Cutting Tools

advertisement

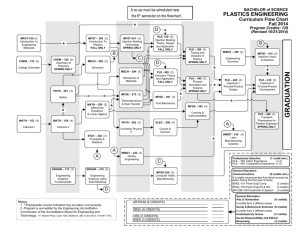

Chapter 1 MACHINE TOOLS AND MACHINING OPERATIONS Prof. Dr. S. Engin KILIÇ MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 1 MACHINING IS THE REMOVAL OF THE UNWANTED METAL FROM A WORKPIECE IN THE FORM OF CHIPS SO AS TO OBTAIN A FINISHED PRODUCT OF DESIRED SIZE, SHAPE, AND FINISH. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 2 History of Machining Before 18th century main material used was wood. Development of metal machining starts with invention of steam engine (1776). The production of cylinders of the engine was a problem. Wilkinson invented horizontal boring machine to cope with this problem. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 3 Fundamentals of Machining The principle used in all machine tools is generating the surface required by providing suitable relative motions between cutting tool and the work piece. Metal removed is called chip. Two types of relative motion must be provided by a metal cutting machine tool: Primary and feed motion. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 4 Fundamentals of Machining The primary motion is the main motion provided by a machine tool or manually to cause relative motion between the tool and the work piece so that the face of the tool approaches to the work piece material. Usually the primary motion absorbs most of the total power required to perform a machining operation. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 5 Fundamentals of Machining The feed motion is a motion that may be provided to the tool or work piece by a machine tool which, when added to the primary motion, leads to a repeated or continuous chip removal. This motion may proceed by steps or continuously; in either case it usually absorbs a small proportion of the total power required. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 6 Relative motion between tool and workpiece Primary motion Secondary motion Cutting motion Feed motion Cutting speed Feed speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 7 Classification of the chip removing methods according to relative motions MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 8 Resultant cutting motion in cylindrical turning MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 9 ISO Machine Tool Axis Definition MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 10 AXIS MACHINE TOOL WITH SPINDLE Z Axis of spindle, (+Z) as tool goes away from work-piece MACHINE TOOL WITH ROTATING WORKPIECE X Y Radial and parallel to cross slide, (+X) when tool goes away from the axis of spindle MACHINE TOOL WITH NO SPINDLE Perpendicular to the work holding surface, (+Z) as tool goes away from work-piece MACHINE TOOL WITH ROTATING TOOL HORIZONTAL AXIS Horizontal and parallel to work holding surface, (+X) to the right when viewed from spindle towards workpiece VERTICAL AXIS Horizontal and parallel to work Parallel to and holding surface, positive in the (+X) to the right principle direction when viewed of cutting (primary from spindle motion) towards column. Apply right hand rules MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 11 RIGHT HAND RULE MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 12 RIGHT HAND RULE Vertical Machine Horizontal Machine MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 13 Types of cutting tools CUTTING TOOL SİNGLE POİNT CUTTİNG TOOL MULTI POİNT CUTTİNG TOOL ABRASIVE TOOL MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 14 Typical single-point cutting tool MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 15 Machine tools using single-point cutting tools Lathes Shapers Planers Boring M/C’s MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 16 Machine tools using multiple-point cutting tools Drilling M/C’s Milling M/C’s Broaching M/C’s Hobbing M/C’s MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 17 Machine tools using abrasive tools Grinding M/C’s Honing M/C’s MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 18 Machine Tool Provides work holding tool holding relative motion between tool and workpiece MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 19 LATHES MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 20 Components of a Lathe Bed Headstock Assembly Tailstock Assembly Carriage Assembly Quick-change Gear Box Lead Screw and Feed Rod. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 21 A typical turning machine z X Y MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 22 Engine Lathe z X Y MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 23 Types of Lathes Engine lathe Tool-room lathe Turret lathe CNC lathes Automatic screw machines Swiss-type automatic screw machines MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 24 Cutting Tools For cutting tools used in lathes, geometry depends mainly on the properties of the tool material and the work material. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 25 Tool geometry for a single point tool Cutting part Face Tool axis Minor cutting edge Shank Base Major cutting edge Minor flank Major flank Corner MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 26 Tool geometry for a single point tool MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 27 Tool geometry for a single point tool MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 28 Operations that can be performed on a lathe Turning Boring Facing Parting (Cutoff) Threading MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 29 Typical Lathe Operations MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 30 Typical Lathe Operations MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 31 Turning Turning is the machining operation that produces axisymmetrical parts MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 32 Turning The process of machining external cylindrical surfaces Usually performed on a lathe MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 33 Turning defined as the machining of an external surface with the work-piece rotating, with a single-point cutting tool fed parallel to the axis of the work-piece at a distance from the work axis to remove a layer from the outer surface of the work. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 34 Turning process and adjustable parameters Depth of cut (back engagement) Feed Spindle speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 35 Turning process MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 36 Average cutting speed Vave .nw.(dw dm) 2 nw:rotational frequency of workpiece dw:diameter of workpiece dm:diameter of machined surface MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 37 Metal removal rate Zw .f.a p.nw.(dm ap) F : ap : nw : dm: Feed back engagement (depth of cut) rotational frequency of workpiece diameter of machined surface MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 38 Boring involves the enlarging of an existing hole, which may have been made by a drill or may be the result of a core in a casting MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 39 Typical boring operation MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 40 Metal removal rate Zw .f.a p.nw.(dm ap) f : feed ap : back engagement nw : rotational frequency of workpiece dm: diameter of machined surface MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 41 Facing is the process to produce a flat surface normal to work axis in turning MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 42 Typical facing operation MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 43 Maximum cutting speed vmax .nw.dm nw: rotational frequency of workpiece dm: diameter of machined surface MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 44 Metal removal rate Zw,max Zw, max .f.a p.nw.dm f :feed ap :back engagement nw :rotational frequency of workpiece dm :diameter of machined surface MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 45 Parting is the operation by which one section of a workpiece is severed from the remainder by means of a cutoff tool MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 46 Typical parting operation MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 47 In threading primary motion of tool is combination of –C’ and –Z’ to generate a helix on the workpiece by setting the gears that drive the lead screw to give the required pitch of the machined threads. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 48 Typical threading operation MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 49 Vertical Boring Machine Similar to lathes but with a vertical axis to accommodate large and heavy workpieces MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 50 A typical Vertical Boring Machine MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 51 Horizontal Boring Machine They are very versatile and thus particularly useful in machining large parts MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 52 Essential features of Horizontal Boring Machine A rotating spindle that can be fed horizontally. A table that can be moved and fed in two directions in a horizontal plane. A headstock that can be moved vertically MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 53 Horizontal Boring Machine z X Y MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 54 Shaping and Planing Shaping is used to produce flat surfaces only suitable for small parts in low –batch quantities MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 55 Shaping and Planing Among the oldest single-point machining processes Largely replaced by milling and broaching In shaping, workpiece is fed at right angles to the cutting motion between successive strokes of the tool. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 56 Shaping and Planing A shaper and a planer from 18th century MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 57 Classification of shapers according to their general design features Horizontal Pull-cut Push-cut Vertical Regular Keyseater Special MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 58 Horizontal Push-cut Shaper z X Y MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 59 A typical vertical shaper MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 60 Vertical Shaper (Slotter) Y Z X •Vertical and inclined surfaces •External and internal cylindrical surfaces •Circular feeding of table between strokes •Keyseater specially designed for mach. keyways inside wheel and gear hubs MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 61 Shaping and Planing Planing is used to produce flat surfaces on workpieces that are too large to be accommodated on shapers. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 62 Classification of Planers according to their general design features Double-housing type planers Edge planers Open side planers Pit planers MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 63 Typical Planers Z X Y MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 64 Machines Using Multipoint-Cutting Tools MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 65 Drilling Machine (Drill Press) MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 66 Drilling Used to produce holes. Constitutes about 25% of all machining processes MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 67 Parts of a Typical Drilling Machine Powerhead Column Spindle Table Base MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 68 Various types of Drilling Machines Gun (deep hole) drilling Gang Drilling Turret Drilling MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 69 Typical operations performed on drilling machines Center Drilling Reaming Spot facing Spot Facing MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 70 Drilling, formulations f ac sin r 2 ac :undeformed chip thickness f :feed Кr :Major cutting edge angle MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 71 Machining time: lw tm f.n t lw:lenght of specimen f:feed nt:rotational frequency of the tool MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 72 Metal removal rate: Zw .f.d .nt 2 m 4 f:feed nt:rotational frequency of the tool dm:diameter of the machined surface MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 73 Metal removal rate for hole enlargement: Zw .f.(d d ).nt 2 m 2 w 4 f:feed nt:rotational frequency of the tool dm:diameter of the machined surface MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 74 MILLING MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 75 Milling A process by which a surface is generated by progressive chip removal. Performed on a wide variety of milling machines. The cutting tool is used is known as milling cutter. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 76 Major components of a milling machine MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 77 Types of milling machines Horizontal Milling Machines Vertical Milling Machines MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 78 Milling operation MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 79 Milling operation with coolant MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 80 Horizontal Milling Machines In horizontal milling machines the milling cutter is mounted on a horizantal arbor driven by the main spindle. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 81 A typical Horizontal Milling Machine MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 82 Slab Milling Operation Used to generate a horizantal surface on the workpiece MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 83 Slab milling formulations MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 84 Maximum undeformed chip thickness: ME 535 METAL CUTTING 85 Time for machining: MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 86 Metal removal rate: Zw= ae. ap.vf ae :working Engagement ap :width of cut Vf :feed speed of the workpiece MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 87 Vertical milling machines In vertical milling machines the milling cutter is mounted on a vertical arbor driven by the main spindle MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 88 Vertical milling operations End Milling Face Milling MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 89 A Vertical Milling Machine MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 90 Face milling Used to generate surface that is at right angle to the cutter axis MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 91 Various face and end milling operations MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 92 In Face Milling feed is ; V f f nt f:feed Vf:Feed speed of the workpiece nt:rotational frequency of the cutter MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 93 Maximum undeformed chip thickness: ac, max V f N.nt Vf:Feed speed of the workpiece nt:rotational frequency of the cutter N:Number of teeth on the cutter MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 94 Machining time if the path of the tool axis passes over the workpiece: lw :Lenght of the specimen dt :Diameter of the tool v f :Feed speed of the workpiece MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 95 Milling time analysis MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 96 Machining time if the path of the tool axis does not pass over the workpiece: lw 2 ae(dt - ae) tm Vf lw:Length of the specimen ae:Working engagement dt:Diameter of the tool Vf:Feed speed of the workpiece MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 97 Milling Operatios MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 98 BROACHING MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 99 Broaching is the machining of metal by means of a tool which is composed of a series of single point cutting edges each slightly larger than the previous one, made on bar. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 100 Broaching Finishes an entire surface in a single pass. Is used in production to finish holes, splines and flat surfaces. Is one of the most productive of the basic machining processes. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 101 Vertical broaching MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 102 The average metal-removal rate (Zw) can be estimated by dividing the total volume of metal removed by the machining time. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 103 Machining time for broaching: lt tm v lt:Lenght of the Broach V:Cutting Speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 104 Feed is the motion which an imaginary single cutting edge would have to be given by the machine tool to produce the same result as the array of cutting edges with which the tool is actually provided. It is the height difference between the two successive teeth. Uncut chip thickness: a =af=f c af:Feed engagement f:Feed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 105 ABRASIVE MACHINING PROCESSES MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 106 Abrasive Machining The basic process in which chips are formed by very small cutting edges that are integral parts of abrassive particles MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 107 Abrasive Machining Two unique characteristics: Cutting edge is very small, very fine cuts are possible. Cutting edges are actually extremely hard abrasive particles therefore very hard materials can be machined MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 108 Abrasive machining: Grinding A material removing process that involves the interaction of abrasive grits with the work piece at high speeds and shallow penetration depths. Abrasive machining is the oldest machining operation. Cutting edges are very small and can cut simultaneously. Very fine and smooth surfaces can be obtained MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 109 Types of grinding operations Traverse Grinding: The primary feed motion is the reciprocating traverse motion along the length (or axis) of the part with an intermittent infeed (cylindrical grinding)/cross feed (surface grinding) at the end of each stroke. Plunge Grinding: Intermittent feed motion is normal to the work surface (infeed) at the end of each stroke of the traverse motion (surface grinding); infeed motion (normal to work surface) without traverse motion (cylindrical grinding). MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 110 Types of grinding machines Horizontal-Spindle Surface-grinding Machine Vertical-Spindle Surface-grinding Machine Cylindrical-grinding Machine Internal-grinding Machine MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 111 Horizontal-Spindle Surface-Grinding Machine Has a horizontal spindle that provides primary motion to the wheel. The feed motion is the reciprocation of the worktable on which the work is mounted. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 112 Horizontal-spindle surface-grinding machine Traverse grinding MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 113 Metal removal rate for traverse grinding: Z f.a p.vtrav. f:Feed ap:Back Engagement Vtrav.:Traverse Speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 114 Machining time: bw tm 2.f.n r bw:Witdh of the workpiece F:Feed nr:Frequency of reciprocation MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 115 Plunge grinding process with horizontal-spindle surface-grinding machine MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 116 Metal removal rate for plunge grinding: Z f.a p.vtrav. f :Feed ap :Back Engagement Vtrav.:Traverse Speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 117 Machining time: at tm ts 2.f.n r at :tool depth of workpiece f :feed nr :frequency of reciprocation ts :sparking-out time MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 118 Vertical-Spindle Surface-Grinding Machine Employs a cup-shaped abressive wheel and performs an operation similar to face milling operation. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 119 Vertical-Spindle Surface-Grinding Machine Metal removal rate: Z f.a p.vtrav. f:Feed ap:Back Engagement Vtrav.:Traverse Speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 120 Vertical-Spindle Surface-Grinding Machine Machining time: at tm ts 2.f.n w at:tool depth of workpiece f:Feed nw:Frequency of reciprocation worktable ts:Sparking-out time MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 121 Cylindrical grinding MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 122 Traverse grinding on a cylindrical grinder Max. metal removal rate: Zwmax .f.d w.vtrav. f :feed per stroke of the machine table dw :diameter of the work surface Vtrav.:traverse speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 123 Traverse grinding on a cylindrical grinder Machining time: at tm ts 2.f.n r at:tool depth of workpiece f:Feed nr:Frequency of reciprocation ts:Sparking-out time MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 124 Plunge grinding on a cylindrical grinder Max. metal removal rate Zwmax .ap.dw.vf ap:back engagement dw:diameter of the work surface Vf.:feed speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 125 Plunge grinding on a cylindrical grinder Machining time: at tm ts vf at:tool depth of workpiece vf:Feed speed ts:Sparking-out time MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 126 Internal-grinding machine Commonly used for producing internal cylindrical surfaces MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 127 Traverse grinding on an internal grinder Max.metal removal rate: Zwmax .f.d m.vtrav. f :feed per stroke of the machine table dm :diameter of the machined surface Vtrav.:traverse speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 128 Traverse grinding on an internal grinder The machining time: at tm ts 2.f.n r at:tool depth of workpiece f:Feed nr:Frequency of reciprocation ts:Sparking-out time MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 129 Plunge grinding on a internal grinder Max.metal removal rate: Zwmax .ap.dm.vf ap:back engagement dm:diameter of the machined surface Vf.:feed speed MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 130 The machining time is; t m s f a t t v at:tool depth of workpiece vf:Feed speed ts:Sparking-out time MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 131 Abrasive machining: Honing A stock removal process that uses fine abrasive stones to remove very small amounts of metal. Cutting speed is much lower than that of grinding. Used to size and finish bored holes. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 132 Specific Cutting Energy For a given work material machined under given conditions, the energy required to remove a unit volume of material (ρs) can be measured. This mainly depends on the work material. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 133 Machining power Pm = ps Zw Ps:Specific cutting energy Zw:Metal removal rate MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 134 Electrical motor power Pe Pm m Pm: Power required to perform machining ηm: Overall efficiency of the machine tool MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 135 Unit for specific cutting enegy MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 136 Specific Cutting Energy ps vs Uncut Chip Thickness ac a a a MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 137 Selected Problems 1.1. 2000 bars 80 mm in diameter and 300 mm long must be turned down to 65 mm diameter for 150 mm of their length. The surface finish and accuracy requirements are such that a heavy roughing cut (removing most of the material) followed by a light-finishing cut are needed. Both the roughing and the light finishing cuts are to be taken at maximum power. The light finishing cut is to be taken at a feed of 0.13 mm, a cutting speed of 1.5 m/s. Assume that the lathe has a 2 kW motor and an efficiency of 50 %, specific cutting energy for the work material is 2.73 GJ/m3, the time taken to return the tool to the beginning of the cut is 15 s, and the time taken to load and unload a workpiece is 120s. a) Calculate the total production time in kiloseconds (ks) for the batch of work b) Calculate the machining time of one part in the roughing cut c) Calculate the machining time of one part in the light finishing cut MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 138 Selected Problems 1.1. SOLUTION Given: Nb=2000 dw=80 mm dm=65 mm lm=150 mm Psmax= 0.5x2= 1 kW = 1000 W ps=2.73 GJ/m3 flf= 0.3mm vlf = 1.5 m/s tr=15 s tl = 120 s tpr= Nb(tl + tmr + tmlf + 2 tr ) only the machining times for the roughing and the light finishing cuts are unknown Machining time can be found by dividing the volume to be removed for a given operation to the metal removal rate for the operation. Hence we need to find the metal removal rate first. MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 139 Selected Problems 1.1. SOLUTION (cont.’d) Zw= Psmax /ps Since for both the roughing and the light cutting operations maximum available power at the spindle are to be utilized; the metal removal rate for both of the operations wiil be the same. Hence: Zw= (1000 J/s)/(2.73 J/mm3) = 366 mm3/s a) tmT= tmr+ tmlf = Vr/ Zw + Vlf / Zw =(Vr+ Vlf)/Zw =VT/ Zw VT= (dw2 - 652).lw/4 = (802+ 652). 150/4 = 256236 mm3 tmT= 256236 /366.3≈ 700 s tpr= 2000(120 + 2x15 +700) = 1700ks MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 140 Selected Problems 1.1. SOLUTION (cont.’d) b) tmr= Vr/ Zw = 196985/366.3 ≈ 538 s c) tmlf = Vlf /Zw = 59251/366.3 = 162 s Machining time for light finishing operation can also be found by using the given cutting parameters, i.e. v=1.5 m/s and f= 0,13 mm ap = Zw /(fv) = 366.3/(0.13x1500) = 1.88 mm tmlf = dlfave lm/vf dlfave = dw+ ap= 65+ 1.88 = 66.88 mm tmlf = ( x 66.88 x 150)/(1500 x 0.13) = 162 s MFGE 307 THEORY OF MANUFACTURING TECHNOLOGY II 141