Product Design - Department of Chemical Engineering

advertisement

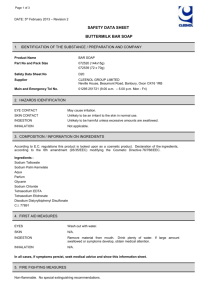

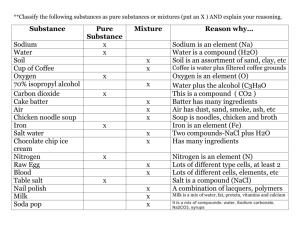

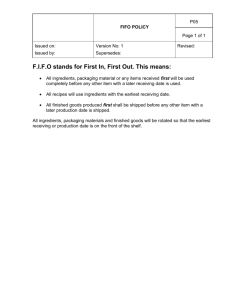

Product Design 25% of ChE’s work on Products, not Processes Chapter 1, 2 Article on Product Design CH EN 4253 Terry A. Ring ChE Education Chemical Products Products Are Everywhere • But, how are they designed? – Formulated Products – Engineered Products • Let’s look at some examples. – – – – – – What are the ingredients? What are the ingredients used for? What are the characteristics of the product? What is the science behind the product? Why is this product desirable? Why does the product sell? Engineered Products • Hemodialysis Device • Hand Warmer – Fe Powder • Heat Patch – Fe + C Powders • • • • Solar Desalination Unit for Home Zap Pak – Heat Pack Aroma/Insect Repellant Wall Plugs Alcohol Fuel Cells Hemodialysis Device Hemodialysis • Counter Current (Shell & Tube HX design) Membrane – Blood – DI Water • Series of Resistances – Mass Transfer • Blood • Water – Diffusion in Membrane • Urea • Byproducts Home Desalination Unit • Transparent Cover – Allows Sunlight in – Condenses Vapor H2O Salt Sol’n Heat Patch/Hand Warmer • 4Fe(s) +3 O2Fe2O3 + ΔH – ΔH = -824.2 kJ/mol oxide – Graphite (dilutent+ shelf life) – NaCl “Catalyst” – Control Kinetics of Reaction Zap Pack • Heat of Crystallization – NaC2H3O2*3H2O -4.7 kcal/mole – Na2S2O3*5H2O -11.4 kcal/mole – Ca(NO3)2*4H2O -8.0 kcal/mole Solid Cl Meta-stable Solid-Liquid Line eq Zap Pack Step1: Activate by flexing metal disc Step 2: Liquid crystallizing and heating Step 3: Pad is hot and ready for use The clever bit is that the reaction is reversible by just boiling the thing in water Air Freshener • Oil mixture • Heated – Selective Evaporation of oil mixture – Partial Pressure as a function of Temperature Direct methanol Fuel Cell • PEM Fuel Cell – With Special Catalyst • Anode (oxidation) Formulated Products • Let’s look at some examples. – – – – – – What are the ingredients? What are the ingredients used for? What are the characteristics of the product? What is the science behind the product? Why is this product desirable? Why does the product sell? Formulated Products • • • • • Toothpaste Shampoo Deodorant Mouthwash Dish soap Active Ingredients – Sodium monofluorophosphate 0.76% • Inactive Ingredients – – – – – – – Glycerin Sorbitol Hydrated silica Propylene glycol Sodium bicarbonate Aluminum oxide Water – – – – – – – – – – Pentasodium triphosphate Tetrasodium pyrophosphate Sodium lauryl sulfate Flavor sodium hydroxide calcium peroxide Sodium saccharin Carrageenan cellulose gum titanium dioxide Note; Bingham Plastic Rheology • Active Ingredients – Sodium fluoride 0.24% • Inactive Ingredients – – – – – Water Glycerin Sorbitol Hydrated silica Pentasodium triphosphate – Sodium lauryl sulfate • Flavor • Tetrasodium pyrophosphate • PVM/MA copolymer • Sodium hydroxide • Cellulose gum • Sodium saccharin • Carrageenan • Polyethylene • Titanium dioxide • FD&C blue no. 1 • Active Ingredients – Sodium fluoride 0.25% • Inactive Ingredients – – – – – Sorbitol Sodium bicarbonate Hydrated silica Glycerin Water – Tetrasodium pyrophosphate – Sodium lauryl sarcosinate – Flavor – Sodium saccharin – Cellulose gum – Sodium lauryl sulfate – Titanium dioxide Mouthwash • Active Ingredients – Thymol 0.064% – Eucalyptol 0.092% – Methyl Salicylate 0.006% • oil of wintergreen – Menthol 0.042% • Also Contains – – – – – – Water Alcohol 26.9% Benzoic Acid Poloxamer 407 Sodium Benzoate Caramel Definitions • Disinfectants – antimicrobial agents that are applied to non-living objects to destroy microorganisms. • Kill > 99.9999% • Sanitizer – substances that reduce the number of microorganisms to a safe level. One official and legal version states that a sanitizer must be capable of killing 99.999%, known as a 5 log reduction, of a specific bacterial test population, and to do so within 30 seconds. • Antiseptics – Antiseptics destroy microorganisms on living tissue. Deodorant • Active Ingredients – Aluminum Zirconium Tetrachlorohydrex glycin complex • Inactive Ingredients – – – – – – – – – – Water Cyclomethicone SD alcohol40 Tripropylene glycol Dimethicon Propylene Glycol Phenyl trimethicone PEG/PPG-18/18 Dimethicone Fragrance Shampoo • Ingredients – – – – – – – – – – – – – – – Water PEG-80 Sorbitan laurate Cocamidopropyl betaine Sodium trideceth sulfate Glycerin Lauroamphoglycinate PEG-150 distearate Sodium laureth-13 carboxylate Fragrance polyquaternium-10 Tetrasodium EDTA Quaternium-15 Citric Acid D&C Yellow No. 10 Orange No. 4 Shampoo • Ingredients – – – – – – – – – – – – – – – – – – Water Ammonium Lauryl sulfate Ammonium laureth sulfate Ammonium chloride Cocamide MEA Fragrance PEG-5 cocamide Hydroxypropyl methylcellulose Tetrasodium EDTA DMDM hydantoin Citric Acid Tocopheryl Acetate (Vitamin E Acetate) PPG Methylchloroisothiazolinone Apple Extract Ethylisothiazolinone Glycerin FD&C Yellow No. 5, Blue No. 1 Body Shop Natural Shampoo • Ingredients – – – – – – – – – – – – Water Sodium Laureth sulfate Cocamidoproply betaine Cvocamide DEA Coco-Glucoside Perfume Phenoxyethanol laureth-2 Benzyl Alcohol Sodium Benzoate Propylene glycol Citric Acid Polyquarternium-10 – – – – – – – – – – – – Methylparaben Agave extract Benzophenone-4 Disodium EDTA Bladderwrack powder Butylparaben Ethylparaben Isobutylparaben Propylparaben Potassium sorbate Peony Extract D&C No. 5 Packaging attracts the customer • Package Needs – – – – – Name of Product Sales Pitch How to use Warnings Size (wgt. or vol.) of package – Ingredients List – Product Safety Info. – Who to call for info. and Help Product Characteristics • • • • Color Taste Smell Feel – Rheology – Surface tension – Adhesion • Other • What makes the product desirable? – To whom? • What is the product’s competition? • What makes it better than the competition? • What makes it profitable? – Price to produce? – Cost of marketing – Profit margins • Middle men (Sales Reps.) • Retail Outlet Ingredients • Commercial Availability • Necessary for the • Multi-source formulation? • Quality • What Concentration? – Impurities • Any difficulty in the • Price • Quantities Available process? – Packaging – Easy to mix – Packaging made easy • Anti-ageing – Shelf life Product Description • • • • Quality Factors Use Factors Materials Factors Process Factors Chemical Product Pyramid Figure of Merit Drug Cream Formulation Shear force during application Drug Cream Formulation • Ingredients – – – – – – Drug Oil - dissolves drug Water Surfactant to stabilize emulsion Fragrance Preservative – keeps bacteria from growing in formula Drug Cream Figure of Merit • Interest Factors – Drug moves from oil in emulsion through water phase into blood – J=(D/δ)(Co/Kd-0) – Kd=Co/Cw – δ=(μe Vhand Whand/(2 Papp))1/2 – Easy to apply Fick’s 1st Law Distribution Coeff Reynolds’ Equation Lubrication theory – Friction Coefficient = (μe Vhand /(2 Papp Whand))1/2 – Figure of Merit = High Flux, low friction 2 DC o Papp (D/ )(C o / K d ) FM 1/2 ( e Vhand /(2 Papp Whand )) K d e Vhand FM Values • • • • Formulation Formulation 1 Formulation 2 Formulation 3 FM 0.1 120 2 Cost ($/kg) 20 82 22 Example-1 • Ice Cream – Quality Factors • Flavor • Creaminess • Smoothness • Coldness • Flavor controlled by – Ingredients • Partial Pressure of Flavinoids to Nose • Creaminess – Controlled by • processing conditions • Ingredients • Smoothness – Controlled by – Processing condition • Ice Crystals less than 100 microns – Ingredients • Fat, air bubbles • Coldness – Controlled by – Product Temperature Example - 2 • Fragrance – Olfactory Factors – Quality factors • Impact (in first moments) - relative volatility and sensitivity of nose (detection threshold) • Diffusion distance soon after opening • Tenacity - distance long after opening • Volume – how many of different sensors in nose are affected long after opening Process to develop a New Product • Stage Gate Methodology – Set targets that the Product must meet • E.g. New Refrigerant must have Carnot efficiency of X% or coefficient of performance of Y% • Meet target with several new refrigerants by given date • New refrigerant must not be corrosive to materials of construction –corrosion tests done by given date • New refrigerant can be used for a long time with certain polymer seals – lifetime tests done by given date • Environmental disposal questions settled by given date • Impact on Ozone in high atmosphere settled by given date Production costs evaluated by given date Potential price and sales volume evaluated by marketing department by given date EPA (or other government agency) Registration Build plant to manufacture investment funding, design, construct, debottleneck, run Steps allow go/no go decisions by management at various Stage Gate Reviews After a production process is running • Program of quality control and constant product improvement • Six Sigma • ISO-9000 Cost of Defects • Six-Sigma – No. of defects per million • 3.4/million (6 sigma) • 1,350/million (3 sigma) • 308,770/million (1 sigma) • Costs – Single product – Assembled product • Failure per part • Total Failure of Assembly – Importance of Failure » Shampoo » Car » Spaceship • Costs – Lost production • cost to produce • Rework cost – Lost Sale • Ship back cost • Loss of Customer – Failure in Service • Damage to property • Personal Injury • Lost of Life 6 sigma design • Define Project (Gantt Chart) – Steps – Time needed • Allocate Resources • Identify Product Requirements • Select Product Concept • Develop Product Design – Test Competing Designs – Plan Product Manufacture • Quality Assurance • Estimate process Variance – determine sigma • Implement Design – Pilot Scale • Verify Manufacturability • Verify Quality • Verify Profitability – Full Scale Getting a Product Approved • FDA – Foods – Drugs • DOT – Shipping • Spills • fires – MSDS • EPA – Disposal or spill • Waste water • Air quality MSDS • • • • • • • Section I. Material Identification: Chemical Name Copper sulfate penta-hydrate CAS# 7758-99-8 Wt% 5 Comments: Product is an aqueous solution of copper sulfate and also contains stabilizing agents. Section II. Physical Data • • • • • • Physical State: Blue-green liquid Boiling Point: 212 F (100 C) Melting Point: Not applicable Specific Gravity: 0.995 Solubility in water: Not Applicable Solubility in other solvents: Soluble in methanol, glycerol and ethanol. • Appearance: Blue-green liquid. • Odor: Odorless Section III. Fire and Explosion Data • Flash Point: Not applicable • • Flammability Limits: Not Flammable. If heated and boiled away to crystals, it can decompose above 400 C and emit toxic copper oxide and sulfur fumes. Above 500 C it emits SO2 fumes. • • Extinguishing Media: Does not burn or support combustion. Use water, CO2 or dry chemicals. • • Special Fire Fighting Instructions: If water is used it will be contaminated with copper sulfate and care should be taken to be such water out of streams and other bodies of water. • • Fire and Explosion Hazards: None Section IV. Reactivity Data • Stability: Stable • Conditions to Avoid: Dilution of product into streams or other bodies of water. • • Incompatibility: Solution is mildly corrosive to steel. Store solution in plastic or rubber or 304, 347 or 316 stainless steel. • • Hazardous Decomposition Products: None at normal conditions. If dried crystals are heated above 400C toxic fumes of copper oxide and sulfur may evolve. • • Polymerization: Will not occur. Section V. Health and Hazard Information • Swallowing: Toxic orally in accordance with FHSLA regulations. Oral toxicity LD59 (male rats) = 3.44 gm/kg. • • Skin: Non-toxic. Avoid contact with skin. Non-irritant (rabbit) • • Eyes: Causes moderate, but temporary eye irritation. • • Inhalation: Inhalation of mist may cause irritation to the upper respiration tract. • • Carcinogenicity: None as per NTP, OSHA and IARC Section VI. First Aid Procedures • Swallowing: Give large amounts of milk or water. Induce vomiting. Call Poison Control Center or a physician. • • Skin: Wash thoroughly with soap and water. Remove and wash contaminated clothing before reuse. • • Eyes: Immediately flush eyes with plenty of water for 15 minutes. Hold eyelids apart during irrigation. Call physician. • • Inhalation: Remove person to fresh air and call a physician. • • Carcinogenicity: None Section VII. Handling Precautions • Personal Protective Equipment: Chemical Safety Goggles Rubber gloves and rubber apron may be worn. • • Ventilation: TWA = 1 mg/l for copper sulfate. When TWA exceeds this limit in the work place, provide appropriate ventilation. Wear an approved respirator for mists: MSHA/NIOSH approved number prefix TC-21C, or a NIOSH approved respirator with any R, P or HE filter. • • Alternatively, provide respiratory protection equipment in accordance with Paragraph 1910.134 of Title 29 of the Code of Federal Regulations. Section VIII. Environmental and Disposal Information • Aquatic Toxicity: – – – • • • • • • • LC50, 24 hours, Daphnia magna = 0.182 mg/l. Rainbow trout = 0.17 mg/l. Blue Gill =1.0 mg/l. All values are expressed as Copper sulfate pentahydrate. Test water was soft. Spills and Leaks: Comply with Federal, State and local regulations on reporting spills. Do not wash away spilled solution. Collect and treat solution by reacting with soda ash to form an insoluble copper carbonate solid that can be scooped up. Waste Disposal: Comply with Federal, State and local regulations on waste disposal. React solution with soda ash to form an insoluble copper carbonate solid that can be disposed of in an approved landfill. Environmental Effects: May be dangerous if it enters public water systems. Follow local regulations. Toxic to fish and plants. Fish Toxicity critical concentration is 235 mg/l and plant toxicity is 25 mg/l both expressed as copper sulfate pentahydrate. Section IX. Special Precautions • Storage:Store in a cool, dry, wellventilated area. Do not freeze. • • Other Precautions: Keep this product and all other chemicals out of children’s reach. Section X. Regulatory Information Section XI. Shipping Information • DOT Shipping Name: Corrosive Liquid, N.O.S. (Contains copper sulfate). • Primary Hazard Class/Division: 8 • UN/NA number: 1760 • Packing Group: III • Marine Pollutant ERG 171. Section XII. Other Information • NFPA Codes: • Health:2 Fire: 0 Reactivity: 0 • • HMIS Codes: • Health: 2 Fire: 0 Reactivity: 0 Protection: B • • Section XIII. MSDA Preparation Information Product Innovation Equation • Innovation = insight + ideas + impact • Companies are increasingly making innovation part of their culture and corporate strategy. • Ideas need SUN behavior – Suspend judgment, Understand the idea, Nurture it along