Handtool design - the Mining Quiz List

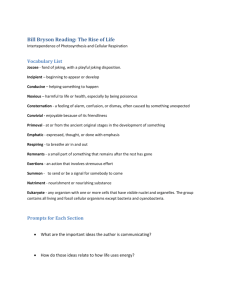

advertisement

Handtool design The human hand is able to perform a large variety of activities, ranging from those that require fine control to others that demand large forces. Introduction-factors effecting operating effectiveness Environment Capabilities of Operator Anthropometry Anatomy Physiology Practice Training Control body linkage Extremity -hand Type of grip Type of coupling Static, dynamic coupling Clothing restrictions Design variables Shape Material Size Surface Operating effectiveness Performance, stress, strain, safety Control task Position axis Resistance Accuracy Speed frequency Continuous -discrete DOF Direction, extent path of motion Outline Hand task activities Accurate and fast movements Forceful exertions Couplings Designing hand tools Design rules for handtools Injury reduction Force and gloves Lab Hand task activities The following are various hand work activities. Fine manipulation of objects with little displacement and force. Fast movements toward an object, requiring moderate accuracy but a fairly small force. Frequent movements between targets usually with some accuracy, but little force. Forceful activities with little or moderate displacement. Forceful activities with large displacements. Accurate and fast movements Speed and accuracy can best be described by Fitt’s Law. MT = a +b Log2 2A W MT = movement time, A is amplitude, W is target size, and a and b are constants. Fitts found when precision of the target was fixed, motion time increased with the logarithm of distance. Forceful exertions Exerting force with the hands is complex: The thumb is the strongest digit – the little finger the weakest. The gripping and grasping strengths of the whole hand are larger than any digit alone. The forearm can produce fairly large twisting torques. Large torques are produced with the elbow at right angles. Torque about the elbow depends upon the angle of the elbow. The strongest pulling or pushing forces toward or away from the shoulder can be exerted with an extended arm. Couplings See handout Designing hand tools Hand tools need to fit the contours of the hand. They need to be held securely with a straight wrist and suitable arm posture. The posture must utilise strength and energy capabilities, without overloading the body. Design rules for handtools Push or pull in the direction of the forearm, with the handle directly in front of it: keep the wrist straight. Provide good coupling between hand and handle by shape and friction. Avoid pressure spots or pinch points. Round edges and pad surfaces. Avoid tools that transmit vibrations to the hand. Do not operate tools frequently and forcefully by hand. Injury reduction techniques Frequency of forceful hand exertions. Peak grip forces during manual exertions, Awkward postures during hand exertions, Vibration of power tools. Cold temperature. Force For an eight-hour workday, the force applied whether in gripping or pinching, should be less than 30% of MVC. The duration of the task needs to be reduced for each increase in force exerted above 30% MVC. For non-repetitive operations (a few times a day) 50% MVC is acceptable. For repetitive operations 20%, MVC is acceptable. For continuous static force requirements, force should be limited to 15%. Gloves Gloves are used in operations that require forceful hand exertions. The type of glove worn is dependant upon the task undertaken to ensure: Good traction A good fit Size of object being handled Orientation of the forces of the hand. Laboratory Using the handouts and video clips, redesign the work tools to comply with the theoretical principles covered in class.