Inventory Management and Risk Pooling (1)

advertisement

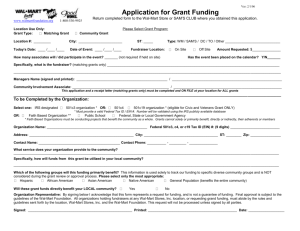

International Issues in Supply Chain Management Designing & Managing the Supply Chain Chapter 8 Yun-Ho Song ezeckiel@pusan.ac.kr 1/31 Outline CASE : Wal-Mart Changes Tactics to Meet International Tastes INTRODUCTION RISK AND ADVANTAGES OF INTERANTIONAL SUPPLY CHAINS ISSUES IN INTERATIONAL SUPPLY CHAIN ANAGEMENT REGIONAL DIFFERENCES IN LOGISTICS SUMMARY 2/31 Wal-Mart Changes Tactics to Meet International Tastes Wal-Mart Stores is finding out that what plays in Peoria isn’t necessarily a hit in suburban Sao Paulo Tanks of live trout are out; sushi is in American footballs have been replaced by soccer balls American-style jeans price at $19.99 have been dropped in favor of $9.99 knock-offs Adapting to local tastes may have been the easy part Three years after embarking on a blitz to bring “everyday low price” to the emerging market of Brazil and Argentina Wal-Mart is finding the going tougher than expected However Wal-mart produced red ink Brutal competition Don’t achieve efficiency through economies of scale 3/31 DEEP POCKET Wal-Mart has revised its merchandising in Brazil and Argentina and made other changes 4 newest stores are smaller than the initial outlets in San Paulo and Buenos Aires It located at Mid size cities where competition isn’t so force 8 stores are planned to open in both Argentina and Brazil next year, doubling the number now in each country Wal-Mart’s global expansion drive, which is targeting not only South America but also China Indonesia The markets of China and Indonesia are promising and pitfalls The growth is dwindling in America 4/31 A SMALL OPERATION SO FAR The six-year-old international operation is relatively tiny It accounted for only 4.8 percent of Wal-Mart’s 1996 sales Most of the company’s international revenue comes from Canada Mr. Glass expects international growth to account for a 1/3 of War-Mart’s annual increase in sales and profits within three to five years 5/31 LOSSES FORECAST SA, expect Wal-Mart to lose $20 million to $30 million in Brazil this year, on top of an estimated $48 million in losses since starting up in South America in 1995 Some store in Buenos Aires, a few shoppers are in the store during peak hours one Sunday • Little difference between the goods at Wal-Mart and those at near by Carrefour • Competitor’s chain supermarket supply fresh meat Carrefour drives Hard bargains with its suppliers, can afford to play low-ball because it has the critical mass that War-Mart lacks here Carrefour holds down overhead by stocking far-narrow selection of merchandise • Ex) Carrefour in La Plata, Argentina, stocks 22,000 items, while the Wal-Mart next door carries 58,000 items 6/31 DISTRIBUTION PROBLEMS Wal-Mart’s effort to stock such a wide variety of merchandise is hurting it Squeezing out costs in the supply chain is crucial to it’s EDL pricing formula Bumper-to-bumper traffic of San Paulo The biggest issue Wal-Mart is shipping product on time and getting on the shelf Wal-Mart recently built a warehouse in Argentina and Brazil to reduce distribution problem 7/31 VARIOUS MISTAKES Wal-Mart’s troubles in South America stem partly from its own mistakes Some goods are useless in San Paulo • Ex) Live trout, American footballs, Cordless tools Wal-Mart brought in stock-handling equipment that didn’t work with standardized local pallets Installed a computerized bookkeeping system that failed to take into account Brazil’s wildly complicated tax system 8/31 PROBLEMS CALLED TEMPORARY Wal-Mart’s Mr. Glass characterized the missteps are regarded as temporary problems and inevitable in entering a new market. 9/31 INTRODUCTION Important of Global operation and Supply chain Dornier’s statistics • About 1/5 of the output of U.S. firms is produced overseas • 1/4 of U.S. imports are between foreign affiliates and U.S. parent companies • Since the late 1980s, over half of U.S. companies increased the number of countries in which they operate 10/31 INTRODUCTION International distribution systems Manufacturing occur domestically, but distribution and typically some marketing take place overseas International suppliers Raw materials and Components furnished by foreign suppliers , but final assembly is performed domestically, in some case, the final product is shipped to foreign markets Offshore manufacturing Product is typically sourced and manufactured in a single foreign location, and then shipped back to domestic warehouses for sale and distribution Fully integrated global supply chain Products are supplied, manufactured and distributed from factories located throughout the world 11/31 Global Market Forces Involve the pressures created by foreign competitors as well as the opportunities created by foreign customers As in the dry breakfast cereal business, dominated by Kellogg Co. in US and Nestle in Europe • They failed attempts in the past to penetrate each other’s home markets, combined with the threat of retaliation, are enough to maintain the status quo Overflow of information can be one reason of global demand Ex) Television, E-mail, Internet 12/31 Technological Forces Related to the product themselves Various subcomponents and technologies are available in different regions and locations around the world Global location of research-and-development facilities is becoming more common product cycles become shorter and time more important, companies have discovered how useful it is to located research facilities close to manufacturing facilities Specific technical expertise may be available in certain areas or regions • Ex) Microsoft recently opened a research lab in Cambridge, England to take advantage of the expertise available in Europe 13/31 Global Cost Forces Global location decisions In the past the low cost of unskilled labor was decisive factor in determining factory location Recently, other global cost forces have become more significant • Many of the analyses and programs that US consulting firms undertook to address the Year 2000 problem were done in India, where programming skills are much cheaper • Capital cost of building a new facility often dominate labor cost 14/31 Political and Economic Forces Affect the drive toward globalization Regional trade agreements drive companies to expand into one of the countries in the regional group • A company’s advantage to obtain raw materials from or to manufacture within European, Pacific Rim, or North America trading block Various trade protection mechanisms can affect international supply chain decisions. Tariffs and quotas affect what can be imported, and lead a company to decide to manufacture within the market country or region • Ex) Local content 15/31 RISK AND ADVANTAGES OF INTERANTIONAL SUPPLY CHAINS Cost can be lowered with greater potential raw material, labor, and outsourcing sources and a greater number of potential manufacturing sites. Management understand the different demand characteristics and cost advantages of different regions The global supply chain can provide a firm with the flexibility to address the in international markets Flexibility can ne used to counteract the inherent risks from various factor that are relevant to global companies 16/31 Risks Fluctuating exchange rates Change relative value of production and profit Operating exposure Customer reactions • How a firm adjusts prices in various market Competitor reactions • Competitor’s relative cost decrease more, a firm can be underpriced in the market Government reactions Intervene to stabilize currencies or even directly support endangered firms by providing subsidies or tariffs 17/31 Addressing Global Risks Speculative Strategies A company bets on a single scenario, with often spectacular results if the scenario is realized, and dismal ones if it is not Hedge Strategies A company designs the supply chain in such a way that any losses in part of the supply chain will be offset by gains in another part Flexible Strategies(1/2) Enable a company to take advantage of different scenarios Typically, flexible supply chains are designed with multiple suppliers and excess manufacturing capacity in different countries Factories are designed to be flexible, so that products can be moved at minimal cost from region to region as economic conditions demand 18/31 Addressing Global Risks Flexible Strategies(2/2) several approaches • Is there enough variability in the system to justify the use of flexible strategies? • Do the benefits of spreading production over various facilities justify the cost? • Does the company have the appropriate coordination and management mechanisms in place to take rapid advantage of flexible strategies? 19/31 Addressing Global Risks Production shifting Flexible factories and excess capacity and suppliers can be used to shift production from region to region to take advantage of current circumstances Information sharing Information can be used to anticipate market changes and find new opportunities Global coordination Having multiple facilities worldwide provides a firm with a certain amount of market leverage that it might otherwise lack(Ex 8-2 253p) Political leverage The opportunity to move operations rapidly gives firms a measure of political leverage in overseas operations • governments are lax in enforcing contracts or international law, or present expensive tax alternatives, firms can move their operations 20/31 Requirements for Global Strategy Implementation Product development It is important to design products that can be modified easily for major markets, and which can be manufactured in various facilities Purchasing A company will find it useful to have management teams responsible for the purchase of important materials from many vendors around the world • easier to ensure that the quality and delivery options from various suppliers are compatible Production Excess capacity and plants in several regions are essential if firms are to take full advantage of the global supply chain by shifting production as conditions warrant • Centralized management are essential in this case 21/31 Requirements for Global Strategy Implementation Demand management It involves setting marketing and sales plans based on projected demand and available product, is carried out on a regional basis Order fulfillment To successfully implement a truly flexible supply chain management system, a centralized system must be in place so that regional customers can receive deliveries from the global supply chain with the same efficiency as they do from local or regionally based supply chain 22/31 Review the last part Following Forces are lead the Globalization Global market forces - opportunity Technological forces - product Global cost forces- location, labor, Y2k Political and economic forces – local contents Addressing global risk Speculative Strategies – set one scenario Hedge Strategies – one part loss, but other part get income Flexible Strategies – typically contract many supplier and design the surplus produce capacity • Production shifting • Information sharing • Global coordination – market leverage 23/31 ISSUES IN INTERATIONAL SUPPLY CHAIN MANAGEMENT Region-specific products Some products have to be designed and manufactured specifically for certain regions • For example, automobile designs are often Region specific • Ex) Honda Accord has 2 type of body • Ex 8-3 255p True global products These products are truly global, in the sense that no modification is necessary for global sales Ex) Coca-Cola, Levi’s jeans and McDonald’s burgers Consider carefully which of the 2 product type is more appropriate for a particular situation 24/31 Local Autonomy versus Central Control Centralized control can be important in taking advantage of some of the strategies But in many cases it makes sense to allow local autonomy in the supply chain Regional operation have proven to be successful Regional business depending on the characteristics of the region • Japan, German, U.S Ex 8-4 p 256 25/31 Miscellaneous Dangers Exchange rate fluctuation Offshore facilities Cheap labor Expensive training Local collaboration (Ex8-5 202p) Dangers related to foreign governments Ex) To deal with China and gain access to that country’s huge markets, many companies are handing over critical manufacturing and engineering expertise to the Chinese government or to Chinese partners protectionism (Ex8-6 202p) 26/31 REGIONAL DIFFERENCES IN LOGISTICS Cultural Differences Cultural differences can critically affect the way international subsidiaries interpret the goals and pronouncements of management • Language - expression, gestures, context • Belief - differ widely from culture to culture • Customs - differ widely from culture to culture 27/31 REGIONAL DIFFERENCES IN LOGISTICS Infrastructure First World Infrastructure Highly developed Emerging Under developed Third World Insufficient to support advanced logistics First World, relative economic conditions have affected the mix of logistics and supply chain components Emerging nations, the supply chain infrastructure is usually not fully in place. logistics as a necessary expense and not a strategic advantage, so they limit investments in logistics infrastructure Third World, the infrastructure is generally insufficient to support advanced logistics operations 28/31 REGIONAL DIFFERENCES IN LOGISTICS Performance Expectation and Evaluation First World, operating standards are generally uniform and high emerging nations, operating standards typically vary greatly • Ex) contract, appointment In the Third World, traditional performance measures have no meaning • Shortages are common • Customer service measure have no meaning 29/31 REGIONAL DIFFERENCES IN LOGISTICS Information System Availability First World, computer technology has increased at same rate across different nations • POS, EDI Emerging nations, Support systems may not be in place to implement efficient information systems • Communication network incomplete and not reliable Third World, Advanced information technology is simply not available • Inefficient communication system 30/31 REGIONAL DIFFERENCES IN LOGISTICS Human Resources First World, technically and managerially competent workers are available • Unskilled labor is relatively expensive Emerging nations, skilled managerial and technical personnel are frequently not available Third World, Although it may be possible to find employees that are appropriate to the available technology level • Difficult to find Trained logistics professionals and managers familiar with modern management techniques 31/31