Industrial Automation

advertisement

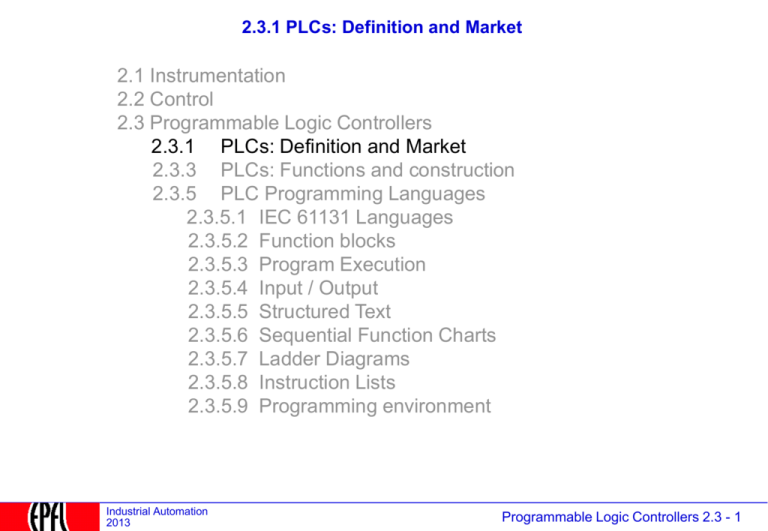

2.3.1 PLCs: Definition and Market

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Input / Output

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Instruction Lists

2.3.5.9 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 1

PLC = Programmable Logic Controller: Definition

AP = Automates Programmables industriels

SPS = Speicherprogrammierbare Steuerungen

Definition:

“small computers, dedicated to automation tasks in an industrial environment"

Formerly:

cabled relay control (hence 'logic'), analog (pneumatic, hydraulic) “governors”

Today:

real-time (embedded) computer with extensive input/output

Function:

Measure, Control, Protect

Distinguish

Instrumentation

flow meter, temperature, position,…. but also actors (pump, …)

Control

programmable logic controllers with digital peripherals & field bus

Visualization

Human Machine Interface (HMI) in PLCs (when it exists) is limited

to service help and control of operator displays

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 2

Simple PLC

network

digital inputs

analog inputs / outputs

digital outputs

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 3

PLC in a cabinet

CPU1

CPU2

serial connections

redundant field

bus connection

inputs/outputs

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 4

example: turbine control (in the test lab)

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 5

PLC: functions

(Messen, Schützen, Regeln = MSR)

PLC = PMC: Protection, Measurement and Control

• Measure

• Control (Command and Regulation)

• Protection

•Event Logging

•Communication

•Human interface

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 6

PLC: Characteristics

• large number of peripherals: 20..100 I/O per CPU, high density of wiring, easy assembly.

• digital and analog Input/Output with standard levels

• operate under harsh conditions, require robust construction, protection against dirt,

water and mechanical threats, electro-magnetic noise, vibration, extreme temperature

range (-30C..85C), sometimes directly located in the field.

• programming: either very primitive with hand-help terminals on the target machine

itself, or with a laptop

• network connection for programming on workstations and connection to SCADA

• field bus connection for remote I/Os

• primitive Human-Machine-Interface for maintenance, either through LCD-display or

connection of a laptop over serial lines (RS232) or wireless.

• economical - €1000.- .. €15'000.- for a full crate.

• the value is in the application software (licenses €20'000 ..€50'000)

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 7

PLC: Location in the control architecture

Enterprise Network

Engineer

station

Operator

station

Supervisor

Station

gateway

direct I/O

Industrial Automation

2013

Field Stations

COM 2

CPU

I/O

gateway

COM

CPU

COM

I/O

I/O

COM

I/O

CPU

COM

I/O

I/O

I/O

I/O

CPU

PLC

Field Bus

FB

gateway

small PLC

data concentrators,

not programmable,

but configurable

COM1

I/O

Control Station

with Field Bus

Field Bus

COM

directly connected

I/O

I/O

I/O

I/O

COM 2

COM1

PLC

CPU

I/O

I/O

I/O

I/O

I/O

COM1

large

PLCs

CPU

Control Bus

(e.g. Ethernet)

Field Devices

Sensor Bus (e.g. ASI)

Programmable Logic Controllers 2.3 - 8

Why 24V / 48 V supply ?

… After the plant lost

electric power, operators

could read instruments only

by plugging in temporary

batteries…

[IEEE Spectrum Nov 2011

about Fukushima]

Photo TEPCO

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 9

Global players

Total sales in 2004: 7’000 Mio €

Source: ARC Research, 2005-10

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 10

Kinds of PLC

(1)

Compact

Monolithic construction

Monoprocessor

Fieldbus connection

(2)

Modular PLC

Modular construction (backplane)

One- or multiprocessor system

Fieldbus and LAN connection

Small Micro Memory Card (MMC) function possible

(3)

Soft-PLC

Linux or Windows NT or CE-based automation products

Direct use of CPU or co-processors

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 11

Compact PLC

courtesy ABB

courtesy ABB

courtesy ABB

Monolithic (one-piece) construction

Fixed casing

Fixed number of I/O (most of them binary)

No process computer capabilities (no MMC)

Can be extended and networked by an extension (field) bus

Sometimes LAN connection (Ethernet, Arcnet)

Monoprocessor

Typical product: Mitsubishi MELSEC F, ABB AC31, SIMATIC S7

costs: € 2000

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 12

Specific Controller (example: Turbine)

tailored for a specific application, produced in large series

Programming port

Relays and fuses

Thermocouple

inputs

binary I/Os,

CAN field bus

RS232 to HMI

courtesy Turbec

cost: € 1000.-

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 13

Modular PLC

• can be tailored to needs of application

development

environment

RS232

• housed in a 19" (42 cm) rack

(height 6U ( = 233 mm) or 3U (=100mm)

• high processing power (several CPUs)

LAN

• large choice of I/O boards

backplane

parallel bus

• concentration of a large number of I/O

courtesy ABB

• interface boards to field busses

fieldbus

• requires marshalling of signals

Power Supply

• primitive or no HMI

• cost effective if the rack can be filled

CPU CPU

Analog I/O

Binary I/O

fieldbus

• supply 115-230V~ , 24V= or 48V= (redundant)

• cost ~ €10’000 for a filled crate

Typical products: SIMATIC S5-115, Hitachi H-Serie, ABB AC110

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 14

Small modular PLC

courtesy ABB

courtesy Backmann

mounted on DIN-rail, 24V supply

cheaper (€5000)

not water-proof,

no ventilator

extensible by a parallel bus (flat cable or rail)

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 15

Compact or modular ?

field bus

extension

€

compact PLC

(fixed number of I/Os)

modular PLC (variable number of I/Os

Limit of local I/O

# I/O modules

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 16

Industry- PC

courtesy INOVA

courtesy MPI

Wintel architecture

(but also: Motorola, PowerPC),

HMI (LCD..)

Limited modularity through mezzanine boards

(PC104, PC-Cards, IndustryPack)

Backplane-mounted versions with PCI or Compact-PCI

Industrial Automation

2013

Competes with modular PLC

no local I/O,

fieldbus connection instead,

costs: € 2000.-

Programmable Logic Controllers 2.3 - 17

Soft-PLC (PC as PLC)

23

4

3

3

2

12

2

• PC as engineering workstation

• PC as human interface (Visual Basic, Intellution, Wonderware)

• PC as real-time processor

• PC assisted by a Co-Processor (ISA- or PC104 board)

• PC as field bus gateway to a distributed I/O system

I/O modules

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 18

Protection devices

substation

measurement

transformers

communication to operator

Ir

Is

It

Ur

Us

UT

Human interface

for status

and

settings

Programming

interface

trip relay

Protection devices are highly specialized PLCs that measure the current and voltages in an electrical

substation, along with other statuses (position of the switches,…) to detect situations that could

endanger the equipment (over-current, short circuit, overheat) and trigger the circuit breaker (“trip”) to

protect the substation.

In addition, they record disturbances and send the reports to the substation’s SCADA.

Sampling: 4.8 kHz, reaction time: < 5 ms.

costs: € 5000

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 19

Comparison Criteria – what matters

Brand

Siemens

Hitachi

Number of Points

Memory

1024

10 KB

640

16 KB

Programming Language

• Ladder Diagrams

• Instruction List

• Logic symbols

• Hand-terminal

• Ladder Diagrams

• Instruction List

• Logic symbols

• Basic

• Hand-terminal

Programming Tools

Download

Graphical (on PC)

no

Graphical (on PC)

yes

Real estate per 250 I/O

2678 cm2

1000 cm2

Label surface

per line/point

5.3 mm2

7 characters

6 mm2

6 characters

Network

10 Mbit/s

19.2 kbit/s

Mounting

DIN rail

cabinet

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 20

2.3.3 PLCs: Function and construction

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Structured Text

2.3.5.5 Sequential Function Charts

2.3.5.6 Ladder Diagrams

2.3.5.7 Instruction Lists

2.3.5.8 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 21

Implementation

• PLC operates periodically

• Samples signals from sensors and converts them to digital form with

A/D converter

• Computes control signal and converts it to analog form for the

actuators.

1. Wait for clock interrupt

2. Read input from sensor

3. Compute control signal

4. Send output to the actuator

5. Update controller variables

7. Communication

6. Repeat

Waiwera Organic Winery, Distillation Plant

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 22

The signal chain within a PLC

y(i)

y

time

analog

variable

(e.g. 4..20mA)

time

filtering

&

scaling

sampling

analogdigital

converter

1

binary

variable

y(i)

filtering

011011001111

counter

amplifier

analog

variable

e.g. -10V..10V

transistor

or

relay

0001111

y

digitalanalog

converter

processing

sampling

(e.g. 0..24V)

time

binary

variable

non-volatile

memory

time

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 23

General PLC architecture

RS 232

CPU

Real-Time

Clock

ROM

flash

EPROM

serial port

controller

Ethernet

ethernet

controller

extension

bus

parallel bus

fieldbus

controller

buffers

analogdigital

converters

digitalanalog

converters

Digital Output

Digital

Input

signal

conditioning

power

amplifiers

relays

signal

conditioning

external

I/Os

direct Inputs and Outputs

field bus

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 24

Example Architecture: Internals of a protection device

Can you find all the components from the previous slide?

In addition this device uses a DSP module for complex computations.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 25

2.3.5 Programming languages

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.3 PLCs: Functions and construction

2.3.5 Programming languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Input / Output

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Instruction Lists

2.3.5.9 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 26

The long march to IEC 61131

PLC industry needs aggreement on

• Data types (operations may only be executed on appropriate types)

• Programming languages

• Software structure (program organization units for modularity, encapsulation)

• Discrete event system handling

• Execution

NEMA Programmable Controllers Committee formed (USA)

GRAFCET (France)

DIN 40719, Function Charts (Germany)

NEMA ICS-3-304, Programmable Controllers (USA)

IEC SC65A/WG6 formed

DIN 19 239, Programmable Controller (Germany)

IEC 65A(Sec)38, Programmable Controllers

MIL-STD-1815 Ada (USA)

IEC SC65A(Sec)49, PC Languages

IEC SC65A(Sec)67

IEC 848, Function Charts

IEC 64A(Sec)90

IEC 1131-3

it took 20 years to make that standard…

Type 3 report

recommendation

IEC 61131-3

name change

70

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

Source: Dr. J. Christensen

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 27

Matching the analog and binary world

Binary World

Analog World

Pneumatic and electromechanical

controllers

Relay control, pneumatic

sequencer

I1

A

B

C

P1

P2

combinatorial

Regulation, controllers

continuous processes

sequential

discrete processes

Described by variables of nonoverlapping values. The transition from

one state to another is abrupt, it is

caused by an external event.

The time constant of the control

system must be at least one order

of magnitude smaller than the

smallest time constant of the plant.

PLC

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 28

"Real-Time" languages

Extend procedural languages to

express time

Languages developed for cyclic

execution and real-time

("application-oriented languages")

(“introduce programming constructs to

influence scheduling and control flow”)

• ADA

•

Ladder Diagrams

• Real-Time Java

•

function block language

• MARS (TU Wien)

•

instruction lists

• Forth

•

GRAFCET

• “C” with real-time features

•

SDL

• etc…

could not impose themselves

Industrial Automation

2013

etc...

wide-spread in the control industry.

Now standardized as IEC 61131

Programmable Logic Controllers 2.3 - 29

The five IEC 61131-3 Programming languages

graphical languages

Function Block Diagram (FBD)

http://www.isagraf.com

Sequential Flow Chart (SFC)

CALC1

PUMP

CALC

AUTO

>=1

IN1 OUT

DO

START STEP

T1

V

MAN_ON

STEP A

IN2

ACT

N

ACTION D1

D1_READY

D

ACTION D2

D2_READY

N

ACTION D3

D3_READY

D

ACTION D4

D4_READY

T2

STEP B

Ladder Diagram (LD)

T3

CALC1

AUTO

CALC

IN1 OUT

OUT

PUMP

ACT

IN2

MAN_ON

Instruction List (IL)

A: LD

%IX1 (* PUSH BUTTON *)

ANDN %MX5 (* NOT INHIBITED *)

ST

%QX2 (* FAN ON *)

Industrial Automation

2013

textual languages

Structured Text (ST)

VAR CONSTANT X : REAL := 53.8 ;

Z : REAL; END_VAR

VAR aFB, bFB : FB_type; END_VAR

bFB(A:=1, B:=‘OK’);

Z := X - INT_TO_REAL (bFB.OUT1);

IF Z>57.0 THEN aFB(A:=0, B:=“ERR”);

ELSE aFB(A:=1, B:=“Z is OK”);

END_IF

Programmable Logic Controllers 2.3 - 30

61131 Elementary Data Types

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Keyword

BOOL

SINT

INT

DINT

LINT

USINT

UINT

UDINT

ULINT

REAL

LREAL

TIME

DATE

TIME_OF_DAY or TOD

DATE_AND_TIME or DT

STRING

BYTE

WORD

DWORD

LWORD

Industrial Automation

2013

Data Type

Bits

Boolean

Short integer

Integer

Double integer

Long integer

Unsigned short integer

Unsigned integer

Unsigned double integer

Unsigned long integer

Real numbers

Long reals

Duration

Date (only)

Time of day (only)

Date and time of day

Character string

Bit string of length 8

Bit string of length 16

Bit string of length 32

Bit string of length 64

1

8

16

32

64

8

16

32

64

32

64

variable

variable

variable

variable

variable

8

16

32

64

Programmable Logic Controllers 2.3 - 31

Importance of IEC 61131

IEC 61131-3 is the most important automation language in industry.

80% of all PLCs support it, all new developments are based on it.

Depending on the country, some languages are more popular than others.

More information:

http://www.plcopen.org/pages/tc1_standards/downloads/plcopen_iec611313_feb2014.pptx

http://www.plcopen.org/pages/pc2_training/downloads/index.htm

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 32

2.3.5.2 Input and Output

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Input & Output

2.3.5.3 Function blocks

2.3.5.4 Program Execution

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Instruction Lists

2.3.5.9 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 33

Connecting to Input/Output, Method 1: dedicated I/O blocks

The Inputs and Outputs of the PLC must be connected to (typed) variables

IN_1

OUT_1

The I/O blocks are configured to be attached to the

corresponding I/O groups.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 34

Connecting to Input / Output, Method 2: Variables configuration

All program variables must be declared with name and type, initial value and volatility.

A variable may be connected to an input or an output, giving it an I/O address.

Several properties can be set: default value, fall-back value, store at power fail,…

These variables may not be connected as input, resp. output to a function block.

predefined addresses

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 35

2.4.2.3 Function Blocks Language

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1

IEC 61131 Languages

2.3.5.2

Input / Output

2.3.5.3

Function blocks language

2.3.5.4

Program Execution

2.3.5.5

Structured Text

2.3.5.6

Sequential Function Charts

2.3.5.7

Ladder Diagrams

2.3.5.8

Instruction Lists

2.3.5.9

Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 36

Function Block Languages

(Funktionsblocksprache, langage de blocs de fonctions)

(Also called "Function Chart" or "Function Plan" - FuPla)

The function block languages express "combinatorial"

programs in a way similar to electronic circuits.

They draw on a large variety of predefined and custom functions

This language is similar to the Matlab / Simulink language

used for simulations

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 37

Function Block Examples

Example 1:

A

B

&

C

Example 2:

external outputs

external inputs

Trigger

Tempo

&

S Q

Spin

Running

Reset

R

Graphical programming language, similar to electrical and block

diagrams. Mostly expresses combinatorial logic, but blocks may have

memory (e.g. RS-flip-flops)

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 38

Function Block Elements

Function block

input signals

Example

set point

measurement

parameters output signals

PID

command

overflow

"continuously"

executing block,

independent,

no side effects

The block is defined by its:

• Data flow interface (number and type of input/output signals)

• Black-Box-Behavior (functional semantic, e.g. in textual form).

Signals

Typed connections that carry a pseudo-continuous data flow.

Connects the function blocks.

set point

Example

Industrial Automation

2013

(set point)

(set point)

Programmable Logic Controllers 2.3 - 39

Function Block Example

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 40

Function Block Rules

There exist exactly two rules for connecting function blocks by signals

(this is the actual programming):

• Each signal is connected to exactly one source.

This source can be the output of a function block or a plant signal.

• The type of the output pin, the type of the input pin and the signal type

must be identical.

The function plan should be drawn so the signals flow from left

to right and from top to bottom. Some editors impose additional rules.

Retroactions are an exception to this rule. In this case, the signal direction is

identified by an arrow (forbidden in some editors – use global variables instead).

a

b

x

z

c

Industrial Automation

2013

y

Programmable Logic Controllers 2.3 - 41

Types of Programming Organisation Units (POUs)

1) “Functions”

- are part of the base library.

- have no memory.

Examples: and gate, adder, multiplier, selector,....

2) “Elementary Function Blocks” (EFB)

- are part of the base library

- have a memory ("static" data).

- may access global variables (side-effects !)

Examples: counter, filter, integrator,.....

3) “Programs” (Compound blocks)

- user-defined or application-specific blocks

- may have a memory

- may be configurable (control flow not visible in the FBD

Examples: PID controller, Overcurrent protection, Motor sequence

(a library of compound blocks may be found in IEC 61804-1)

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 42

Function Block library

The programmer chooses the blocks in a block library, similarly to the

hardware engineer who chooses integrated circuits in a catalogue.

The library describes the pinning of each block, its semantics and the

execution time.

The programmer may extend the library by defining function block macros

composed of library elements.

If some blocks are used often, they will be programmed in an external

language (e.g. “C”, micro-code) following strict rules.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 43

Library functions for discrete and continuous plants

Basic blocks

logical operations(AND, OR, …)

Flip-flop

Selector m-out-of-n

Multiplexer m-to-n

Timer

Counter

Memory

Sequencing

Compound blocks

Display

Manual input, touch-screen

Safety blocks (interlocking)

Alarm signaling

Logging

Industrial Automation

2013

Basic blocks

Summator / Subtractor

Multiplier / Divider

Integrator / Differentiator

Filter

Minimal value, Maximum value

Radix

Function generator

Regulation Functions

P, PI, PID, PDT2 controller

Fixed set-point

Ratio and multi-component regulation

Parameter variation / setting

2-point regulation

3-point regulation

Output value limitation

Ramp generator

Adaptive regulation

Drive Control

Programmable Logic Controllers 2.3 - 44

Function Block library for specialized applications

MoveAbsolute

AXIS_REF

BOOL

REAL

REAL

REAL

REAL

REAL

MC_Direction

Axis

Execute

Position

Velocity

Acceleration

Deceleration

Jerk

Direction

Axis

Done

CommandAborted

Error

ErrorID

AXIS_REF

BOOL

BOOL

BOOL

WORD

standardized blocks are defined in libraries, e.g. Motion Control or Robotics

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 45

Specifying the behaviour of Function Block

Time Diagram:

0

T

y

x

x

y

T

Truth Table:

x1

x2

Mathematical Formula:

Textual Description:

Industrial Automation

2013

x

x1

x2

y

S

0

0

previous state

R

0

1

0

1

0

1

1

1

1

t

dx

Kpx Kd Ki xd

dt

0

y

Calculates the root mean square of the input with a filtering constant

defined in parameter „FilterDelay“

Programmable Logic Controllers 2.3 - 46

Function Block specification in Structured Text

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 47

IEC 61131-3 library (extract)

Boolean Functions

Selector

Arithmetic Functions

Binary

selection

Select one of N

inputs depending

on input K

Flip-flop

Up counter

dominant set

Q:=S1|(Q&!R)

dominant reset

Q:=!R1&(Q|S)

Trigger

rising edge

detector

CU – input (rising

edges count up)

R – reset counter

(CV:=0)

PV – preset value

Q – 1 if CV >= PV

CV – current value

ADD

adder

SUB

subtractor

MUL

multiplier

DIV

divider

INT

Reset

PV

In

Integrator

(if reset)

Out := PV,

else

Out:= Δt *In +

Out

More details http://calc1.kss.ia.polsl.pl/content/dydaktyka/PC/PLC_IEC61131-3.pdf

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 48

Exercise: What do the following blocks do ? (Δt = 1)

2.

1.

In1

(1024)

In

ADD

(10)

Out

(initially 2)

DIV

In2

INT

Reset = 0

PV

In

Out

(initially 0)

(2)

What are the values of Out?

What happens if out is initially 1024?

What are the values

of Out?

3.

Remember:

INT

If (Reset) :

Out := PV,

Else:

Out := Δt *In + Out

t1

CTU

CU

RESET Q

CV

PV

t2

t3 t4 t5 t6

t7

t8

CU

Reset = 0, PV = 3, CV = #up Q = (CV >= PV) ?

Flipflop: dominant set or reset?

4.

SR

S

S1

R

R

Q

RS

S

R1

Q

Q

dominant set

Q:=S1|(Q&!R)

dominant reset

Q:=!R1&(Q|S)

http://tinyurl.com/IAFunctionBlock

https://docs.google.com/forms/d/1ynmoXf3JTcRn2yv2_4bKhcK0HJNDYpiTnQQm13lDSso/viewform

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 49

Exercise: What do the following blocks do ?

1.

2.

2, 12, 22, 32, 42

If out is initially 0:

0, 0, 0, 0, 0

If out is initially 1024: 1024, 1024, 1024,

3.

CV = 1, 1, 2, 2, 3, 3, 4, 4

Q = 0, 0, 0, 0, 1, 1, 1, 1

4.

S

SR

S1

R

R

Q

dominant set

Q:=S1|(Q&!R)

Q

https://docs.google.com/forms/d/1ynmoXf3JTcRn2yv

2_4bKhcK0HJNDYpiTnQQm13lDSso/viewform

Industrial Automation

2013

ftp://advantechdownloads.com/Traini

ng/KW%20training/

Programmable Logic Controllers 2.3 - 50

Exercise: Asymmetric Sawtooth Wave

Build an asymmetric sawtooth wave generator with

IEC 61131 function blocks

5s

12s

75

0

-25

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 51

Exercise: Asymmetric Sawtooth Wave

Build an asymmetric sawtooth wave generator with

IEC 61131 function blocks

5s

12s

75

0

-25

Hints:

- Compute the slopes

- Use integrators, comparators, flip-flops and selectors

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 52

Exercise: Saw-tooth FBD

Out

75.0

0

-25.0

+ 8.3

-20.0

Other solutions exists.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 53

Function Block decomposition

A function block describes a data flow interface.

Its body can be implemented differently:

Elementary block

The body is implemented in an external language

(micro-code, assembler, IEC 61131 ST):

=

Compound block

procedure xy (a,b:BOOLEAN; VAR b,c: BOOLEAN);

begin

......

....

end xy;

The body is realized as a function block program

.

Each input (output) pin of the interface is implemented as

exactly one input (output) of the function block.

All signals must appear at the interface to guarantee

freedom from side effects.

=

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 54

Function Block segmentation

An application program (task) is decomposed into segments ("Programs")

for easier reading, each segment being represented on one (A4) printed page.

• Within a segment, the connections are represented graphically

.

• Between the segments, the connections are expressed by signal names

.

Segment A

X1

M2

M1

Y1

Segment B

X2

Y2

M1

X3

Industrial Automation

2013

M2

Programmable Logic Controllers 2.3 - 55

2.3.5.3 Program execution

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Input / Output

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Instruction Lists

2.3.5.9 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 56

Execution of Function Blocks

Segment or POU

(program organization unit)

A

B

C

F1

The function blocks are

translated to machine language

(intermediate code, IL),

that is either interpreted or

compiled to assembly language

Blocks are executed in sequence,

normally from upper left to lower right

The sequence is repeated every t ms.

Industrial Automation

2013

X

F2

F4

F3

Machine Code:

X01

X02

function

input1

input2

output

Y

F1

A

B

X01

F2

X01

X

F3

B

C

X02

F4

X

X02

Y

Programmable Logic Controllers 2.3 - 57

Input-Output of Function Blocks

Run-time:

read

inputs

I

write

outputs

X

execute

O

I

X

O

individual period

I

X

O

time

The function blocks are executed cyclically.

• all inputs are read from memory or from the plant (possibly cached)

• the segment is executed

• the results are written into memory or to the plant (possibly to a cache)

The order of execution of the blocks generally does not matter.

To speed up algorithms and avoid cascading, it is helpful to impose an

execution order to the blocks.

The different segments may be assigned a different individual period.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 58

Program configuration

The programmer divides the program into tasks (sometimes called

pages or segments), which may be executed each with a different

period.

The programmer assigns each task (each page) an execution

period. Since the execution time of each block in a task is fixed, the

execution time is fixed.

Event-driven operations are encapsulated into blocks, e.g. for

transmitting messages.

If the execution time of these operations take more than one period,

they are executed in background.

The periodic execution always has the highest priority.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 59

IEC 61131 - Execution engine

configuration

resource

resource

task

task

program

program

FB

task

task

program

program

FB

FB

global and directly

FB

represented variables

access paths

communication function

Legend:

FB

execution control path

variable access paths

function block

variable

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 60

Parallel execution

Function blocks are particularly well suited for true multiprocessing (parallel

processors).

The performance limit is given by the needed exchange of signals by shared memory.

Semaphores are not used since they could block an execution and make the concerned

processes non-deterministic.

processor

1

processor

2

processor

3

input/

output

shared

memory

shared

memory

shared

memory

shared

memory

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 61

2.3.5.5 Structured Text

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Input / Output

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 62

Structured Text

(Strukturierte Textsprache, langage littéral structuré)

Structured Text is an imperative language similar to Pascal (If, While, etc..)

The variables defined in ST can be used in other languages

ST is used to do complex data manipulation and write blocks

Caution: writing programs in structured text can breach the real-time rules !

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 63

Data Types

Function Blocks are typed: the types of connection, input and output must match.

•Elementary Types are defined either in Structured Text or in the FB configuration.

analog types:

binary types:

BOOL

BYTE

WORD

DWORD

1

8

16

32

REAL

LREAL

(Real32)

(Real64)

•Derived Types are user-defined and must be declared in Structured Text

subrange,

enumerated,

arrays,

structured types

(e.g. AntivalentBoolean2)

Variables can receive initial values and be declared as non-volatile (RETAIN), so

after restart they contain the last value before power-down or reset.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 64

Example of Derived Types

TYPE

ANALOG_CHANNEL_CONFIGURATION

STRUCT

RANGE: ANALOG_SIGNAL_RANGE;

MIN_SCALE : ANALOG_DATA ;

MAX_SCALE : ANALOG_DATA ;

END_STRUCT;

ANALOG_16_INPUT_CONFIGURATION :

STRUCT

SIGNAL_TYPE : ANALOG_SIGNAL_TYPE;

FILTER_CHARACTERISTIC : SINT (0.99)

CHANNEL: ARRAY [1..16] OF ANALOG_CHANNEL_CONFIGURATION;

END_STRUCT ;

END_TYPE

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 65

Structured Text Examples

IF tank.temp > 200 THEN

pump.fast :=1;

pump.slow :=0;

pump.off :=0;

ELSIF tank.temp > 100 THEN

pump.fast :=0;

pump.slow :=1;

pump.off :=0;

ELSE

pump.fast :=0;

pump.slow :=0;

pump.off :=1;

END_IF;

IF( Switch_0 AND Switch_1 ) THEN

Start_Motor := 1;

Start_Count := Start_Count + 1;

END_IF;

pos := 0;

WHILE((pos < 100)

& s_arr[pos].value <> target)) DO

pos := pos + 2;

String_tag.DATA[pos] :=

SINT_array[pos];

END_WHILE;

Predefined functions, e.g.:

SIZE(SINT_array, 0, SINT_array_size);

Count the number of elements in SINT_array (array that contains inputs) and store

result in SINT_array_size (DINT tag).

[http://literature.rockwellautomation.com/idc/groups/literature/documents/pm/1756-pm007_-en-p.pdf]

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 66

Structured Text Example

Move ASCII characters from a SINT array into a string tag. (In a SINT array, each element holds one

character.) Stop when you reach the carriage return.

element_num := 0;

SIZE(SINT_array, 0, SINT_array_size);

WHILE SINT_array[element_num] <> 13 DO

String_tag.DATA[element_num] := SINT_array[element_num];

element_num := element_num + 1;

String_tag.LEN := element_num;

IF element_num = SINT_array_size then

exit;

END_IF;

END_WHILE;

Explanations:

1. Initialize element_num to 0.

2. Count the number of elements in SINT_array (array that contains the ASCII characters) and store the result

in SINT_array_size (DINT tag).

3. If the character at SINT_array[element_num] = 13 (carriage return), then stop.

4. Set String_tag[element_num] = the character at SINT_array[element_num].

5. Add 1 to element_num. This lets the controller check the next character in SINT_array.

6. Set the Length member of String_tag = element_num. (This records the number of characters in String_tag

so far.)

7. If element_num = SINT_array_size, then stop. (You are at the end of the array and it does not contain a

carriage return.)

8. Go to 3.

[http://literature.rockwellautomation.com/idc/groups/literature/documents/pm/1756-pm007_-en-p.pdf]

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 67

Structured Text Exercise

A user-defined data type (structure) stores information about an item in an Inventory array:

• Inventory[i].ID: Barcode ID of the item (string data type)

• Inventory[i].Qty: Quantity in stock of the item (DINT data type)

An array of the above structure contains an element for each different item in your inventory. You

want to search the array for a specific product (by its barcode) and determine the quantity in stock.

Pseudocode:

1. Get size (number of items) of Inventory array and store result in Inventory_Items (DINT tag).

2. Loop over positions in array.

3. If Barcode matches the ID of an item in the array, then:

a. Set the Quantity tag = Inventory[position].Qty

b. Stop.

[http://literature.rockwellautomation.com/idc/groups/literature/documents/pm/1756-pm007_-en-p.pdf]

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 68

Structured Text Exercise Solution

A user-defined data type (structure) stores information about an item in an Inventory array:

• Inventory[i].ID: Barcode ID of the item (string data type)

• Inventory[i].Qty: Quantity in stock of the item (DINT data type)

An array of the above structure contains an element for each different item in your inventory. You

want to search the array for a specific product (by its barcode) and determine the quantity in stock.

Pseudocode:

1. Get size (number of items) of Inventory array and store result in Inventory_Items (DINT tag).

2. Loop over positions in array.

3. If Barcode matches the ID of an item in the array, then:

a. Set the Quantity tag = Inventory[position].Qty

b. Stop.

Solution:

SIZE(Inventory,0,Inventory_Items);

FOR position:=0 to Inventory_Items - 1 DO

IF Barcode = Inventory[position].ID THEN

Quantity := Inventory[position].Qty;

EXIT;

END_IF;

END_FOR;

[http://literature.rockwellautomation.com/idc/groups/literature/documents/pm/1756-pm007_-en-p.pdf]

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 69

2.3.5.6 Sequential Function Charts

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Input / Output

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 70

SFC (Sequential Flow Chart)

(Ablaufdiagramme, diagrammes de flux en séquence )

START STEP

T1

STEP A

N

ACTION D1

D1_READY

D

ACTION D2

D2_READY

STEP B

T2

• Describes sequences of operations and interactions between parallel processes.

• Derived from Grafcet and SDL (Specification and Description Language, used for

communication protocols), mathematical foundation lies in Petri Nets.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 71

SFC: Elements

S0

event condition

("1" = always true)

"1"

transitions

Sa

Ea

states

example transition condition

Ec = ((varX & varY) | varZ)

Sb

Eb

token

Sc

The sequential program consists of states connected by transitions.

A state is activated by the presence of a token (the corresponding variable becomes TRUE).

The token leaves the state when the transition condition (event) on the state output is true.

Only one transition takes place at a time, the execution period is a configuration parameter

(task to which this program is attached)

Rule: there is always a transition between two states,

there is always a state between two transitions

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 72

SFC: Initial state

State which come into existence with a token are called initial states.

All initial states receive exactly one token, the other states receive none.

Initialization takes place explicitly at start-up.

In some systems, initialization may be triggered in a user program

(initialization pin in a function block).

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 73

SFC: Switch and parallel execution

E0

"1"

token switch : the token crosses the first active

Sa

transition (at random if both Ea and Eb are true)

Note: transitions are after the alternance

Ea

Eb

Sc

Ec

Sb

Sd

Ed

Se

token forking : when the transition Ee is true, the token

is replicated to all connected states

Ee

Note: transition is before the fork

Ef

token join : when all connected states have tokens

and transition Eg is true, one single token is forwarded.

Sg

Sf

Note: transition is after the join

Eg

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 74

SFC: P1, N and P0 actions

State1

P1 State1_P1: do at enter

N

State1_N: do while

P0 State1_P0: do at leaving

P1 (pulse raise) action is executed once when the state is entered

P0 (pulse fall) action is executed once when the state is left

N (non-stored) action is executed continuously while the token is in the state

P1 and P0 actions could be replaced by additional states.

The actions are described by a code block written e.g. in Structured Text.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 75

Special action: the timer

rather than define a P0 action “ reset timer….”, there is an implicit variable defined as

<state name>.t that express the time spent in that state.

S

S.t > t#5s

Sf

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 76

SFC: graphic rules

The input and output flow of a state are always in the same vertical line (simplifies structure)

Alternative paths are drawn such that no path is placed in the vertical flow

(otherwise would mean this is a preferential path)

intentional displacement to

avoid optical preference of a

path.

Priority:

• The alternative path most to the left has the

highest priority, priority decreases towards the right.

• Loop: exit has a higher priority than loopback.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 77

SFC: Exercise

Variables

Input:

I0, I1, I2, I3 (boolean);

Output:

Trap = {0: closed; 1: open}

Speed = {+20: +1 m/s; +1: +5 cm/s; 0: 0m/s}

Register = {0: closed; 1: open}

negative values: opposite direction

trap

I0

Register = {0: closed; 1: open}

+speed

I1

I2

I3

Inputs generate “1” as long as

the tag of the vehicle (1cm) is

over the sensor.

Speed = 5 cm/s from I1 to I0 and from I2 to I3, faster otherwise.

Initially: move vehicle at reduced speed until it touches I0 and open the trap for 5s

(empty the vehicle).

1 - Let the vehicle move from I0 to I3

2 - Stop the vehicle when it reaches I3.

3 - Open the tank during 5s.

Industrial Automation

2013

4 - Go back to I0

5 - Open the trap and wait 5s.

repeat above steps indefinitely

Programmable Logic Controllers 2.3 - 78

Exercise SFC Example Solution

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 79

SFC: Structuring

Every flow chart without a token generator may be redrawn as a

structured flow chart (by possibly duplicating program parts)

Not structured

structured

A

a

A

B

a

b

B

d

d

C

b

c

C

B'

c

b

d

A'

Industrial Automation

2013

a

Programmable Logic Controllers 2.3 - 81

SFC: Complex structures

These general rules serve to build networks, termed by DIN and IEC as flow charts

Problems with general networks:

Deadlocks, uncontrolled

token multiplication

Industrial Automation

2013

Solution:

assistance through the flow chart editor.

Programmable Logic Controllers 2.3 - 82

Function Blocks And Flow Chart

Function Blocks:

Continuous (time) control

Sequential Flow Charts:

Discrete (time) Control

Many PLC applications mix continuous and discrete control.

A PLC may execute alternatively function blocks and flow charts.

Communication between these program parts must be possible.

Principle:

A flow chart taken as a whole can be considered a function

block with binary inputs (transitions) and binary outputs (states).

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 83

Executing Flow Charts As blocks

A function block may be implemented in different ways:

procedure

xy(...);

begin

...

end xy;

extern (ST/IL)

function blocks

flow chart

Function blocks and flow chart communicate over binary signals.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 84

Flow Charts or Function Blocks ?

A task can sometimes be written indifferently as function blocs or as flow chart.

The application may decide which representation is more appropriate:

Flow Chart

Function Block

a

"1"

b

S

R

c

NOT

c

d

b

d

a

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 85

Flow Charts Or Blocks ? (2)

Flow Chart

Function Blocks

init

"1"

≥

S

&

a

a

B

S

b

C

A

R

A

B

R

c

&

b

S

C

R

&

c

In this example, a flow chart seems to be more appropriate:

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 86

Exercise: write the SFC for this task

V1

L1

V3

open V1 until tank’s L1 indicates upper level

open V2 during 25 seconds

open V3 until the tank’s L1 indicates it reached the lower level

while stirring.

heat mixture during 50 minutes while stirring

empty the reactor while the drying bed is moving

repeat

V2

upper

lower

MS

H1

T

heater

(actor)

temperature

(sensor)

V4

MD

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 87

2.3.5.7 Ladder Diagrams

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.2 PLCs: Kinds

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Input / Output

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 88

Ladder Diagrams (1)

(Kontaktplansprache, langage à contacts)

Ladder Diagrams is the oldest programming language for PLC

- based on relay intuition of electricians.

- widely in use outside Europe.

- not recommended for large new projects.

Input instructions (conditions)

Output (actions)

Rung 0

Rung 1

Rung 2

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 89

Ladder Diagrams (2)

The contact plan or "ladder diagram" language allows an easy transition from the

traditional relay logic diagrams to the programming of binary functions.

It is well suited to express combinational logic

It is not suited for process control programming (there are no analog elements).

The main Ladder Diagrams symbols represent the elements:

make contact

contact travail Arbeitskontakt

break contact

contact repos Ruhekontakt

relay coil

Industrial Automation

2013

bobine

Spule

Programmable Logic Controllers 2.3 - 90

Ladder Diagrams Example (3)

origin:

electrical

circuit

make contact

(contact travail)

01

02

relay coil

(bobine)

03

50

break contact

(contact repos)

02

01

corresponding

ladder diagram

50

03

50

05

44

Industrial Automation

2013

rung

"coil" 50 is used to move

other contact(s)

Programmable Logic Controllers 2.3 - 91

Ladder Diagrams (4)

Binary combinations are expressed by series and parallel relay contact:

Ladder Diagrams representation

Series

+

01

“logic" equivalent

01

02

50

02

50

Coil 50 is active (current flows) when 01 is active and 02 is not.

Parallel

+

01

40

02

01

02

40

Coil 40 is active (current flows) when 01 is active or 02 is not.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 92

Ladder Diagrams (5)

The Ladder Diagrams is more intuitive for complex binary expressions than literal languages

textual expression

1

2

3

4

! 1 & 2 & ( 3 & ! 4 | ! 5 & 6 ) = 50

50

5

6

Or

N1 & 2 STR 3 & N4 STR N5 & 6

/ STR & STR = 50

0

1

4

5

12

50

2

3

10

6

11

Industrial Automation

2013

7

N0 & 1 STR 2 & 3 / STR STR 4

& 5 STR N 6 & 7

/ STR & STR STR 10

& 11 / STR & 12 = 50

Programmable Logic Controllers 2.3 - 93

Ladder Diagrams (6)

Ladder Diagrams stems from the time of the relay technology.

As PLCs replaced relays, their new possibilities could not be expressed any more

in relay terms.

The contact plan language was extended to express functions:

00

01

FUN 02

literal expression:

200

!00 & 01 FUN 02 = 200

The intuition of contacts and coil gets lost.

The introduction of «functions» that influence the control flow itself, is problematic.

The contact plan is - mathematically - a functional representation.

The introduction of a more or less hidden control of the flow destroys the

freedom of side effects and makes programs difficult to read.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 94

Ladder Diagrams Example

Ladder Diagrams diagram for a batch process: filling a container with a liquid,

mixing the liquid, and draining the container. The sequence of events is as follows:

1. fill valve opens and lets the liquid into the container until it is full.

2. liquid in the container is mixed for 3 minutes.

3. a drain valve opens and drains the tank.

O = output

I = input

Source: http://teacher.buet.ac.bd/zahurul/ME6401/ME6401_PLC.pdf

Industrial Automation

2013

Address of variable

(module number, port

number)

Programmable Logic Controllers 2.3 - 95

Ladder Diagrams Exercise

Consider a PLC with one input module and one output module. Two external switches (SW-0

& SW-1) are connected via terminal IN-0 and In-1 of input module. Two terminals of the output

module (OUT-0 & OUT-1) drive two indicator lamps (Lamp-0 & Lamp-1).

Which lamps are lit with the current switch positions?

What happens if you change the position of Switch SW-1?

Source: http://teacher.buet.ac.bd/zahurul/ME6401/ME6401_PLC.pdf

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 96

Ladder Diagrams Exercise Solution

The top rung will light Lamp-0 if both SW-0 and SW-1 are closed. The bottom rung will light

Lamp-1 if either SW-0 or OUT-0 are closed.

In the current position LAMP-1 is lit.

If we change the position of Switch SW-1 then LAMP 0 will be lit too.

Source: http://teacher.buet.ac.bd/zahurul/ME6401/ME6401_PLC.pdf

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 97

Ladder Diagrams (7)

Ladder Diagrams provides neither:

• sub-programs (blocks), nor

• data encapsulation nor

• structured data types.

It is not suited to make reusable modules.

IEC 61131 does not prescribe the minimum requirements for a compiler / interpreter

such as number of rungs per page nor does it specifies the minimum subset to be

implemented.

Therefore, it should not be used for large programs made by groups of people

It is very limited when considering analog values (it has only counters)

→ used mostly in manufacturing, not in process control

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 98

2.3.6 Instruction Lists

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.2 PLCs: Kinds

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Input / Output

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Instructions Lists

2.3.5.9 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 99

Instruction Lists (1)

(Instruktionsliste, liste d'instructions)

Instruction lists is the machine

language of PLC programming

It has 21 instructions (see table)

Three modifiers are defined:

"N" negates the result

"C" makes it conditional and

"(" delays it.

All operations relate to one result

register (RR) or accumulator.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 100

Instruction Lists (2)

(Instruktionsliste, liste d'instructions)

Accumulator-based pogramming:

• First, values are loaded into the accumulator (LD instruction)

• Then, operations are executed with first parameter taken out of accumulator

and second parameter of operand.

• Result put in the accumulator, from where it can be stored (ST instruction)

Conditional executions or loops are supported by comparing operators like

EQ, GT, LT, GE, LE, NE and jumps (JMP, JMPC, JMPCN, for the last two the

accumulators value is checked on TRUE or FALSE)

Syntax:

- each instruction begins on a new line and contains an operator and,

depending on the type of operation, one or more operands separated by commas

- before an instruction there can be a label, followed by a colon (:), as target for jumps

- use brackets to define order of execution

- comments must be placed last

- empty lines are allowed.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 101

Instruction Lists Example (3)

End:

ST

speed3

(* result *)

Instructions Lists is the most efficient way to write code, but only for specialists.

Otherwise, IL should not be used, because this language:

• provides no code structuring

• has weak semantics

• is machine-dependent

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 102

Instruction Lists Examples (4)

Labels

LD TRUE

ANDN BOOL1

JMPC mark

(*load TRUE into the accumulator*)

(*execute AND with the negated value of the BOOL1 variable*)

(*if the result was TRUE, then jump to the label "mark"*)

LDN BOOL2

ST RES

JMP continue

(*load the negated value of BOOL2 into the accumulator*)

(*store the content of the accumulator in RES*)

(*jump to label “continue"*)

mark:

LD BOOL2

ST RES

(*save the value of *)

(*BOOL2 in RES*)

continue:

…

Brackets (without)

LD 2

MUL 2

ADD 3

ST RES

(*7 is stored in RES*)

Industrial Automation

2013

(with)

LD 2

MUL(2

ADD 3

)

ST RES (* 10 is stored in RES*)

Programmable Logic Controllers 2.3 - 103

Instruction Lists Exercise(3)

End:

ST

speed3

(* result *)

What is the resulting speed3 for the following input?

a)

Temp1 = 10

Temp2 = 15

Speed1 = 50

Speed2 = 100

Industrial Automation

2013

b)

Temp1 = 10

Temp2 = 5

Speed1 = 50

Speed2 = 100

Programmable Logic Controllers 2.3 - 104

Exercise IEC 61131 Languages

Ladder Diagram

A B

Function Block Diagram

C

A

-| |--|/|----------------( )

B

Instruction List

?

?

?

?

?

?

?

?

C

?

Structured Text

C:= ?

http://tinyurl.com/IA61131

https://docs.google.com/forms/d/1lGkFXQrlwlnoKc8gUg-_ESAdtVy-RgIOLnFbkIOGNa8/viewform

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 105

Exercise IEC 61131 Languages

Ladder Diagram

A B

Function Block Diagram

C

A

-| |--|/|----------------( )

AND

C

B

Instruction List

LD

A

ANDN

B

ST

C

Structured Text

C:= A AND NOT B

http://tinyurl.com/IA61131

https://docs.google.com/forms/d/1lGkFXQrlwlnoKc8gUg-_ESAdtVy-RgIOLnFbkIOGNa8/viewform

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 106

2.3.5.9 Programming environment

2.1 Instrumentation

2.2 Control

2.3 Programmable Logic Controllers

2.3.1 PLCs: Definition and Market

2.3.2 PLCs: Kinds

2.3.3 PLCs: Functions and construction

2.3.5 PLC Programming Languages

2.3.5.1 IEC 61131 Languages

2.3.5.2 Function blocks

2.3.5.3 Program Execution

2.3.5.4 Input / Output

2.3.5.5 Structured Text

2.3.5.6 Sequential Function Charts

2.3.5.7 Ladder Diagrams

2.3.5.8 Instructions Lists

2.3.5.9 Programming environment

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 107

Programming environment capabilities

A PLC programming environment (e.g. ABB ControlBuilder,

Siemens Step 7, CoDeSys,...) allows the programmer to

- program in one of the IEC 61131 languages

- define the variables (name and type)

- bind the variables to the input/output (binary, analog)

- run simulations

- download programs and firmware to the PLC

- upload from the PLC (if provided, rare)

- monitor the PLC

- document and print

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 108

61131 Programming environment

configuration, editor,

compiler, library

symbols

workstation

code

firmware

download

variable

monitoring

and

forcing

for debugging

network

PLC

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 109

Program maintenance

The source of the PLC program is generally on the laptop of the technician.

This copy is frequently modified, it is difficult to track the original in a process

database, especially if several people work on the same machine.

Therefore, it would be convenient to be able to reconstruct the source programs

out of the PLC's memory (called back-tracking, Rückdokumentation, reconstitution).

This supposes that the instruction lists in the PLC can be mapped directly to graphic

representations -> set of rules how to display the information.

Names of variables, blocks and comments must be kept in clear text, otherwise the

code, although correct, would not be readable.

For cost reasons, this is rarely implemented.

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 110

Is IEC 61131 FB an object-oriented language ?

Not really: it does not support inheritance.

Blocks are not recursive.

But it supports interface definition (typed signals), instantiation,

encapsulation, some form of polymorphism.

Some programming environments offer “control modules” for better

object-orientation

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 111

Limitations of IEC 61131

- No support to distribute execution of programs over several devices

- No support for event-driven. Blocks may be triggered by a Boolean

variable (intentionally, for good reasons).

- If structured text increases in importance, better constructs are

required (object-orientation)

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 112

Assessment

Which are programming languages defined in IEC 61131 and for what are they used ?

In a function block language, which are the two elements of programming ?

How is a PLC program executed and why is it that way ?

Draw a ladder diagram and the corresponding function block chart.

Draw a sequential chart implementing a 2-bit counter

Program a saw tooth waveform generator with function blocks

How are inputs and outputs to the process treated in a function block language ?

Write a program for a simple chewing-gum coin machine

Program a ramp generator for a ventilator speed control (soft start and stop in 5s)

Industrial Automation

2013

Programmable Logic Controllers 2.3 - 113