12 SCS.DPIP.C - CERTIFICATION TESTING

advertisement

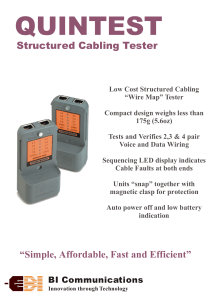

CABLING SYSTEM CERTIFICATION TESTING TWISTED-PAIR CABLING TESTING General • This section determines the characteristics of field test instruments, test methods, test configurations and minimum transmission requirements for the Signamax Cabling System, based on 100-Ohm twisted-pair cable and connecting hardware according to the rules set forth in the Manual. • The requirements are aimed at field-testing of installed twisted-pair cabling Channels/Permanent Links using field test instruments. TEST CONFIGURATIONS Test Configurations • Certification testing may be performed for either of two or both models of the cabling system: – Channel – Permanent Link Channel Model • The Channel test configuration should be used to verify the overall Channel performance. Channel starts here Channel starts here WA TR A B TO FIELD TESTER C CP D E HC FIELD TESTER Channel Model • The Horizontal subsystem maximum Channel configuration consists of – up to 90 m (295 ft) of Horizontal subsystem cable – a Work Area equipment cord – a Telecommunications Outlet – an optional Consolidation Point connector – a patch cord/jumper – an equipment cord – two connectors in the Telecommunications Room • The total length of the equipment cords, patch cords or jumpers and Work Area cords shall not exceed 10 m (33 ft) (26 m (85 ft) when the MuTOA is used) for 22-24 AWG. Channel Model • The Backbone subsystem maximum Channel configuration consists of – up to 90 m (295 ft) of Backbone subsystem cable – equipment cords – patch cords/jumpers – two connectors in the telecommunications spaces • The total length of equipment cords, patch cords or jumpers shall not exceed 10 m (33 ft) (25 m (82 ft) for the fixed cable length of less than 70 m) for 22-24-AWG. Channel Model 1 2 Any Channel models of the twisted-pair Horizontal and Backbone subsystems with the cable overall length of under 100 m (328 ft), including connecting hardware and equipment cords, shall pass 100% certification testing. The Channel models of the twisted-pair Horizontal and Backbone subsystems require the testing results to be recorded with the tester settings for the Channel model testing. Channel Model • The Channel certification testing of the twisted-pair Signamax Cabling System may apply the testing settings of the field testers for the compliance of the cabling system Channel transmission performance parameters with the requirements of various standards (ISO, TIA, CENELEC, AS/NZ and any others available in the field tester software). Permanent Link Model • The Permanent Link test configuration should be used to verify the efficiency of permanently installed cabling. Link starts here WA A B TO FIELD TESTER Link starts here C CP TR D HC FIELD TESTER Permanent Link Model • The Horizontal subsystem maximum Permanent Link configuration consists of – up to 90 m (295 ft) of Horizontal subsystem cable – one connector at each end – an optional Consolidation Point connector Permanent Link Model • The Permanent Link excludes both the cable portion of the field test instrument cord and the connection to the field test instrument. Link starts here WA A B TO FIELD TESTER Link starts here C CP TR D HC FIELD TESTER Permanent Link Model 3 4 Any Permanent Link models of the twisted-pair Horizontal and Backbone subsystems with the cable length of less than 90 m (295 ft) shall pass 100% certification testing. The Permanent Link models of the twisted-pair Horizontal and Backbone subsystems require the testing results to be recorded with the tester settings for the Permanent Link model testing. Permanent Link Model • The Permanent Link certification testing of the twisted-pair Signamax Cabling System may apply the testing settings of the field testers for the compliance of the cabling system Channel transmission performance parameters with the requirements of various standards (ISO, TIA, CENELEC, AS/NZ and any others available in the field tester software). TEST PARAMETERS Test Parameters 5 On testing of the category 5e, 6, and 6A Channels and Permanent Links of the twisted-pair cabling system the following parameters shall be tested: – – – – – – – – Wire map and screen continuity Return loss (RL) Insertion loss (IL) Propagation delay (PD) Propagation delay skew (PDS) Pair-to-pair near-end crosstalk loss (NEXT) Power-sum near-end crosstalk loss (PSNEXT) Pair-to-pair attenuation-to-crosstalk ratio, far end (ACRF) – Power-sum attenuation-to-crosstalk ratio, far end (PSACRF) Test Parameters 1 On testing of the category 6A Channels and Permanent Links the following parameters are recommended to be tested, but not required for the Signamax Cabling System warranty provision: – Alien near-end crosstalk (ANEXT) loss – Alien far-end crosstalk (AFEXT) loss – Average power sum alien near-end crosstalk (average PSANEXT) loss – Power sum attenuation to alien crosstalk ratio far-end (PSAACRF) – Average power sum attenuation to alien crosstalk ratio farend (average PSAACRF) Test Parameters 2 It is recommended to test length for all category 5e, 6, and 6A twisted-pair Channels and Permanent Links. Wire Map • Wire map testing is used to determined correctness and quality of the cable conductor termination in the connecting hardware contacts of the links and channels. • Shield continuity of the screened cabling systems is tested during the wire map testing. Wire Map • The following errors may be detected in the course of the wire map testing: – discontinuity between two ends of the Channel or Permanent Link – shorts between any two or more conductors – reversed pairs – split pairs – transposed pairs – any other miswiring, which is a combination of the listed above Wire Map • Possible wire map errors: Correct pairing 1 2 3 6 5 4 7 8 Reversed pair 1 2 3 6 5 4 7 8 1 2 3 6 5 4 7 8 Transposed pairs 1 2 3 6 5 4 7 8 1 2 3 6 5 4 7 8 Split pairs 1 2 3 6 5 4 7 8 1 2 3 6 5 4 7 8 1 2 3 6 5 4 7 8 Length • The physical length of the Permanent Link/Channel is the sum of the physical lengths of cables between the two end points. • The physical length of the Permanent Link/Channel may be determined by the following three methods: – Physically measured by the cable lengths – Determined by the cable length marks – Estimated by the electrical length measurement • The electrical length is derived from the signal propagation delay and depends on the cable construction and material properties. Length • The electrical length is derived from the signal propagation delay and depends on the cable construction and material properties. • When physical length is determined by the electrical length, the physical length of the Permanent Link/Channel calculated by the shortest electrical delay pair shall be reported and used for making the Pass or Fail decision. • The Pass or Fail criteria is based on the maximum length permitted for the Channel or Permanent Link plus 10% of nominal velocity of propagation (NVP) uncertainty. Length • Calibration of NVP is essential for the accuracy of length measurements. Almost all Signamax brand cable products are labeled with NVP value, determined by the manufacturer for the certain nomenclature product number. NVP value is applied on the cable sheath surface within the standard marking. • Incorrectly set NVP may also significantly influence Insertion Loss test results when testing per ISO/IEC 11801 specifications. The ISO/IEC 11801 Insertion Loss limit formula includes dependency on the length of the cabling segment under test. Length • On warranty registration of the Signamax Cabling System, the length of the Channels and Permanent Links shall be determined ONLY BASED ON THE PHYSICAL LENGTH OF THE CABLE JACKET. • Testing of the cable segment length with the field tester is performed only to detect the installation errors and ensure that the signal propagation path is maintained within the permissible time limits. Insertion Loss • Insertion loss is a measure of signal loss in the Permanent Link or Channel. • Insertion Loss increases with temperature. • The maximum insertion loss contribution permissible for equipment and patch cords is 20% higher than for the Horizontal cable. • The maximum insertion loss contribution permissible for twisted-pair equipment and patch cords is 50% higher than for the Horizontal cable. Insertion Loss • The Channel insertion loss is determined as the sum of: – IL of four (4) connectors – IL of Work Area, equipment, and cords at 20 °C (68 °F): • 10 m (33 ft) of 22-24-AWG cords • 8 m (26 ft) of 26-AWG cords – IL of 90-m (295-ft) cable segment at 20 °C (68 °F) • The Permanent Link insertion loss is determined as the sum of: – IL of three (3) connectors – IL of 90-m (295-ft) cable segment at 20 °C (68 °F) NEXT Loss • Pair-to-pair NEXT loss is a measure of signal coupling from one pair to another within a twisted-pair cabling Channel/Permanent Link and is calculated by swept/stepped frequency or equivalent voltage measurements. • The result of NEXT testing shall be comprised by 12 values. • NEXT loss values greater than 60/65 dB shall revert to a requirement of 60/65 dB. PSNEXT Loss • PSNEXT loss is determined with regard to the combined crosstalk (statistical) on a receive pair from all near-end disturbers operating simultaneously. The PSNEXT loss is calculated as a power-sum on a selected pair from all other pairs. • The result of PSNEXT testing shall be comprised by 8 values. • PSNEXT loss values over 57/62 dB should be reverted to the requirement of 57/62 dB. FEXT/ELFEXT/ACRF Loss • FEXT loss is a measure of the undesirable signal coupling from the near-end transmitter into the other pair measured at the far-end. Pair-to-pair ACRF is expressed in dB as the difference between the measured FEXT loss and the disturbed pair insertion loss: ACRF = FEXT – IL, dB • The result of ELFEXT/ACRF testing shall be comprised by 24 values. • In ANSI/TIA/EIA-568-B.1 and ANSI/TIA/EIA-568-B.2, ACRF was referred to as ELFEXT. PSACRF Loss • Power-sum attenuation-to-crosstalk ratio far-end takes into account the combined crosstalk (statistical) on a receive pair from all far-end disturbers operating simultaneously. PSACRF is calculated as a power-sum on a selected pair from all other pairs: PSACRF = PSFEXT – IL, dB • The result of PSELFEXT/PSACRF testing shall be comprised by 8 values. • In ANSI/TIA/EIA-568-B.1 and ANSI/TIA/EIA-568-B.2, PSACRF was referred to as PSELFEXT. Return Loss • Return loss is a reflected energy measure produced by the cabling system impedance mismatches and especially important for applications using simultaneous bi-directional transmission. Return loss is the ratio of the reflected signal power to the input power derived from dB-measured voltages. • Owing to the terminal accuracy of the field testers, if the return loss values are less than 3 dB, such values shall not be used for the Pass/Fail test conclusion. • The return loss values over 25 dB may be displayed by the tester as “>25 dB”. Propagation Delay • Propagation delay is the time for the signal propagation from one end of the Channel or Permanent Link to the other. • For field testing all category Channels, it is sufficient to test at 10 MHz only and Channel propagation delay at 10 MHz shall not exceed 555 ns. • For field testing all category Permanent Links, it is sufficient to test at 10 MHz only and Permanent Link propagation delay at 10 MHz shall not exceed 498 ns. Propagation Delay Skew • Delay skew is a measurement of the signaling delay difference from the fastest pair (with the lowest PD value) to the slowest (with the highest PD value). • The maximum permissible value of the PDS shall be maintained for the operation of applications using the parallel signal transfer technologies over the several pairs. Propagation Delay Skew • For all frequencies within the corresponding category frequency range, the maximum propagation delay skew for all category Channel configurations shall be less than 50 ns. • For all frequencies within the corresponding category frequency range, the maximum propagation delay skew for all category Permanent Link configurations shall be less than 44 ns. • For field testing all category Channels and Permanent Links, it is sufficient to test at 10 MHz only. PSANEXT Loss • PSANEXT loss is the power-sum of the unwanted signal coupling from multiple disturbing pairs of one or more 4-pair Channels, Permanent Links to a disturbed pair of another 4pair Channel or Permanent Link, measured at the near-end. • PSANEXT loss takes into account the combined alien crosstalk (statistical) on a receive pair from all external nearend disturbers operating simultaneously. • Calculations that result in PSANEXT loss values greater than 67 dB shall revert to a requirement of 67 dB minimum. Average PSANEXT Loss • Average PSANEXT loss is calculated by averaging the individual PSANEXT loss values, in dB, for all four pairs in the disturbed Channel or Permanent Link at each frequency point. • Calculations that result in Average PSANEXT loss values greater than 67 dB shall revert to a requirement of 67 dB minimum. PSAACRF Loss • AFEXT loss is the coupling of crosstalk at the far-end from external cabling pairs into a disturbed pair of the 4-pair cabling under test. • PSAACRF is the calculated power-sum from all external cabling pairs into the disturbed pair: PSAACRF = PSAFEXT – IL, dB • Calculations that result in PSAACRF loss values greater than 67 dB shall revert to a requirement of 67 dB minimum. Average PSAACRF Loss • Average PSAACRF is calculated by averaging the individual PSAACRF values in dB for all four pairs in the disturbed Channel or Permanent Link at each frequency point. • Calculations that result in average PSAACRF loss values greater than 67 dB shall revert to a requirement of 67 dB minimum. TEST RESULTS PASS/FAIL Criteria • A Pass or Fail result for each parameter shall be determined by the permissible parameter limits. • The parameter test result shall be marked with an asterisk (*) when it is closer to the test limit than the measurement accuracy published by the field tester manufacturer for the Permanent Link and Channel. PASS/FAIL Criteria 1 2 3 4 PASS PASS* FAIL* FAIL 1 – Allowable parameter limit 2 – Measurement accuracy upper limit 3 – Measured parameter value 4 – Measurement accuracy lower limit PASS/FAIL Criteria • PASS: • A measured value, the upper and the lower margins of the measurement accuracy of the field tester are below the permissible limit. • It gives rise to unambiguous interpretation of the result as positive. • The test result is positive, “passed testing.” PASS/FAIL Criteria • PASS*: • In spite of the fact that the measured value is below the permissible level, the upper margin of the measurement accuracy is below the permissible level, therefore there is a certain probability of permissible limit overrunning by the actual parameter value. • The test result is “conditionally passed testing.” PASS/FAIL Criteria • FAIL*: • In spite of the fact that the measured value is above the permissible level, the lower margin of the measurement accuracy is below the permissible level, therefore there is a certain probability of the actual parameter value to be kept within the permissible limits. • The test result is “conditionally failed testing.” PASS/FAIL Criteria • FAIL: • The measured value, the upper and the lower margins of the measurement accuracy of the field tester are above the permissible level. • It undoubtedly indicates the negative result. • The test result is negative, “failed testing.” PASS/FAIL Criteria • An overall Pass or Fail condition shall be determined by the results of mandatory individual tests. • Any Fail or Fail* shall result in a general Fail. • In order to achieve a general Pass condition, any individual results must be Pass or Pass*. PASS/FAIL Criteria 6 The test results marked PASS obtained as a result of testing of all the parameters determined in 5 shall be registered and submitted for the warranty provision. The test results marked PASS*, FAIL* and FAIL shall not be registered and submitted for the warranty provision. Test Results Saving 7 Any positive test results shall be recorded in an electronic format with software supplied by the field tester manufacturer. The test results supplied in the format not supported by the field tester software shall not be accepted for registration. FIELD TESTERS Qualified Field Testers 8 Warranty certification testing of transmission performance of the Signamax Cabling System twistedpair Channels and Permanent Links shall be performed by one or several of the following field testers: – Agilent Technologies: WireScope 350, WireScope Pro, FrameScope 350 – Fluke Networks: OMNIScanner, OMNIScanner2, DSP-4000, DSP-4100, DSP-4300, DTX-1800, DTX-1200, DTX-LT – IDEAL Industries: LT 8100A, LT 8155T, LT 8600T, LANTEK 6, LANTEK 7, LANTEK 7G, LanTEK II-500, LanTEK-1000 – Megger SCT1500, SCT2000 Software 9 Qualified field tester used for the Signamax Cabling System testing shall operate with the latest software version as of the date of such testing. Test results obtained with outdated software version are invalid and shall not be accepted for the system warranty registration. Test Setup 10 On the Signamax Cabling System certification testing, the modes of the Channel or Permanent Link automatic testing for the compliance with the relevant standards by the field tester shall be switched over to the default configuration set up by the manufacturer. Test results obtained with the automatic testing mode settings of the field tester different from the configuration set up by the manufacturer, are invalid and shall not be accepted for the warranty system registration. Factory Calibration 11 Qualified field tester used for the Signamax Cabling System certification testing shall be regularly calibrated at the manufacturer’s facilities or the agency authorized by the manufacturer for the compliance with the specifications of its operating characteristics. On the Signamax Cabling System warranty registration, Signamax Connectivity Systems may request a copy of the calibration certificate for the field tester used for the certification testing. Testing results obtained by the tester with expired calibration certificate are invalid and may be rejected on submission for the system warranty registration. Test Cords 12 Any cords used for testing of the Permanent Link model shall be supplied and qualified by the test equipment manufacturer for conformity with the requirements of the applicable standards to the testing of the cabling systems of the certain transmission performance category. Test Adapters 13 The transmission performance category of adapters used to connect the test equipment to the connecting hardware of the cabling system shall comply with the category of operating characteristics of the relevant Permanent Link model. Measurement Accuracy • Minimum efficiency levels were defined for field testers: – Level IIe – category 3, 5, 5e cabling systems – Level III – category 3, 5, 5e, 6 cabling systems – Level IIIe – category 3, 5, 5e, 6 , 6A cabling systems – Level IV – category 3, 5, 5e, 6 , 6A, 7, 7A cabling systems Measurement Accuracy 14 Warranty registration testing of the Signamax Cabling System may be only performed using Level IIe, III, and IIIe field testers: – Category 5e cabling – Level IIe, III, IIIe, IV field testers – Category 6 cabling – Level III, IIIe, IV field testers – Category 6A cabling – Level IIIe, IV field testers OPTICAL FIBER CABLING TESTING General • This section provides a description of the certification testing rules for the Signamax optical fiber cabling system based on multimode (OM1, OM2, OM3, OM4) and singlemode (OS1, OS2) transmission media. The purpose of this section is to provide field test procedures and acceptance values, address the testing and link performance requirements of singlemode and multimode optical fiber systems in the Horizontal and Backbone infrastructure. TEST CONFIGURATIONS Optical Fiber Link • An optical fiber link segment is the passive cabling, to include cable, connectors, and splices (if present), between two optical fiber connecting hardware termination points. Optical Fiber Link • A typical Horizontal subsystem link segment runs from the Telecommunications Outlet to the Horizontal Crossconnect. TR TO HC Optical Fiber Link WA Optical Fiber Link • There are three standard Backbone subsystem link segments: – Main Cross-connect to Intermediate Cross-connect – Main Cross-connect to Horizontal Cross-connect – Intermediate Cross-connect to Horizontal Cross-connect TR TR MC IC IC HC Optical Fiber Link • Centralized optical fiber cabling provides a link from the Telecommunications Outlet to the centralized crossconnect through a splice or interconnect in the Telecommunications Room. ONE JUMPER REFERENCE METHOD Step 1 (Calibration) • Connect the light source and power meter with the reference jumper #1. • Measure the power level and write it down as P1. • P1 – calibration power. Step 2 (Calibration) • Disconnect the reference jumper #1 from the power meter. • Connect the jumper #2 to the power meter. • Connect the reference jumper #1 with the jumper #2 with any relevant connecting hardware (adapter). Step 3 (Calibration) • Measure the power and write it down as P1-2. • Disconnect the jumpers, then re-connect them and measure the power once again. • Repeat this procedure several times (3-5). • Any measured values shall not exceed 0.75 dB (P1-2 – P1) and have only a slight difference between each other (<0.2 dB). • The values above 0.75 dB indicate on one or both defective jumpers. Step 3 (Calibration) • During the measurement procedure do not disconnect the reference jumper #1 from the light source and the jumper #2 from the power meter and do not switch off power of the light source and the power meter. • If you did it accidentally, repeat the procedures 1 through 3. Step 4 (Measurement) • Disconnect the jumpers. • Connect the reference jumper # 1 and jumper #2 to the relevant ends of the optical fiber link to be tested. • Measure the power and write down the result as P2. • Loss inserted by the optical fiber link: IL (dB) = P1 – P2 One Jumper Reference • In procedures 2 and 3 of one reference jumper method the quality of the test cords used for the optical fiber link testing is verified. • While using the certified test optical fiber cords, the power meter and light source with the storage function of the calibration power value (autocalibration function) some of the previously mentioned procedures may be excluded from the general measurement design. TEST PARAMETERS Test Parameters • Testing of the optical fiber components and systems includes measurements of several major characteristics. • For the certification testing of the majority of the optical fiber cabling systems, installed in the buildings and campus environments, it is usually sufficient to get the data on insertion loss and optical length. • Bandwidth (multimode) and dispersion (singlemode) are important performance parameters, however as they cannot be adversely affected by installation practices, they should be tested by the fiber manufacturer and do not require any field testing. Insertion Loss • Link insertion loss is based on the use of the One Reference Jumper Method specified by ANSI/TIA/EIA-526-14-A, Method B and ANSI/TIA/EIA-526-7, Method A.1. • The test configuration of the link insertion loss does not include any active or passive devices other than cable, connectors and splices (i.e., optical bypass switches, couplers, repeaters or optical amplifiers). Insertion Loss 15 Any optical fiber Links of the Horizontal and Backbone cabling subsystems shall be tested for insertion loss Insertion loss test shall be carried out by the one reference jumper method. Insertion Loss 3 Any insertion loss measurement results are recommended for the registration with one significant decimal digit in the fractional part of the measured value (for example, “–14.3 dBm”). Horizontal Cabling • The Horizontal optical fiber cabling subsystem link segments require the testing at only one wavelength. • Owing to the short cabling length (90 m (295 ft) or less), attenuation deltas due to wavelength are insignificant. Horizontal Cabling 16 The Horizontal optical fiber cabling subsystem links shall be tested for insertion loss at 850 nm or 1300 nm at least in one direction. The insertion loss test results shall not exceed: – 2.0 dB for uninterrupted Horizontal cabling subsystem segment – 2.75 dB for Open Office cabling implemented with a Consolidation Point Backbone Cabling 17 The Backbone optical fiber cabling subsystem links shall be tested for insertion loss at least in one direction at both operating wavelengths: – 850 and 1300 nm for multimode optical fiber – 1310 and 1550 nm for singlemode optical fiber The insertion loss test results shall not exceed the acceptance values derived by the link insertion loss formulas and rules supplied in 19. COA 18 The Centralized Optical Architecture cabling links shall be tested for insertion loss at 850 nm or 1300 nm at least in one direction. The insertion loss test results shall not exceed the acceptance values derived by the link insertion loss formulas and rules supplied in 19. Insertion Loss Limits 19 Insertion loss limits of the optical fiber Links of the Backbone Cabling Subsystem and the Links of over 90 m (295 ft) in length shall be calculated based on the following formula: ILLink = ILCable + ILConnectors + ILSplices, where ILCable(dB) = ILCCable(dB/km) x LCable(km), continued on next slide Insertion Loss Limits 19 ILC Cable – cable insertion loss coefficient: – 3.5 dB/km at 850 nm (MM) – 1.5 dB/km at 1300 nm (MM) – 0.5 dB/km at 1310 nm (OSP SM) – 0.5 dB/km at 1550 nm (OSP SM) – 1.0 dB/km at 1310 nm (ISP SM) – 1.0 dB/km at 1550 nm (ISP SM) LCable – cable length (km) continued on next slide Insertion Loss Limits 19 IL Connectors(dB) = NConnector Pairs x ILCConnector(dB), NConnector Pairs – number of connector pairs in the link, ILCConnector. – connector insertion loss coefficient, 0.75 dB; ILSplices(dB) = NSplices x ILCSplice(dB), NSplices – number of splices in the link, ILCSplice – splice insertion loss coefficient, 0.3 dB Insertion Loss Limits • If the link consists of both inside and outside plant cables (e.g., campus Backbone subsystem), the formula shall be based on the length of each cable type. Length 4 It is recommended to test optical length for all Horizontal and Backbone multimode and singlemode optical fiber links. The measurement results should be kept within the limits determined for the length of Signamax Optical Fiber Cabling System in sections “HORIZONTAL SUBSYSTEM” and “BACKBONE SUBSYSTEM” of the SCS Manual. Return Loss 5 It is recommended to test optical return loss for all Horizontal and Backbone singlemode optical fiber links at 1310 and 1550 nm wavelengths. FIELD TESTERS Qualified Field Testers 20 Warranty certification insertion loss testing of the Signamax Optical Fiber Cabling System shall be performed with: – Power meter and light source, or – Test equipment listed in 8, including the optical fiber detectors within their sets, facilitating insertion loss tests. Characteristics of the test equipment shall comply with the specifications given in sections “12.2.4.4 Power meters” and “12.2.4.5 Light sources” of this Manual. Factory Calibration 21 Light source and power meter used for the Signamax Cabling System certification testing shall be regularly calibrated at the manufacturer’s facilities or the agency authorized by the manufacturer for the compliance with the specifications of its operating characteristics. On the Signamax Cabling System warranty registration, Signamax Connectivity Systems may request a copy of the calibration certificate for the field tester used for the certification testing. Testing results obtained by the tester with expired calibration certificate are invalid and may be rejected on submission for the system warranty registration. Test Cords 6 The test cord fibers should have a core diameter and numerical aperture nominally equal to those values of the cabling system to be tested. The jumpers should be 1- to 5-m (3- to 15-ft) long, containing fibers with cladding light removing coatings. Terminations should be compatible with the light source, power meter and cabling system interfaces. Test Cords 7 The following test cords may be used for certification testing of the Signamax Cabling System: – Acquired from the test equipment manufacturer – Acquired from Signamax – Acquired from the third-party manufacturers