Chapter 1 - Dynamic Learning

Chapter 5.1

Finishing processes:

Dyeing and printing

Contents

○ Learning objectives

○ Colour and textiles

○ Computers and dyeing

○ What is dyeing?

○ The process of dyeing

○ Types of dye

○ Methods of dyeing

○ What is printing?

o Methods of printing o Finishing printed products o Dyeing, printing and the environment o Digital printing o Health and safety o Summary o Key terms

AQA GCSE Design and Technology

:

textiles technology

Learning objectives

To develop knowledge and understanding of: o the application of dyes to fabrics o how different printing and dyeing methods are used o the environmental issues related to dyeing and printing o the health and safety issues related to dyeing and printing

AQA GCSE Design and Technology

:

textiles technology

Colour and textiles

The importance of colour

o Colour is an important component in textiles and fashion design and manufacturing process o It is a key marketing tool in any promotion of textile products o The process of adding colour to textile products is complex o Colours are tested and checked before being applied o It is important to understand the properties of different fibres and fabrics, as different dyes are used for different fabrics

AQA GCSE Design and Technology

:

textiles technology

Colour and textiles

Colours for products

o Colours are dictated to designers by trends and personal likes and dislikes o Colours can have different cultural meanings in different countries o Designers need to consider these cultural meanings when developing design ranges o All aspects of the production of a fashion and textile product are dictated by the application of colour

AQA GCSE Design and Technology

:

textiles technology

Colour and textiles

o Colour ideas for designs can start when collating ideas for mood boards

AQA GCSE Design and Technology

:

textiles technology

Colours and textiles

o A specialist called a colourist is employed to oversee how colours are chosen and applied to textile products o They work with the design and production teams to ensure products have been correctly dyed and printed o The key problems that can occur are:

‒

shade variation

‒ fading

‒ bleeding

‒ colour staining

‒ streaking

AQA GCSE Design and Technology

:

textiles technology

Colour and textiles

Testing colour o The multifibre strip allows companies to test the take-up of dye across different fibres o It consists of a woven strip made up of several fibres, both synthetic and natural o The multifibre strip can be placed in a sample dye bath to see how the colours will react to different fibres o This is important as garments and other products are made of different fibres o It is important that all components in a product will be the same colour

AQA GCSE Design and Technology

:

textiles technology

Colour and textiles

o Multifibre strip: it is used to illustrate the take up of dye across several different fibres

AQA GCSE Design and Technology

:

textiles technology

Computers and dyeing

Using computer systems

o Sophisticated computer systems, known as shade or colour management systems, are used for dyeing o Advantages of using computer systems are:

‒

reduced dyeing and colour faults

‒ increased accuracy and consistency

‒ reduced costs

‒ saves time

‒ can create dye formulations for small or large-scale printing

AQA GCSE Design and Technology

:

textiles technology

What is dyeing?

o Dyeing is the process of adding colour to fibres, yarns, fabrics or garments o A dye solution is made up of water, dyestuffs (also called colourants) and mordants o Mordants are then added to ensure that the dye particles stick to the fibre being dyed o Dyes can be made from synthetic chemicals or from natural substances continued...

AQA GCSE Design and Technology

:

textiles technology

What is dyeing?

o Many companies will combine dyes with special finishes to give garments a different look, e.g. in the denim fashion industry o Synthetic, natural and mixed or blended fibres and fabrics can all be dyed

AQA GCSE Design and Technology

:

textiles technology

What is dyeing?

Fitness for purpose?

o Dyed products must have:

‒

fastness to light

‒ fastness to perspiration

‒ fastness to washing and laundering

‒ fastness to dry-cleaning

‒ fastness to chlorine (e.g. swimwear)

‒ fastness to rubbing o All these are key elements that need to be considered so a textile or fashion product is fit for use

AQA GCSE Design and Technology

:

textiles technology

The process of dyeing

Drying

The textiles and the dye liquid are combined together.

This might be for a few minutes or hours

Finishing

The excess dye is removed from the product and scoured with soaps and detergents

Scouring

An important part of the process in dyeing fabrics because, if insufficient dye is removed, the product can develop faults, such as streaking

AQA GCSE Design and Technology

:

textiles technology

Types of dye

○ There are five main classifications of dyes used in the textiles and fashion industry:

‒ acid

‒ direct

‒ disperse

‒ reactive

‒ pigments

AQA GCSE Design and Technology

:

textiles technology

Types of dye

Dye type Uses

Acid Protein fibres; synthetic fibres

Direct Mostly cellulosics

(e.g. cotton and linen)

Disperse Mostly nylon, acetate, modacrylic, polyester and olefin fibres

Reactive Mostly cellulosic fibres

Pigments Can be used on all fibres

Key issues

Bright colours; fastness: light and perspiration good, dry cleaning and silk excellent

Fastness: washing poor, light variable, perspiration and dry-cleaning excellent

Fastness: wash varies, perspiration excellent, light variable

Very bright shades; excellent light fastness

Applied to resin or binder base; can stiffen fabric; good fastness to light and hand-washing

AQA GCSE Design and Technology

:

textiles technology

Methods of dyeing

o The dyeing of fabrics is done on a large, industrial scale o The dyeing process has to be accurate to ensure that the same colours can be repeated o The type of dyeing process used is dependent on:

‒ type of fabric

‒ the fibres it contains

‒ whether the product to be dyed is in fibre form, fabric or ready made garment

‒ end use of the product

AQA GCSE Design and Technology

:

textiles technology

Continuous dyeing

o Continuous dyeing, one of processes used for dyeing textile products

AQA GCSE Design and Technology

:

textiles technology

Methods of dyeing

o Different types of dyeing equipment used for textile and fashion products

AQA GCSE Design and Technology

:

textiles technology

Methods of dyeing

The key methods of dyeing textile products are o stock dyeing o yarn dyeing o batch dyeing o continuous dyeing (pad dyeing) o garment dyeing

AQA GCSE Design and Technology

:

textiles technology

Methods of dyeing

Method How is it done?

Stock

Yarn

The dyeing of fibres before being spun into yarn. The most costly of all the dyeing processes.

Used mostly for fabrics where stripes, patterns or multicoloured effects are needed. Can also be done by hand, used a lot for homespun yarn.

Batch Dyeing a set weight of fabric and giving it a batch number so batches can be matched prior to garment manufacture. Colour of batches can vary.

Continuous

(pad)

Lengths of fabrics pass through a pad and container of dye, and are then squeezed to remove excess dye.

Garment Bulk-dyeing of simple garments. This method produces the least waste.

AQA GCSE Design and Technology

:

textiles technology

Methods of dyeing

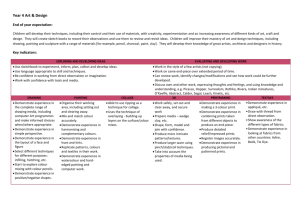

o Example of student work looking at dyeing and printing techniques

AQA GCSE Design and Technology

:

textiles technology

Methods of dyeing

Resist dyeing o In resist methods of dyeing, the pattern is restricted from moving around the fabric, using a resist, e.g. string, as in tie dye, or wax as in batik. o Once the resist is removed the pattern in the fabric is revealed

AQA GCSE Design and Technology

:

textiles technology

Methods of dyeing

Method

Tie-dye

Batik

Tritik

Shibori

How is it done?

The fabric is tied, folded or wrapped and placed in a dye bath. When it is removed, it is rinsed. Once dried, the ties/folds/wraps are undone, revealing the pattern. Multicoloured patterns can be achieved by refolding/tying/wrapping the fabric and dyeing with another colour.

Works well on natural fabrics.

Pattern applied to fabric using a paste, which can be rice-, flour- or wax-based. After dyeing the pattern is removed. Complex designs can be created. Works well on natural fabrics.

Fine, running stitches are applied to fabric, then pulled tight before fabric is dyed. After dyeing, stitching is removed, revealing pattern.

Good for intricate designs. Best results achieved using natural fabrics.

Japanese method of folding or tying fabrics, then applying a combination of heat and dyes, or chemicals. When fabric is dried, the ties are removed. Works on all types of fibres and fabrics.

AQA GCSE Design and Technology

:

textiles technology

What is printing?

o Printing is the process of applying a pattern and/or text to fabrics or other products o Printed designs can be applied by hand or by machine, using a number of different methods o Printing is widely used in the textiles industry as one of the primary methods of adding colour to fabrics o This process is known as adding surface pattern o CAD/CAM play an important part in the design and manufacturing of printing on to fabrics

AQA GCSE Design and Technology

:

textiles technology

Methods of printing

AQA GCSE Design and Technology

:

textiles technology

Methods of printing

o Roller printing: a traditional method

AQA GCSE Design and Technology

:

textiles technology o Digital printing: a new method

Finishing printed products

o After dyeing or printing, textiles products have to pass through a finishing process to remove excess dyes or print paste o This finishing process is also used to set the dyes into the fabrics, so that they do not run when washed. This finishing process also involves removing oils or other substances that gather on the fabric as it is being produced o The four key finishing processes that fabrics may go through either before or after printing are: fixation , washing , drying , heat setting

AQA GCSE Design and Technology

:

textiles technology

Dyeing and printing and the environment

o Dyes and pigments can be dangerous to the environment, especially to water supplies o Printing processes such as screen and rotary printing use a lot of water in the cleaning process o Companies must now follow strict government rules and

EU regulations for disposing of waste o Companies are developing more ecologically friendly dyes and are developing methods to reduce their water use continued...

AQA GCSE Design and Technology

:

textiles technology

Dyeing and printing and the environment

○ Many companies are now developing new dyes and printing materials that are organic, or water-based, so they do not need chemicals to clean equipment

○ EU Ecolabel

AQA GCSE Design and Technology

:

textiles technology

Digital printing

The impact of digital printing o The use of digital printing is beginning to make an impact on the textile printing industry o It provides a key way of making printing localised and reduces the need for lots of natural resources o Many designers are seeing it as an alternative for creating designs, as there is little waste produced, and it uses little or no water in the finishing process

AQA GCSE Design and Technology

:

textiles technology

Digital printing

o Combining the use of CAD with digital printing to develop designs.

The designs can be tested and checked before production. Testing is supported by annotation.

AQA GCSE Design and Technology

:

textiles technology

Health and safety

o Take care when using dyes, pigments and chemicals o Most textiles products come into contact with the skin, so all dyes used on garments or textile products must follow strict health and safety guidelines o In the classroom:

‒ dyes are also dangerous if inhaled, so it is important that you wear the appropriate protective equipment: this may include gloves, safety goggles and a protective apron

‒ follow the safety guidelines

AQA GCSE Design and Technology

:

textiles technology

Health and safety

o Safety symbol COSHH

AQA GCSE Design and Technology

:

textiles technology o Safety warning symbols

Summary

o Dyeing and printing are the key methods of applying colour to textile products o The colour of textiles is used as a key marketing tool by companies to promote their products o The dying and printing process uses a lot of water and companies are looking at ways of reducing this o As dyes and print pastes contain chemicals, they have to be disposed of very carefully continued...

AQA GCSE Design and Technology

:

textiles technology

Summary

o Many companies are now developing new dyes and printing materials that are organic, or water-based, so they do not need chemicals to clean equipment o Digital printing is being seen as an environmentally friendly process of printing

AQA GCSE Design and Technology

:

textiles technology

Key terms

o Colourant – a chemical agent added to the dye bath to produce colour o Commercial methods – production processes on a large scale, using machinery o Drying – removing excess moisture from fabrics o Dyeing – the process of applying colour to a textile product, which is soaked in a coloured solution o Fixation – fixing dyes and colours to fabric so they do not stain or run

AQA GCSE Design and Technology

:

textiles technology

Key terms

o Hand methods – using hand tools to manufacture products on a small scale or producing a small quantity o Heat setting – used mainly for synthetic fabrics, but most fabrics will undergo some sort of setting process to ensure that they are as they should be in appearance and stability o Mordants – used to control colour fastness o Printing – the process by which colour, type or pattern can be transferred to a textile or other substrate o Washing – cleaning fabrics prior to printing and dyeing

AQA GCSE Design and Technology

:

textiles technology