Personal Protective Equipment (PPE)

Personal Protective Equipment

(PPE)

1

Purpose of PPE

To protect employees from hazards not eliminated from the workplace

2

Protective Equipment

Personal protective equipment

–

–

–

–

Eyes

Face

Head

Extremities

Protective clothing

Respiratory devices

Protective shields and barriers

3

Design and Condition

Safe design and construction for work performed

Sanitary and reliable condition

–

–

–

Provided

Used

Maintained

Laundered

Repaired

Replaced

Defective and damaged equipment shall not be used

Must properly fit users

4

Purchase of PPE

The employer is normally responsible for the cost of personal protective equipment.

PPE used by trades may be an exception

5

Protect Against Hazards

–

–

–

Hazards

Physical

Chemical

Biological/Infectious

Capable of causing injury or impairment in the function of any part of the body through

(routes of entry)

–

–

–

–

Inhalation

Skin absorption

Ingestion

Contact with skin and/or eyes

6

Required Implementation

Engineering Control

–

–

–

–

Ventilation

Isolation

Selected Equipment

Redesign process or procedure

Administrative Control

–

–

–

–

–

Personal Hygiene

Maintenance

Hand washing

Scheduled breaks

Assignment schedules

7

Certified Hazard Assessment

Prepared by

–

–

Consultant

VA Personnel

Insert - date of written hazard assessment

Insert - how to obtain a copy of the written hazard assessment

Required by 29 CFR 1910.132d

8

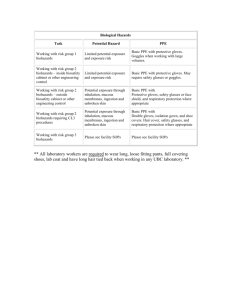

Overview of Hazard

Assessment

Bloodborne pathogens

–

–

Latex gloves

Gown

–

–

Safety glasses

Hand washing

Handling trash

– Rubber gloves

– Safety shoes

Shops

–

–

–

Safety glasses

Safety shoes

Hearing protection

Facilities

–

–

–

Rubber gloves

Non-slip shoes

Safety glasses (when mixing detergents)

9

Reassessment of Hazards

Facility safety officer is responsible to reassess workplace hazards as necessary by:

–

–

–

Identifying and evaluating new equipment and processes

Reviewing accident records

Re-evaluating the suitability of previously selected PPE

10

Personal Protective Equipment

Program

Defined by insert appropriate facility policy

–

–

–

–

Ordering

Repair

Maintenance

Other requirements

11

Occupational Safety and Health

Administration (29 CFR 1910)

General Requirements --

Eye and Face Protection --

Respiratory Protection --

Head Protection --

Foot Protection --

135

Electrical Protection --

132

133

134

136

137

Hand Protection --

Hearing Protection --

138

95

Specialized Standards -- e.g., 1030

12

Eye and Face Protection

(29 CFR 1910.133)

13

Hazards to Eyes/Face

Physical

–

–

–

Flying Particles

Molten Metal

Potentially Injurious

Light Radiation

– Ultraviolet (UV) light

Chemical

– Gases or Vapors

–

–

Liquids

Acids or Caustics

Biological/Infectious

–

–

–

–

–

Blood

Saliva

Semen

Body Tissue

Wastes

–

–

Animal Tissue

Potentially Infectious

Materials

14

Safety Glasses

Can be used with side shields (Required if flying objects are present)

Plastic

–

–

Can fit over corrective lenses

Can be worn alone

Can accommodate most types of prescriptive lenses

15

Goggles

Should fit face snugly (sealing entire eye area)

Specially-coated lenses or ventilation holes may prevent fogging

Anti-fogging materials can be used

When removing goggles, tilt head down so that debris on top of goggles does not fall into eyes

16

Other Eye and Face Protection

Face Shields

–

–

–

Worn for extremely hazardous jobs

Worn with safety glasses or goggles

Do not completely protect face

Hoods

–

–

Protect entire head and face

Can be worn with respirators

Sunglasses

–

–

–

–

Provide protection against sun

Should filter 99 to 100 percent UV

Provide no protection against flying objects

Can reduce chances of cataracts

17

Inspection and Maintenance of

Eye and Face Protection

Must be kept clean

Must be free of scratches and other defects that may obstruct vision

Must be disinfected

–

–

Periodically, if used by same person

After each use, if shared

Headband should be replaced when slack, worn, or dirty

18

Eye Safety

Review Material Safety Data Sheets (MSDSs) for chemicals used

–

–

Identify eye protection required

Become familiar with emergency response procedures

Contact Lenses

–

–

Do NOT provide protection

Should NOT be worn around chemicals or chemical vapors

19

Laser Eye Safety

Follow guidance of laser manufacturer

Wear safety glasses with filters that protect against the wavelength of light for the laser being used

Partial reflections from Class IV lasers can cause permanent eye damage

20

Head Protection

(29 CFR 1910.135)

21

Hazards to Head

Falling or flying objects

Electrical conductors

Contamination from bloodborne pathogens

Sunburn and sunstroke

Cold temperatures

22

Types and Classes of

Head Protection

Types of protective hats

–

–

Type 1, Helmets - full brim (at least 1.25”)

Type 2, Brimless helmets with peak extending forward from the crown

Classes of industrial head protection

–

–

Class A, General service - limited voltage protection

Class B, Utility service - high voltage protection

– Class C, Special service - no voltage protection

23

Hard Hats (Class A)

Hard exterior shell

Shock-absorbing lining

–

–

Headband

Crown straps

Protects against impact hazards

Used in construction

24

Electrical Bump Hats (Class B)

Protects against impact and penetration

AND against high-voltage shock or burn

Can be used where there is a possibility of bumping against a fixed object

Used by electrical workers

Sometimes used in construction

25

Other Head Protection

Safety Hat or Cap

(Class C)

–

–

–

Protects against impacts

Provides lightweight comfort

Provides no electrical protection

Hat or Cap

–

–

–

Protects against exposure to sun (4 inch brim)

Protects against exposure to cold (ear flaps)

Generally not considered PPE

26

Specialized Head Protection

Hairnets

–

–

Food service employees

Sanitation and cleanliness

Hoods

–

–

–

Can be used in extremely hazardous situations

Can be used with respirators

Can provide eye and face protection

Surgical Caps

–

–

Infection control and cleanliness

Worn during medical procedures that involve large amounts of blood

Autopsies

Orthopedic surgery

27

Inspection and Maintenance of

Head Protection

–

–

–

–

–

–

Damage

Dents

Cracks

Penetration

Abuse

Mutilation

Other damage that might reduce the degree of protection provided

Visually inspect daily

Clean periodically

May adversely affect protection provided

–

–

–

Paint

Sunlight

Extreme temperatures

28

Foot Protection

(29 CFR 1910.136)

29

Foot Hazards and Protection

Hazards to Feet

–

–

–

–

Falling or rolling objects

Objects that pierce the sole

Electrical exposures

Slipping

Foot Protection

–

–

–

–

–

Safety Shoes

Slip Resistant Soles

Shoe Covers

Rubber or Synthetic

Boots

Leather Work Boots

30

Safety Shoes

Steel-reinforced toe (protects foot from being pierced or crushed)

Puncture-resistant or heat-resistant soles

(optional)

Metal-free non-conductive materials

(working around exposed electrical conductors)

31

Other Foot Protection

Boots

–

–

Rubber/Synthetic

May be required when working around chemicals

Autopsies

Leather

Recommended for outdoor maintenance activities

Avoid wearing around chemicals

Shoe Covers

– May be required for some medical procedures

Slip-resistant Soles

–

–

OSHA recommends

Will reduce the number of injuries resulting from slips, trips, or falls

32

Electrical Protection

(29 CFR 1910.137)

33

Electrical Protective

Equipment (Insulated Rubber)

Required when exposed to electrical hazards

–

–

–

–

–

–

Blankets

Matting

Covers

Line hose

Gloves

Sleeves

Maintained in a safe and reliable condition

Cleaned as needed

Requires periodic electrical testing

34

Inspections

Before each day’s use

Following any incident that caused damage

Insulating properties cannot be degraded

Insulating equipment failing to pass inspections or electrical tests may not be used unless specific requirements are met

Cannot use equipment with:

–

–

–

–

Hole, tear, puncture, or cut

Ozone cutting or ozone checking

Embedded foreign objects

Swelling, softening, hardening, stickiness, or inelasticity

35

Storage

Location and manner of storage must protect from:

–

–

–

–

–

Light

Temperature extremes

Excessive humidity

Ozone

Other injurious substances and conditions

36

Hand Protection

(29 CFR 1910.138)

37

Hand Protection

–

–

–

–

–

Provided to protect against

– Absorption of harmful substances

Severe cuts or lacerations

Severe abrasions

Punctures

Chemical or thermal burns

Harmful temperature extremes

–

–

–

–

Types of hand protection

–

Machine guards

Electric eyes

Push sticks

Controls requiring two hands

Gloves

38

Glove Selection Criteria

Selection based on evaluation of performance characteristics

–

–

–

–

Task(s) to be performed

Conditions present

Duration of use

Hazards and potential hazards identified

Selection based on individual characteristics

–

–

–

–

–

Grip

Dexterity

Flexibility

Hand size

Glove length

Too tight - may rip

Too loose - affects grip and comfort

39

General Purpose Gloves

Cotton

–

–

–

Can be specially coated

Allows handling of delicate components

Absorbs oil

Leather

–

–

–

Rough surfaces

Heat

Sparks

Protect against

–

–

–

–

–

Abrasion

Cuts

Punctures

Snags

Temperature extremes

40

Cut-resistant Gloves

Designed for use with sharp knives and blades

May contain

–

–

–

Cut-resistant yarns

Composite materials

Metal mesh (Required of most meatcutting and de-boning operations)

Protect against

–

–

Cuts

Abrasion

Some may protect against punctures

41

Special Purpose Gloves

Surgical

Examination

Firefighters

Smelters

Welders

Clean rooms

Protect against specific hazards

–

–

HIV/Hepatitis

Heat and burns

– Patient protection

42

Latex Gloves

Natural

–

–

–

–

Required for surgery

Can be used for examinations

Label NOT required

Hypoallergenic gloves

NOT tested for natural rubber proteins

(source of latex allergies)

Synthetic

–

–

–

Cannot be used for surgery

Can be used for examinations

Label NOT required

43

Chemical-resistant Gloves

Must be selected for the specific chemical used

(Consult manufacturer’s guidance)

Non-porous

Selection based on

–

–

–

Potential toxic effects of chemicals used

Likely routes of entry

Degree of hazard

Protect against

–

–

–

Dermatitis

Chemical burns

Cancer

Resist

–

–

–

Penetration

Permeation

Degradation

44

Penetration

Natural rubber

–

–

Protects against liquids that mix with water

Provides no protection against petroleum or oil-based solvents

Synthetic rubber resists

–

–

Oils

Greases

–

–

–

Acids

Caustics

Many petroleum products

45

Permeation

Must consult manufacturer’s technical data for specific chemical used

No protective barrier provides permeation protection for all chemicals

Often coated with

–

–

–

–

Polyvinyl chloride

(PVC)

Nitrile

Neoprene

Latex

46

Degradation

Signs of degradation

–

–

–

–

Stiffer

More brittle

Softer

Weaker

Major indication that gloves should be replaced

Inspect before each use

–

–

Rips

Holes

–

–

Weak seams

Imperfections

47

Hand Safety

Do NOT wear gloves that are damaged

Clean off contaminants before you remove gloves

Remove gloves safely

Properly decontaminate and store gloves

Monitor the condition of your gloves as you work

Follow manufacturer’s guidance for maintenance and storage

Dispose of gloves properly

48

Skin Protection

49

Hazards to Skin

Hazards

–

–

–

–

–

Sunburn

Skin Cancer

Dermatitis

Poison ivy, oak, sumac

Insect and animal bites

Protections available

–

–

–

–

–

Protective clothing

Sunscreen

Insect repellent

Scheduling of work

Ointments

50

Prevention of Sun Damage

Avoid the sun’s strongest rays

(10 a.m. - 4 p.m.)

Wear protective clothing

–

–

Broad-brimmed hats

Long pants

– Long-sleeved shirts

Wear sunglasses

(99 - 100% UV ray protection)

Always wear a sunscreeen with SPF of 15 or more

Avoid sunlamps, tanning beds, and tanning parlors

51

Torso Protection

52

Hazards to Torso

Hazards

–

–

–

–

–

–

Heat

Splashes from hot metals and liquids

Impacts

Cuts

Acids

Radiation

53

Types of Protection

Options

–

–

–

–

–

–

–

Vests

Jackets

Aprons

Coveralls

Full body suits

Lead lined coverings

Gowns

Materials

–

–

–

–

–

Fire retardant wool

Specially treated cotton

Leather

Rubberized fabrics

Disposable suits

54

Lifting or Back Belts

Must follow manufacturer’s guidance

Back belts can be obtained by contacting

55

Appropriate PPE for Exposure to Bloodborne Pathogens

Does NOT permit blood or other potentially infectious materials to pass through to

–

Employee’s work

– clothes

Employee’s street clothes

– Undergarments

Under normal conditions of use

Does NOT permit blood or other potentially infectious materials to reach

–

–

Skin

Eyes

–

–

Mouth

Other mucous membranes

For the duration of time to be used

56

PPE for Bloodborne Pathogens

Gloves

Gowns or aprons

Laboratory coats

Face shields or masks and eye protection

Goggles or glasses with side shields

Mouthpieces

Surgical caps or hoods

Shoe covers or boots

Clinic jackets

Resuscitation bags

Pocket masks

Other ventilation devices

57

Gloves Required for Exposure to Bloodborne Pathogens

When reasonably anticipated that employee may have hand contact with

– Blood

–

–

–

Other potentially infectious materials

Mucous membranes

Non-intact skin

When performing vascular access procedures

When handling or touching contaminated items or surfaces

58

Hearing Protection

(29 CFR 1910.95)

59

Hearing Protectors

If exposed to 85 dB or greater for eight-hour

TWA:

–

–

Hearing protection must be available

Hearing protection must be worn if

No baseline audiogram has been established

Hearing threshold has changed an average of 10 dB or more at 2000,

3000, or 4000 hertz in either ear

Must be worn if:

Duration Sound Level

(hours per day) (dBA)

4

3

2

8

6

90

92

95

97

100

1.5

1

0.5

0.25 or less

102

105

110

115

60

Locations Requiring

Noise Protection

Building #

–

–

–

Room ###

Mechanical room

Penthouse

Building #

–

–

Room ###

Shop area

Building #

– Insert appropriate locations

Building #

– Insert appropriate locations

61

Types of Hearing Protectors

Earplugs

–

–

–

–

–

Lightweight

Comfortable for long periods of time

Made of soft fibers or foam

(self-forming)

Disposable or reusable

Performed, pre-molded, or custom molded

Earmuffs

–

–

–

–

Easily put on or removed

Require entire ear to fit inside cup (seal)

May interfere with glasses or goggles

Can be designed for use with hard hats

62

General Considerations

Proper initial fit required

Must be used correctly

Must receive training in the use and care of hearing protectors provided

Must be allowed to select hearing protectors from a variety of suitable hearing protectors provided by employer

Must be replaced as necessary

63

Hearing Safety

If you have to shout to talk to someone within 2 or 3 feet - Wear hearing protection

Off-the-job activities (woodworking, shooting, etc.) can hurt your hearing - Hearing protection is recommended

Never remove hearing protection in high noise areas

Do NOT share hearing protection with others

64

Respiratory Protection

(29 CFR 1910.134)

65

Hazards Requiring Respirators

Protect against breathing air contaminated with harmful:

–

–

–

–

–

–

–

–

Dusts

Fogs

Fumes

Mists

Gases

Smokes

Sprays

Vapors

– Infectious biological agents

Healthcare-related exposures that may require respirators:

–

–

–

–

Tuberculosis

Ethylene oxide

Some chemicals used for disinfection or preservation

(morgues)

Animal fecal matter

Other related exposures

–

–

Asbestos

Paint fumes

66

Respirators

–

–

–

Types of Facepieces

Half-face

Full-face

Hoods

Types of Respirators

–

–

Air Purifying

N95 (Tuberculosis)

Dust, fume, mist

Powered air purifying

Air Supplied

Self-contained breathing apparatus

Air Line

67

General Considerations

Written program required

Medical examination in accordance with ANSI

Z88.6

Annual follow-up

Certification by NIOSH

Selection in accordance with ANSI Z88.2

Fit testing required in accordance with ANSI

Z88.10

Cleaning and disinfection

Proper storage

68

Emergency Response

(29 CFR 1910.120)

Facility Emergency

Response Plan addresses

PPE if:

–

–

An industrial facility intends to use the medical center, if there is an emergency

Medical center provides support during responses to natural phenomenon

Level A - Encapsulating chemical protective suit

Level B - Respiratory protection

69

Summary

–

–

–

PPE must

Protect against the hazard

Protect the route of entry

Be maintained in a safe and sanitary condition

– Be used properly

PPE is available by contacting

–

–

Your supervisor

Facility safety office personnel

If you have questions concerning PPE provided contact

–

–

Your supervisor

Facility safety personnel

If you have questions concerning the health effects associated with

PPE contact employee health personnel

70