Design and Layout of a 128-bit Static Random

Access Memory

Chirag Agrawal, Benjamin Chai, Abhinav Dubey, Greg Slovin

University of Florida

EEE5322 - VLSI Circuits and Technology

Abstract- This paper presents the design of a 16x8 static random

address memory block using .24um technology. The memory

block consists of 128 SRAM 6T- cell, a row decoder, a column

multiplexer, precharge circuitry, as well as read and write

circuitry. The SRAM cells are organized into 16 rows by 8

columns. The key idea of this paper is to explain how each

portion of the memory block was designed as well presenting a

minimized SRAM area with minimum power dissipation. The

final SRAM dimensions was 66.84(um) x 123.84(um). That is

equal to an area of 8.25(mm2). The maximum operating speed of

the SRAM was 300 MHz and the maximum power dissipation of

the memory block is 1.37mW.

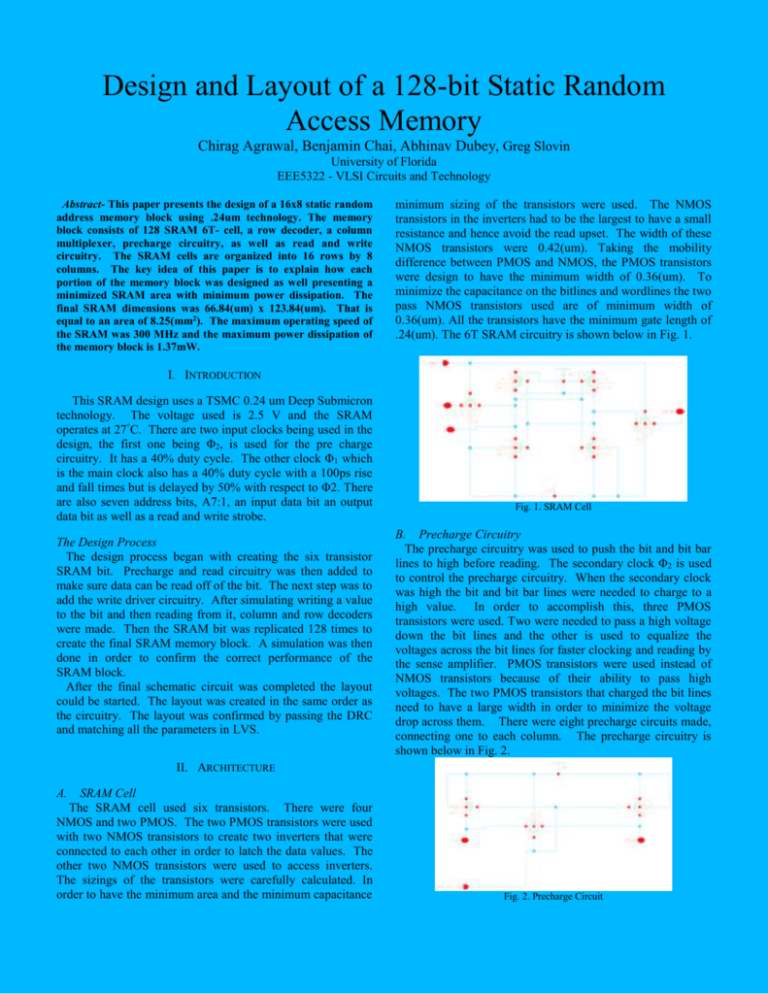

minimum sizing of the transistors were used. The NMOS

transistors in the inverters had to be the largest to have a small

resistance and hence avoid the read upset. The width of these

NMOS transistors were 0.42(um). Taking the mobility

difference between PMOS and NMOS, the PMOS transistors

were design to have the minimum width of 0.36(um). To

minimize the capacitance on the bitlines and wordlines the two

pass NMOS transistors used are of minimum width of

0.36(um). All the transistors have the minimum gate length of

.24(um). The 6T SRAM circuitry is shown below in Fig. 1.

I. INTRODUCTION

This SRAM design uses a TSMC 0.24 um Deep Submicron

technology. The voltage used is 2.5 V and the SRAM

operates at 27°C. There are two input clocks being used in the

design, the first one being Φ2, is used for the pre charge

circuitry. It has a 40% duty cycle. The other clock Φ1 which

is the main clock also has a 40% duty cycle with a 100ps rise

and fall times but is delayed by 50% with respect to Φ2. There

are also seven address bits, A7:1, an input data bit an output

data bit as well as a read and write strobe.

The Design Process

The design process began with creating the six transistor

SRAM bit. Precharge and read circuitry was then added to

make sure data can be read off of the bit. The next step was to

add the write driver circuitry. After simulating writing a value

to the bit and then reading from it, column and row decoders

were made. Then the SRAM bit was replicated 128 times to

create the final SRAM memory block. A simulation was then

done in order to confirm the correct performance of the

SRAM block.

After the final schematic circuit was completed the layout

could be started. The layout was created in the same order as

the circuitry. The layout was confirmed by passing the DRC

and matching all the parameters in LVS.

Fig. 1. SRAM Cell

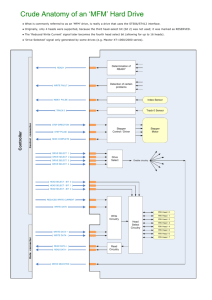

B. Precharge Circuitry

The precharge circuitry was used to push the bit and bit bar

lines to high before reading. The secondary clock Φ2 is used

to control the precharge circuitry. When the secondary clock

was high the bit and bit bar lines were needed to charge to a

high value. In order to accomplish this, three PMOS

transistors were used. Two were needed to pass a high voltage

down the bit lines and the other is used to equalize the

voltages across the bit lines for faster clocking and reading by

the sense amplifier. PMOS transistors were used instead of

NMOS transistors because of their ability to pass high

voltages. The two PMOS transistors that charged the bit lines

need to have a large width in order to minimize the voltage

drop across them. There were eight precharge circuits made,

connecting one to each column. The precharge circuitry is

shown below in Fig. 2.

II. ARCHITECTURE

A.

SRAM Cell

The SRAM cell used six transistors. There were four

NMOS and two PMOS. The two PMOS transistors were used

with two NMOS transistors to create two inverters that were

connected to each other in order to latch the data values. The

other two NMOS transistors were used to access inverters.

The sizings of the transistors were carefully calculated. In

order to have the minimum area and the minimum capacitance

Fig. 2. Precharge Circuit

C. Sense Circuitry

The sense circuitry was created in order to read the value

stored in the SRAM cell. As clocked sense amplifier saves the

power it was used to determine the difference in voltage

between the bit and bit bar lines when the SRAM cell was

accessed to read. It is implemented using the two PMOS

isolation transistor and a regenerative feedback circuitry.

When the sense enable is high and is in phase with clock, two

isolation NMOS transistors are turned on to connect the bit

and bit bar lines to the sense amplifier. An isolation PMOS

and NMOS transistor of sense circuitry were also turned on at

the same time connecting VDD and ground to the amplifier

using inverter. These isolation transistors are used to save the

power by keeping the sense amplifier off when it is not in use.

All NMOS and PMOS transistors used the minimum width of

.36(um) in order to conserve space in the layout. The sensing

circuitry is shown below in Fig. 3.

implement as multiplexer switch. The input reording has been

done to minimize the propagation delay considering the

probability of the inputs. The column decoder circuitry is

shown below in Fig. 5.

Fig. 5. Column Decoder

Fig. 3. Sense Circuitry

D. Write Driver

The write driver circuitry consists of four NMOS transistors

and an inverter. When the write strobe is high, the top two

NMOS transistors are on and hence the bit and bit bar lines are

connected to data line transistors .As a result either of them is

pulled down depending on the data line bit. All of the

transistors in the write driver circuitry have the minimum

width of 0.36(um) in order to conserve space in the layout.

The write driver circuitry is shown below in Fig. 4.

F. Row Decoder

The row decoder is a 4:16 static decoder implemented using

the predecoder stage. Because of predecoder stage it helps to

minimize the transistor count and also reduces the propagation

delay by a factor of 4. Using address lines A1:4, the decoder

circuitry chooses which word line to turn on. Each output of

the decoder is anded with the primary clock, Φ1. This avoids

any word lines from being high when the clock is low. As a

result of which no two rows are activated at the same time.

Two input NOR gates are used instead of larger input NOR

gates in the predecoder stage to limit the fan in capacitances

and the two inputs nand gates are used in the output stage with

the inverters acting as buffers to drive the large loads. Since

PMOS devices have lower mobility stacking devices in series

must be avoided as much as possible and hence nand logic is

implemented in the output stage. The row decoder circuitry is

shown below in Fig. 6.

Fig. 4. Write Driver

E. Column Multiplexer

The Column Multiplexer is a three to eight mux designed

using 3:8 decoder and the pass gate. Using address lines A5:7,

the mux circuitry chooses which set of bit and bit bar lines are

going to be connected to the sense circuitry and the write

driver circuitry. The decoder logic consist of two input NOR

gates and inverters. Two input NOR gates are used instead of

3 input NOR gates to limit the fan in capacitances. This may

result in larger logic circuitry, but the propagation delays are

much shorter. Pass gates are used to connect the selected bit

and bit bar lines to the sense circuitry and write driver to

Fig. 6. Row Decoder

III. PERFORMANCE

A. Overall SRAM Area

The entire SRAM block has a width of 66.84(um). It has a

height of 123.48(um). Therefore the entire SRAM has an area

of 8.25(mm2).

B. Read Access Time

The 50% delay from the rising edge of clock phase Φ 1 to the

output data transition from 0 to 1 is 492ps. The 50% delay

from the rising edge of clock phase Φ1 to the output data

transition from 1 to 0 is 312 ps.

C. Write Access Time

The 50% delay from the rising edge of clock phase Φ 1 to the

final writing of the input data into the memory form 0 to 1 is

920.9 ps. The 50% delay from the rising edge of clock phase

Φ1 to the final writing of the input data into the memory form

1 to 0 is 848.4 ps.

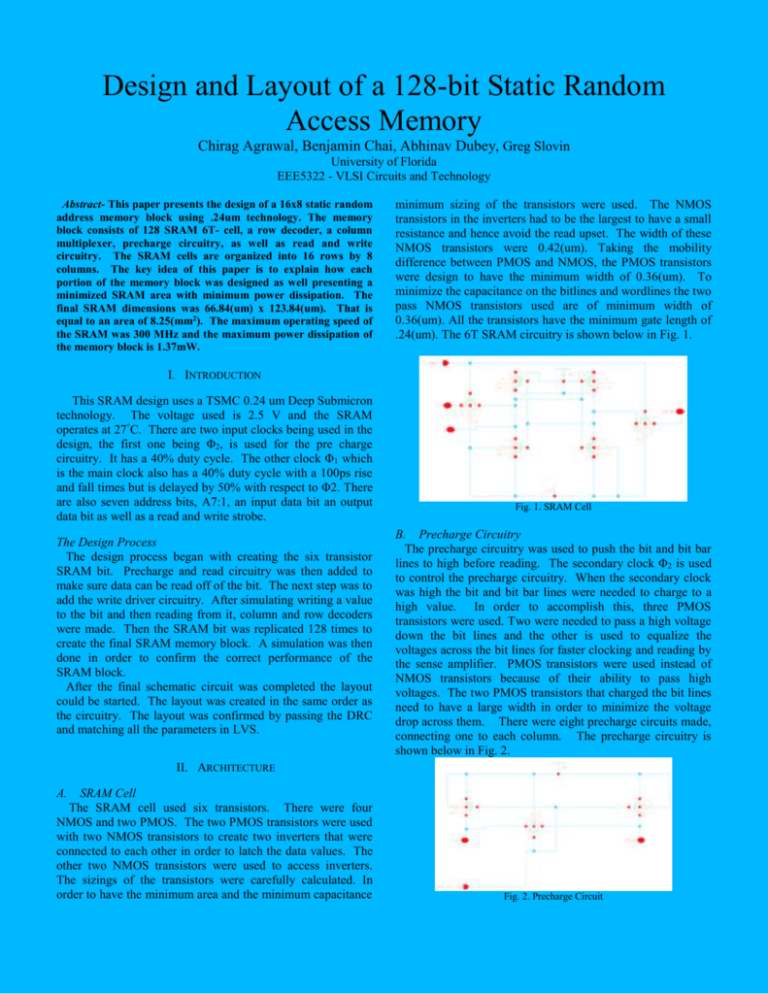

Sense Amplifier And

Write Driver

Bit Line Conditioning

R

O

W

D

E

C

O

D

E

R

SRAM Memory

Block

D. Power Dissipation

The maximum operating frequency of the SRAM device is

300 MHz. The average current over 20 clock cycles is 540 uA

from the voltage source by the SRAM block. With the voltage

source equal to 2.5 V, the power dissipation by the SRAM

block over 20 clock cycles, is approximately 1.37mW.

E. Energy-Delay Product

The energy delay product is the product of the average power

dissipation by the SRAM and the shortest clock cycle squared.

The shortest clock cycle is 13.33 ns. Therefore the energydelay product of the SRAM is 1.4 x 10-20 watt.sec2.

IV. LAYOUT

The capacitance added to the word lines and bit lines is made

up of the diffusion and gate capacitance of the access

transistors. The gate capacitance of each access transistor is

0.74 fF and their diffusion capacitance is 0.80 fF. The total

capacitance added to the word and bit lines by the access

transistors is 3.08 fF. The block diagram of the layout is

shown below in Fig. 7.

PREDECODE

R

COLUMN MUX

Layout of the 128 Bit SRAM Memory Block

V. STATIC NOISE MARGINS

The static noise margins measures the SRAM’s hold, read

and write stability. The hold static noise margin for the

SRAM cell is 1.032. The read static noise margin for the

SRAM cell is 0.298. The write static noise margin for the

SRAM cell is 0.5.

Fig. 7. SRAM Block Diagram

Write Cycle output

VI. CONCLUSION

Read Cycle output

This project gave us a valuable opportunity to learn various

tools of the custom IC design and also gave us a chance to

explore all the challenges which we came across while

implementing it. This design and implementation of the

SRAM proved to be a very challenging and valuable learning

experience. If given the opportunity, we could have tried to

reduce the size and delay to the minimum possible limit and

could have tried to optimize the trade-off between power

dissipation and delay and size area.

REFERENCES

[1]

[2]

J. Rabaey, A. Chandrakasan, and B. Nikolic, Digital Integrated Circuits,

Pearson Prentice Hall, 2nd ed, pp.623-719, 2003.

N. Weste, D. Harris, A. Banerjee, A CMOS VLSI Design, 3rd ed.

Pearson Prentice Hall, 2005, pp.73-160.