06 03 Align Theory Class

advertisement

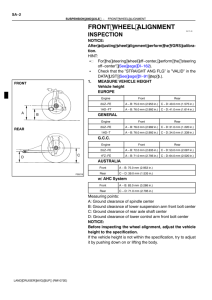

Instructors’ ‘27 T Roadster Class Participation Rules Please Participate – Agree, disagree, comment, share your opinion and experiences, ask questions etc. but just don’t sit there. – Remember this class is a lot more fun when I’m not the only person talking. Seminar Itinerary Break(s) as needed through out the class. – How many of you have not had lunch? 150 slides in the alignment theory portion of the class. Class time today 12 to 6 pm. Tomorrow class time is 1 pm to 7 pm. Shop time will be the later part of the class today and tomorrow. Remember please participate. Class presentation prepared by: Understanding The Angles Automotive Wheel Geometry A Technician’s Guide to Wheel Alignment Quick, name 15 alignment related angles/references that you will deal with on every wheel alignment! 1. Camber (front) 2. Caster (front) Is there ever rear caster? 3. Toe (front) 4. Camber (rear) 5. Toe (rear) 6. Thrust 15 alignment related angles/references cont. 7. GCL (Geometric Center Line) 8. VCL (Vehicle Center Line) 9. Scrub Radius 10. RSR (Road Surface Resistance of the tire) 11. Camber Roll 12. Slip Angle 13. Over Steer, Under Steer, Neutral Steer 14. Dominant Force 15. Dynamic loaded angle changes (toe compliance) Now name 15 more alignment related angles/references What do you mean that you can’t think of another 15 alignment related angles/references that affect the tire wear and handling of a vehicle? Doesn’t everyone know about the 2000 model year spindle offset change GM made on some of their FWD cars and what it does for handling? Do you know about increased spindle height? Why Ford is using it on their new SUV’s and why it’s almost a 100% positive design feature with virtually no negative features. 16. 17. 18. 19. 20. 21. 22….. Ride Height Ride Height Ride Height is not listed in your student book as a separate section. How ride height affects various alignment adjustments and setting is covered under the various individual sections. i.e.. Camber, Caster, Scrub. The following Ride Height information is presented to give everyone the same foundation about Ride Height problems. Ride Height • Check Spec Manual for Specs and Measurement Points Ride Height Measurements Facts Just measuring for a side-to-side or front-to-rear comparison is not measuring ride height. Even within a car family, similar body styles shared between different name plates, the ride height specs are not always the same. Sometimes measuring ride height correctly is a real pain. Ride Height Related Problems Q. Which alignment angle is affected most by a rear to front ride height problem? (The rear of the vehicle is lower than the front.) A. Caster, the suspensions upper pivot points move rearward. Q. How much caster change, and which way, + or -, do you get when the trunk is loaded and the rear of the car angles 3 degrees downward? A. A 3 degree positive caster change. Ride Height Related Problems Q. Why does a car handle so poorly when the trunk is overloaded, i.e.. 8 bags of cement mix, if caster moves positive when the rear of the car drops (supposedly you get more stability with increased caster)? A. Because of the weight transfer to the rear there is now less RSR (road surface resistance) between the front tires and the road. Ride Height Related Problems Q. If you have a vehicle with one corner lower than the other, sagged or broken spring, what alignment related angles or directional influences come into play? A. Camber change, caster change (with rear spring problem), understeer/oversteer depending on which spring has problem and at least five other angles. Vehicle Handling Characteristics Oversteer (Loose) Understeer (Pushing) Neutral Steer Oversteer The rear tires drift out when the vehicle is driven in a circle, when the front wheels are turned from straight ahead. The vehicle will have a tendency to turn tighter than steering wheel input. When power is put to the wheels the car will turn sharper. Usually referred to as being “loose”. Understeer Front tire drift causes the vehicle to refuse to turn as sharply as the wheels are pointed. With the steering wheel held in place and the throttle constant a vehicle will make an ever increasing larger circle (pushing) outward. Most FWD (Front Wheel Drive) vehicles have built in Understeer tendencies. Neutral Steer Front and rear tire drift is the same. The vehicle goes where it is pointed. Would create a driving safety hazard for most people. Especially those who use a cell phone and don’t pay attention to where they are steering. Isn’t used on the average vehicle sold in the U.S. Neutral steer doesn’t idiot proof a vehicle. Camber Camber Definition Viewed from the front, camber is the inward or outward tilt of a tire and wheel assembly from true vertical. – Tilted outward = Positive Camber – Tilted inward = Negative Camber Camber Example RF + 1 ½ degree camber LF -1 degree camber This vehicle has a 2 ½ camber split (spread) and should have a severe pull to the right. Camber Facts All other things being equal a vehicle will pull/drift toward the side with the most positive camber. Camber is always assumed to be positive. If you are stating or writing about negative camber you must say negative or use the minus sign. If no sign minus sign (-) is present the reading/specification is positive. Camber Facts A tire with positive camber is attempting to roll around the apex of the cone created by positive camber. A tire with positive camber will wear on the outside edge. A tire with negative camber will wear on the inside edge. Camber Facts This RF tire would attempt to roll right. If the left side did not have an equal amount of offsetting camber the vehicle would go right. Apex of the cone RF tire Direction of travel Road Surface Proving Camber Facts Take a Styrofoam coffee cup and lay it on its side (empty it first). Visually extend a line down the side to the table surface. This is the apex of the cone. Gently blow on the side of the cup and note that is is pivoting around the point where the line contacts the table top. Camber Pull Demonstration This tire/wheel will pull to the right as it attempts to rotate around the apex of the cone established by the tilt of the tire/wheel assembly. Vehicles direction of travel. Imagine that this is the right front tire with positive camber (outward tilt of the tire). Camber Pull Demonstration Right Front Cup Started X Here Apex of the cone If the left front tire does not have an opposing force the vehicle will go to the right. Remember that the spindle and knuckle are attached to the tire/wheel so whatever force is present at the tire will be transferred to the vehicle. Camber Facts Because the entire tire must rotate at the same RPM, speed, and because the one side has a smaller diameter than the other scuffing will occur, on the outside edge. RF tire Direction of travel Smaller diameter Road Surface Camber Facts If a tire/wheel is angled inward, toward the engine, camber is negative. If a tire/wheel is angled outward, away from the engine, camber is positive. Many late model (1998 & later) vehicles have set static camber negative. There are over 23 million vehicles on the road that have camber specified negative. Why? Camber Effect & Radial Tires Radial ply tires are not affected by camber as much as bias-belted or bias-ply tires are. – On the rear of a FWD vehicle it usually takes more than 1 degree of camber before any tire wear is present provided toe is set correctly. – On the rear of a vehicle if toe is out of adjustments even slightly any amount of camber over .5 degree will usually amplify the misadjusted toe condition. Camber Effect & Radial Tires Because camber doesn’t greatly affect handling on a vehicle equipped with radial ply tires whenever possible it is best to compensate for road crown with caster. It is best to compensate for road crown with caster even if you must install an aftermarket adjustment kit to do so. Camber Roll Spindle Height- Spindle Spread Definition: – The mid-point of distance between the pivot points of the spindle (the ball joint tapered holes at the end of the spindle). Purpose: – Greater spindle height/spread minimizes camber changes during vehicle dive and chassis roll. Spindle Height is the midpoint between the upper and lower ball joints. This midpoint is shown by the RED arrow on the picture at the right. Upper ball joint Lower ball joint The greater the spindle height/spread/length the less side force is placed on ball joints during jounce, rebound, vehicle dive and chassis roll. Refer to the TOTAL ALIGNMENT AUTOMOTIVE WHEEL GEOMETRY “UNDERSTANDING THE ANGLES” A Technicians Guide To “Wheel Alignment book for further information. Caster Caster Definition Zero Caster Negative Caster Positive Caster Viewed from the side caster is the forward or rearward tilt of a line drawn through the steering axis compared to true vertical. Caster Definition & Facts Remember that the steering axis is defined as a line drawn through the suspension pivot points (ball joints) compared to true vertical. Note that the true vertical line is always measured straight up from Negative Caster the center of the tire contact patch X Positive Caster Caster Reaction Zero Caster Negative Caster Positive Caster Positive Caster = Directional stability. Excessive positive caster means hard steering but the power steering easily overcomes the effect. Negative Caster = Less stability especially at highway speed. Excessive negative caster gives the feeling of instability, wandering and light steering. Caster Reaction Zero Caster Negative Caster Positive Caster Provided there is no other dominant force a vehicle will pull to the side having the least amount of positive Caster. That is the same as the most negative caster. Caster is not a direct tire wearing angle until you turn the wheels from a straight ahead position then the camber roll, caused by positive caster, can cause tire wear. 0 Degree Caster Load Point Location With 0 Caster the point of load is directly in line with the true vertical line. Upper BJ RF RF RF Lower BJ RF Direction of travel Direction of travel shown in red. Positive Caster Load Point Location With Positive Caster the point of load is in front of the true vertical line. True Vertical Line Upper BJ RF Lower BJ Direction of travel Direction of travel Positive Caster Effect Increased Positive Caster = – Increased Vehicle Stability. – Increased Steering Effort. (Easily overcome by the vehicles Power Steering). – Increased steering wheel returnability after a turn. – Increased road shock from bumps. – Increase in the effect of bump steer problems. Positive Caster Effect Without Positive Caster Angel The Caster Line is through the center of the upper and lower ball joints. The actual center of the spindle has been moved back from the caster line. This gives a Caster effect without a high Caster angle. ASE Test Question Caster causes tire wear: – – – – – A: Directly B: Indirectly C. Not at all D. Depends on the suspension design. E. This is really a lousy ASE test question. Caster causes tire wear: When the wheels of a vehicle with positive caster are turned from a straight ahead position caster causes the camber to change (roll). The more positive caster you have the more camber roll (change) you get. The more you turn the wheels the more camber roll (change) you get. 4 x 4 Trucks & Camber Roll The larger the diameter and the wider the tire the more camber wear problems you will have because of camber roll. Visualize a 4x4 truck with “mudder” type of tires and a caster setting of 5 ½ degrees (positive) being constantly driven in town making tight turns. You can now understand why the tire will chunk out and show irregular thread block wear. The only solution is to lower the caster and this is only a partial solution. Rotation also helps but nothing is a cure. Plus Size Tires & Camber Roll The larger the diameter and the lower the profile (aspect ratio) the more tire wear problems you will have because of camber roll. Plused sized tires with lower aspect ratios have shorter sidewalls than higher profile tires. This means that the springing effect of the tires sidewall is demised. Any force put into the tire will have a higher degree of reaction on the tire face. In other words the tires edge will be loaded quicker and with more force because the sidewall of the tire does not flex as much. Bump Steer Bump Steer Definition An uncontrolled amount of unequal individual toe change that takes place when the suspension of a vehicle moves, either in jounce or rebound. This will cause a vehicle to dart/dive to the right or left depending on which tire toes in and which toes out. Bump Steer (Orbital Steer) Bump Steer Causes R&P Steering Causes for bump steer on R&P equipped vehicle: – Crossmember location, accident, cradle movement etc. – Rack mounting bushing worn. – Body damage, when rack is mounted on the firewall. – Severely worn inner or outer tie rod end. – Ride height problem on one side compared to the other Checking For Bump Steer R&P Steering With the vehicle on a alignment rack measure from the R&P steering gear to the alignment rack air jack. – Find a similar point on the R&P gear hosing and measure the right and left sides. – The measurement should be within ¼” sideto-side. Be sure that you don’t have a basic ride height problem that is throwing off the measurement. Bump Steer Causes Parallelogram Steering Causes on Parallelogram Steering systems: – – – – – – – – Frame horn/rail bent from an accident. Adjustable idler arm not adjusted correctly. Worn idler arm, up and down movement. Loose steering gear box mounting to frame rail. Bent steering linkage. Wrong tie rod ends installed on vehicle. Basic ride height problem. Weak coil springs: Compress under engine torque Compress under vehicle load Checking For Bump Steer Parallelogram Steering With the vehicle on a alignment rack and with the wheels steered straight ahead measure from the air jack to the grease fitting on the inner tie rod ends. The measurement should be within ¼” side to side. Toe Toe Definition When measured in inches: Toe relates to the difference in the distance between the front of the tires and the rear of the tires on the same axle. 65” Always select toe to be displayed in degrees on your alignment equipment. 66” 28.625” 66 ½” 67 ½” If you choose to display toe reading in inches your alignment equipment assumes a 28.625 (O.E.) size tire is on the car. If the tires has been “plused” sized you will have an inaccurate toe setting. Toe Definition When measured in degrees: Toe angle relates to the difference in the angle of each individual wheel from straight ahead or being at a right angle to the GCL of the vehicle. Positive toe is when a tire is toed in. Negative toe is when a tire is toed out. Always select toe to be displayed in degrees on your alignment equipment. The number of degrees from straight ahead doesn’t change with tire diameter. When the toe measurement is selected as degrees tire diameter doesn’t make any difference. You are measuring the amount of degree variation from the tire being straight ahead. Toe Conditions Toe Facts When measured by using the center scratch and toe bar measurement technique the overall tire diameter doesn’t make any difference as you are actually measuring the physical distance between the scratch marks on the front of the tires and the back of the tires. This method is as accurate as measuring degrees from straight ahead. Toe Facts Using a spreader bar will greatly increase the accuracy when adjusting static toe. When you have a vehicle with negative scrub place the spreader bar rearward of the spindles. When you have a vehicle with positive scrub place the spreader bar forward of the spindles. Toe Facts The following statements apply to electronic alignment equipment, not to mechanical or laser equipment. Whenever possible select toe to be measured in degrees. When toe is measured in inches is assumes a standard tire size of 28.625”. If the vehicle has “plus size” tires installed on it the end result is that the toe setting is not accurate. Toe Facts When toe is measured in degrees it is a measurement of the angle the tire is from being straight ahead. The overall diameter of the tire does not change this angle measurement. Toe Facts Front toe will always equally divide itself when a vehicle is driven. On some vehicles toe changes dramatically as the outer tie rod swings forward and backwards (articulates). Toe Facts Dynamic and static toe settings can be two completely different things. When you turn the wheels from a straight ahead position the total toe changes. Toe, front or rear is a vehicle handling angle long before it is a tire wearing angle. Toe Facts Rear toe is more critical to vehicle handling than front toe. Rear toe when not equally adjusted on both wheels will create a thrust angle. When you turn the wheels from a straight ahead position the individual toe changes on each wheel are not equal. Toe Facts Scrub will affect the amount of dynamic toe change that takes place from the static toe setting. Vehicles with negative scrub tend to toe in when driven. Vehicles with positive scrub tend to toe out when driven. Toe Facts Worn inner R&P tie rod ends allow radical dynamic toe changes. Outer tie rod ends that have lateral (side to side) looseness allow radical dynamic toe changes. RBS tie rod ends restrict dynamic toe change. Thrust Angle Thrust Angle Definition Thrust angle is established by a line, bisecting rear toe, drawn at a right angle to the mid-point of the rear axle and compared to the GCL (Geometric Center Line). – The GCL is established by drawing a line connecting the mid-points of the front spindles and the rear spindles. Thrust Angle Geometric Centerline Thrust line Positive Thrust Negative Thrust Thrust Specifications It is generally accepted that the maximum allowable thrust angle for FWD vehicles is .125 – For a average vehicle .125 thrust means that the rear tires will move sideways ¼” for every vehicle length it moves forward. – Assumes a average vehicle length of 10’. Tire Reaction to Thrust .125 Thrust = ¼”. Tire sideways movement of ¼” for each 10’ of forward movement equals 11’ sideways drag per mile of forward movement. – 5280’ per mile = 528 vehicle lengths per mile – 528 vehicle lengths X ¼” per length = 132, ¼” – 132, ¼” = 11 feet (sideways drag per mile) Understanding Thrust Remember any thrust angle means that the rear tires are not pointed straight ahead. On a FWD vehicle the front tires are the driving force (pulling force). The rear wheels are just along for the ride (following). Why Thrust Wears Tires The rear tires will be pulled forward and will try to go right or left (positive or negative thrust) following the thrust angle. After the tire tread can no longer go in two directions (forward & sideways) it will flex as the tire is pulled back under the vehicle to a straight ahead direction. This Is The Cause Of Rear Diagonal Tire Wear A Statement About Thrust Someone once said: –“The front wheels, of a vehicle, steer a vehicle from straight ahead. The rear wheels determine what straight ahead is”! Thrust Toe Relationship You can have a toe problem and not have a thrust problem. – This would be true if toe were set, inward or outward, equally out of specifications on both rear wheels. Even though the tendency is to do so rear toe can not divide itself equally as a FWD vehicle is driven. – Unless the FWD vehicle has 4-wheel steering. Toe Out On Turns (Turning Radius) Toe Out On Turns (Turning Radius) Definition The design feature, created by the inward angling of the steering arms, where when the front wheels are turned the inner tire/wheel assembly turns at a tighter angle than the outer tire/wheel. Toe Out On Turns (Turning Radius) 18o turn 20o turn When a car steers into a turn, the two steerable tires must turn on two different size circles. The entire car turns about a common center. This means that the two steerable tires must turn on two different size angles, with the tire on the inside of the turn having the greater angle All Wheels Turn on a Common Center Toe Out On Turns (Turning Radius) TOOT (Toe Out On Turns) Turning Radius Turning Angle Ackerman Steering All of the above terms mean the same thing. When the front wheels are turned from a straight ahead direction the inner wheel turns tighter than the outer wheel. Toe Out On Turns (Turning Radius) Can be measured with modern alignment equipment as a separate measurement. – Can be viewed as the movement reaction of the caster indicators on some alignment equipment. Can be measured by the movement of the turntables in relationship to each other. Must have toe first adjusted “in the ball park” or a erroneous TOOT reading will result. Toe Out On Turns (Turning Radius) When measured with modern alignment equipment: – The centering of the wheels on the turn tables is not critical. – The squareness of the vehicle on the rack is not critical. – The basic toe setting is important (must be within reading specifications and should be within 1 degree of specifications). Toe Out On Turns (Turning Radius) When measured by the degree of movement of the turn tables: – The centering of the wheels on the turn tables is extremely critical. – The squareness of the vehicle on the rack is very critical. – The basic toe setting is critical (must be within ¼” (1/2 degree) of specifications. Toe Out On Turns (Turning Radius) When measured by the degree of movement of the turn tables: – The turning motion should be done from the steering wheel not by forcing the tires left and right. – It critical that the wheels are blocked tight and that the parking brake is applied. The vehicle must not roll when the wheels are tuned. – The turntables must move without resistance. Set Back Set Back Definition (Front Setback) As measured from an imagery line across the front of the vehicle. Front setback is present when one wheel of the front axle is farther back or forward than the other wheel. Setback Setback occurs when one wheel on an axle is set back farther than the other wheel on the axle. Set Back (+ & -) Positive set back (+) is present when the right front wheel is set back farther than the left front wheel. – If set back is not indicated as being negative (-) it is assumed to be positive. Negative set back (-) is present when the left front wheel is set back farther than the right front wheel. Illustration is of positive set back Set Back Facts Because a vehicle has a set back condition, positive or negative, doesn’t mean that it has a problem. – Some vehicles have been designed and manufactured with set back (1/2”). A ½” set back (+ or -) reading is considered acceptable. O.E. set back specifications are seldom published. Set Back Facts Set back differences will affect the wheel base measurement. In theory a vehicle will pull/drift to the side with the shortest wheelbase (most positive setback). Set back is usually not a “DF” (dominant force) factor and seldom is the true cause of a vehicle pull. Set Back Facts Caster will affect set back reading but…. – A normal caster split will not cause a set back reading to be out of the generally acceptable range of ½”. – The type of suspension system will cause the amount of set back in relationship to caster split to vary. If you think you truly have a set back problem try the “three finger test”. Cradle Position Adjustment FWD Engine Cradle Camber is High SAI is Low Included Angle is OK Camber is Low SAI is High Included Angle is OK Cradle Shifted FWD Engine Cradle Adjustment Adjustable front cradles on FWD vehicles can affect – – – – – – – Front camber Front caster Front GCL Front set back Scrub radius TOOT Rear Thrust FWD Engine Cradle Adjustment A FWD vehicle with an adjustable front cradle should have the cradle adjusted before adjusting rear toe and camber. The reason this must be done is …………. Engine Cradle Adjustment Sequence The cradle is the front reference point for the GCL. – The GCL and individual rear toe (bisected at a right angle to the rear axle) establishes thrust. As you move the front GCL side to side you change the thrust angle. Engine Cradle Adjustments Some vehicles use the adjustable feature of the front cradle to set front caster. Cradle adjustments are most controllable when the vehicle has part of the weight taken off the tires. Engine Cradle Adjustments Alignment angle readings and their changes, when you move the cradle, may be read directly through live camber and caster reading when you select the raise vehicle/jack & hold feature on your alignment equipment Scrub Radius Scrub Radius Definition Viewed from the front scrub radius/offset is the distance between the tire centerline at the contact area, and a line extended downward through the steering axis. Scrub Radius The dotted lines represent movement of the tire outward at the top because of positive camber. This movement does not affect scrub. True Vertical Line This lines does not change because of a camber change. Shown is an example of positive scrub. Note that the intersection of a line through the pivot points and the tire road contact center point is what establishes scrub. McPherson Strut Negative Scrub Radius Remembering The Facts About The “True Vertical” Line True vertical is established upward from a reference point at the center of the tire contact patch. The true vertical line does not move with a camber change. Remembering The Facts About The “True Vertical” Line The true vertical line does not move when caster is adjusted. The true vertical line does move when wheels with a different offset are installed. Remembering The Facts About The “True Vertical” Line The true vertical line doesn’t move when plus size tires are installed unless the rim offset is changed. The true vertical line doesn’t change when wider tires are installed on stock offset and stock width wheels. Remembering The Facts About The “True Vertical” Line The only way you can change the true vertical lines location is to move the center of the tire inward or outward. The true vertical line will move slightly when the suspension moves through it range of jounce and rebound. Wide Rim Effect Scrub Radius will always change with a change in rim offset. Scrub Radius effect (not actual scrub) changes with rim width changes. Remember the true vertical line measurement point. 0 Degree Caster & Camber Load Point Location LF RF Direction of travel FWD Vehicle With Negative Scrub LF Direction of travel Load Point With Positive Caster LF RF Direction of travel Load Point With Positive Caster LF RF The tires are attempting to pivot inward rotating on the POL POL Point POL Point Direction of travel FWD Vehicle With Negative Scrub Tire To Road Friction Will BE Called RSR (Road Surface LF Resistance) RF POL Point POL Point POL (Point of Load) The tires are attempting to pivot inward rotating on the POL FWD Vehicle With Negative Scrub Tire To Road Friction Will BE Called RSR (Road Surface LF Resistance) RF POL Point POL Point 100 units of RSR 100 units of RSR In this example both tires are trying to rotate inward equally.Bo FWD Vehicle With Negative Scrub When A Tire Goes Flat The RSR Increases LF RF POL Point Flat tire = 400 units of RSR POL Point 100 units of RSR The flat tire will make the vehicle pull left, the RSR will make it pull right. The vehicle may go right, go left or go straight depending on how much initial scrub it has. When One Front Brake Fails The RSR Of The Two Front Tires Is No Longer Equal LF RF POL Point Working brake = 300units of RSR POL Point 100 units of RSR The working brake will make the vehicle pull to the left but the increase RSR will make it go to the right. In some cases the vehicle will actually pull right. The Reason That One Tire Forces The Other To Move Is That They Are Connected By The Steering Linkage. Working brake = 300units of RSR POL Point 100 units of RSR Linkage is forced to the left because of the dominant inward pivoting force of the left tire. This forces the right to turn outward. Steering Axis Inclination Steering Axis Inclination SAI = Steering Axis Inclination KPI = King Pin Inclination MSI = McPherson Strut Inclination MLI = Multi-Link Inclination The above terms all mean the same thing. They will be referred to in this class as SAI. Steering Axis Inclination Definition Viewed from the front it is the angle established by a line extended through the suspension pivot points and true vertical. SAI, KPI, MSI Definition SAI = Steering Axis Inclination KPI = King Pin Inclination MSI = McPherson Strut Inclination MLI = Multi-Link Inclination SAI is always viewed from the front. By everyone’s definition it is a line drawn through the upper and lower suspension pivot points compared to a true vertical line measure from the center of the tire upward”. Checking SAI On Modern Alignment Equipment Usually part of the weight is taken off the tires when taking an SAI reading. This eliminates the possibility of a worn suspension part, I.e. side play in a lower ball joint, from skewing the readings. Checking SAI On Modern Alignment Equipment When supporting a vehicle on air jacks while taking a SAI reading you should lock the air jack in position. Any change in vehicle height while taking a SAI reading will give inaccurate results. Follow your alignment equipments directions for leveling and locking the heads. Steering Axis Inclination (SAI) SAI Line SAI, KPI, MSI all measure the same angle, a line through the upper and lower pivot points compared to true vertical. How about a multi-link suspension system? Steering Axis Inclination (SAI) Everyone definition says that the load of the vehicle is carried through the SAI line. – Remember the SAI line is stated as being through the suspension pivot points. So what happens when the load is not carried through the pivot points such as …………………. SAI Definition Exceptions When you have two upper and/or two lower pivot points (ball joints). When you have a multi-link type of suspension where the load line and the pivot points are on two different planes. Where is the SAI reference line on the above “exceptions”? SAI Definition Exceptions On multi-link suspensions the SAI line is an imaginary line somewhere between the load line and the pivot points. This point moves in and out as the suspension moves through it range of motion. In other words the reference points float along with the influence of SAI as the suspension moves up and down. Audi A-4 Suspension System Features two upper and two lower ball joints. Where is the SAI measures on this suspension? If it’s through the upper and lower pivot points which one? The forward or rearward upper and lower pivot point, (ball joint)? 2003 Ford Expedition The load line is through the strut/shock, the pivot point is through the upper and lower ball joint. Where is the SAI line? Remember the SAI Definition Exceptions: On multi-link suspensions the SAI line is an imaginary line somewhere between the load line and the pivot points. This point moves in and out as the suspension moves through it range of motion. In other words the reference points float along with the influence of SAI as the suspension moves up and down. Another Example of an SAI Definition Exception 2002 Ford Thunderbird Front Suspension What Happens To SAI When You Install An Alignment Kit At The Locations Shown By The Arrows? Does SAI Change? Specialty Products Company 2002 Ford Thunderbird Rear Suspension Included Angle Included Angle Definition Included angle is SAI and camber added together, when camber is positive, or SAI minus camber when camber is negative. Included angle is used as a diagnostic angle. Included angle specifications are usually not published. Included Angle Diagnostics The following Included Angle diagnostic charts will assist you determining what parts are causing camber/SAI problems. Note that there are different charts for different types of suspensions. Rear Thrust on RWD Vehicles With Leaf Springs Thrust on RWD Vehicles w/solid rear axles. Thrust is adjustable on many RWD vehicles using solid axles and leaf springs. Individual toe (thus rear thrust) is changed by shifting one side of the axle forward and the other backward. Thrust on RWD Vehicles w/solid rear axles. Thrust angle is measures the same as on FWD vehicles. Thrust is established from the same reference points. Thrust influence is far less on RWD vehicles with solid rear axles than on FWD vehicles. It usually takes over .5 (1/2 degree) of thrust before it affects vehicle handling. RWD Vehicles With Leaf Springs Can Have The Thrust Corrected. Rear Thrust Alignment Plate For Solid Axle Leaf Spring Vehicles A RWD Thrust Plate Is Put Only On One Side Rear Thrust on RWD Vehicles With Independent Rear Suspensions Thrust on RWD Vehicles W/Independent Rear Suspensions. Adjusted by O.E. or aftermarket cams, shims or lateral link adjustments. Each individual wheel is adjusted to be at a specific angle in relationship to the GCL of the vehicle. Can establish oversteer or understeer handling characteristics depending if the individual toe is adjusted (equally) inward or outward. Idler Arm Facts Idler Arm Looseness Check Apply 25 lbs.. of force in a upward and downward manner. 1/4” total movement is accepted What three angles/readings/settings, previously shown, will a loose idler arm affect? What three angles/readings/settings, previously shown, will a loose idler arm affect? 1. Bump steer 2. Total Toe 3. Individual Toe Vehicle Handling Problems Caused By Tires Radial Ply Tire Pulls – Radial tires create a lateral (side force) when they rotate. – This force is at the contact patch of the tire. This force can be present for two reasons: – Tire ply-steer – Tire concinnity Vehicle Handling Problems Caused By Tires – (Ply-Steer). The steel belts under the thread of a radial ply tire can create a lateral force when: – They are laid in off-center. Vehicle Handling Problems Caused By Tires – (Tire Concinnity). If a tire has an unequal amount of sidewall stiffness side-to-side it has a concinnity problem. A vehicle will go toward the side with the softest (shortest under load) sidewall. Other alignment angles can amplify a concinnity problem or they may offset a concinnity problem.