budget: Project 3 (9 projects/18 partners for first round) Research budget: $20.7M (at 50%) Project 3 Head Office: AIAC, 60 Queen Street, Suite 1200, Ottawa, ON Project 1 Admin budget: (12% of total budget) $23.2M (4 years) $2.5M (at 75%) GARDN Key Performance Indicators (KPI) Research Program • Network researchers • Number of projects • Research budget • TRL progression Highly Qualified People (HQP) • Number of students and universities • Number of theses (MS, Ph.D.), etc Knowledge and Technology Transfer • Patent applications / Granted patents • TRL-6 achievements • Technical reports Partnerships, Networking & International Relationships • Number of partners (national & international) • SMEs outreach Governing & Managing • Achievements vs objectives • Administration budget percentage Growing Lack of Tech. Demos and Funding for TRL 4 to 7 “Valley of Death in Innovation Supply Chain” TRL 1 Research TRL 4 Tech. Platforms TRL 7 Development TRL 9 & Demos Technology Acquisition Technology Infusion Technology Development / Demonstration Product & Manufacturing Methods Dev Basic Research Applied Research Universities CFI NRC (IAR) NSERC Industrial Research Chairs CRIAQ SDTC BL-NCE and ? IRAP SR&ED Tax Credit DIRP NRC/CANMET TPC/SADI Regional Agencies ……Industrial and Regional Benefits…….. Production BDC Markets EDC CCC DFAIT IC Technology & Product Development in Aeronautics Europe and Canada Research and Technology Acquisition TRL 1 Product Development TRL 4 TRL 7 TRL 9 Fundamental Knowledge Technology Development Technology Validation Demonstrators Prototypes Product Definition Product Design & Develolopment Product Demonstration Production EU Framework Program Level 1 Strategic Project (STREPS) NSERC (CRD & IRC), ISTC & CRIAQ Level 2 Integrated Projects (IP) SDTC & BL-NCE (GARDN) Level 3 Joint Technology Initiative JTI) Tech. Demos: No Funding EU One Program Canada 6-10 Programs No Demo GARDN Strategic Plan: Linking to Canadian and International Aerospace Environmental Initiatives Canadian Aerospace Environmental Collaborative Projects - Total Budget $70M (0.35% of Sales) Environmental Roadmap CAEWG CRIAQ (MDEIE/NSERC) GARDN Research Committee Environmental themes 18 projects, 36 partners, $10.3M P&WC (ISTC) Bio-fuels for Aviation 10 projects, 12 partners, $5.5M Acoustics Chair (NSERC) P&WC (SDTC) Low Emission Combustion 11 projects, 5 partners, $22M 9 projects, 18 partners, $23M P&WC/Integran/Comtek (SDTC) Environmental Advanced Materials BA/P&WC (SDTC) Sherbrooke / BA, Bell, P&WC 10 projects, 3 partners, $3.3M EUFP7 Industry Canada-NRC-Industry BioFuels Aircraft Demo FMP-SAGE Demo AIAC-Industry Canada 1.7 Billion Euro (1.8% of Sales) SDTC Advanced Materials For Reduced Engine Emissions (AMREE) Research Areas • Composites - Polymer-matrix composites for containment, CMC for static turbine and combustor parts, Bio-Fibres • Nano Coatings - Hydrophobic, Wear-resistant • Grain Boundary Engineered (GBE) Materials - GBE Nickel Alloy for containment • High Temperature Coatings - Cathodic Arc oxidation-resistant coatings, ½K TBC, EBC for CMC • Abradable Coatings - Erosion-resistant Ten Partners: Integran, Comtek, Composite Innovation Centre, Goodrich, NRC, Universities: Toronto, Ryerson, Ottawa, Concordia and Laval Total Budget: $30M (2010-2014) P&WC $ 11M ; Partners $8.5M ; SDTC $10.5M 32 SDTC BioFuel Aircraft Demonstrator Objective BA Q400 • Flight demonstration involving Porter Airlines / Bombardier Q400 / P&WC PW150 • 2011 flight testing with Porter Airlines, Toronto Ottawa • Blend of (Drop-in) 3rd Porter Airlines Feedstock P&WC PW150 generation biojet fuel • Program led by Bombardier with strong P&WC support Funding • SDTC funding application due September 2009 Refining Process FMP-SAGE Demo: Technology & Funding Road Map 2000-2006 2007-2008 2009 2010 (TRM) AIAC 2025 Vision AeroMontreal Forum Industry Canada TRM White Paper AIAC – CAP - CATN Industry Canada Working Groups (Composites-DPHM) Technology Road Map AIAC - FMP Technology Working Group Projects Industry Canada MDEIE Funding SAGE Demo Execution AIAC-FMP Technology Demonstration Smart Affordable Green Efficient “SAGE” Four Vehicles Demos and Eight Technology Platforms Two Vehicle Demos Two Transverse Systems Demos Eco-Design Regional/ Commercial Business Jets Helicopter Product Development Engines Manufacturing Environment More Intelligent Systems Systems AIAC-FMP, Final Report, May 2008 Materials More Electric Systems Avionics Human PerformanceAugmentation 35 Canadian Aerospace Collaborative Environmental Initiatives TRL 1 TRL 4 TRL 7 CRIAQ- MDEIE/NSERC 2002 2004 2006 2008 Environmental themes 18 projects, 36 partners, $10.3M CRIAQ/P&WC - ISTC/MDEIE Bio-fuels for Aviation 10 projects, 12 partners, $5.5M Acoustics Chair - NSERC Sherbrooke / BA, Bell, P&WC 10 projects, 3 partners, $3.3M P&WC - SDTC Low Emission Combustion 11 projects, 5 partners, $22M BL-NCE 2009 9 Projects 18 Partners $23M P&WC/Integran/Comtek – SDTC (Spring 2009) Environmental Advanced Materials BA/P&WC – SDTC (Fall 2009) BioFuels Aircraft Demo FMP-SAGE Demo 2010 Industry Canada – MDEIE ($$TBD) AIAC-CRIAQ-AeroMontreal