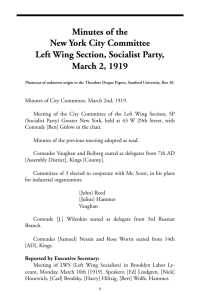

Self-monitoring programme for a Swedish power plant

advertisement

Self-monitoring programme for a Swedish power plant Hans-Roland Lindgren Director Swedish EPA 1 Monitoring programme Linköping power plant • General information • Description of the plant and its emissions • Permit conditions • Environmental monitoring • Process monitoring (instructions and recording) •Recipient monitoring (air, water) •External inspections (boiler, CFC-inst. etc.) •Reporting •Annexes (drawings of boilers, emission points, treatment plants and coal storage area) Hans-Roland Lindgren 2 The plant and its emissions •Waste and hazardous •Location waste disposal •Coal-, oil-, wood boilers •Noise and turbines •Fuels (amounts, types •Air emission sources and and storage) •Chemicals (urea for its control NOx reduction, boiler •Description of water and water treatment system and water treatment chemicals) Hans-Roland Lindgren 3 Air emission monitoring of coal boiler • Continuous monitoring of nitrogen oxides, sulphur dioxide, dust, oxygen, and carbon monoxide • Once a year as part of external inspections are dinitrogen oxide, ammonia and phthalates monitored • Lead, cadmium and zinc once a month on a collective sample and during inspections Hans-Roland Lindgren 4 Air emission monitoring of oil boiler • Continuous monitoring of nitrogen oxides, oxygen, and carbon monoxide • Once a year as part of external inspections are dinitrogen oxide, ammonia and dust monitored • Sulphur is monitored in oil at every delivery Hans-Roland Lindgren 5 Monitoring of condensate from wood boiler • Continuous monitoring of ammonium nitrate, pH and water flow • Twice a year and in addition as part of external inspections are suspended solids measured Hans-Roland Lindgren 6 Monitoring of water from ash handling, cooling and oil storage • Suspended solids, pH and total sulphur is monitored in water from ash separator once a year • Flow (continuously) and total extractable organic compounds during water pumping from oil storage by spot samples • Daily average flow of cooling water during periods of power generation (May-Sept.) Hans-Roland Lindgren 7 Process monitoring • Instructions for operation and maintenance of boilers • Instructions for operation and maintenance of air emission control equipment • Instructions for calibration of monitoring equipment Hans-Roland Lindgren •Recording of operational parameters •Recording of calibrations and maintenance •Recording of disturbances in the production of importance for the environment 8 Environment quality monitoring • Joint ambient air quality monitoring through the Association for Air Quality in the County to which the company contributes • Water recipient quality monitoring through Motala Ström Water Association Hans-Roland Lindgren 9 External inspections • Inspection of installations and records. Changes in production etc. which influence emissions are recorded • Monitoring of noise is made • Inspection and calibration of monitoring equipment Hans-Roland Lindgren •Measurement of combustion and air emission parameters on all boilers and spot samples on all waste waters •Report on all inspected objects. Results, evaluation, defects and planned changes 10 Reporting • Regular reporting every three months not later the 2 months of the end of the period • Reporting on inspections within 2 months after inspection • Reporting on disturbances and accidents immediately • Yearly reporting within 2 months after end of year Hans-Roland Lindgren 11 Yearly reporting • General information • Description of operations • Permits and permit conditions • Environmental report • Production time and conditions Hans-Roland Lindgren •Monitoring results and emissions, accuracy of installed monitoring equipment •Comments on permit conditions and possible actions •CFC-reporting •Signature 12