thermo finished

advertisement

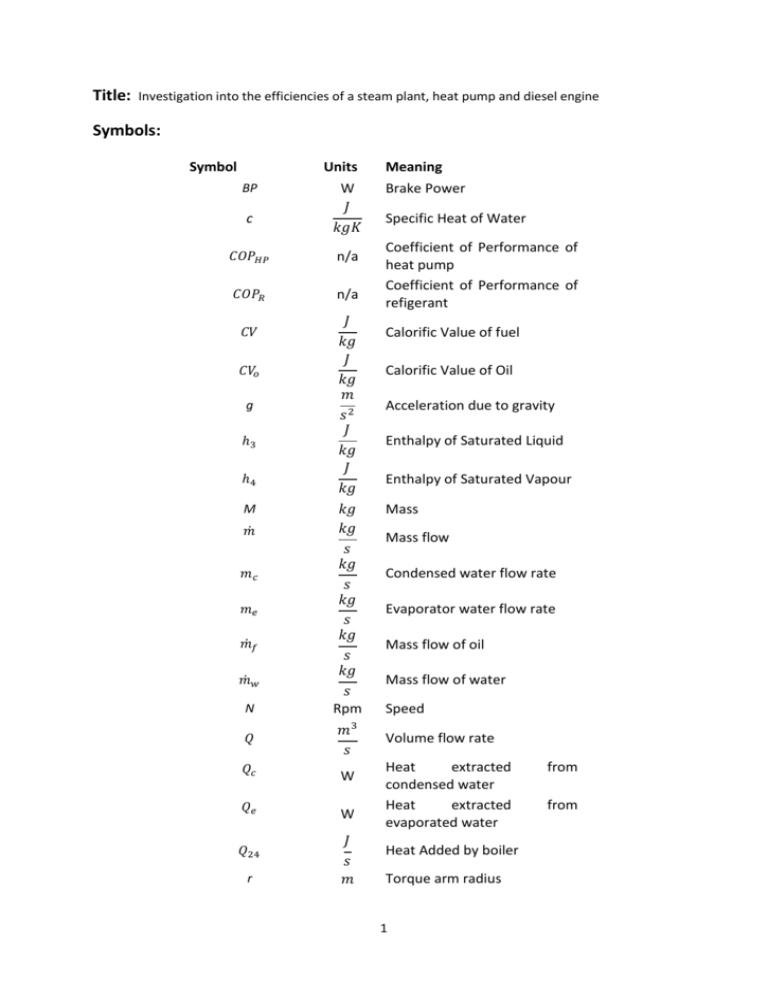

Title: Investigation into the efficiencies of a steam plant, heat pump and diesel engine Symbols: Symbol BP c Units W 𝐽 𝑘𝑔𝐾 𝐶𝑂𝑃𝐻𝑃 n/a 𝐶𝑂𝑃𝑅 n/a 𝐶𝑉 𝐶𝑉𝑜 g ℎ3 ℎ4 M 𝑚̇ 𝑚𝑐 𝑚𝑒 𝑚̇𝑓 𝑚̇𝑤 N 𝑄 𝐽 𝑘𝑔 𝐽 𝑘𝑔 𝑚 𝑠2 𝐽 𝑘𝑔 𝐽 𝑘𝑔 𝑘𝑔 𝑘𝑔 𝑠 𝑘𝑔 𝑠 𝑘𝑔 𝑠 𝑘𝑔 𝑠 𝑘𝑔 𝑠 Rpm 𝑚3 𝑠 𝑄𝑐 W 𝑄𝑒 W 𝑄24 r 𝐽 𝑠 𝑚 Meaning Brake Power Specific Heat of Water Coefficient of Performance of heat pump Coefficient of Performance of refigerant Calorific Value of fuel Calorific Value of Oil Acceleration due to gravity Enthalpy of Saturated Liquid Enthalpy of Saturated Vapour Mass Mass flow Condensed water flow rate Evaporator water flow rate Mass flow of oil Mass flow of water Speed Volume flow rate Heat extracted condensed water Heat extracted evaporated water Heat Added by boiler Torque arm radius 1 from from Dynamometer Load S 𝑁 s T N 𝑘𝑔 ℎ 𝑊 𝑁𝑚 𝑡 𝑠 𝑇𝐷 𝑁𝑚 Dynamometer Torque 𝑇𝑖 °𝐶 Condenser inlet temp 𝑇𝑜 °𝐶 Condenser outlet temp 𝑡1 𝑠 Time 𝑡2 𝑠 Time W W Compressor Power 𝑊𝑥 W Torque Power 𝑥1 𝑚 3 𝑥2 𝑚3 ∆𝑡𝑐 °𝐶 ∆𝑡𝑒 °𝐶 𝜂𝐵 n/a Volume of condensate Change in temperature of condensed water Change in temperature of evaporated water Boiler Efficiency 𝜂𝑏 n/a Brake Thermal Efficiency 𝜂𝐶 n/a Cycle Efficiency 𝜂𝐺 n/a 𝑘𝑔 𝑚3 𝑘𝑔 𝑚3 𝑘𝑔 𝑚3 Generator Efficiency S.F.C 𝜌 𝜌𝑜 𝜌𝑤 Spring Force Specific Fuel Consumption Torque time Volume of oil used Density of fuel Density of oil Density of Water 2 Contents 1. 2. 3. page Investigation into a boiler, turbine and steam plant efficiency ...................................................... 4 1.1 Introduction ............................................................................................................................ 4 1.2 Objectives................................................................................................................................ 4 1.3 Theoretical Analysis ................................................................................................................ 4 1.4 Experimental Work ................................................................................................................. 5 1.4.1 Apparatus ........................................................................................................................ 6 1.4.2 Procedure ........................................................................................................................ 6 1.5 Results ..................................................................................................................................... 6 1.6 Discussion................................................................................................................................ 6 1.7 Conclusions ............................................................................................................................. 6 Determining the Coefficient of performance for a refrigerator and heat pump system ............... 7 2.1 Introduction ............................................................................................................................ 7 2.2 Objectives................................................................................................................................ 7 2.3 Theoretical Analysis ................................................................................................................ 7 2.4 Experimental Work ................................................................................................................. 8 2.4.1 Apparatus ........................................................................................................................ 8 2.4.2 Procedure ........................................................................................................................ 8 2.5 Results ..................................................................................................................................... 8 2.6 Discussion................................................................................................................................ 9 2.7 Conclusions ............................................................................................................................. 9 Measuring the brake thermal efficiency of a diesel engine.......................................................... 10 3.1 Procedure .............................................................................................................................. 10 3.2 Results ................................................................................................................................... 10 3.3 Discussion.............................................................................................................................. 11 4. References .................................................................................................................................... 11 5. Appendices .................................................................................................................................... 11 3 1. Investigation into a boiler, turbine and steam plant efficiency 1.1 Introduction Steam plants such as moneypoint power station, require a boiler efficiency, generator efficiency and cycle efficiency as close to ideal values for optimal usage. This section aims to determine experimentally the boiler efficiency, turbine efficiency and steam plant efficiency. The full set of results is included in appendix 1. 1.2 Objectives To calculate the boiler efficiency of the boiler in the University of Limerick To determine the generator efficiency of the steam plant in the University of Limerick To determine the cycle efficiency of the steam plant in the University of Limerick 1.3 Theoretical Analysis The mass flow rate of oil can be calculated using 𝑚̇𝑓 = 𝑥1 𝜌 𝑡1 𝑜 Eqn. 1 The mass flow rate of water can be calculated using 𝑚̇𝑤 = 𝑥2 𝜌 𝑡2 𝑤 Eqn. 2 The heat added by the boiler 𝑄24 = 𝑚𝑤 [(ℎ4 − ℎ3 ) + 𝑐(𝑇𝑜 − 𝑇𝑖 )] Eqn. 3 The boiler efficiency can then be calculated 𝜂𝐵 = 𝑄24 (𝐶𝑉𝑜 )𝑚̇𝑓 Eqn. 4 4 The dynamometer torque is obtained using 𝑇𝐷 = 𝑆𝑟 Eqn. 5 Turbine power in kW is 𝑊𝑥 = 2𝜋𝑁𝑇𝐷 60 Eqn. 6 The generator efficiency is 𝜂𝐺 = 𝑉𝐼 𝑄24 Eqn. 7 The cycle efficiency is 𝜂𝐶 = 𝑊𝑥 𝑄24 Eqn. 8 1.4 Experimental Work Fig. 1 Power Plant efficiency set up 5 1.4.1 Apparatus Pump, boiler, turbine, generator, condenser, cooling water, thermometer. 1.4.2 Procedure The power plant (fig. 1) was turned on and allowed to reach equilibrium. The atmospheric pressure was measured using a barometer. Once the power plant was at equilibrium the dynamometer load was measured. The temperature was recorded for the inlet and outlet of the steam and the water. The flow rate of oil and water was measured using a flow meter. The pressure inside the boiler was measured using a barometer. The turbine speed was measured using a tachometer. The time it took the excess condensate to fill 30L was measured. The voltage and current for the system were recorded. 1.5 Results Table 1 The boiler efficiency, generator efficiency and cycle efficiency of the power plant. Generator efficiency 𝜼𝑮 Cycle efficiency 𝜼𝑪 Boiler Efficiency 𝜼𝑩 0.850813 0.011688 0.735808 1.6 Discussion Appendix 1 shows the values obtained experimentally in the power plant and the various values obtained. The boiler efficiency was 73.5%, 1.16% for cycle efficiency and 85% for the generator efficiency. The cycle efficiency is extremely low and would require an improved steam plant set up to increase the cycle efficiency 1.7 Conclusions The power plant has numerous losses and would require significant changes to improve cycle efficiency. 6 2. Determining the Coefficient of performance for a refrigerator and heat pump system 2.1 Introduction The coefficient of performance for a refrigeration and heap pump systems are essential in knowing the amount of heat moved for the amount of work put in. The experiment was carried out twice at two different condenser water flow rates and plotted on a P-h graph. The full set of data is included in appendix 2. 2.2 Objectives To find the coefficient of performance of a heat pump To find the coefficient of performance of refrigeration To plot the results on a p-h graph 2.3 Theoretical Analysis 𝑊= 3600 166.7𝑡 Eqn. 9 𝑄𝑒 = 𝑚𝑒 𝑐∆𝑡𝑒 Eqn. 10 𝑄𝑐 = 𝑚𝑐 𝑐∆𝑡𝑐 Eqn. 11 𝐶𝑂𝑃𝑅 = 𝑄𝑒 𝑊 Eqn. 12 𝐶𝑂𝑃𝐻𝑃 = 𝑄𝑐 𝑊 Eqn. 13 𝐶𝑂𝑃𝑅 + 1 = 𝐶𝑂𝑃𝐻𝑃 Eqn. 14 7 2.4 Experimental Work Fig. 2 Schematic of Hilton mechanical heat pump 2.4.1 Apparatus Flow meter, pressure guage, flow control valve, cooling fan, watt hour meter, thermometer. 2.4.2 Procedure The flow rate of the condenser was started at 50kg/hr and the system (fig. 2) was allowed to reach equilibrium. Once equilibrium was reached, the flow rate of the evaporator was recorded. The temperature and the pressure of the condenser, evaporator and refrigerant were also recorded. The time for 1 revolution of the wattmeter was recorded. The flow rate of the condenser was changed to 100kg/hr and the process was repeated. 2.5 Results Figure 3 is a P-h graph for the heat pump and refrigeration systems, test 1 is the blue line with test 2 being the red line. Test 1 was carried out at 50 kg/hr of condensed steam with the second test carried out at 100kg/hr. 8 Fig. 3 P-h graph for 50kg/hr and 100kg/hr condenser flow rate (Bar – kJ/kg plot) Table 2 Coefficient of performance for a refrigerator and heat pump under two different condensate flow rates. condenser flow rate (kg/hr) 𝑪𝑶𝑷𝑹 𝑪𝑶𝑷𝑯𝑷 Test 1 Test 2 50 100 2.385219 1.898336 2.653347 2.337852 2.6 Discussion Appendix 2 shows the results obtained for the two different condensate flow rates The theoretical coefficient of performance for the heat pump should be higher than the coefficient of performance of the refrigeration system (Eqn. X). The heat being moved from the refrigerant is not 100% efficient therefore the heat pump has a lower COPHP . 2.7 Conclusions The process has a higher coefficient of performance when the condenser is going at a slower speed to allow more heat to be transferred from the steam to the refrigerant. 9 3. Measuring the brake thermal efficiency of a diesel engine 3.1 Procedure A load is applied to the diesel engine. The speed was reduced to the lowest stable speed (1005 RPM). The speed and torque were recorded. Fuel consumption was recorded by using a graduated cylinder filled with fuel. Engine speed was increased. The process was repeated for 6 different speeds (1204 RPM, 1407 RPM, 1626 RPM, 1792 RPM and 2078 RPM). 3.2 Results Figure 4 shows the brake power plotted against engine speed for a diesel engine, BP Brake Power (kW) 14 12 10 8 6 BP 4 2 0 0 500 1000 1500 2000 2500 Engine Speed (RPM) Fig. 4 Brake power of a diesel engine plotted against engine speed (kW-RPM plot) Figure 5 shows the specific fuel consumption and the brake thermal efficiency plotted Specific Steam Consumprtion(Kg/kW h) Brake Thermal Efficiency (unitless) separately against varying engine speeds for a diesel engine. 0.4 0.35 0.3 0.25 0.2 S.F.C 0.15 B.T.E 0.1 0.05 0 1005 1204 1407 1626 1792 Engine Speed (RPM) 10 2078 Fig. 5 Specific fuel consumption versus engine speed (Kg/kW h – RPM plot) and Brake thermal efficiency versus engine speed (n/a – RPM plot) for a diesel engine 3.3 Discussion The brake thermal efficiency increases as the speed increases until it reaches 1792RPM when it starts decreasing. The brake thermal efficiency was the highest when the engine speed is at 1792 RPM, meaning the engine is more efficient when operating at this speed as less fuel is required to create 1kW h. The specific fuel consumption decreases after 1792RPM which can be caused due to lack of air being available for the combustion, a turbocharger could be installed to increase the efficiency of the engine. 4. References Eason, D. C. (2010). Thermodynamic 2 Spring 2010. Limerick: Universtiy of Limerick. Eastop, T., & mcConkey, A. (1996). Applied Thermodynamics for Engineering Technologists. New Jersey: Prentice Hall. Rogers, G., & Mayhew, Y. (1992). Engineering thermodynamics : work and heat transfer. Essex: Harlow : Longman Scientific & Technical. 5. Appendices Appendix 1 the results obtained from the power plant. Time 𝒕𝟏 to us 𝒙𝟏 of oil Mass flow of oil 𝒎̇𝒇 Time 𝒕𝟏 to us 𝒙𝟏 of condensate mass flow of water, 𝒎̇𝒘 Boiler Pressure (bar) Steam main temp (°𝑪) Inlet water temp (°𝑪) h3 (kJ/kg) c(T3-T1) (kJ/kg) h4 (kJ/kg) (h4-h3)xc(T3-T1) (kJ/kg) Heat added by boiler (kW) Heat energy in fuel (kW) Boiler Efficiency 𝜼𝑩 Condenser water flow rate 𝒎̇𝑪 Condenser inlet temp (°𝑪) Condenser outlet temp (°𝑪) Heat loss - McC(To-Ti) Dynamometer load (N) Torque arm radius (r) Dynamometer torque (Nm) Turbine speed (RPM) Turbine power (kW) Volts (V) Current (A) Electrical power (kW) Generator efficiency 𝜼𝑮 Cycle efficiency 𝜼𝑪 15 in 3600 s 0.003417 30 in 634 s 0.047319 7 163 10 697 642.6 2764 2709.6 128.2145 0.000174 0.735808 11 3.333333 9.5 19 133 39 0.162 6.318 2265 1.498567 150 8.5 1.275 0.850813 0.011688 Appendix 2 the results obtained from the refrigeration and heat pump system Test 1 Test 2 refrigerant entry temp evap (°𝑪) -7 -11 refrigerant exit temp evap (°𝑪) 0 -6 refrigerant entry temp cond (°𝑪) 64 59 refrigerant exit temp cond (°𝑪) 14 12 water entry temp evap (°𝑪) 10 10 water exit temp evap (°𝑪) 3 3 water entry temp cond (°𝑪) 10 10 water exit temp cond (°𝑪) 29 17.5 Compressor power(kW) condenser flow rate (kg/hr) 𝒎𝒄 (kg/s) evaporator flow rate (kg/hr) 𝒎𝒆 (kg/s) refrigerant flow rate (kg/hr) 𝒎𝒇 (kg/s) Atmospheric pressure (𝑵/𝒎𝟐 ) Evaporator guage pressure (𝑵/𝒎𝟐 ) Actual evaporator pressure (𝑵/𝒎𝟐 ) Condenser guage pressure (𝑵/𝒎𝟐 ) Actual condenser pressure (𝑵/𝒎𝟐 ) time for 1 rev of wattmeter (s) Refrigerant used 0.417711 0.374275 Heat extracted from evap water (kW) 0.996333 0.7105 Heat extracted from cond water (kW) 1.108333 0.875 𝑪𝑶𝑷𝑹 2.385219 1.898336 𝑪𝑶𝑷𝑯𝑷 2.653347 2.337852 Test 1 Test 2 50 100 0.013889 0.027778 122 87 0.033889 0.024167 4.8 4.1 0.001333 0.001139 102000 102000 138000 100000 240000 202000 930000 730000 1032000 832000 51.7 57.7 134a 134a Appendix 3. Results obtained during the diesel engine test CV (MJ/kg) Test No. Test Speed N (rpm) Mg (N) Spring force s (rpm) Mg – s (N) T = (Mg - s)r (Nm) BP (kW) t (s) Q (𝒎𝟑 /𝒔) 𝒎̇ (kg/hr) S.F.C (kg/kW hr) Fuel Power (kW) B.T.E 𝜼𝒃 45 1 1005 88.29 6 82.29 32.916 3.464187311 51 3.92157E-07 1.157647059 0.334175654 14.47058824 0.239395058 𝝆 (𝒌𝒈/𝒎𝟑 ) 2 1204 98.1 2.5 95.6 38.24 4.821394 37 5.41E-07 1.595676 0.330957 19.94595 0.241723 12 820 3 1407 117.72 6 111.72 44.688 6.584355 30 6.67E-07 1.968 0.29889 24.600 0.267657 r (m) 4 1626 127.53 5 122.53 49.012 8.345478 24 8.33E-07 2.46 0.29477 30.750 0.271398 0.4 5 1792 137.34 5 132.34 52.936 9.933845 21 9.52E-07 2.811429 0.283015 35.14286 0.28267 6 2078 147.15 0 147.15 58.86 12.80838 16 1.25E-06 3.69 0.288093 46.125 0.277688