working capital management

SINTECH PRECISION PRODUCTS LIMITED

C-189 & 190, Site No. 1, B.S. Road, Ind. Area, Ghaziabad [U.P.]

Phone No.: 0120-2866320/21,3290635/37/38 Fax No. 0120-2867715

E-mail: marketing@sintechpumps.com

Web Site: www.sintechpumps.com

CERTIFICATE

This is to certify that the Summer-Training Project of FINANCE Titled

“WORKING CAPITAL MANAGEMENT and ITS APPRAISAL” is an original work and that this work has not been submitted anywhere in any form. My indebtedness to other works/publications has been duly acknowledged at the relevant places. The project work was carried from 1 st June, 2009 to 31 st July

2009 in SINTECH PRECISION PRODUCT LIMITED.

Date: 31 st July 2009

Signature

(Bulbul Sharma)

PGDM ( 2009-10)

Signature

(Mr. Sanjeev Garg)

Sintech Precision Product Limited

ACKNOWLEDGEMENT

Words are indeed inadequate to convey my deep sense of gratitude to all those who have helped me in completing this summer project to the best of my ability. Being a part of this project has certainly been a unique and a very productive experience on my part.

I am really thankful to Mr. Sanjeev Garg, Finance Manager for making all kinds of arrangements to carry the project successfully and for guiding and helping me to solve all kinds of quarries regarding the project work. His systematic way of working and incomparable guidance has inspired the pace of the project to a great extent.

I would also like to thank my mentor and project – coordinator, Mr. Parminder

Singh, Asstt. Manager, (Finance & Accounts) for assigning me a project of such a great learning experience and acquainting me with real life project financing and appraisal.

I am very grateful to CA Neeta Sahu (Training & Placement Officer) AJAY

KUMAR GARG INSTITUTE OF MANAGEMENT, Ghaziabad. Who has given me the opportunity to do this project in the Sintech Precision Product Ltd. and very thankful to all lecturers of AKGIM, Ghaziabad for their useful guidance and advise.

This project would not have been successful without the help of Mr.N.C. Dhingra

(Chairman) Mr. Sahil Dhingra (Managing Director) of Sintech.

Last but not least I would like to thank all the employees of Sintech Precision

Product Ltd.

who have directly or indirectly helped me with their moral support for the completion of my project.

( Bulbul Sharma

)

TABLE OF CONTENTS

Acknowledgement

Abstract

1. Introduction

The problems

Purpose of study

Research methodology

Scope of the study

Data sources

Limitations

2. Industry Profile a. Indian Economy b. Pump industry c. Global Pump Market Outlook

3. Sintech Precision Product Ltd.

– An Overview

Company’s Profile

Vision, Misson & Quality

Product Range

Sectoral Overview

4. Conceptual Framework

Introduction to Working Capital Management

Significance of working capital management

Liquidity vs Profitability: Risk – Return trade off

Classification of working capital

Types of working capital needs

Financing of working capital

Factors determining working capital requirements

Working capital cycle

Sources of working capital

Inventory management

Cash management

Receivables management

Managing payables (Creditors)

5. Working Capital Analysis and its Appraisal

6. Major Findings

7. Conclusion

8. Suggestions and Recommendations

9. Bibliography

10. Appendices

ABSTRACT

This project is based on the study of working capital management in Sintech

Precision Product Ltd. An insight view of the project will encompass – what it is all about, what it aims to achieve, what is its purpose and scope, the various methods used for collecting data and their sources, including literature survey done, further specifying the limitations of our study and in the last, drawing inferences from the learning so far.

Sintech Precision Products Ltd., founded in 1986, by an enterprising technocrat

Mr. N.C.Dhingra is recognized as one of the largest pumping solutions provider today in India. Sintech is an advanced pumping solution provider for water intensive heavy industries. With a very diverse product portfolio, Sintech provides solutions for multifarious applications like clear water, process, slurry, liquid with suspended solids, sewage, acids, alkalies, seawater and many more.

Sintech has branch offices and dealership network in throughout the nation as well as catering the international market.

The working capital management refers to the management of working capital, or precisely to the management of current assets. A firm’s working capital consists of its investments in current assets, which includes short-term assets— cash and bank balance, inventories, receivable and marketable securities.

This project tries to evaluate how the management of working capital is done in

Sintech through inventory ratios, working capital ratios, trends, computation of cash, inventory and working capital, and short term financing.

INTRODUCTION

The problems

Purpose of study

Research methodology

Scope of the study

Data sources

Limitations

INTRODUCTION:

The project undertaken is on “WORKING CAPITAL MANAGEMENT IN

SINTECH PRECISION PROUCT LTD”.

It describes about how the company manages its working capital and the various steps that are required in the management of working capital.

Cash is the lifeline of a company. If this lifeline deteriorates, so does the company's ability to fund operations, reinvest and meet capital requirements and payments. Understanding a company's cash flow health is essential to making investment decisions. A good way to judge a company's cash flow prospects is to look at its working capital management (WCM).

Working capital refers to the cash a business requires for day-to-day operations or, more specifically, for financing the conversion of raw materials into finished goods, which the company sells for payment. Among the most important items of working capital are levels of inventory, accounts receivable, and accounts payable. Analysts look at these items for signs of a company's efficiency and financial strength.

The working capital is an important yardstick to measure the company’s operational and financial efficiency. Any company should have a right amount of cash and lines of credit for its business needs at all times.

This project describes how the management of working capital takes place at

SINTECH.

The Problems

In the management of working capital, the firm is faced with two key problems:

1.

First, given the level of sales and the relevant cost considerations, what are the optimal amounts of cash, accounts receivable and inventories that a firm should choose to maintain?

2.

Second, given these optimal amounts, what is the most economical way to finance these working capital investments? To produce the best possible results, firms should keep no unproductive assets and should finance with the cheapest available sources of funds. Why? In general, it is quite advantageous for the firm to invest in short term assets and to finance short-term liabilities.

PURPOSE OF STUDY

The objectives of this project were mainly to study the inventory, cash and receivable at SINTECH PRECISION PRODUCT LTD., but there are some more and they are -

The main purpose of our study is to render a better understanding of

the concept “Working Capital Management”.

To understand the planning and management of working capital at

SINTECH .

To measure the financial soundness of the company by analyzing various ratios.

To suggest ways for better management and control of working capital at the concern.

RESEARCH METHODOLOGY

This project requires a detailed understanding of the concept –

“Working Capital Management”. Therefore, firstly we need to have a clear idea of what is working capital, how it is managed in SINTECH, what are the different ways in which the financing of working capital is done in the company.

The management of working capital involves managing inventories, accounts receivable and payable and cash. Therefore one also needs to have a sound knowledge about cash management, inventory management and receivables management.

Then comes the financing of working capital requirement, i.e. how the working capital is financed, what are the various sources through which it is done.

And, in the end, suggestions and recommendations on ways for better management and control of working capital are provided.

SCOPE OF THE STUDY

This project is vital to me in a significant way. It does have some importance for the company too. These are as follows –

This project will be a learning device for the finance student.

Through this project I would study the various methods of the working capital management.

The project will be a learning of planning and financing working capital.

The project would also be an effective tool for credit policies of the companies.

This will show different methods of holding inventory and dealing with cash and receivables.

This will show the liquidity position of the company and also how do they maintain a particular liquidity position.

DATA SOURCES:

The following sources have been sought for the preparation report:

Primary sources such as business magazines, current annual reports, book on Financial Management by various authors and internet websites the imp amongst them being : www.sintechpumps.com, www.indiainfoline.com, www.studyfinance.com .

Secondary sources like previous years annual reports, CMA Data, reports on working capital for research, analysis and comparison of the data gathered.

While doing this project, the data relating to working capital, cash management, receivables management, inventory management and short term financing was required.

This data was gathered through the company’s websites, its corporate intranet, Sintech’s annual reports and CMA Data of the last three years.

A detailed study on the actual working processes of the company is also done through direct interaction with the employees and by timely studying the happenings at the company.

Also, various text books on financial management like Khan & Jain,

Prasanna Chandra and I.M.Pandey were consulted to equip ourselves with the topic.

LIMITATIONS OF THE STUDY:

We cannot do comparisons with other companies unless and until we have the data of other companies on the same subject.

Only the printed data about the company will be available and not the back–end details.

Future plans of the company will not be disclosed to the trainees.

Lastly, due to shortage of time it is not possible to cover all the factors and details regarding the subject of study.

The latest financial data could not be reported as the company’s websites have not been updated.

INDUSTRY PROFILE

Indian Economy

Pump Industry

Global pump market outlook and growth driver

INTRODUCTION TO THE INDUSTRY

Indian Economy

In the beginning of the year 2008 the economy was on a higher growth path with the macro-economic fundamentals inspiring confidence and a general optimism about the medium to long term prospects of the economy. The economy was expected to slow down marginally from the three years of 9% plus growth in real GDP reflecting a cyclical downturn in the global economy and expectations were that the growth would be around 8.5%. High oil prices and domestic inflation and worsening of international financial crisis which had surfaced in 2007 have been definite areas of concern. But the global situation deteriorated massively after mid-September 2008 following collapse of series of investment banks in the US. This resulted in choking of credit and global crash in stock markets. Crisis of this magnitude in industrialized countries has impact around the world especially in the emerging market countries like India. The Indian economy which started with a strong economic performance lost the momentum once the ripple effects of the gloom in the global economy set in.

Sensex in January 2008 was all time high at 21206, came down to around 9000 towards the end. The high cost of crude oil around US$ 150 per barrel in August,

2008 added to the country’s woes in terms of higher import bill. Rupee weakened against dollar sliding down from Rs.39 in the beginning of the year to Rs.48 towards the end.

According to the estimates released by Central Statistical Organisation (CSO) the real GDP growth was 7.6% in the second quarter of 2008-09 as compared to 9.3% of the corresponding quarter of 2007-08, reflecting deceleration in growth of industry and services. The agricultural production was below the estimate. The index of industrial production recorded 3.9% as compared to 9.2% in the previous year.

India’s balance of payments position witnessed widening of trade deficit. The crisis in global financial markets deepened since mid September, 2008 exerting pressure on financial markets and crashing of equity markets leading to wide spread volatility.

The global turmoil in the financial markets spilled over the emerging markets. This has finally affected the manufacturing sector. As a result, authorities in several countries embarked upon an unprecedented way of policy initiatives to contain systematic risk, arrest the plunge in asset prices and shore of the confidence in the international banking system. This has brought about some level of stability. The

Indian Government has not lagged behind. It has been successful in bringing down inflation from 12.9% in August, 2008 to around 6% towards the end of the year. The challenges of high growth and now global recession have become more complex especially with increased globalization of world economy and growing influence of global developments, economic and no economic. Upgrading infrastructure – such as energy, roads, inflation management, promoting growth of industrial sector, stability in financial market, containing deficit, both domestic and external, promoting exports amidst global recession are the major challenges that are faced by Indian economy.

Pumps Industry

Indian pumps, catering to a range of sectors from agriculture to nuclear power generation, are expected to capture a bigger slice of the world market. With exports already reaching around 70 countries, the Indian pump industry is poised to register a faster growth rate than the global average, says an industry study. The Indian pump industry is set to grow at 6-7 percent over the next three years (against the 4 percent of the world pump market).

The growth witnessed by the Pumps Industry was in line with the performance of the

Indian economy. The growth in these sectors mainly came from Energy sector. This was the result of capacity additions in Super Critical plants including Ultra Mega

Plants. On the other hand, increased forays from Chinese contractors into Energy

Sector continued to exert pressure on the demand. Demand for Submersible pumps is weather dependent and varies with geographical location. Growth in standard industrial pumps is closely linked to the development in the industrial sector of the economy. Trends in waste water sewage market are encouraging due to increased

Government spending. The earlier buoyant demand for industrial valves tapered off in the latter part of the year due to drop in activities in Steel and General Industry.

The industry, now holding euro 500 million worth of global market share, "is expected to grow at a rate faster than the world pump market growth, capturing a larger share of the market," states the study released by the Confederation of Indian Industry

(CII). According to industry estimates, India produces around one million pumps of various kinds. There are around 800 large, medium and small units producing the pumps for sectors from agriculture to nuclear power generation. "Indian pump manufacturers are able to meet most of the domestic market demand," said Sarita

Nagpal, head of manufacturing services of CII, which works closely with the Indian

Pump Manufacturers Association.

Exports have registered a 11 percent growth in the last two years after reversing a negative 11.5 percent trend in 2002-03 to clock 45 percent growth in 2003-04. India has today become a reliable, technically competent, competitive and enterprising outsourcing option for many multinational companies in industrial pumps and systems.

The growth story has emerged through technical collaborations and joint ventures that Indian companies have had with multinational majors. Technical know-how of global standard has thus been well absorbed.

In addition, various research institutes such as the Small Industries Testing and

Research Centre (Si'Tarc) in Coimbatore, have developed energy-efficient designs for pumps to meet the norms of Indian standards.

The Indian pump industry has an outstanding record of indigenous research and development in all three areas of technological intensities - from mass-produced pumps for agriculture to gigantic pumps for interlinking rivers, and pumps for critical services such as nuclear power generation. The Bureau of Indian Standards has developed 42 specifications for indigenous pumps.

GLOBAL PUMP MARKET OUTLOOK AND GROWTH

DRIVERS

The world pump market is governed by the demand in United States, European

Union and Japan. With these countries burdened by recession, market forecasts up to 2013 have been revised to a compounded average growth rate of just 0.3% from

3-4%. The global market for centrifugal pumps in 2009 and 2010 is likely to contract, while that for positive displacement pumps will post good gains. Consolidation of players in the pump industry through mergers and acquisitions, may catch momentum in 2009 -10 in spite of the present recessionary trends.

Although water and sewage, power, building services, industry, oil and gas are major drivers of the global pump market, for KBL, water, power and irrigation will continue to be chief market drivers.

Factors affecting growth of the global pump industry:

Per capita availability of water in Asia is less than other continents; and it will continue to grow rapidly, thus increasing demand for delivery and treatment of that water. Rising consumption with decreasing supplies of uncontaminated water is pushing up the market of desalination plants for treating seawater.

Urbanization of Asia has seen relocation of more than one billion migrants from villages to cities. This is creating pressure on the existing infrastructure including delivery of utility water and removal and treatment of wastewater.

Most governments in Asia and in Africa are likely to increase their spending on infrastructure projects like irrigation and drinking water schemes.

The world is moving towards energy efficient products and services to be able to sustain the growth rates achieved in the past few years with petroleum being the primary energy source.

Sintech Precision Product Ltd. – An Overview

Company’s Profile

Vision, Misson & Quality

Product Range

Key Players

Sectoral Overview

Introduction to the Company

Company Profile

Sintech Precision Products Ltd., founded in 1986, by an enterprising technocrat Mr.

N.C.Dhingra is recognized as one of the largest pumping solutions provider today in

India. With headquarters located in NCR of India, Ghaziabad, Sintech Precision

Products Ltd has built a strong presence in the domestic market over the past three decades.

Sintech is an advanced pumping solution provider for water intensive heavy industries. With a very diverse product portfolio, Sintech provides solutions for multifarious applications like clear water, process, slurry, liquid with suspended solids, sewage, acids, alkalies, seawater and many more. Sintech has branch offices and dealership network in throughout the nation as well as catering the international market.

With tremendous growth potential in future pumping technology market, Sintech

Precision Products Ltd has acquired certification from Moody International based in

UK, who operates in terms of the UKAS license requirements. Our system is regularly audited for compliance to these International Standards.

Sintech Precision Products Ltd. an ISO 9001 certified company is now a leading & respected pump manufacturer in India. Sintech make pumps are manufactured as per DIN-24256/ISO-2858/IS – 5120 /HIS/IS - 1520 standards and tested as per IS-

9137, API-610 & ISO

– 2548 standards. Sintech make pumps constitutes of highly standardized and is designed with modular structures and offers the best possible interchangeability. This largely reduces spares inventory. Sintech has a high production system with two Manufacturing units.

Sintech Precision Products Ltd. has now expanded in all type of pumps suitable for diverse multifarious applications like clear water, process, slurry, liquid with suspended solids, sewage, acids, alkalies, sea water and many more application.

Till date “SINTECH” has supplied thousands of pumps for various critical and non critical applications, which are working quietly and efficiently to the entire customer satisfaction.

Vision

Sintech seeks to be recognised as the Innovator and thought leader of pumping related products and technologies in domestic and global markets.

Mission

Improve customer returns

Create value through a culture of excellence

Innovate product and service delivery

Imbibe Quality as company’s bloodline

Quality

Sintech Precision Products Ltd ‘s Q3 model is a move in that direction. Principally based on three quality-integrated pillars, the Q3 model reflects the inside out approach of the organization, that incorporates -

Q1 Applied engineering expertise

Q2 Superior pumping capabilities

Q3 Exceptional service

QUALITY ASSURANCE PROCEDURES

Our Quality Assurance Department is manned by qualified engineers to ensure completion of raw materials and final pumps with relevant quality norms. The activities are divided into raw material inspection, in-process inspection and final inspection.

Sintech Precision Products Limited has in house facilities and equipments required for ensuring quality, such as –

Hydrostatic machine for hydrostatic test of the casing

Dynamic balancing machine for dynamic balancing of the impeller.

For non-destructive testing such as ultrasonic test magnetic particle test inspection is carries out through external reputed agencies.A well laid test field for performance testing having sophisticated flow meter with digital display by which flow of the liquid can be tested accurately is available at our works.

Product Range

Type Design Rating

SMS

Multistage Pump

Capacity : upto 1,000 m3/hr

Head upto 1,100 m

Application/Sector

Boiler Feed

Mine De-watering

Water Supply

Jockey

Condensate Transfer

Descaling Operations

SCS &

SCSD

Horizontal Split

Casing Pump

Capacity : upto 10,000 m3/hr

Head upto 180 m

SWP &

CPS

Water Pump

Process Pump

Capacity : upto 1,000 m3/hr

Head upto 140 m

Industrial and

Municipal Water

Supply

Cooling Towers

Injection Water

Spray Pond

Air-conditioning

Water

Treatment Plant

Fire Fighting

Irrigation

Water Supply

Drip Irrigation

Cooling Tower

Condensate handling

Air-conditioning

Fire Fighting

Service Water

Chemical Process

Effluent Treatment

Hydrocarbon

Viscous Liquid

Acids Juice Pump

Distillery

SAF

Axial Flow Pump

Capacity : upto 20,000 m3/hr

Head upto 10 m

Sea Water

River Water

Canal Water

Sewage

SSHQ

Non Clog Pump

Capacity : upto 2,000 m3/hr

Head upto 60 m

SMF

Mixed Flow Pump

Capacity : upto 7,000 m3/hr

Head upto 45 m

Sewage

Effluent Treatment

Unscreened Juice

Slurry

Drainage

River water

Sludge

Grain Wash

Syrup

Melt

Mud

Injection Water

Sewage

Effluent Treatment

Drainage

River Water

Water Supply

SVT

SVMF

SVAF

Vertical Turbine

Vertical Mixed

Flow

Vertical Axial Flow

Capacity : upto 20,000 m3/hr

Head upto 300 m

General Water

Supply

Cooling Tower

Spray and Injection

Water

Irrigation

Hydropower

SV

Liquid Ring

Vacuum

Pump

Free Air Capacity : upto 4,975 m3/hr

Vacuum upto 685 mmHg

Chemicals

Pharmaceuticals

Food

Sugar

Plastic

Paper

Pulp

SGP

Gear Pump

Capacity : upto 150 m3/hr

Head upto 100 m

Thick Viscous Liquid

Dyes

Coaltar

Mollasses

Soaps

Paint

ST

STF

Lobe Pump

/ Star Pump

Capacity : upto 100 m3/hr

Head upto 50 m

Thick Mollasses

Highly Viscous Liquid

Torque Flow

Pump

Capacity : upto 1,500 m3/hr

Head upto 100 m

Abrasive Slurries

Sewage

Industrial Waste

Sugar

Pulp and Paper

Steel

Power

Fibre

Textile

Waste Water

Grain Wash

Solid Handling

Cement Aquaculture

Massecuite

Magma

EB

&

EBM

Rota Pump

Capacity : upto 100 m3/hr

Head upto 50 m

SSPL

Self Priming

Pump

Capacity : upto 250 m3/hr

Head upto 50 m

Sump Drainage

Dewatering

Ash Slurry

Wet Scrubber

SECTORAL OVERVIEW

Power

This business group caters to the needs of power industry - conventional and renewable. Considering the chronic shortage of power, this sector is bound to emerge as a major market driver for decades to come. The Power group is proud to have successfully completed the sump model test of cooling water system for

India's first ultra mega power project of 4000 MegaWatt (5 x 800 MW) at

Kirloskarvadi. Orders received include:

Raka Saudia Power & Water -

Co. Ltd.

Bhakra Beas Management -

Board (P.W.)

Shri Chamundeswari Sugars -

SWRO Barge Project

Pong Power Project

Co-gen Plant Limited

(Through Avant Garde)

Clear Water Limited

Clear Water Limited

-

-

2x250 MW Korba East

2x210 MW Rayalaseema

TPS Stage II, Unit 3 & 4

Water Resource Management

This business group addresses the needs of water supply, water treatment and waste water treatment segments. Water, like power is a major market driver for the pump industry and equipment peripheral to water industry. Water stressed regions in the world are on the rise, thanks to uncurbed urbanization, growing industrialization, increasing pollution levels and absence of sufficient teeth to the legislation to deal with water pollution across the world. India is no exception. Such a scenario demands better and better water management, with latest technologies, cheaper methods and sustainable operations.

This business group continues to serve municipal corporations, water and sewerage boards of India. Delhi Jalboard's Vishwakarma project, Nagpur municipal corporation's Gorewada and Mahadula projects and Maharashtra Jal

Pradhikaran's Malegaon project went on stream this year.

We made significant in-roads in waste water treatment segment in India as well as overseas, based on the Gondwana Engineers Limited's strengths. Orders received include:

Steel Authority of India Llimted, Bhilai for a 30 million liters per day (MLD) sewage treatment plant

Vadodara municipal Sewa Sadan for a 8.5 MLD sewage treatment plant

Pune municipal corporation for a 40 MLD sewage treatment plant

Sugar Industry

Some prestigious projects in sugar industry are :

Balrampur Chini Mills Limited – Khumbi Project

Balrampur Chini Mills Limited

–

Gularia Project

Bajaj Hindusthan Limited - Kinauni Project

Bajaj Hindusthan Limited

Uttam Sugar Mills Limited

Uttam Sugar Mills Limited

-

-

-

Kinauni Expansion

Barkatpur Project

Shermau Project

Paper / Etp / Chemical / Food

Some prestigious projects in Paper / Etp / Chemical / Food are :

Satyam Industries Pvt. Ltd -

Clear Water Limited -

Clear Water Limited -

Steel

Panipat Project

Bhiwadi Project

Kanoria Chemical &

Ghaziabad Organics Ltd.

Indus.Ltd.

Adinath Enterprises

Winsor Sathyam Engineering -

- Ghaziabad Project

- FMC – Satnam Agro Project

Bombay Rayon Fashion

Limited

Some prestigious projects in steel industry are :

Maa Chinnamastika Steel & - Steel Project Power

IST Steel & Power Limited -

Shri Mahavir Ferro Alloys P Ltd. -

Limited

Bellary Project

Rourkela Project

Mines

Some prestigious projects in mines industry are :

Singareni Colleries Co. Ltd. -

Singareni Colleries Co. Ltd. -

Singareni Colleries Co. Ltd. -

Singareni Colleries Co. Ltd. -

15 HP

40 HP

75 HP

125 HP

WORKING CAPITAL MANAGEMENT

CONCEPTUAL FRAMEWORK

Introduction

Significance of working capital management

Liquidity Vs. profitability: Risk – Return trade off

Classification of working capital

Types of working capital needs

Factors determining working capital requirements

Working capital cycle

Sources of working capital

Working capital position

Inventory management

Cash management

Receivables management

Managing payables (Creditors)

Financing current assets

Working capital & short-term financing

Financing Current Assets

Introduction to working capital

“Working Capital is the Life-Blood and Controlling Nerve Center of a business”

The working capital management precisely refers to management of current assets.

A firm’s working capital consists of its investment in current assets, which include short-term assets such as:

Cash and bank balance,

Inventories,

Receivables (including debtors and bills),

Marketable securities.

Working capital is commonly defined as the difference between current assets and current liabilities.

Working Capital = Current Assets-Current Liabilities

There are two major concepts of working capital:

Gross working capital

Net working capital

Gross working capital:

It refers to firm's investment in current assets. Current assets are the assets, which can be converted into cash with in a financial year. The gross working capital points to the need of arranging funds to finance current assets.

Net working capital:

It refers to the difference between current assets and current liabilities. Net working capital can be positive or negative. A positive net working capital will arise when current assets exceed current liabilities. And vice-versa for negative net working capital. Net working capital is a qualitative concept. It indicates the liquidity position of the firm and suggests the extent to which working capital needs may be financed by permanent sources of funds. Net working capital also covers the question of judicious mix of long-term and short-term funds for financing current assets.

Significance Of Working Capital Management

EASY LOAN

FROM

BANKS

PAYMENT

TO

SUPPLIERS

SIGNIFICAN

--CE OF

WORKING

CAPITAL

DIVIDEND

DISTRIBU-

TION

INCREASE

EFFECIENY

INCREASE

DEBT

CAPACITY

INCREASE

IN FIX

ASSETS

The management of working capital is important for several reasons:

For one thing, the current assets of a typical manufacturing firm account for half of its total assets. For a distribution company, they account for even more.

Working capital requires continuous day to day supervision. Working capital has the effect on company's risk, return and share prices,

There is an inevitable relationship between sales growth and the level of current assets. The target sales level can be achieved only if supported by adequate working capital Inefficient working capital management may lead to insolvency of the firm if it is not in a position to meet its liabilities and commitments.

Liquidity Vs Profitability: Risk - Return trade off

Another important aspect of a working capital policy is to maintain and provide sufficient liquidity to the firm. Like the most corporate financial decisions, the decision on how much working capital be maintained involves a trade off- having a large net working capital may reduce the liquidity risk faced by a firm, but it can have a negative effect on the cash flows. Therefore, the net effect on the value of the firm should be used to determine the optimal amount of working capital.

Sound working capital involves two fundamental decisions for the firm. They are the determination of:

The optimal level of investments in current assets.

The appropriate mix of short-term and long-term financing used to support this investment in current assets, a firm should decide whether or not it should use short-term financing. If short-term financing has to be used, the firm must determine its portion in total financing. Short-term financing may be preferred over long-term financing for two reasons:

The cost advantage

Flexibility

But short-term financing is more risky than long-term financing. Following table will summarize our discussion of short-term versus long-term financing

Maintaining a policy of short term financing for short term or temporary assets needs (Box 1) and long- term financing for long term or permanent assets needs

(Box 3) would comprise a set of moderate risk

–profitability strategies. But what one gains by following alternative strategies (like by box 2 or box 4) needs to weighed against what you give up.

CLASSIFICATION OF WORKING CAPITAL

Working capital can be classified as follows:

On the basis of time

On the basis of concept

Types of Working Capital Needs

Another important aspect of working capital management is to analyze the total working capital needs of the firm in order to find out the permanent and temporary working capital. Working capital is required because of existence of operating cycle. The lengthier the operating cycle, greater would be the need for working capital. The operating cycle is a continuous process and therefore, the working capital is needed constantly and regularly. However, the magnitude and quantum of working capital required will not be same all the times, rather it will fluctuate.

The need for current assets tends to shift over time. Some of these changes reflect permanent changes in the firm as is the case when the inventory and receivables increases as the firm grows and the sales become higher and higher. Other changes are seasonal, as is the case with increased inventory required for a particular festival season. Still others are random reflecting the uncertainty associated with growth in sales due to firm's specific or general economic factors.

The working capital needs can be bifurcated as:

Permanent working capital

Temporary working capital

Permanent working capital:

There is always a minimum level of working capital, which is continuously required by a firm in order to maintain its activities. Every firm must have a minimum of cash, stock and other current assets, this minimum level of current assets, which must be maintained by any firm all the times, is known as permanent working capital for that firm. This amount of working capital is constantly and regularly required in the same way as fixed assets are required. So, it may also be called fixed working capital.

Temporary working capital:

Any amount over and above the permanent level of working capital is temporary, fluctuating or variable working capital. The position of the required working capital is needed to meet fluctuations in demand consequent upon changes in production and sales as a result of seasonal changes.

The permanent level is constant while the temporary working capital is fluctuating increasing and decreasing in accordance with seasonal demands as shown in the figure. In the case of an expanding firm, the permanent working capital line may not be horizontal. This is because the demand for permanent current assets might be increasing (or decreasing) to support a rising level of activity. In that case line would be rising.

FACTORS DETERMINING WORKING CAPITAL REQUIREMENTS

There are many factors that determine working capital needs of an enterprise. Some of these factors are explained below:

Nature or Character of Business.

The working capital requirement of a firm is closely related to the nature of its business. A service firm, like an electricity undertaking or a transport corporation, which has a short operating cycle and which sells predominantly on cash basis, has a modest working capital requirement. Oh the other hand, a manufacturing concern like a machine tools unit, which has a long operating cycle and which sells largely on credit, has a very substantial working capital requirement.

Sintech is a manufacturing concern so this requires them to keep a very sizeable amount in working capital.

Size of Business/Scale of Operations.

Sintech has a good position in its segment and they are also spending their operations in the domestic market as well as in foreign market. The scale of operations and the size it holds in the market makes it a must for them to hold their inventory and current asset at a huge level.

Rate of Growth of Business.

The rate of growth of sales indicates a need for increase in the working capital requirements of the firm. As the firm is projected to increase their sales by 69% from what it was in 2009, it is required to guard them against the increasing requirements of the net current asset by way of efficient working capital management. The sales and projected sales level determine the investment in inventories and receivables.

Price Level Changes.

Changes in the price level also affect the working capital requirements. It was the reduced margins in the price of the raw materials that had prompted them to go for bulk purchases thus making on additions to their net current assets. They might have gone for this large-scale procurement for availing discounts and anticipating a rise in prices, which would have meant that more funds are required to maintain the same current assets.

SOURCES OF WORKING CAPITAL

Sintech has the following banks available for the fulfillment of its working capital requirements in order to carry on its operations smoothly:

Banks :

These include the following banks – o Indian Bank o Syndicate Bank

NAME OF THE BANK

INDIAN BANK

SYNDICATE BANK

TOTAL

FUND BASED

300

200

500

NON-FUND BASED

250

100

350

WORKING CAPITAL CYCLE

The upper portion of the diagram below shows in a simplified form the chain of events in a manufacturing firm. Each of the boxes in the upper part of the diagram can be seen as a tank through which funds flow. These tanks, which are concerned with day-to-day activities, have funds constantly flowing into and out of them.

CASH RAW

MATERIAL

DEBTORS &

BILLS

RECEIVABL-

ES

OPERATING CYCLE

WORK IN

PROGRESS

SALES

FINISH

GOODS

The chain starts with the firm buying raw materials on credit.

In due course this stock will be used in production, work will be carried out on the stock, and it will become part of the firm’s work-in-progress.

Work will continue on the WIP until it eventually emerges as the finished product.

As production progresses, labor costs and overheads need have to be met.

Of course at some stage trade creditors will need to be paid.

When the finished goods are sold on credit, debtors are increased.

They will eventually pay, so that cash will be injected into the firm.

Each of the areas- Stock (raw materials, WIP, and finished goods), trade debtors, cash (positive or negative) and trade creditors – can be viewed as tanks into and from which funds flow.

Working capital is clearly not the only aspect of a business that affects the amount of cash.

The business will have to make payments to government for taxation.

Fixed assets will be purchased and sold

Lessors of fixed assets will be paid their rent

Shareholders (existing or new) may provide new funds in the form of cash

Some shares may be redeemed for cash

Dividends may be paid

Long-term loan creditors (existing or new) may provide loan finance, loans will need to be repaid from time-to-time, and

Interest obligations will have to be met by the business

Unlike, movements in the working capital items, most of these ‘non-working capital’ cash transactions are not every day events. Some of them are annual events (e.g. tax payments, lease payments, dividends, interest and, possibly, fixed asset purchases and sales). Others (e.g. new equity and loan finance and redemption of old equity and loan finance) would typically be rarer events.

INVENTORY MANAGEMENT

Inventories

Inventories constitute the most important part of the current assets of large majority of companies. On an average the inventories are approximately 60% of the current assets in public limited companies in India. Because of the large size of inventories maintained by the firms, a considerable amount of funds is committed to them. It is therefore, imperative to manage the inventories efficiently and effectively in order to avoid unnecessary investment.

Nature of Inventories

Inventories are stock of the product of the company is manufacturing for sale and components make up of the product. The various forms of the inventories in the manufacturing companies are:

Raw Material : It is the basic input that is converted into the finished product through the manufacturing process. Raw materials are those units which have been purchased and stored for future production.

Work-in-progress : Inventories are semi-manufactured products.

They represent product that need more work they become finished products for sale.

Finished Goods : Inventories are those completely manufactured products which are ready for sale. Stocks of raw materials and workin-progress facilitate production, while stock of finished goods is required for smooth marketing operations. Thus, inventories serve as a link between the production and consumption of goods.

Inventory Management Techniques

In managing inventories, the firm’s objective should be to be in consonance with the shareholder wealth maximization principle. To achieve this, the firm should determine the optimum level of inventory. Efficiently controlled inventories make the firm flexible. Inefficient inventory control results in unbalanced inventory and inflexibility-the firm may sometimes run out of stock and sometimes pile up unnecessary stocks.

Economic Order Quantity (EOQ) : The major problem to be resolved is how much the inventory should be added when inventory is replenished. If the firm is buying raw materials, it has to decide lots in which it has to purchase on replenishment. If the firm is planning a production run, the issue is how much production to schedule. These problems are called order quantity problems, and the task of the firm is to determine the optimum or economic lot size. Determine an optimum level involves two types of costs:-

Ordering Costs : This term is used in case of raw material and includes all the cost of acquiring raw material. They include the costs incurred in the following activities:

Requisition

Purchase Ordering

Transporting

Receiving

Inspecting

Storing

Ordering cost increase with the number of orders placed; thus the more frequently inventory is acquired, the higher the firm’s ordering costs. On the other hand, if the firm maintains large inventory’s level, there will be few orders placed and ordering costs will be relatively small. Thus, ordering costs decrease with the increasing size of inventory.

Carrying Costs: Costs are incurred for maintaining a given level of inventory are called carrying costs. These include the following activities:

Warehousing Cost

Handling

Administrative cost

Insurance

Deterioration and obsolescence

Carrying costs are varying with inventory size. This behavior is contrary to that of ordering costs which decline with increase in inventory size. The economic size of inventory would thus depend on trade-off between carrying costs and ordering cost.

ABC System

:

ABC system of inventory keeping is followed in the factories. Various items are categorized into three different levels in the order of their importance. For e.g. items such as memory, high capacity processors and royalty are placed in the ‘A’ category. Large number of firms has to maintain several types of inventories. It is not desirable the same degree of control all the items. The firm should pay maximum attention to those items whose value is highest. The firm should therefore, classify inventories to identify which items should receive the most effort in controlling. The firm should be selective in approach to control investment in various types of inventories. This analytical approach is called “ABC Analysis”. The high-value items are classified as “A items” and would be under tightest control. “C items” represent relatively least value and would require simple control . “ B items” fall in between the two categories and require reasonable attention of management.

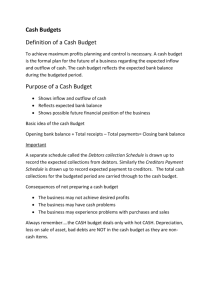

CASH MANAGEMENT

Sources of Cash:

Sources of additional working capital include the following:

Existing cash reserves

Profits (when you secure it as cash!)

Payables (credit from suppliers)

New equity or loans from shareholders

Bank overdrafts or lines of credit.

Long-term loans

If you have insufficient working capital and try to increase sales, you can easily over-stretch the financial resources of the business. This is called overtrading.

Early warning signs include:

Pressure on existing cash

Exceptional cash generating activities e.g. offering high discounts for early cash payment

Bank overdraft exceeds authorized limit.

Seeking greater overdrafts or lines of credit

Part-paying suppliers or other creditors

Paying bills in cash to secure additional supplies

Management pre-occupation with surviving rather than managing

Frequent short-term emergency requests to the bank (to help pay wages, pending receipt of a cheque).

CASH MANAGEMENT IN SINTECH PRECISION PRODUCT

LTD.

The cash management system followed by the SINTECH is mainly lock box system.

Cash Management System involves the following steps:

1. The branch offices of the company at various locations hold the collection of cheques of the customers.

2. Those cheques are either handed over to the CMS agencies or bank of the particular location take charge of whole collection.

3. These CMS agencies or bank send those cheques to the clearing house to make them realized. These cheques can be local or outstation.

4. The CMS agencies or bank send information to the central hub of the company regarding realization/cheque bounced.

5. The central hub passes on the realized funds to the company as per the agreed agreements.

6. The CMS agencies or concerned bank provides the necessary MIS to the company as per requirement.

In cash management the collect float taken for the cheques to be realized into cash is irrelevant and non-interfering because banks such as Standard

Chartered, HDFC and CitiBank who give credit on the basis of these cheques after charging a very small amount. These credits are given to immediately and the maximum time taken might be just a day. The amount they charge is very low and this might cover the threat of the cheque sent in by two or three customers bouncing. Even otherwise the time taken for the cheques to be processed is instantaneous. Their Cash Management System is quite efficient.

RECEIVABLES MANAGEMENT

Cash flow can be significantly enhanced if the amounts owing to a business are collected faster. Every business needs to know.... who owes them money.... how much is owed.... how long it is owing.... for what it is owed.

Late payments erode profits and can lead to bad debts.

Slow payment has a crippling effect on business; in particular on small businesses whom can least afford it. If you don't manage debtors, they will begin to manage your business as you will gradually lose control due to reduced cash flow and, of course, you could experience an increased incidence of bad debt.

The following measures will help manage debtors:

1. Have the right mental attitude to the control of credit and make sure that it gets the priority it deserves.

2. Establish clear credit practices as a matter of company policy.

3. Make sure that these practices are clearly understood by staff, suppliers and customers.

4. Be professional when accepting new accounts, and especially largerones.

5. Check out each customer thoroughly before you offer credit. Use credit agencies, bank references, industry sources etc.

6. Establish credit limits for each customer and stick to them.

7. Continuously review these limits when you suspect tough times are coming or if operating in a volatile sector.

8. Keep very close to your larger customers.

9. Invoice promptly and clearly.

10.Consider charging penalties on overdue accounts.

11.Consider accepting credit /debit cards as a payment option.

12.Monitor your debtor balances and aging schedules, and don't let any debts get too old.

Debtors due over 90 days (unless within agreed credit terms) should generally demand immediate attention. Look for the warning signs of a future bad debt. For example…..

1. Longer credit terms taken with approval, particularly for smaller orders.

2. Use of post-dated checks by debtors who normally settle within agreed terms.

3. Evidence of customers switching to additional suppliers for the same goods.

4. New customers who are reluctant to give credit references.

5. Receiving part payments from debtors.

Here are few ways in collecting money from debtors: -

Develop appropriate procedures for handling late payments.

Track and pursue late payers

Get external help if you own efforts fail.

Don’t feel guilty asking for money .. its yours and you are entitled to it.

Make that call now. And keep asking until you get some satisfaction.

In difficult circumstances, take what you can now and agree terms for the remainder, it lessens the problem.

When asking for your money, be hard on the issue

– but soft on the person. Don’t give the debtor any excuses for not paying.

Make that your objective is to get the money, not to score points or get even.

MANAGING PAYABLES (Creditors)

Creditors are a vital part of effective cash management and should be managed carefully to enhance the cash position.

Purchasing initiates cash outflows and an over-zealous purchasing function can create liquidity problems.

Consider the following: -

Who authorizes purchasing in your company - is it tightly managed or spread among a number of (junior) people?

Are purchase quantities geared to demand forecasts?

Do you use order quantities, which take account of stock holding and purchasing costs?

Do you know the cost to the company of carrying stock?

How many of your suppliers have a return policy?

Are you in a position to pass on cost increases quickly through price increases to your customers?

If a supplier of goods or services lets you down can you charge back the cost of the delay?

There is an old adage in business that "if you can buy well then you can sell well". Management of your creditors and suppliers is just as important as the management of your debtors. It is important to look after your creditors- slow payment by you may create ill feeling and can signal that your company is inefficient (or in trouble!).

Remember that a good supplier is someone who will work with you to enhance the future viability and profitability of your company.

Financing Current Assets

The firm has to decide about the sources of funds, which can be availed to make investment in current assets.

Long term financing:

It includes ordinary share capital, preference share capital, debentures, long term borrowings from financial institutions and reserves and surplus.

Short term financing:

It is for a period less than one year and includes working capital funds from banks, public deposits, commercial paper etc.

Depending on the mix of short and long term financing, the company

can follow any of the following approaches.

Matching Approach

In this, the firm follows a financial plan, which matches the expected life of assets with the expected life of source of funds raised to finance assets.

When the firm follows this approach, long term financing will be used to finance fixed assets and permanent current assets and short term financing to finance temporary or variable current assets.

Conservative Approach

In this, the firm finances its permanent assets and also a part of temporary current assets with long term financing. In the periods when the firm has no need for temporary current assets, the long-term funds can be invested in tradable securities to conserve liquidity. In this the firm has less risk of facing the problem of shortage of funds.

Aggressive Approach

In this, the firm uses more short term financing than warranted by the matching plan. Under an aggressive plan, the firm finances a part of its current assets with short term financing.

WORKING CAPITAL POSITION ANALYSIS IN SINTECH PRECISION

PRODUCT LIMITED

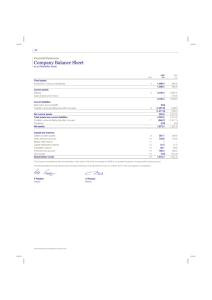

Net working Capital ( CURRENT ASSETS – CURRENT LIABILITIES)

(Rs.in lacks)

YEAR 31.03.07 31.03.08 31.03.09

CURRENT ASSETS

INVENTORIES 180.26 291.13 653.95

SUNDRY DEBTORS 114.33 390.84 219.79

CASH AND BANK 10.81 34.30 28.22

OTHER CURRENT ASSETS 6.67 28.08 21.99

-

LOANS & ADVANCES 21.44 78.74 83.92

-------------- -------------- ---------------

TOTAL CURRENT ASSESTS 333.51 823.09 1008.67

-------------- -------------- ---------------

LESS:-

CURRENT LIABILITIES AND PROVISIONS

Short term borrowing 94.54 336.70 315.76

Sundry creditors 159.49 256.33 305.99

Advanced received 25.30 18.16 59.88

Provisions 21.56 59.05 64.05

Instalments of term loan 14.66 21.11 72.00

Other current liabilities 16.82 29.36

70.34

-------------- -------------- -----------

---

TOTAL CURRENT LIABILITIES 332.37 720.71 888.02

---------------- ---------------- ------------

---

NET WORKING CAPITAL 1.14 102.38 120.65

48

NET WORKING CAPITAL

140

120

100

80

60

40

20

0

1.14

102.38

120.65

2007 2008

YEAR

2009

Data Interpretation

If we analysis the three years working capital position of the company, we find out that company has sufficient working capital to meets its short term liability, it is good indicator for the company but in 2008, working capital is increased by 101.24 lacs which shows that a sufficient amount has been blocked in working capital which could be used for some other more beneficial purpose.

49

INVENTORY ANALYSIS

Inventory means stock of three things :-

1. Raw materials

2. Semi finished goods.

3. Finished goods.

Position of inventory in Sintech Precision Product Ltd.

(Rs.in lacks)

YEAR 31.03.07 31.03.08 31.03.09

Stores, Spare Parts etc. 10.10 .87 25.57

Stock In trade-

Finished Goods 37.04 26.93 41.76

Raw Materials 78.74

184.53 340.08

Material under process 54.38 78.80 246.54

--------------- ---------------- ---------------

180.26 291.13 653.95

------------------- ---------------- -------------

Analysis through chart:

700

600

500

AMOUNT (IN 400

LACKS) 300

200

100

0

2007 2008

YEAR

2009

INTERPRETATION:

By analyzing the 3 years data, We are looking increasing pattern in inventories. We can see that inventories are increased from 180.26 lacs to 291 lacs in the year 2008 and in the year

2009 it is increased from 291 lacs to 653 lacs. By seeing this pattern we can say that the company is managing the inventory according to the sale. Company have a great demand for the pump in the year 2010 that is biggest reason for increase in inventories. From other point of view we can say that the liquidity of firm is blocked in inventories but to stock is very good due to uncertainty of availability of raw material in time.

50

SUNDRY DEBTORS ANALYSIS

Debtors or an account receivable is an important component of working capital and fall under current assets. Debtors will arise only when credit sales are made.

Position of Sintech Precision Product Ltd.

(Rs.in lacks)

YEAR 31.03.07 31.03.08 31.03.09

Sundry Debtors 114.33 390.84 219.79

------------- ------------- --------

114.33

390.84

219.79

--------------- ---------------- ----------

Analysis through chart:

400

300

AMOUNT ( IN

200

LACKS)

100

0

2007 2008

YEAR

2009

INTERPRETATION

In the table and figure we see that there is rise in the debtors in the year 2008 and decrease in the year 2009. A simple logic is that debtors increase only when sales increase and decrease if sales decrease. In the year 2008, sales is increased by 72.30% and decreased by 19.24% in the year 2009.

We can say that it is a good sign as well as negative also. Company policy of debtors is very good but a risk of bad debts is always present in high debtors. when sales is increasing with a great speed the profit also increases. If company decreases the Debtors they can use the money in many investment plans.

51

CASH AND BANK BALANCE ANALYSIS

Cash is called the most liquid asset an vital current assets, it is an important component of working capital. In a narrow sense, cash includes notes, bank draft, cheque etc while in a broader sense it includes near cash assets such as marketable securities and time deposits with bank.

Position of Cash and Bank Balance in Sintech Precision Product Limited

(Rs.in lacks)

YEAR 31.03.07 31.03.08 31.03.09

Cash Balance in hand 1.45 27.30 2.90

Bank Balance-

With Scheduled Banks 9.36 7.00 26.12

------------- ------------- ------------

10.81 34.30 29.02

------------- ------------- ------------

Analysis through chart:

AMOUNT ( IN 20

LACKS ) 15

10

5

0

35

30

25

2007 2008

YEAR

2009

INTERPRETATION

If we analyze the above table and chart we find that it follows a uneven pattern. In the year

2007 it had maintained a low amount of cash and bank balance. But in the year 2008, cash and the bank balances has increased from 10.81 lacs to 34.30 lacs which is not a good sign for the company because it shows that company is not using its cash for beneficial activities. Although, in the year 2009, cash has reduced from 34.30 lacs to 29.02 lacs but this is very good sign for company because they are not holding the cash in hand but using the cash for better projects, but still it is not conducive. From the other point of view, company will not face the problem of liquidity as company is maintaining the cash balance.

52

LOANS AND ADVANCES ANALYSIS

Loans and Advances here refers to any to amount given to different parties, company, employees for a specific period of time and in return they will be liable to make timely repayment of that amount in addition to interest on that loan.

Position of Other Loans & Advances in Sintech Precision Product Limited

(Rs.in lacks)

YEAR 31.03.07 31.03.08 31.03.09

Advances to suppliers 10.91 39.69 44.62

Advances 10.53 39.05 39.30

Deposits 6.67 28.08 21.99

--------------- --------------- ------------

28.11 106.82 105.91

-------------- ---------------- -----------

Analysis through chart:

INTERPRETATION

If we analyze the table and the chart we can see that it follows an increasing trend which is a good sign for the company. We can see that from the year 2007 to 2008 it increased more than triple. We can see that the increase of 275% and 6.08% in 07-08 and 08-09 respectively from previous year.

The increasing pattern shows that company is giving advances for the expansion of plants and machinery which is good sign for better production of pumps and other goods. Although company’s cash is blocked but this is good that company is doing modernization of plants In time to compete with other competitors in market.

53

CURRENT LIABILITIES ANALYSIS

Current liabilities are any liabilities that are incurred by the firm on a short term basis or current liabilities that has to be paid by the firm with in one year.

Position of Other Current Liabilities in Sintech Precision Product Limited

(Rs.in lacks)

YEAR 31.03.07 31.03.08 31.03.09

Current Liabilities –

Sundry Creditors 159.49 256.33 305.99

Bank Loan 94.54 336.70 315.76

Advance Received 25.30 18.16 59.88

Provisions for taxes 21.56 59.05 64.05

Other Liabilities 16.82 29.36 70.34

----------------- ----------------- ----------------

-

332.37 720.71 888.02

----------------- ----------------- ----------------

-

Analysis through chart:

1000

800

AMOUNT ( IN

LACKS )

600

400

200

0

2007 2008

YEAR

2009

INTERPRETATION

If we analyze the above table then we can see that it follow an uneven trend. The important component of current liabilities is sundry creditors and other liabilities. In 07-08 it decreased from 359.41 lacs to 256.33 lacs and in 08-09 it increased from 256.33 lacs to 305.99 lacs. This is liability for company so this should be less. when company have minimum liabilities it creates a better goodwill in market. High current liabilities indicate that company is using credit facilities by creditors.

54

SUNDRY CREDITORS ANALYSIS

Creditors or an account payable is an important component of working capital and fall under current liability. Creditors will arise only when credit purchases are made.

Position of Sundry Creditors in Sintech Precision Product Limited

(Rs.in lacks)

YEAR 31.03.07 31.03.08 31.03.09

Sundry Creditors 159.49 256.33 305.99

------------- ------------- ---------

159.49 256.33 305.99

--------------- ---------------- ----------

Analysis through chart:

350

300

250

AMOUNT ( IN 200

LACKS) 150

100

50

0

2007 2008

YEAR

2009

INTERPRETATION

In the table and figure we see that there is continuous rise in the creditors in the company in the successive years. A simple logic is that creditors increase only when purchases increase and if purchase increases on credit it is not good sign for growth. This is liability for company so this should be less. when company have minimum liabilities it creates a better goodwill in market. High current liabilities indicate that company is using credit facilities by creditors.

55

BANK LOANS AND ADVANCES ANALYSIS

Position of Bank Loans & Advances in Birla Corporation Limited

(Rs.in lacks)

YEAR 31.03.07 31.03.08

31.03.09

Bank Loan 94.54 336.70 315.76

Advances from the customers 25.30 18.16 59.88

--------------- --------------- ------------

122.84 354.86 375.64

-------------- ---------------- -----------

Analysis through chart:

400

350

300

AMOUNT ( IN

250

200

LACKS )

150

100

50

0

2007 2008

YEAR

2009

INTERPRETATION

If we analyze the table and the chart we can see that it follows an increasing trend which is not a good sign for the company. We can see that from the year 2007 to 2008 it increased more than double. The increasing pattern shows that company is taking loan for the expansion of plants and machinerecy which is not a good sign because company depends on the external source. On the other hand, company has reduced the bank loan in 2009 and increase in advances received from the customer, this is good sign for company.

56

PROVISIONS ANALYSIS

Position of Other Provisions in Sintech Precision Product Limited

(Rs.in lacks)

YEAR 31.03.07 31.03.08 31.03.09

Provision for Taxes 21.56 59.05 64.05

--------------- --------------- -------------

21.56 59.05 64.05

--------------- ---------------- ------------

Analysis through chart:

70

60

50

AMOUNT ( IN

40

LACKS )

30

20

10

0

2007 2008

YEAR

2009

INTERPRETATION

From the above table we can see that provision shows an increasing trend and the huge amount is being kept in these provisions. Though the profits of the company are increased income tax is also increased which is good that company is creating goodwill in market by paying income tax in time. Although company is paying more income tax but also they are earning more. Other provisions are also for the benefit of employees and public. This is good sign for Company growth.

57

58

Position of WORKING CAPITAL RATIO in Sintech Precision Product Limited

FORMULA

INVENTORY + RECIVEABLE - PAYABLE

WORKING CAPITAL RATIO= -------------------------------------------------------------

(AS % OF SALES) SALES

YEAR 31.03.07 31.03.08 31.03.09

WORKING CAPITAL RATIO 18 32 53

Analysis through chart:

60

50

40

30

20

10

0

2007 2008

YEAR

2009

INTERPRETATION

This ratio indicates whether the investments in current assets or net current assets ( i.e., working capital ) have been properly utilized. In order words it shows the relationship between sales and working capital. Higher the ratio lower is the investment in working capital and higher is the profitability. But too high ratio indicates over trading.

This ratio is an important indicator about the working capital position. Now if we analyze the three years data, we find that it follows an increasing trend which means that its investment in working capital is lower and the company is utilizing more of its profit. But we find that ratio is increasing at a very fast rate which is not a good sign for the company and the company is required to look into these matters closely.

59

Position of CURRENT RATIO in Sintech Precision Product Limited

FORMULA

TOTAL CURRENT ASSETS

CURRENT RATIO= --------------------------------------------

TOTAL CURRENT LIABILITIES

YEAR 31.03.07 31.03.08 31.03.09

CURRENT RATIO 1.00 1.14 1.14

Analysis through chart:

1.2

1.15

1.1

1.05

1

0.95

0.9

2007 2008

YAER

2009

INTERPRETATION

This ratio reflects the financial stability of the enterprise. The standard of the normal ratio is 2:1 but in most of companies standard is taken according to Tandon Committee which is taken as

1.33:1.

Now if we analyze the three years data it can be predicted that it holds a stable position all through out period but it is seen that it holds a low position than the standard one and the company is required to improve its position.

60

Position of QUICK RATIO in Sintech Precision Product Limited

FORMULA

TOTAL CURRENT ASSETS - INVENTORIES

QUICK RATIO= -----------------------------------------------------------------

TOTAL CURRENT LIABILITIES

YEAR 31.03.07 31.03.08 31.03.09

QUICK RATIO 0.46 0.74 0.40

Analysis through chart:

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

2007 2008

YEAR

2009

INTERPRETATION

It is the ratio between quick liquid assets and quick liabilities. The normal value for such ratio is taken to be 1:1. It is used as an assessment tool for testing the liquidity position of the firm. It indicates the relationship between strictly liquid assets whose realizable value is almost certain on one hand and strictly liquid liabilities on the other hand. Liquid assets comprise all current assets minus stock.

By analyzing the three years data it can be said that its position was weak in the year 2007 but it improved significantly in the next year and again it is declined during the 2009. It is to be said that it does not meet with the standard but in the year 2008 it was very close to the standard and it can be said that its liquidity position is not good & stable.

61

Position of CURRENT ASSETS TO FIXED ASSETS RATIO in Sintech Precision Product

Limited

FORMULA

CURRENT ASSETS

CA TO FA RATIO = -----------------------------

FIXED ASSETS

YEAR 31.03.07 31.03.08 31.03.09

CATO FA RATIO 1.65 2.93 3.21

Analysis through chart:

3.5

3

2.5

2

1.5

1

0.5

0

2007 2008

YEAR

2009

INTERPRETATION

Assuming a constant level of fixed assets, a higher CA/FA ratio indicates a conservative current assets policy and a lower CA/FA ratio means an aggressive current assets policy assuming other factors to be constant. A conservative policy i.e. higher CA/FA ratio implies greater liquidity and lower risk; while an aggressive policy i.e. lower CA/FA ratio indicates higher risk and poor liquidity.

Now if we analyze the three year data we find the CA TO FA Ration in increasing pattern, so we can say that company is following the conservative policy to finance its short term capital requirement.

62

Position of INVENTORY TURNOVER RATIO in Sintech Precision Product Limited

FORMULA

AVERAGE STOCK

STOCK TURN OVER RATIO ( IN DAYS )= --------------------------------------- * 365

COST OF GOODS SOLD

YEAR 31.03.07 31.03.08 31.03.09

INVENTORY TURNOVER RATIO 104 79 227

( in Days)

Analysis through chart:

250

200

150

100

50

0

2007 2008

YEAR

2009

INTERPRETATION

This ratio tells the story by which stock is converted into sales. A high stock turnover ratio reveals the liquidity of the inventory i.e., how many times on an average, inventory is turned over or sold during the year. If a firm maintains a minimum stock level in order to maximize sales by quick rotation of inventory and the holding cost of inventory will be minimum. A low stock turn over ratio reveals undesirable accumulation of obsolete stock.

By analyzing the three year data it seen that it follows an uneven trend. We see that it is reduced to 79 from the 104 days in 2008 and in 2009 it is increased by 148 days, Which is not a good indicator for the company. Company should have to reduce the inventory conversion period in order to reduce the cost.

63

Position of RECEIVABLE RATIO in Sintech Precision Product Limited

FORMULA

DEBTORS

RECEIVABLE RATIO = ---------------- * 365

SALES

YEAR 31.03.07 31.03.08 31.03.09

RECEIVABLE RATIO (IN DAYS) 54 70 104

Analysis through chart:

120

100

80

60

40

20

0

2007 2008

YEAR

2009

INTERPRETATION

Generally a low debtors turnover ratio implies that it considered congenial for the business as it implies better cash flow. The ratio indicates the time at which the debts are collected on an average during the year. Needless to say that a high Debtors Turnover Ratio implies a shorter collection period which indicates prompt payment made by the customer.

Now if we analyze the three year data we can say that it holds a good position while receiving its money from its debtors. The ratios are in an decreasing ternd, which implies that recovery position is not good company and Company have to reduce the receivable period.

64

Position of PAYABLE RATIO in Sintech Precision Product Limited

FORMULA

CREDITORS

PAYABLE RATIO= ----------------------------- * 365

COST OF SALES

YEAR 31.03.07 31.03.08 31.03.09

PAYABLE RATIO (IN DAYS) 92 69 135

Analysis through chart:

160

140

120

100

80

60

40

20

0

2007 2008

YAER

2009

INTERPRETATION

Actually this ratio reveals the ability of the firm to avail the credit facility from the suppliers throughout the year. Generally a low creditors turnover ratio implies favorable since the firm enjoys lengthy credit period

Now if we analyze the three years data we find that in the year 2008 the ratio was very high which means that its position of creditors that year was not good, but in the 2009 it is seen that it has followed a decreasing trend which is very good sign for the company. So we can say it enjoys a very good credit facility from the from the suppliers .

65

Position of Operating Cycle in Sintech Precision Product Limited

Formula = Inventory Conversion Period + Receivable Conversion Period – Deferral

Period

Calculation of Operating Cycle at Sintech:- ( All Figures in Days)

Particulars

ICP

2007-08

104

2008-09

79

2009-10

227

RCP

Gross Operating

Cycle

DP

54

158

92

Net OP 66

Analysis through chart:

70

149

69

80

104

431

135

296

350

300

250

200

150

100

50

0

2007-08 2008-09

YEAR

2009-10

Interpretation

When a company has lower d/e ratio, it means that company is utilizing its own funds and reserves rather than taking loans from outsiders. Company have a uneven trend in d/e ratio. In the year 2007 it was 1.02 but in the year 2009 it is declined to .55 so we can say that now company is using more its fund as compare to previous year, but still the ratio is high. Company have to reduce the ratio.

66

MAJOR FINDINGS

Statement Showing Difference from Previous Year

(amt. in lacks)

Particulars

Working Capital

Sales

Current Assets

Sundry Debtors 391

↑ by 243%

220

↓ by 44%

07-08 08-09

102

↑ by 5000%

1323

↑ by 72%

823

↑ by 146%

121

↑ by

19%

-1069

↓ by

19.10%

1009

↑ by

23%

Inventories 291

↑ by 62%

654

↑ by 125%

Cash & Bank 34

↑ by 209%

-29

↓ by 15%

Bank Loan and

Advances

Current Liabilities

Sundry Creditors

107

↑by 269%

256

↓ by 42%

106

↓ by .93

306

↑ by 19.53%

721

↑ by 117%

888

↑ by

23%

Bank Loan and

Advances

355

↑by 196%

376

↑by 6%

Provisions &

Deposits

80.16

↑by121.31%

136

↑by70%

Other Liabilities 29.36

↓ by 74.55%

70.34

↑ by 139.5%

67

1. Working Capital is increased by 19% only in 2008-09 as compare to 5000% increase in

2007-08 and if we analysis the working capital with sales, the sales is decreased by 19% in 200809, that’s why working capital is increased by 19% only.

2. Current assets and Current liabilities are increased by 23% in 2008-09 as compare to previous year but current assets are increased by 146% in 2007-08 as compare to 117% increase in current liabilities, so we can say that working capital is increased because of increase in current assets.

1. Inventory is increased by 125% in 2008-09 as compare to 2007-08, so we can say that current assets are increased due to the increase in the inventory.

2. Cash and the bank balances are decreased by 15% which shows company might face the liquidity problem.

3. Debtors are decreased by 44% in 2008-09 whereas creditors are increased by 19.37% in 2008-09, which shows that company enjoys the good payable period and goodwill among the creditors.

4. Bank loan and Advances are increased by 6% only as compare to 196% increase in 2007-08, which shows that company using more of its debt to fund the short term requirements.

3. Operating cycle of the company is increasing which shows the poor receivable collection policy

68

CONCLUDING ANAYSIS

The working capital position of the company is sound and the various sources through which it is funded are optimal.

The company has used its purchasing, financing and investment decisions to good effect can be seen from the inferences made earlier in the project.