PPE Program Checklist - Yale School of Medicine

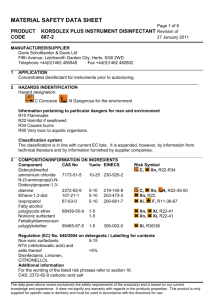

advertisement

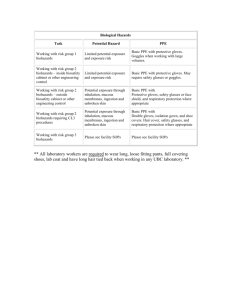

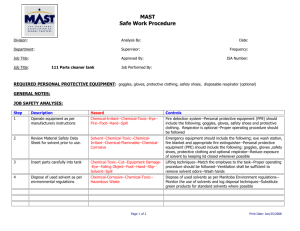

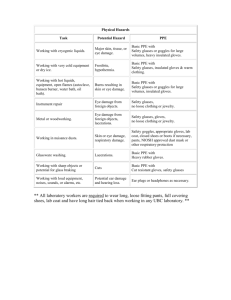

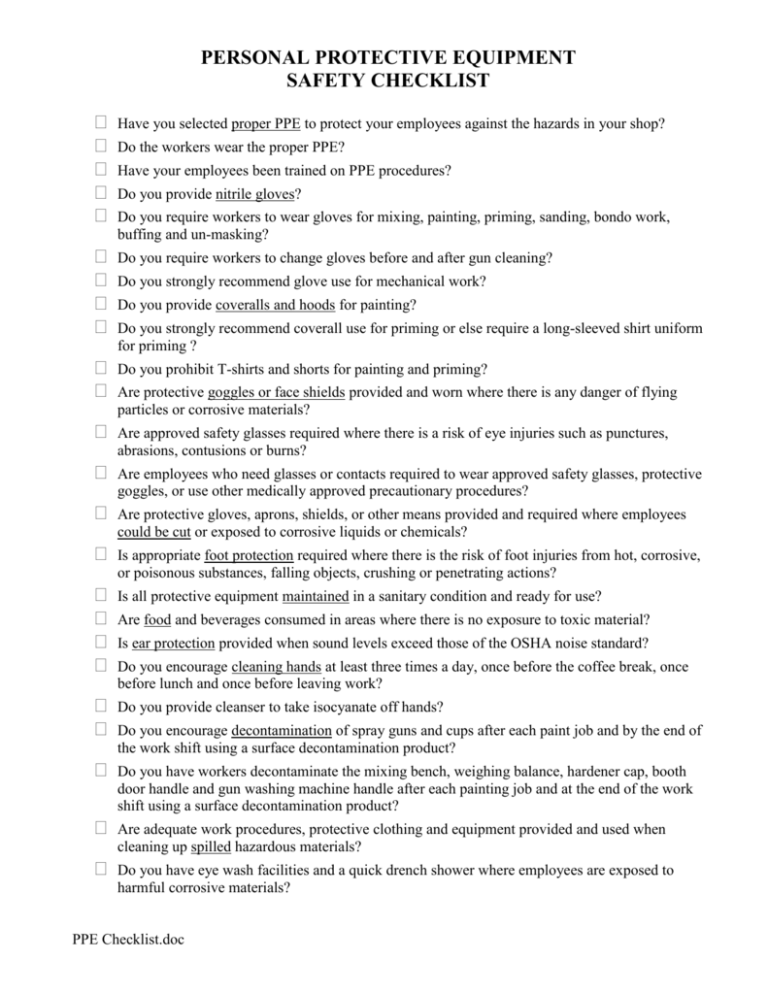

PERSONAL PROTECTIVE EQUIPMENT SAFETY CHECKLIST Have you selected proper PPE to protect your employees against the hazards in your shop? Do the workers wear the proper PPE? Have your employees been trained on PPE procedures? Do you provide nitrile gloves? Do you require workers to wear gloves for mixing, painting, priming, sanding, bondo work, buffing and un-masking? Do you require workers to change gloves before and after gun cleaning? Do you strongly recommend glove use for mechanical work? Do you provide coveralls and hoods for painting? Do you strongly recommend coverall use for priming or else require a long-sleeved shirt uniform for priming ? Do you prohibit T-shirts and shorts for painting and priming? Are protective goggles or face shields provided and worn where there is any danger of flying particles or corrosive materials? Are approved safety glasses required where there is a risk of eye injuries such as punctures, abrasions, contusions or burns? Are employees who need glasses or contacts required to wear approved safety glasses, protective goggles, or use other medically approved precautionary procedures? Are protective gloves, aprons, shields, or other means provided and required where employees could be cut or exposed to corrosive liquids or chemicals? Is appropriate foot protection required where there is the risk of foot injuries from hot, corrosive, or poisonous substances, falling objects, crushing or penetrating actions? Is all protective equipment maintained in a sanitary condition and ready for use? Are food and beverages consumed in areas where there is no exposure to toxic material? Is ear protection provided when sound levels exceed those of the OSHA noise standard? Do you encourage cleaning hands at least three times a day, once before the coffee break, once before lunch and once before leaving work? Do you provide cleanser to take isocyanate off hands? Do you encourage decontamination of spray guns and cups after each paint job and by the end of the work shift using a surface decontamination product? Do you have workers decontaminate the mixing bench, weighing balance, hardener cap, booth door handle and gun washing machine handle after each painting job and at the end of the work shift using a surface decontamination product? Are adequate work procedures, protective clothing and equipment provided and used when cleaning up spilled hazardous materials? Do you have eye wash facilities and a quick drench shower where employees are exposed to harmful corrosive materials? PPE Checklist.doc