Air Conditioning Lab Unit Manual: AC 01 - SOLTEQ

SOLTEQ ®

Equipment for Engineering Education & Research

AIR CONDITIONING LABORATORY

UNIT

MODEL: AC 01

T

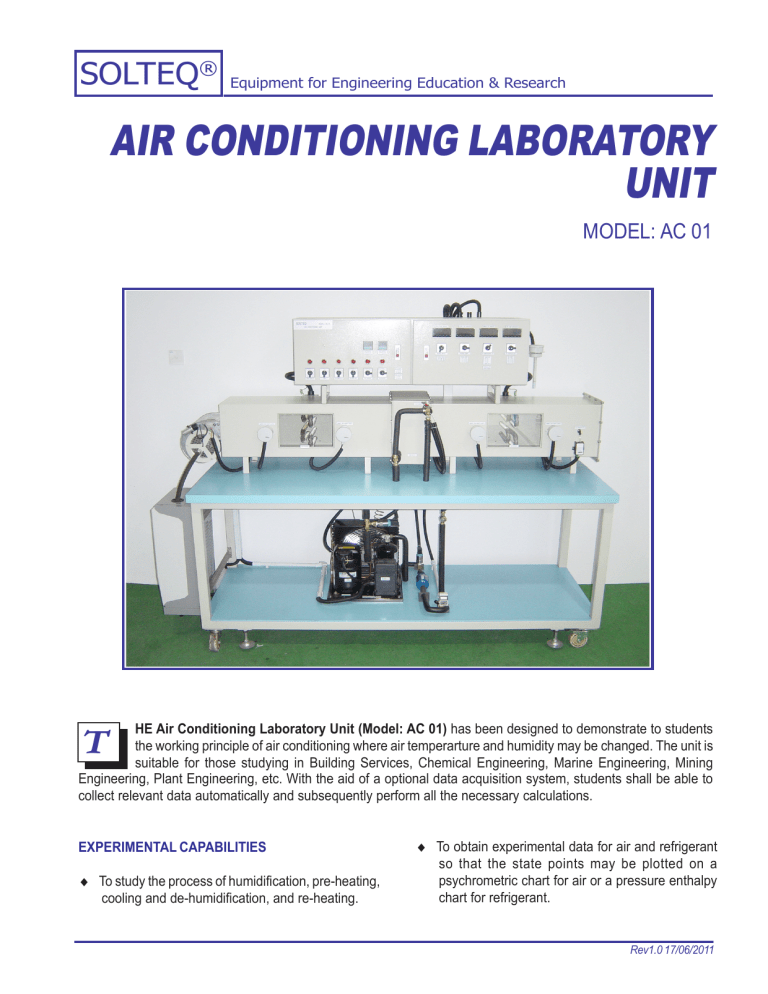

HE Air Conditioning Laboratory Unit (Model: AC 01) has been designed to demonstrate to students the working principle of air conditioning where air temperarture and humidity may be changed. The unit is suitable for those studying in Building Services, Chemical Engineering, Marine Engineering, Mining

Engineering, Plant Engineering, etc. With the aid of a optional data acquisition system, students shall be able to collect relevant data automatically and subsequently perform all the necessary calculations.

EXPERIMENTAL CAPABILITIES

♦ To study the process of humidification, pre-heating, cooling and de-humidification, and re-heating.

♦

To obtain experimental data for air and refrigerant so that the state points may be plotted on a psychrometric chart for air or a pressure enthalpy chart for refrigerant.

Rev1.0 17/06/2011

SOLTEQ ®

Equipment for Engineering Education & Research

♦ To determine the thermodynamic properties (e.g.

specific enthalpy, specific volume, specific humidity, etc.)

♦ To compare the enthalpy change of the air during the above processes with the heat transfer at the boiler,

♦ the heat transfer at the pre-heater, the enthalpy change of the refrigerant, and the heat transfer at the re-heater.

To compare the change of the specific humidity of the air during cooling with the condensate formed.

DESCRIPTION

This self-contained unit consists of several components joined by ducting through which the air flows. These components, commonly found in an industrial or commercial air conditioning unit, include a fan, a heater, a cooler, a humidifier, a de-humidifier (may be in conjunction with cooler) and a filter. The ducting and the components are supported on a steel frame with lockable castors.

The unit comes with a pressure boiler (for humidification) and refrigeration plant (for cooling and de-humidification) which are housed in the lower part of the frame.

The ducting through which the air flows has a crosssectional area of about 0.9 m2. Air from the atmosphere enters a variable speed centrifugal fan before going into the ducting. While the air is entering the fan, steam can be injected to increase the moisture contents so that a homogenous mixture of air and steam flows into the duct.

Upon leaving the fan the air passes over two 1 kW externally finned electric elements (pre-heating) which may be individually switched. The warmed air then enters a stabilising section where its condition is determined by humidity or temperature sensor. Next the air flows through the evaporator of the refrigeration unit where it may be cooled and will deposit some of its moisture content as liquid. The cool and drier air passes into another stabilising section with humidity or temperature sensor before passing over two individually switched 0.5

kW re-heating elements. The condition of the reheated air is determined and it then passes back to the atmosphere through an air flowmeter.

The boiler which supplies the steam for humidification is controlled by a steam generation controller so that the rate of steam production rate may be varied. An electronic level switch is installed in the boiler so that, in conjuction with a solenoid valve, the water level can be maintained.

The refrigeration circuit is charged with refrigerant

R134a. During the proces vapour formed in the evaporator is drawn into a hermetic compressor which discharges into an air cooled condenser. The

R134a liquid then passes through a flowmeter and thermostatically controlled expansion valve to the evaporator. Temperature and pressure measuring points are provided in the refrigeration circuit.

The fan speed may be varied by a thyristor mounted on the control panel switches and indicators are mounted on the control panel.

SPECIFICATIONS

Air Throughput: 0.14 m3s-1 (max.)

Fan: Centrifugal (variable speed)

Pre-heater: Two extended fin electric heating elements, each 1.0 kW, individually switched

Cooler: Direct expansion, finned coil. Cooling rate approximately 2.0 kW but varies with conditions

Re-heater: Two extended fin electric heating elements, each 0.5 kW, individually switched

Boiler: Electrically heated, Fitted with level switch and solenoid valve to maintain level. Variable steam generation controller

Refrigerator: Hermetic compressor with air cooled condenser. Refrigerant R134a.

Duct cross section: 30.0 cm x 30.0 cm

Rev1.0 17/06/2011

SOLTEQ ®

Equipment for Engineering Education & Research

SAFETY

Refrigerator : High pressure and low pressure cut-out

.

Boiler : All heaters protected by temperature controller. Water level is maintained by means of level switch and solenoid valve.

♦ Real-Time Display

♦ Tabulated Results

♦

Graph of Experiment Results

- CAL

SOLCAL COMPUTER AIDED LEARNING

SOFTWARE i) Interactive multimedia features ii) Graphical simulation iii) Experiment results samples iv) Full experiment manuals

OPTIONAL ITEMS

-EI

DIGITAL INSTRUMENTATIONS i) 4 units of Digital Indicators ii) 6 units of temperature sensor c/w transmitter iii) 1 unit of refrigerant flowmeter iv) 1 unit of air flowmeter v) 5 units of temperature/humidity sensor c/w transmitter vi) 2 units of pressure transmitter

-DAS

SOLDAS DATA ACQUISITION SYSTEM i) A PC with latest Pentium Processor ii) An electronic signal conditioning system iii) Stand alone data acquisition modules iv) Windows based software

♦ Data Logging

♦ Signal Analysis

♦ Process Control

REQUIREMENT

Electrical : 10 kW 380-415 VAC/3-Phase/50Hz

Water : 10 litre per hour at 10 m head minimum.

OVERALL DIMENSIONS

Height : 1.130 m

Width : 2.230 m

Depth : 0.500 m

MANUAL

The unit is supplied with Operating and Experiment

Manuals in English giving full descriptions of the unit, summary of theory, experimental procedures and typical experimental results.

Rev1.0 17/06/2011

SOLTEQ ®

Equipment for Engineering Education & Research

SOFTWARE & E - LEARNING

Our range of teaching equipment can be complemented with our

SOLDAS and SOLCAL software.

SOLDAS TM - Supervisory Control & Data Acquisition

- Data Logging

- Signal Analysis

- Process Control

- Real-Time Display

- Tabulated Results

- Graph of Experimental Results

SOLCAL TM - Computer Aided Learning

- Multimedia Features

- Interactive

- Graphic Simulation

- Experiment Result Samples

- Full Experiment Manuals

Contact us for a catalog CD

SOLUTION ENGINEERING SDN. BHD.

(Co. No. 174876-M)

Sales Office :

No.3, Jalan TPK 2/4, Taman Perindustrian Kinrara,

47100 Puchong, Selangor Darul Ehsan, Malaysia.

Tel. No. : +(603) 80758000

Fax.No.: +(603) 80755784

R&D Office :

G-2A, Incubator 3, Technology Park Malaysia,

Bukit Jalil, 57000 Kuala Lumpur, Malaysia.

Tel. No. : +(603) 8996 0023

Email : solution@solution.com.my

Web site : http//www.solution.com.my/

AGENT:

BUATAN MALAYSIA

MSC- Status

Company

Rev1.0 17/06/2011