chap13

advertisement

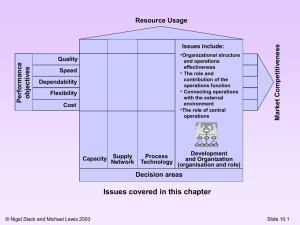

The three levels of operations strategy process Increasing complexity Level 1 - Fit Align resources with requirements Level 2 - Sustainability Develop sustainable competitive advantage Level 3 - Risk Include impact of uncertainty © Nigel Slack and Michael Lewis 2003 Operations Strategy Formulation Putting an operations strategy together presents some particular difficulties: Senior operations managers are often geographically dispersed The operation still needs running Predominance of line management Complexity of operations resources Inertia of operations resources © Nigel Slack and Michael Lewis 2003 Operations Strategy Formulation There are many formulation process stage models. They often include: Links between competitive strategy objectives and operations objectives (strategic fit) The use of ‘competitive objectives’ as the translation device between strategic and operations objectives Judging the importance of competitive objectives against customer/market requirements Current performance judged against competitor performance An iterative process The concept of an ‘ideal’ of ‘greenfield’ operation against which to compare current operations. A gap-based analysis © Nigel Slack and Michael Lewis 2003 Level of market requirements In operations strategy ‘fit’ is the alignment between market and operations capability Alignment between market and operations capability Y X © Nigel Slack and Michael Lewis 2003 Level of operations resource capability ‘Fit’ means that the operations resources and processes are aligned with the requirements of its markets. Market requirements ‘Fit’ can also mean that market requirements are moved to exploit operations resource capabilities Operations resource capability © Nigel Slack and Michael Lewis 2003 Market Segmentation Market Positioning Operations Performance Objectives Operations Strategy Decision Areas Operations Capabilities State market requirements in terms of operations performance objectives Make strategic operations decisions … to enhance core capabilities Competitor Activity Understand markets Define competitive position ‘Fit’ operations resources to market requirements ‘fit’ © Nigel Slack and Michael Lewis 2003 Tangible and Intangible Resources Potential Market Positioning Operations Performance Operations Strategy Decision Areas Operations Capabilities Operations Processes Determine competitive position Define market potential of operations performance Make appropriate strategic operations decisions Identify core capabilities ‘Fit’ market positioning to operations resources capabilities © Nigel Slack and Michael Lewis 2003 Understand resources and processes Critical Critical Critical Critical Critical Critical Critical Capacity Supply Network Quality Market Competitiveness Performance objectives Resource Usage Speed Dependability Flexibility Cost Process Development and Technology Organization Decision areas IBM operations strategy matrix (1970-1985) © Nigel Slack and Michael Lewis 2003 Ideal Minimum resource resource capability capability B Level of market requirements y2 Y Tight fit y1 A ‘Ideal’ market requirements Minimum market requirements x1 X x2 Level of operations resource capability The level of ‘fit’ may not always be ‘tight’ © Nigel Slack and Michael Lewis 2003 ‘Fit’ is concerned with ensuring comprehensiveness, correspondence, coherence and criticality Speed Dependability Flexibility Cost Critical Critical Critical Capacity Critical Supply Network Process Technology Decision areas Comprehensive? © Nigel Slack and Michael Lewis 2003 Critical Market Competitiveness Coherence Quality Correspondence Performance objectives Resource Usage Development and Organization Quality • Provide • Continuous • Built-in quality • Long-term resources to support quality •Use quality as performance criteria quality emphasis with suppliers •Purchase using quality criteria •Work on functional barriers in processes •Statistical process control •Enhance quality capability •Quality as a performance criteria plans •Quality culture •Continuous improvement •Quality performance measurement and control •Operational supervision is important •Communication •Appropriate org. structure Speed Dependability Flexibility Cost Capacity Supply Network Process Development and Technology Organization Decision areas To be strategic, quality initiatives need to comprehensively cover all decision areas © Nigel Slack and Michael Lewis 2003 Market Competitiveness Performance objectives Resource Usage Step 1 Step 2 Step 3 Corporate objectives Marketing strategy How do products or services win orders? • Growth • Profit • ROI • Other ‘financial’ measures • Product/service • Price markets and segments • Range • Mix • Volumes • Standardisation or customisation • Innovation • Leader or follower • Quality • Delivery speed • Delivery dependability Step 4 Operations strategy Process choice • Process technology • Trade-offs embodied in process • Product/service • Role of range inventory • Product/service • Capacity, size, design timing, location • Brand image • Technical service The Hill framework of operations strategy formulation © Nigel Slack and Michael Lewis 2003 Step 5 Infrastructure • Functional support • Operations planning and control systems • Work structuring • Payment systems • Organisational structure OPPORTUNITIES AND THREATS? THE EXISTING OPERATION WHAT THE MARKET WANTS? • Features • Quality • Delivery • Flexibility • Price HOW THE OPERATION PERFORMS • Facilities • Capacity • Span of process • Processes • Human resources • Quality • Control policies • Suppliers • New Products • Features • Quality • Delivery • Flexibility • Price The Platts-Gregory procedure © Nigel Slack and Michael Lewis 2003 WHAT DO WE NEED TO DO TO IMPROVE THE REVISED OPERATIONS STRATEGY? Market requirements Product family Delivery lead-time Achieved performance Ex-stock Short Not significant Long Into stock point Variable Critical: Project delay Good Fit for purpose Few features Many features/ High absolute level Acceptable at price Acceptable Total reliability essential High Reliability Features Quality Flexibility design Standard range only Standard only Volume All designs customer specified All products customised Stable market Little variation required Volume variations low Highly cyclic variable market Volume variations high Price competition dominant Low Non-price competition dominant High Price cost Uses of profiling in the Platts-Gregory procedure © Nigel Slack and Michael Lewis 2003