Not Just in Time Revisited

advertisement

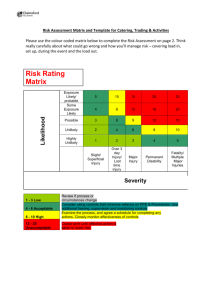

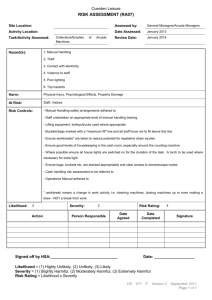

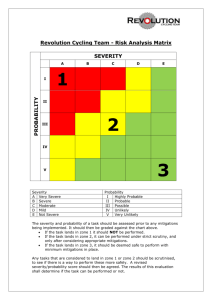

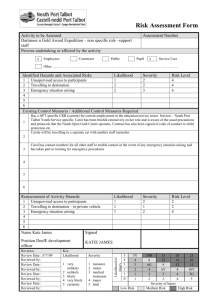

JUST IN CASE NOT JUST IN TIME Greg Hutchins PE Quality Plus Engineering 800.COMPETE or 503.233.1012 GregH@QualityPlusEngineering.com Who is Greg Hutchins? Principal with Quality Plus Engineering (Q+E), Portland Oregon based supply and project management company. Q+E is US Department of Homeland Security Certified/Designated for Critical Infrastructure Protection: Forensics, Assurance, Analytics™ Addresses: – www.QualityPlusEngineering.com – www.ValueAddedAuditing.com – Gregh@europa.com or GregH@QualityPlusEngineering.com – 800.COMPETE Author of ISO 9000 (Wiley, translated into 8 languages), Standard Manual of Quality Auditing (Prentice Hall/ASQ), and Value Added Auditing (WIT) ASQ/IEEE/PMI Columnist My Mission Critical Objective Today: 1. 2. 3. 4. Global sourcing Changing sourcing rules Supply risk management Future of supply management 1. Global Sourcing Today’s Business Model Aerospace and auto companies business model: Design Product Outsource (up to 85% of manufacturing $) Assemble Test Manage their brand Today’s Business Model Impacts Supply Risk Sara Lee Corporation plans to sell its noncore factories. It will focus on its core strengths, specifically developing new products, managing its brands, and increasing market share. Sara Lee will outsource commodity manufacturing and other non-core activities and only retain its ‘highly proprietary’ processes. In other words, it plans to focus on ‘what it does best.’ Recent Supply Chain Articles “Quake Disrupts Key Supply Chains” “Stress Test for the Global Supply Chain” “Long Pause for Japanese Industry Raises Concerns About Supply Chain” “Japan Quake Likely to Affect Business Globally” 2. Changing Sourcing Rules From Just in Time to Just in Case Discussion Just in Time – Lean supply chain – No buffer inventories Just in Case – What if – Risk analysis – Buffer inventories From Single Source to Multiple Sources Discussion Single sourcing makes a lot of sense and offers value However, single source can result in supply risks – Earthquake in China All eggs in one basket No diversification of risk From Single Source to Multiple Sources Discussion Single sourcing makes a lot of sense and offers value However, single source can result in supply risks – Earthquake in China All eggs in one basket No diversification of risk From Price to Risk Based Decision Making Discussion Price or cost has been traditional method of selecting suppliers Now, risk is becoming critical component of selecting suppliers From Looking Backward to Looking Forward Discussion Quality has compliance flavor – Historical focus – Past performance Risk management – Future focus – ‘What if’ analyses From Supplier Trust to Supply Verification Discussion Supplier trust is based on: – Long term, mutually beneficial relationship – Good products supplied Supplier verification – More audits – Trust but verify From Quality Audits to Risk Audits Discussion Quality Audits – ISO 9000 – Compliance based (still) Risk Audits – ‘What if’ audits – White space gaps and risks in supply chain 3. Supplier Risk Management That’s Nice, What Do I Do Now? This Is How You Start! 1. 2. 3. 4. 5. 6. 7. 8. Determine management’s appetite for risk. Identify supply chain risk events. Analyze risk events and assign risk vectors for likelihood and severity. Quantify: determine risk products and prioritize. Begin working with highest risk products (RP). Determine appropriate controls. Implement and monitor risk controls. Manage risks by monitoring and repeating the process. This is Supply Chain Risk Management! Two Risk Definitions Risk – The possibility that an event will occur and adversely affect the achievement of objectives. COSO, Enterprise Risk Management Framework, web, 2003. Risk – A situation or circumstance, which creates uncertainties about achieving program objectives. FAA Programmatic Risk Management, 2002, p. 6. Risk Appetite: Are You a Risk Taker? Risk Identification Process 1. 2. 3. 4. 5. Flowchart the overall supply chain and sub processes. Identify critical supply chain system, process, and production activities. Determine likelihood of unwanted variation (risk events). Identify which sources of variation represent higher severity. Determine risk product profile. Supply Chain Risk Events Early/late shipments or delivery to wrong location Non-conforming/wrong product or quantity Supplier processes Sole source supplier Undesirable events (storm, flood, earthquake, etc.) Contract, legal and regulatory non-conformance. Information system failure and compromises Supplier country political stability Risk Continuum High Likelihood Low Low Severity High Sample Risk Profile for Late or Non-Delivery High Likelihood Specialized Electronic Chips in Household Appliances Off Shore Supplier Low Likelihood Maintenance, Repair and Operational (MRO) Supplies Domestic supplier Low Severity Specialized Electronic Chips in Regulated Products Off Shore Supplier Fasteners in Regulated Products Domestic Supplier High Severity Likelihood of Occurrence Descriptor Highly Probable Probability >75% Rank High Value 5 Probable >50%<75% Medium High 4 Occasional >25%<50% Medium 3 Remote >10%<25% Medium Low 2 Improbable <10% Low 1 Consequence or Severity of Impact Descriptor Rank Value Catastrophic High 5 Critical Medium High 4 Serious Medium 3 Marginal Medium Low 2 Negligible Low 1 Risk Product Profile Severity of Impact Likelihood Highly Probable Probable Occasional Remote Improbable Negligible Marginal 1x5= 2x5= 5 1x4= 10 2x4= 4 1x3= 8 2x3= 3 1x2= 6 2x2= 2 1x1= 4 2x1= 1 2 Serious 3x5= 15 3x4= 12 3x3= 9 3x2= 6 3x1= 3 Critical 4x5= Catastrophic 5x5= 20 4x4= 25 5x4= 16 4x3= 20 5x3= 12 4x2= 15 5x2= 8 4x1= 4 10 5x1= 5 Risk Product (RP) Severity of Impact Likelihood Highly Probable Probable Occasional Remote Improbable Negligible Marginal 1x5= 2x5= 5 1x4= 10 2x4= 4 1x3= 8 2x3= 3 1x2= 6 2x2= 2 1x1= 4 2x1= 1 2 Serious 3x5= 15 3x4= 12 3x3= 9 3x2= 6 3x1= 3 Critical 4x5= Catastrophic 5x5= 20 4x4= 25 5x4= 16 4x3= 20 5x3= 12 4x2= 15 5x2= 8 4x1= 4 10 5x1= 5 High Level SC Risk Matrix Severity of Impact Likelihood Negligible Marginal Serious Critical Highly Probable Pending legislation adds 2 days to on- dock time Probable Non-ISO verified vendors Non-ISO certified vendors Key component delivery late 26% Critical component lost shipments Occasional Remote Improbable Nationaliza -tion of MRO supplier Catastrophic Sole source vendor in tornado alley Develop Strategy: Control Risk Develop Strategy: Accept Risk Develop Strategy: Avoid Risk! “Would you please elaborate on ‘then something bad happened’?” 4. Future of Supply Management Takeaways! Outsourcing increases risk. Leaning of supply chains increases risk. Data chain management increasingly more important (not only chain of custody, but data transferred from system to system). Higher levels of independent verification and validation required. Third party risk assessment of vendors is critical. Takeaways Managing risk is increasingly important and necessary to compete and survive. Terrorism, natural disasters, computer system compromises, are all on the rise. – DHS is developing risk management system Risk based system for import safety SCM professionals are key to an enterprise’s risk management. Be proactive; predict, prevent, and preempt risks. Know Your Risks Before Fishing (Offshoring and Outsourcing)! The Bottom Line “I think we now live in an era when many of the concerns in running organizations are being reframed in terms of risk, which suggests that risk professionals are likely to rise to the top.” Source: ‘Managing Risk in the New World,’ Harvard Business Review (HBR), October, 2009, p. 75. QUESTIONS? THANK YOU FOR INVITING ME! Greg Hutchins Engineering Principal Quality Plus Engineering, LLC 800.COMPETE