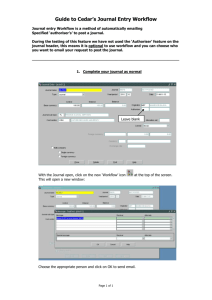

Basic Tools for Business Process Design

advertisement

Basic Tools for Business Process Design Chapter 4 Business Process Modeling, Simulation and Design 1 Overview • Introduction Basic Tools for BPD • Graphical tools – – – – – General Process Charts Process Activity Charts Process Flow Diagrams Flow Charts Service System Mapping • Workflow Design Principles and Tools – – – – – – – Establish product orientation in the process Eliminate buffers One-at-a-time processing Balancing bottleneck flows Minimize sequential processing and handoffs Scheduling based on job characteristics Minimize multiple paths 2 Basic Tools for Process Design • Deterministic tools and modeling approaches to help designers analyze processes and check proposed designs for – Feasibility – Completeness – Efficiency • Quantitative tools require data regarding important process characteristics – Steps required to complete the process – Processing and activity times are key • Tagging is an important technique for gathering process data – Follow a job through the process – Data is collected on a document (a tag) accompanying the job – Particularly useful for gathering data on processing and activity times 3 General Process Charts • Summarizes the current process the redesigned process and the expected improvements • Characterizes the process by – The number of activities per category – The amount of time spent in each activity category – The percentage of the total processing time spent on each category • Clearly indicates – Major problems with the existing process – How the redesigned process remedies these problems • Problems measured in terms of the time and the percentage of time spent on non-value adding activities 4 Illustration of a General Process Chart Activities Current Process Redesigned Process No. Time % No. Time % Operations Inspections Transport. Storage Delays 5 3 10 0 7 30 60 120 0 90 10 20 40 0 30 5 1 2 0 1 30 20 20 0 10 37.5 25.0 25.0 0 12.5 Total 25 300 100 9 80 100 Difference No. 0 -2 -8 0 -6 -16 Time 0 -40 -100 0 -80 -220 5 Process Activity Charts • Complements the general process chart – Provides details regarding the sequence of activities • Disadvantages – Only considers average activity times – If the process includes several variants with different paths (i.e. multiple paths through the process) each variant needs its own activity chart – Cannot depict parallel activities 6 Illustration of a Process Activity Chart Symbols Operation Inspection Process Activity Chart 1 of _____6 Page: ____ Adoption Process: __________________________ 9/14/99 Date: __________ Developed by: ____________________ Current Process Proposed Process Description Time Value code (V/N/C) 1 Find where to go 2-10 N 2 Walk through 10-45 V 3 What’s next? 1-5 N No. X Symbol Storage Delay Transportation of a physical item For each activity, fill in the required information. Also, connect the symbols to show the flow through the process. The value code indicates whether the activity adds value (V), does not add value (N), or controls (C). 7 Process Flow Diagrams (I) • Provide a picture of the spatial relationships between activities – Typical application is for production floor layout problems. • The diagram is used for measuring process performance in units of time and distance – Including both horizontal and vertical movements. – Assumes that moving items requires a time proportional to the distance. • Can be used in conjunction with Process Activity Charts – By labeling areas in the process flow diagram and by adding a column to the activity chart, indicating for each activity which area it belongs to. – Alternatively, the flow diagram includes the activity numbers in the activity chart. 8 Illustration of a Process Flow Diagram Before Redesign After Redesign Finished request A D F A B E D B C F C E Incoming request Incoming request Finished request 9 Process Flow Diagrams (II) • Analysis geared towards reducing excessive and unnecessary transportation and movements of items/jobs – – – – Long distances Crisscrossing paths Repeated movements between the same activities Other illogical flows • Can be used as a basis for computing Load Distance (LD) scores – Useful for quantitatively comparing alternative designs/layouts with regards to flow rates and distances 10 Load Distance Analysis • LD(i,j) = LD score between work centers i and j LD(i,j) = Load(i,j)*Distance(i,j) • The LD score measures the attraction between two work centers (activities) – The larger the traffic volume the higher the score and the higher the incentive to keep the work centers together • The goal is to find a design that minimizes the total LD score (the sum of individual scores between work centers) • The Load Matrix summarizes the load (flow rate = # of jobs) that needs to be shipped between each pair of work centers 11 A Sample Load Matrix A A B C D B 20 C D 20 10 E F 80 75 15 90 70 • See also example exercise on LD Analysis 12 Flow Charts • One of the fundamental graphical tools for process analysis and design – Typically depicts activities sequentially from left to right – Can help to identify, loops, multiple alternative paths, decision points etc. • Symbols often used in flow charting Operation Storage Transportation of a physical item Inspection Delay Transportation of information 13 Illustration of a Sample Flow Chart Operator takes phone order. Orders wait to be picked up. Order waits for sales rep. Orders wait for supervisor. No Is order complete? Orders are moved to supervisor’s in-box. Supervisor inspects orders. Yes Order is fulfilled. 14 Activity Times and Path Frequencies (I) • Flowcharts may be used to estimate the total average process time from the estimated activity times (Unit processing time)*(batch size)+setup time Average activity time = Efficiency – Assumes that the standard processing time is known (estimated) – Assumes that the standard setup time is known (estimated) – The standard times assumes 100% worker efficiency. If the worker is less efficient the times must be adjusted as above. 15 Activity Times and Path Frequencies (II) Example: Inspection activity • • • • Inspection of one unit takes 3 minutes Each inspection batch includes 10 units It takes 15 minutes to prepare for the inspection of a batch The inspector is new on the job and it currently takes 25% longer time to inspect a batch than when she is fully trained What is the estimated activity time for inspecting a batch? The average activity time = ((3*10) + 15)/0.75 = 60 minutes 16 Service System Mapping (I) • An extension of traditional flowcharting – Illustrates how effectively a business process satisfies customers across all encounters – Documents the role played by the customer in the service delivery process – A combination of service blue printing and traditional flowcharting • Goals with SSM – – – – – – Build consistent perceptions of customer’s experience with core processes Identify all points of contact between the process and its customers Provide a basis for developing an economic business model Identify opportunities within the process Provide a design framework Aid in pinpointing control points and strategic performance measures 17 Service System Mapping • An extension of traditional flowcharting – Illustrates how effectively a business process satisfies customers across all encounters – Documents the role played by the customer in the service delivery process SSM Horizontal Bands • The purpose is to organize activities according to the people or “players in the process. – Who does what? • A SSM typically consists of 5 bands 1. 2. 3. 4. 5. Customer band – end user Frontline or distribution channel band Back-room activity band Centralized support or information systems band Vendor or supplier band SSM Process Segments • A process segment or sub process is a set of activities that produces a well defined output given some input 18 Sample SSM for an Order Fulfillment Process Receiving Filling Shipping Billing Customer Band Front line Band Back-room Band IS Band Supplier Band 19 Additional Diagramming Tools • Software products for flowcharting and diagramming… Micrografx RFFlow SmartDraw PaceStar Visual Thought TeamFlow Tension Software Visio 2000 • A specialized approach for “enterprise modeling and analysis” is the so called IDEF methodology – – – A family of structured methods (functional, information and data modeling) Based on an established graphical language SADT (Structured Analysis and Design Technique) Used by many consulting firms not least in design of information systems 20 Workflow Design Principles and Tools (I) Organizing Activities • Two basic ways of organizing activities 1. By process (Process Orientation) 2. By product (Product Orientation) • Process orientation (functional layout) groups activities or workstations according to function – – Most common when the same activity is used for producing different products or services or when serving many different customers Utilization of equipment and personnel tends to be high 21 Workflow Design Principles and Tools (II) • Product orientation groups all necessary activities to complete a finished product into an integrated sequence of work nodes or work stations – A typical example is an assembly/production line for making a particular car model – Activities are organized around the route (needs) of a particular product or service – Advantages with product orientation include • Faster processing rate • Lower WIP • Less unproductive time due to setups • Less transportation time • Less handoffs – A capital intensive way of organizing activities 22 Product v.s. Process Orientation Process Orientation Product Orientation Customer A 1 Customer A 2 1 2 4 5 3 5 3 1 4 2 5 3 4 Customer B (a) Customer B (b) 23 A Hybrid Orientation • To justify a product orientation from a resource utilization perspective the product/service volumes must be quite high. • A popular hybrid between product and process orientation in manufacturing is known as Group Technology (or product clustering) – Groups products with similar characteristics into families and organizes activities around these families instead of around the individual products – “Product Family” orientation • The equivalent in business processes would be to group jobs with similar characteristics into families. • The hybrid orientation simplifies customer routings, reduces process time and can be justified even if the volumes of individual products/services are not that large 24 Illustration of a Hybrid Orientation Customer A 1 2 Customer C 3 Cell AC 4 5 3 1 Customer B Cell BD 3 4 Customer D 2 5 1 25 Workflow Design Principles and Tools (III) Buffer Elimination • Buffers are put in place to protect against variability in demand, processing times, etc. – Jobs stacked up at different parts of the process, waiting to be processed. • WIP = Work In Process inventories. – All jobs currently in the process, i.e. in queues/buffers, under transportation or under processing. • Buffers tend to cause logistical and communication problems due to slower information feedback. – Implies the need for advanced tracking systems to identify what job is in which buffer. • Product orientation implies less WIP but needs to be well balanced in order to minimize buffers. 26 Workflow Design Principles and Tools (IV) One-at-a-time Processing • Reduction of the batch size to the size of one unit • By reducing batch sizes (and setup times) the throughput time and WIP can be minimized • Two types of batches 1. Process batch – All jobs being processed before the resource needs to be changed to process jobs of a different kind 2. Transfer batch – Number of items/jobs transported together to the next resource for processing – Usually the process batch – By reducing the transfer batch total processing time and WIP are also reduced 27 Example – Effect of Reducing Batch Sizes • Three activities in sequence 1, 2 & 3 • Processing times: 1 h/job in 1&3 and 0.5 h/job in activity 2 • Consider the total throughput time for a batch of 100 units when the transfer batch size is: A) 100 B) 20 Process Transfer Batch Batch 1 2 3 100 100 100 50 100 100 100 100 100 250 Process Transfer Batch Batch 1 100 20 2 20 20 100 20 3 20 130 28 Workflow Design Principles and Tools (V) Balancing bottleneck flows • Linked to the OM principle known as Theory of Constraints (TOC) popularized by Eliyahu Goldrat in his book The Goal – Balance flow not capacity! – Keep bottlenecks fed! • Historically manufacturers had tried to balance capacity across processes to match market demands – Making all activity capacities the same makes sense only if processing times are constant or display marginal variability – Variation in processing times causes inventory build up and idleness at different parts of the process • Only two ways of handling variation – Increase WIP to smooth variation – Differentiate/balance capacity according to the job flows 29 Workflow Design Principles and Tools (VI) Line Balancing • A useful approach when processing times are fairly constant – Should not be used when processing times display high variability • The goal is to balance the capacity of the different workstations constituting the production line (the process) Procedure 1. Specify sequential (precedence) relationships among the activities using a precedence diagram 2. Use market demand to determine the line’s desired cycle time per work station (C) C= Process time per day Market demand per day (in # of jobs) 30 Workflow Design Principles and Tools (VII) Line Balancing Procedure (continued) 3. Determine the theoretical minimum # of workstations (TM) TM = Sum of activity times C 4. Select a primary rule to assign activities to workstations and a secondary rule to break ties 5. Assign activities one at a time to workstation 1 as long as the sum of activity times C. Repeat this for workstations 2,3, … – Must satisfy the activities’ precedence relationships 6. Evaluate the line efficiency = Total process time/(C*#stations) 7. Rebalance using a different priority rule in case the efficiency is unsatisfactory 31 Workflow Design Principles and Tools (VIII) Potential Line Balancing Complications • Market demand may require a work station cycle time shorter than the longest activity time Need to change the process in some way! • Approaches: – Split the activity – Use parallel workstations – Train the workers or upgrade machinery for faster processing time – Work overtime – Redesign the entire process 32 Workflow Design Principles and Tools (IX) Minimize Sequential Processing and Handoffs • Sequential processing implies longer process throughput time – Operations are dependent constrained by the slowest activity – No one person is responsible for the entire service encounter Illustrative example (see figure on next slide) • A process with 4 activities, throughput time 30 minutes and processing times 10, 7, 8 & 5 minutes in the 4 activities • Sequential set up – each individual performs a different activity – The process output is 60/10=6 jobs per hour – The efficiency = (10+7+8+5)/(10*4) = 75% • Parallel set up – each individual performs all 4 activities – The process output is now 4*(60/30) = 8 jobs per hour – The efficiency = 30/30 = 100% 33 Illustrative Example – Sequential v.s. Parallel Processing Sequential processing 10 min 7 min 8 min 5 min 6 jobs/hour Parallel processing 30 min 30 min 30 min 30 min 8 jobs/hour 34 Workflow Design Principles and Tools (X) Scheduling based on job characteristics (I) • Scheduling involves sequencing the order at which a number of different jobs are to pass through a workstation or process with limited capacity – Becomes more important as the diversity of jobs increases • Characteristics that are commonly used as a basis for scheduling – – – – Arrival time Estimated processing time Due date Importance 35 Scheduling Based on Job Characteristics (II) • Finding the “right”objective function and the best scheduling characteristic to satisfy this objective is tricky • Three common overall objectives – Maximize process output over a given time period – Satisfying customer desires for quality and promptness – Minimizing current out-of-pocket costs • Common surrogate objectives that are easier to quantify – Minimize the makespan (the throughput time for a defined set of jobs) – Minimize total (or average weighted ) tardiness (the time by which the completion time surpasses the due date) – Minimize the maximum tardiness – Minimize the number of tardy jobs • The weighted tardiness is obtained as the product between the tardiness value and the importance weight of the job in question 36 Scheduling Based on Job Characteristics (III) • Commonly used priority rules are – First-In-First-Out (FIFO) – scheduling according to arrival times – Earliest-Due-Date first (EDD) – Shortest Processing Time first (SPT) (See example illustrating the application and effect of the different rules) • Observations for a single server situation – EDD render the optimal solution to the problem of minimizing the maximum tardiness – SPT render the schedule that minimizes the average throughput time per job for a given set of jobs 37 Scheduling Based on Job Characteristics (IV) Moore’s Algorithm • A method for minimizing the number of tardy jobs, when all jobs are considered equally important 1. Order the jobs according to the EDD rule. 2. Stop if no jobs are tardy – the optimal solution is found! Go to step 6. 3. Find the first tardy job in the sequence. 4. Assuming that this tardy job is the kth in the sequence. Find and remove job j (j=1, 2, 3, …, k) with the longest processing time. 5. Revise the completion times and return to step 2 6. Insert the removed jobs at the end of the sequence in the order they were removed • See example illustrating the application of Moore’s algorithm 38 Workflow Design Principles and Tools (XI) Minimize the number of multiple paths through the process • Reduces complexity and confusion – Simplifies resource management and scheduling – Fewer jobs are routed the wrong path and need to be rerouted or reworked • One way of reducing the number of paths without compromising the efficiency and customization ability is to use case teams, i.e., horizontal compression of work flow 39