syllabus - Universitatea Tehnica din Cluj

advertisement

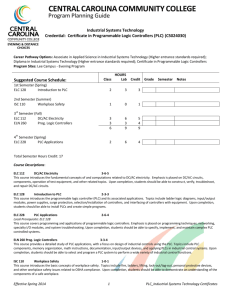

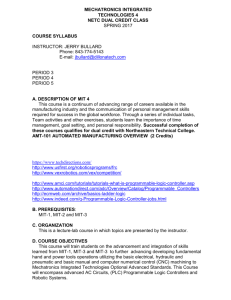

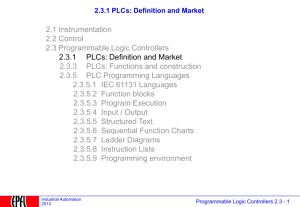

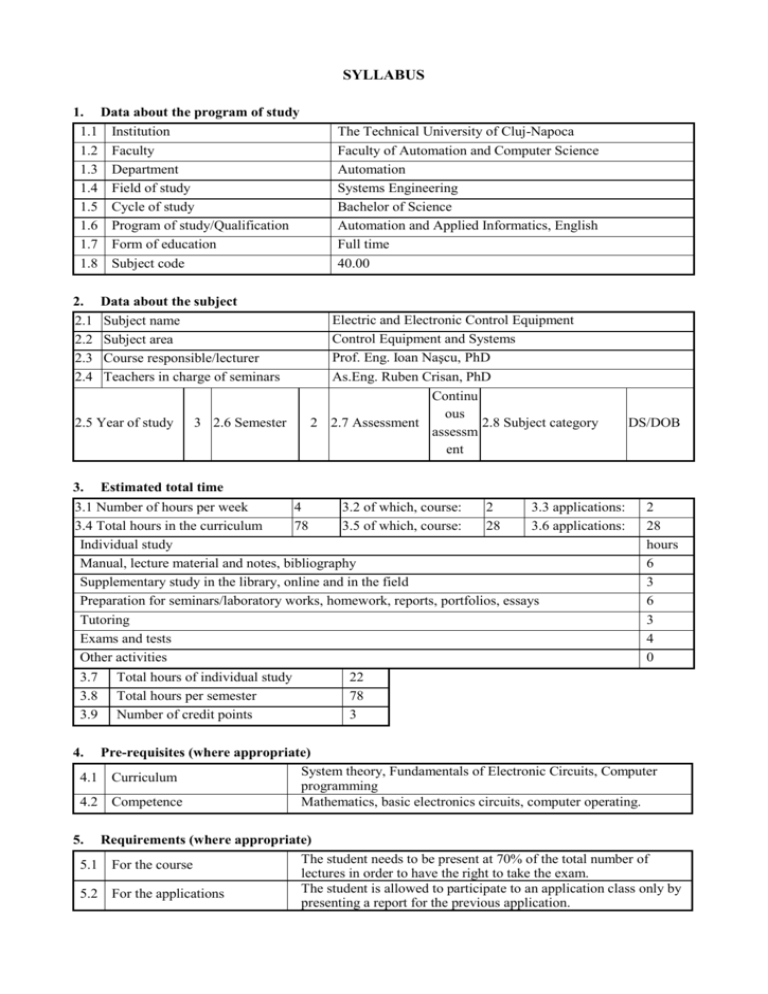

SYLLABUS 1. Data about the program of study 1.1 Institution 1.2 Faculty 1.3 Department 1.4 Field of study 1.5 Cycle of study 1.6 Program of study/Qualification 1.7 Form of education 1.8 Subject code 2. 2.1 2.2 2.3 2.4 Data about the subject Subject name Subject area Course responsible/lecturer Teachers in charge of seminars 2.5 Year of study 3 2.6 Semester The Technical University of Cluj-Napoca Faculty of Automation and Computer Science Automation Systems Engineering Bachelor of Science Automation and Applied Informatics, English Full time 40.00 Electric and Electronic Control Equipment Control Equipment and Systems Prof. Eng. Ioan Naşcu, PhD As.Eng. Ruben Crisan, PhD Continu ous 2 2.7 Assessment 2.8 Subject category assessm ent 3. Estimated total time 3.1 Number of hours per week 4 3.2 of which, course: 2 3.3 applications: 3.4 Total hours in the curriculum 78 3.5 of which, course: 28 3.6 applications: Individual study Manual, lecture material and notes, bibliography Supplementary study in the library, online and in the field Preparation for seminars/laboratory works, homework, reports, portfolios, essays Tutoring Exams and tests Other activities 3.7 3.8 3.9 Total hours of individual study Total hours per semester Number of credit points DS/DOB 2 28 hours 6 3 6 3 4 0 22 78 3 4. Pre-requisites (where appropriate) System theory, Fundamentals of Electronic Circuits, Computer 4.1 Curriculum programming Mathematics, basic electronics circuits, computer operating. 4.2 Competence 5. Requirements (where appropriate) The student needs to be present at 70% of the total number of 5.1 For the course lectures in order to have the right to take the exam. The student is allowed to participate to an application class only by 5.2 For the applications presenting a report for the previous application. Specific competences C4 Design, implementation, testing, operation and maintenance of systems with generic and dedicated equipments, including computer networks for control engineering and applied informatics Cross competences Professional competences 6. 7. N/A Discipline objectives (as results from the key competences gained) 7.1 General objective 7.2 Specific objectives Knowledge of fundamental principles, the constructivetechnological and conceptual issues underlying common automation equipment (transmitters, controllers, indicators, recorders, Programmable Logic Controllers), assimilation of knowledge concerning the possible use of such equipment to implement automatic control systems for industrial processes. Wiring and commissioning of common control systems equipment in typical industrial application. Wiring, commissioning and programming of programmable logic controllers (PLC). Designing and building automation equipment (transmitters, indicators, PID controllers) using microcontroller development systems 8. Contents 8.1. Lecture (syllabus) C1. Introductive notions. Electromechanical relays, 1. electronic relays. 2. C2. Time, magnetic and optic relays. 3. C3. Signal transmitters (temperature). 4. C4. Signal transmitters (ph, pressure, flow). 5. C5. Indicators, recorders, integrators. C6. Automatic Controllers with PID structure: basics, 6. analog controllers, digital controllers, control algorithms. C7. Automatic Controllers with PID structure: values 7. display, wiring, commissioning, auxiliary modules, auxiliary functions 8. C8. Usual digital controllers: configuration C9. Digital systems in industrial process control, 9. SCADA systems. C10. Digital systems in industrial process control 10. Industrial communication Teaching methods Slides presentation, explanations and demonstrations on whiteboard, discussions Notes C11. Programmable logic controllers (PLC): generalities, hardware configuration C12. Programmable logic controllers (PLC): the 12. graphset concept, ladder diagrams C13. Programmable logic controllers (PLC): sequential 13. process control applications. C14. Programmable logic controllers (PLC): continuous 14. process control applications. Bibliography 1. Fundamentals of PLC, sensors and communications, J. Stenerson,2004 2. PID control, F. Haugen, Tapir Uttrykk, 2004. 3. Engineering instrumentation and control, Haslam J. A., 1993 4. Lessons In Industrial Instrumentation, Tony R. Kuphaldt,1990 5. Basic Instrumentation Measuring Devices And Basic Pid Control, CNSC Technical Training Group, 2003 11. 8.2. Applications/Seminars Teaching methods Notes L1. Signal transmitters: connection, configuration, utility 1. L2. Indicators and recorders used in industrial automation 2. L3. Digital controllers: connection, configuration, testing, 3. connection to the PC, distributed control system, supervision, monitoring L4. Autotunning of digital controllers 4. L5. PLC – I/O numerical configuration, applications 5. Brainstorming, L6. PLC – I/O analogue configuration, applications 6. case studies, open L7-L9. Sorting system application, cut to length 7. discussions application L10. PLC - connecting and programming the 8. programmable terminals, applications L11. PID control using PLC 9. L12. Relays: Reed, thermal, optical, magnetic, time 10. Final test 11. Bibliography 1. I. Naşcu, (2002), Sisteme şi echipamente pentru conducerea proceselor continue. Îndrumător de laborator. Universitatea Tehnică din Cluj-Napoca 2. Users Manuals. 3. FESTILA Clement, Regulatoare automate : indrumator de proiectare. Vol. 1, Cluj-Napoca : Universitatea Tehnica din Cluj-Napoca, 1990 9. Bridging course contents with the expectations of the representatives of the community, professional associations and employers in the field Lectures and applications content was discussed with field experts. Over the years the course was favorably assessed by various rating agencies: National Council for Academic Evaluation and Accreditation, Romanian Agency for Quality Assurance in Higher Education. 10. Evaluation Activity type 10.1 Assessment criteria Theory, problems Course Individual work results Applications 10.4 Minimum standard of performance 10.2 Assessment methods Written exam Oral exam 10.3 Weight in the final grade 60% 40% Wiring and configuration of the automatization equipment, connection, wiring and programming tne PLC. Date of filling in Dec. 05 2015 Teacher in charge of lectures Prof. Eng. Ioan Naşcu, PhD Date of approval in the department Teachers in charge of seminars As.Eng. Ruben Crisan, PhD Head of department Prof. Dr. Ing. Honoriu Valean