OPSM 451 Service Operations Management

advertisement

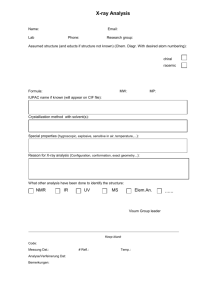

Koç University OPSM 301 Operations Management Class 5: Business process flows: Analysis Zeynep Aksin zaksin@ku.edu.tr Office Hours My office hours, slight modification – Mon. 13-15 TA’s office hours – TA: Canan Uckun, IEOM Graduate Student – Tuesday-Thursday 15:30-17:00 ENG 218 My office hours modified – Monday 13:00-15:00 Announcements First set of study questions Benihana to be discussed on 13/10 Thursday – Read the case, be prepared to discuss – Mini-quiz as part of class participation grade Kristen’s due 18/10 Tuesday First quiz on 18/10 Example: Focusing Improvement Efforts MBPF operations called for the purchase of both sheet metal (raw materials) and prefabricated bases (purchased parts). Garages were made in the fabrication area from sheet metal and then assembled with prefabricated bases in the assembly area. Completed garages were stored in the finished goods warehouse until they were shipped to customers Analyze the firm’s income statement, balance sheet, and cost of goods sold to determine in which department process improvements have the greatest impact on working capital Definition: working capital Working capital requirements include the value of inventories in the process and the value of any accounts receivable. Any reduction in working capital reduces the firm’s interest expense and makes extra cash available for other investments. Consolidated Statements of Income and Retained Earnings NET SALES COSTS AND EXPENSES – Cost of goods sold – Selling, general and administrative expenses – Interest expense – Depreciation – Other (income) expenses – TOTAL COSTS AND EXPENSES INCOME BEFORE INCOME TAXES PROVISION FOR INCOME TAXES NET INCOME RETAINED EARNINGS, BEG. OF YEAR LESS CASH DIVVIDENDS DECLARED RETAINED EARNINGS AT THE END OF YEAR NET INCOME PER COMMON SHARE DIVIDENDS PER COMMON SHARE 250.0 175.8 47.2 4.0 5.6 2.1 234.7 15.3 7.0 8.3 31.0 2.1 37.2 0.83 0.21 Consolidated Balance Sheet of Dec. 31, x Current Assets Cash Short-term investments at cost Receivables, less allowances of $0.7 mil Inventories Other current assets TOTAL CURRENT ASSETS Property, Plant, and Equipment (at cost) Land Buildings Machinery and equipment Construction in progress Subtotal Less accumulated depreciation NET PROPERTY, PLANT, AND EQUIPMENT Investments Prepaid expenses and other deferred charges 1.9 Other assets TOTAL ASSETS 2.1 3.0 27.9 50.6 4.1 87.7 2.1 15.3 50.1 6.7 74.2 25.0 49.2 4.1 4.0 146.9 Inventories and Cost of Goods Details Cost of Goods Sold – Raw Materials – Fabrications (Labor and Overhead) 60.2 – Purchased Parts (Labor and Overhead) – Assembly (Labor and Overhead) – TOTAL 50.1 40.2 25.3 175.8 Inventory – – – – – – Raw Materials (roof) Fabrications WIP (roof) Purchased Parts (base) Assembly WIP Finished goods TOTAL 6.5 15.1 8.6 10.6 9.8 50.6 Process Flows $60.2/yr $50.1/yr $40.2/yr Raw materials $6.5 Purchased Parts $8.6 Fabrication $15.1 $25.3/yr $110.3/yr Assembly $10.6 $40.2/yr Finished goods $9.8 $175.8/yr Detailed look at Inventories and Flow times $60.2/yr $25.3/yr $50.1/yr 110.3/yr $6.5 Raw materials 6.75 week $15.1 Fabrication 7.12 week $175.8/yr $10.6 $9.8 $40.2/yr $8.6 Purchased parts 11.12 weeks Assembly 3.14 weeks Finished goods 2.90 weeks Inventory Value Representation TH (mil/week) Fabrication 0.96 0.77 Purchased Parts Raw materials 11.12 6.75 7.12 Finished goods 2.12 Assembly 3.38 3.14 2.90 Accounts Receivable 5.0 5.80 CT (week) Operational Measure: Flow Time Driver: Activity Times, Critical Activity (Theoretical) Flow Time Critical Activity Flow Time efficiency = Theoretical Flow Time Average Flow Time Most time inefficiency comes from waiting: E.g.: Flow Times in White Collar Processes Industry Process Average Flow Time Theoretical Flow Time Flow Time Efficiency Life Insurance New Policy Application 72 hrs. 7 min. 0.16% Consumer Packaging New Graphic Design 18 days 2 hrs. 0.14% Commercial Bank Consumer Loan 24 hrs. 34 min. 2.36% Hospital Patient Billing 10 days 3 hrs. 3.75% Automobile Manufacture Financial Closing 11 days 5 hrs 5.60% Critical Path & Critical Activities Critical Path: A path with the longest total cycle time. A B D C Critical Activity: An activity on the critical path. X-Ray Service Process 1. Patient walks to x-ray lab 2. X-ray request travels to lab by messenger 3. X-ray technician fills out standard form based on info. From physician 4. Receptionist receives insurance information, prepares and signs form, sends to insurer 5. Patient undresses in preperation of x-ray 6. Lab technician takes x-ray 7. Darkroom technician develops x-ray 8. Lab technician checks for clarity-rework if necessary 9. Patient puts on clothes, gets ready to leave lab 10. Patient walks back to pysicians office 11. X-rays transferred to physician by messenger Example 4.5 1 6 7 start 2 3 20 6 4 5 5 3 6 2 12 3 7 9 10 75% 7 8 25% end 11 20 transport support Value added decision Measured actual flow time: 154 minutes Levers for Reducing Flow Time Decrease the work content of critical activities – work smarter – work faster – do it right the first time – change product mix Move work content from critical to non-critical activities – to non-critical path or to ``outer loop’’ Operational Measure: Capacity Drivers: Resource Loads (Theoretical) Capacity of a Resource Bottleneck Resource (Theoretical) Capacity of the Process X-Ray revisited Resource Pool Res. Unit Load Load Batch Theoretical No of units Theoretical Capacity of in pool capacity of Res. unit pool Messenger 40 1 min/patient 1.5 patients/hr 6 9 Patient/hr Receptionist 5 1 12 1 12 X-ray technician 16 1 3.75 4 15 X-ray lab 7.5 1 8 2 16 Darkroom technician 15 1 4 3 12 Darkroom 15 1 4 2 8 Changing room 6 1 10 2 20 Utilizations given an observed throughput of 5.5 patients/hr Resource pool Theoretical capacity Patients/hr Capacity utilization Messenger 9 61.11 Receptionist 12 45.83 X-ray technician 15 36.67 X-ray lab 16 34.38 Darkroom technician 12 45.83 Darkroom 8 68.75 Changing room 20 27.50 Levers for Increasing Process Capacity Decrease the work content of bottleneck activities – work smarter – work faster – do it right the first time – change product mix Move work content from bottlenecks to non-bottlenecks – to non-critical resource or to third party Increase Net Availability – work longer – increase scale (invest) – increase size of load batches – eliminate availability waste Increasing Process Capacity in the Smiley Factory Focus on the bottleneck – “ensure the bottlenecks’ time is not wasted” • increase availability of bottleneck resources • eliminate non-value added work from bottlenecks – reduce/eliminate setups and changeovers • synchronize flows to & from bottleneck – reduce starvation & blockage – “ the load of the bottlenecks (give it to non-bottlenecks)” • move work from bottlenecks to non-bottlenecks • need resource flexibility – unit capacity and/or #of units. • invest The role of variability 6/hr 6/hr 4 or 8/hr 4 or 8/hr 2 or 10 2 or 10 0 or 12 0 or 12 As variability increases, throughput (rate) decreases Compounding effect of variability and unbalanced task times 6/hr 4/hr 4/hr 4 or 8/hr 2 or 6/hr 3.5/hr 2 or 10 0 or 8 2.5/hr Summary of fundamental process principles identify and eliminate bottlenecks reduce as much variability as possible eliminate handoffs, improve communication to minimize resource interference