Manual Handling Risk Assessment Guidance & Record

advertisement

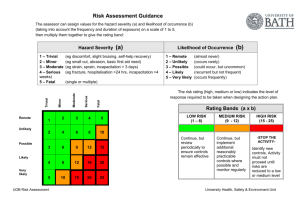

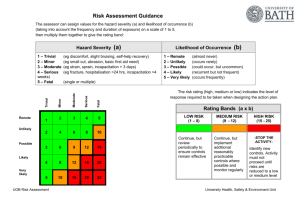

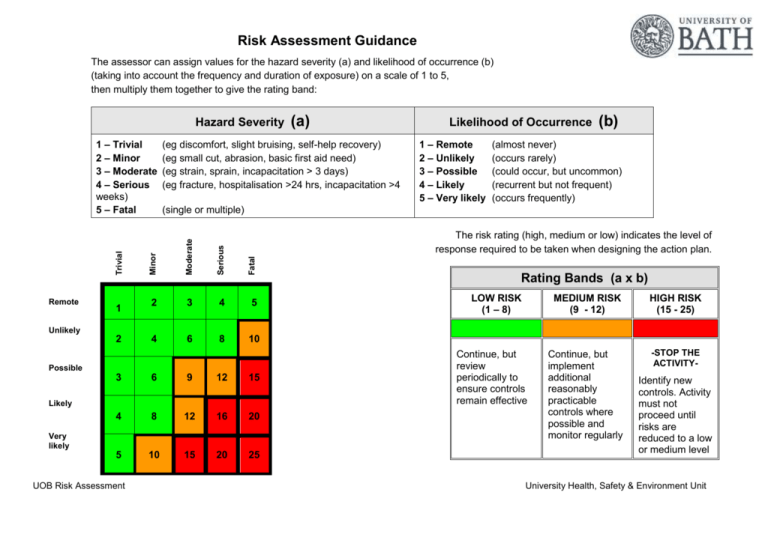

Risk Assessment Guidance The assessor can assign values for the hazard severity (a) and likelihood of occurrence (b) (taking into account the frequency and duration of exposure) on a scale of 1 to 5, then multiply them together to give the rating band: Hazard Severity 1 – Remote 2 – Unlikely 3 – Possible 4 – Likely 5 – Very likely (b) (almost never) (occurs rarely) (could occur, but uncommon) (recurrent but not frequent) (occurs frequently) Fatal The risk rating (high, medium or low) indicates the level of response required to be taken when designing the action plan. Serious 1 Likelihood of Occurrence (single or multiple) Moderate Remote (eg discomfort, slight bruising, self-help recovery) (eg small cut, abrasion, basic first aid need) (eg strain, sprain, incapacitation > 3 days) (eg fracture, hospitalisation >24 hrs, incapacitation >4 Minor Trivial 1 – Trivial 2 – Minor 3 – Moderate 4 – Serious weeks) 5 – Fatal (a) 2 3 4 5 4 6 8 10 Rating Bands (a x b) LOW RISK (1 – 8) MEDIUM RISK (9 - 12) HIGH RISK (15 - 25) Continue, but implement additional reasonably practicable controls where possible and monitor regularly -STOP THE ACTIVITY- Unlikely 2 Possible 3 6 9 12 15 4 8 12 16 20 5 10 15 20 25 Likely Very likely UOB Risk Assessment Continue, but review periodically to ensure controls remain effective Identify new controls. Activity must not proceed until risks are reduced to a low or medium level University Health, Safety & Environment Unit Risk Assessment Record Risk Assessment of: Manual handling tasks Overview of activity / location / equipment / conditions being assessed: Generic or specific assessment? Assessor(s): A. Chapman Date: 18/12/2014 Generic risk assessment for manual handling activities. No specific tasks have been assumed. Context of assessment (delete as appropriate): planning stage / ‘desk-top’ exercise / site visit / in consultation with employees / in consultation with managers / other (please describe) Generic risk assessment Manual handling should be avoided wherever possible. Factors in the assessment should not be taken individually, as a combination of factors may increase the level of risk. For example the need to bend or stoop while pushing a load over a significant distance is likely to incur a greater risk than any one factor taken alone. The activity needs to be assessed as a whole. Assistive equipment should be used, e.g. trolley, sack truck, fork lift truck, wheeled cages, etc. where items need to be moved. Equipment should be chosen carefully to ensure it is suitable for the load, the task, the individual, and the environment it is being used in. Storage of items should take into account the need to move them. Details of the provision of information, instruction, training, and supervision should be included as control measures where appropriate. Manual handling risk assessments should be reviewed at least annually and after any significant change or any injury that could have been caused by manual handling or is likely to be made worse by continuing the task. For further information: see http://www.hse.gov.uk/pubns/indg143.pdf or http://www.hse.gov.uk/toolbox/manual.htm For complex tasks, the HSE MAC tool may be useful: http://www.hse.gov.uk/msd/manualhandling.htm UOB Risk Assessment University Health, Safety & Environment Unit # 1 Hazard(s) identified Persons affected Existing controls & measures A B A x B Additional controls required Hazards related to the load Weight Balance / weight distribution Use HSE’s guideline weights for assessing safe lifting weight in the situation (see http://www.hse.gov.uk/pubns/indg143.pdf Break load down into more manageable weights Use trolley / sack truck etc. Test load before lifting Aim to balance load as evenly as possible across the body for single lifts or between people for team lifts Unstable / contents likely to shift (risk of sudden movement of load) Re-pack contents to improve stability Bulky or unwieldy Break load down into more manageable sizes Consider providing carry handles / suction lifters / other carrying tools Consider appropriate personal protective equipment if hazard cannot be removed Difficult to grasp Sharp / hot / cold / otherwise potentially damaging 2 Hazards related to the individual Strength / fitness / other physical attributes Vulnerable individual e.g. expectant or new mother; young person; previous musculoskeletal injury; other relevant health condition Training / knowledge / experience needed to perform the task safely Ensure the task is within the individual’s physical capability Individual assessments to take into account the specific vulnerability All workers whose roles include significant manual handling must attend training and refresher training UOB Risk Assessment University Health, Safety & Environment Unit # 3 Hazard(s) identified Persons affected Existing controls & measures A B A x B Additional controls required Hazards related to the task Lifting / putting down Good lifting technique Stooping Good posture Reaching up Avoid moving objects above head height Note that use of step stools / ladders will require a Work at Height assessment Reduce weight of load Bring load as close to trunk as possible Avoid by moving the feet and whole body Reduce weight of load Reduce weight of individual loads Have ‘set-down’ points to split up long travel distances Push rather than pull where possible. Ensure force required to start / stop and maintain load in motion is within individual’s capability Vary the work to allow one set of muscles to rest while another is used Reduce weight of loads Vary the work to allow one set of muscles to rest while another is used Holding or manipulating load at a distance from the trunk Twisting the trunk Distance of travel Pushing / pulling Frequent / repetitive or prolonged physical effort Insufficient rest or recovery periods Rate of work imposed by a process or machine Ensure rate of work is within the capability of the individual Vibrating equipment (e.g. cleaning equipment, hand-held power tools) May need to restrict the duration of the task 4 Hazards related to the environment Space constraints preventing good posture Remove obstructions Uneven, slippery, or unstable floors Improve the floor surface where possible UOB Risk Assessment University Health, Safety & Environment Unit # Hazard(s) identified Variation in level of floor or work surface Persons affected Existing controls & measures Avoid steps and steep ramps where possible Avoid where possible Take steps to improve atmospheric conditions e.g dehumidifier; electric fan. Wear suitable clothing Have hot / cold drinks available Take steps to avoid or minimise e.g. by fitting plastic door curtains Allow time for eyes to adjust to lighting conditions Improve lighting where possible Consider automatically opening doors Consider obtaining assistance with opening doors Consider using barriers or clearing the area for the duration of the task Extremes of temperature or humidity Conditions causing gusts of wind or other strong air movement Poor or variable lighting conditions Doors Other people / other activities in the area A B A x B Additional controls required Assessor signature: UOB Risk Assessment Print name: Review date: University Health, Safety & Environment Unit Risk Assessment Action Plan Action Plan in respect of: Ref no. Prepared by: Action to be taken, incl. Cost Responsible manager’s signature: Print name: UOB Risk Assessment By whom Target date Review date Outcome at review date Responsible manager’s signature: Date: Print name: Date University Health, Safety & Environment Unit