Grahame Dunling

advertisement

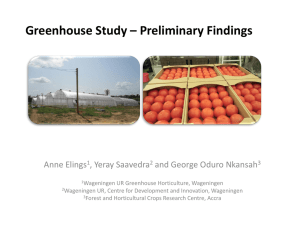

Introduce Modern Growing in G.C.C Presentation By Grahame Dunling The Problem: There are many so called experts that have never grown a commercial crop and they think they can build and advise other non growers how to grow. They say they have the latest technology such as Pad & Fan and Vertical A Frame grow systems. These systems they say can grow three times the crops that European growers achieve, There is one very good reason we in Europe do not grow on these system and that is because the do not work . The one main reason why the Hypermarkets import !! QUALITY the second reason is CONSISTANCY . So we have to grow Quality and we have to grow this year round we also have to have predictability. I plant chillis on the 6th October on the 15th December I start to pick them this way I give my yield per week to the supermarkets and they reduce the number of imports they buy to accommodate my Local supply. The Problem: G.C.C Imports 60% of its salad consumption this is in the Golden winter months ( November to May ) and up to 90% during the summer months of June to October. If the correct greenhouses were built and the correct team in place The G.C.C could grow and supply 90% of this consumption. So why do we struggle to do this? The greenhouse design is based on the Gothic arch type indeed 2 years ago I was called to Bahrain as a consultant and I was told ‘we have the most modern greenhouses in the world’ When I saw them I was shocked as they was 30 years out of date. That Ladies and Gentlemen is the problem we face. The Salad or Horticultural Industry in the GCC is growing ( Sorry ) but the other problem we face is if we grow more then how do we sell this product and where do we sell it. This means we have to grow the same quality as Holland does, so we can not only compete with imports but we can stop imports. If imported Dutch produce cost 1 Bhd a Kg to import then we should be able to sell our product for 0.800 fils and we make a good margin the supermarkets can then lower there price to the consumer but also make the same margin so everyone wins. But we have to change from the very poor quality Gothic Arch or hooped houses to modern Style greenhouses. But with our own touch and our own design. If I built a modern greenhouse in the GCC who could grow in it ? I could but who else, No one because it would be far to technical for them. Who in the GCC steers or stresses the tomatoes no one why ? Because they have not got either the skill set to Do this or they have the wrong greenhouse which does not allow this to happen. Modern Horticulture This is a typical nursery or Farm in the GCC ,Individual Greenhouses so the staff and Produce have to leave the Greenhouse to take produce to the Pack house This is a typical nursery or Farm in the Europe , Greenhouses are in one Large block and the packhouse is usually attached so the staff and Produce NEVER have to leave the Greenhouse to take produce to the Pack house. This creates a safer and cleaner environment for both the staff But even more important The PRODUCE Modern Horticulture Now I am not saying we build a Greenhouse like that one. BUT we can build a VERY Good venlo style Greenhouse and use a cooling system that we design ourselves . This way we reduce the Capital cost by 50% but we increase or yields from 10Kg m2 upto 30-40Kg m2 . After all why use Pad & Fan as this uses Water & Energy for the fan to run. But remember water = humidity and we cool using water? This means we increase humidity in a high humidity region ? Now is does this sound daft to me it does. If we redesign a cooling system we only use energy and we also reduce Humidity levels this In turn gives us year round growing. Consistent product means we can supply Local Supermarkets with year round supply of Local Salads . Therefore reducing imports and helping the countries economy. We can also increase staff efficiency by making the plants come to the staff instead off The staff going to the plants. Floating Raft So the movie you have watched was a floating raft production unit , the next slide is A Baby Leaf production system . This is automated to the extent of sowing and harvesting Using simple technology that can be easily built if the right company is used. By doing this we can employ Local companies to build the system taking the LOCAL feel To a more wider range of industries and creating employment for the Local people. So the Local Salads , Eat Local, Now has Use Local companies, Create Local Employment Giving a whole new meaning of Baby Leaf • • • • • • • • Local Salads for The G.C.C . Why is Local grown produce so important for the G.C.C . How can we improve the quality of the salads in the G.C.C What do we need to do to implement this How can we teach the Local growers this ‘New Technology’ Where do we find this Local skilled workforce How much technology do we really need Do we need to be as high tech as Europe or can we grow using our own developed technology. So the first steps to implement this is Early Stage Ideation 1. Why Local Produce ? Response: Local produce is Fresher, Local produce has a better Taste, Texture & also Quality 2. Local Produce is Poor Quality: Response: The reason for this is down to poor management and also poor greenhouses to grow produce in, We can improve management . 3. How: Response: By Training them and helping them to understand that the Local Workforce should not be seen as cheap labour, but as a valuable Member of a team. After all every team needs a water boy or all is lost. 4. New Technology : Response : We do not throw them in at the deep end we introduce systems slowly over a period of time . This way they learn and we Improve and they embrace the new technology instead of fighting it. Early Stage Ideation 5. Where do we find the workforce ? Response: Local workforce can also learn this way , give them responsibility and also accountability . Give a Bonus for better production 6. How much Technology do we need : Response: This is down to the Capital and also what crop we are growing . But we can start low tech and build up over time as the Management grow used to the systems. 7. Develop our own Hi tech : Response: we need a certain amount of hi tech but no where as high as Europe. We can develop our own what we need here using Local Companies. We have to embrace Local Modern growing NOW. 8. First Steps: Response : First we have to have a design of greenhouse & a cooling system then marry these together The Solution : This is not short term this is long term education for the country and the people but for food security we have to do this. In the GCC most of the food is shipped very long distances to get to our tables - impacting the quality, nutrition, freshness cost and flavour of our food. This entire food distribution system is highly unsustainable and largely dependent upon the same requirements supporting modern agriculture - most notably massive fossil fuel inputs. Our entire food production and distribution system is led by large vertically and horizontally integrated agribusinesses who wield sufficient economic and political power to distort national agricultural policies and priorities to their benefit. what the individual food shopper wants most in their fruits and vegetables is produce that is safe, fresh, nutritious and flavourful at an affordable cost. Or in other words LOCAL FOOD grown by local people and helping the Local economy 1. Building Selection: For all new builds we need to monitor the quality that the grower buys . But we can also in some cases modernize the structures they have now. 2. Indoor Growing / Lighting: New breeds of agricultural lighting are now commercially available at acceptable price points that enable profitable indoor growing. These technologies include LED lighting and Inductive Lighting). 60% Energy savings/low waste heat output/non point lighting for more even coverage. 3. Increasing Yields per Unit of Capital Expenditure: 100% Reliance on new proven artificial agricultural lighting solutions allows the increase of production capacity per square foot of conditioned building area by a factor of 3-15X (depending on the crop) by growing vertically, and by operating year-round under optimal growing conditions. A new proprietary method of micro-bubble aeration of nutrient solutions has already been shown to double vegetative growth rates alone. 4. Energy: Use of onsite CHP thermal and electric power generation offers cost savings through increased efficiencies (70-90% system efficiencies). Waste Vegetable oil can be used as a drop-in fuel, is available in any urban environment of sufficient quantities and reduces our cost of energy by 50% or more and is a carbon neutral renewable power base. 5. Adapting already scaled manufacturing technologies: Use of mass produced pallet rack systems along with robotic pick and place material handling systems. These are available Locally but with a world wide reach 6. New Vertical CEA Platforms found to be highly adaptive: Likely applicable to Nursery industry, Floriculture Industry, Forestry Industry as well as Fruit and Vegetable Production Industry. Nascent opportunity for growing plants to support derivative pharmaceutical crops also likely in play. 7. Propagation, Seed Production and New Crop Variety Development: Significant opportunities exist. Partner with OSU Crop Science and Food Science Departments to identify an opportunity development roadmap. Indoor unit are expensive 1. Challenge: CEA applications are very capital intensive. Response: Design a system that has significantly lower capital costs per unit of economic output. Lower capital costs and/or increase economic outputs per unit of capital. 2. Challenge: CEA applications are very energy intensive and exert a large carbon footprint Response: Design a system that is less energy intensive through greater energy efficiency and/or look for a less costly renewable energy power base. 3. Challenge: High labour costs contribute significantly to a commercial CEA’s cost structure. Response: The application of automated material handling, systems and stationary crop seeding, planting, harvesting, processing and packaging systems. This is only hard because no one has grown commercially. 4. Challenge: A significant portion of the body of knowledge of CEA systems, methods and processes is held as closely guarded proprietary information. Response: This is a false statement it is the fact that in the GCC has a lack of knowledge of modern horticultural practises , The technical control aspect is the easy part 5. Challenge: Crop seed stock and/or plant starts Could be Branded and sourced from world wide leaders in the Horticultural Industry. Response: I have developed relationships with the major seed houses throughout the world, so wherever in the world the quality of seed is guaranteed. 6. Challenge: Most crop varieties were developed for outdoor field cultivation. Response: This is a myth , and we employ a long range partnership with universities who have strong crop science programs to develop new crop varieties bred for flavor that are better suited for CEA applications. 7. Challenge: Most Growers in the GCC grow a range of crops and to educate them that the best way is to grow one very good crop will take time Response: Show them how easy a one crop operation is , show them the quality that can be achieved. Make them PROUD to have grown the crop 8. Challenge: the family of the grower do not want to grow Response: It is not that they do not want to , it is the fact they see growing as a low technical industry . Where in fact it is one of the highest technical industries there is. • Indoor Vertical Growing is one Solution Business Model Design Local Salads can supply One company a Franchise Business opportunity . This Master Franchise will be fully Branded and fully marketable. Our Mission “To become a world leading teacher of Integrated Controlled Environment Agricultural Solutions. Our Vision “To empower a new age in Agriculture and in so doing, help to build a more food secure and sustainable future.” Marketplace Entry and Branding Our Integrated Solutions will be marketed and branded under the trademark of “Local Salads” Growing Solutions. We need education of both the grower and the governments to improve Local Food supply and full food security. Thank you for looking at this presentation Contact : GRAHAME DUNLING E-Mail: grahame@localsalads.com www.localsalads.com