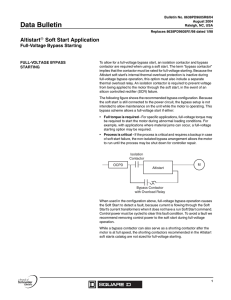

3 Contactor Full Feature Bypass with Disconnect

advertisement

VTAC 9 AC Drive Firmware Version 3.xx Designed to Meet Worldwide Standards • Agency Certification – Listed to UL508C and CAN/CSA-C2.2 – Listed to UL508C for plenums – Marked for applicable European Directives • Designed to meet the appropriate portions of the following specifications: – NFPA 70 – US National Electrical Code – NEMA ICS 3.1 – Safety standards for Construction and Guide for Selection, Installation and Operation of Adjustable Speed Drive Systems – IEC 146 – International Electrical Code – Seismic requirements of the 2003 International Building Code as specified by AC156 Specifications • Ratings: – 2-100HP (208V ac) – 3-200HP (480V ac) • Short Circuit Rating: – 200,000Amps Symmetrical • Efficiency: – 97.5% at rated amps, nominal line voltage • Displacement Power Factor: – 0.98 across speed range • Carrier (PWM) Frequency: – 2 to 10kHz (drive rating based upon 4kHz) Control I/O Digital Inputs (Run, Clear Fault, Enable, Purge, PI Enable, Etc.) Relay Outputs (Fault, Run, Ready, Alarm, At Speed, Current Limit, Etc.) Analog Inputs (Speed Reference, PI Feedback, Etc.) Analog Outputs (Output Freq, Output Amps, Output Power, PI Ref, Etc.) 2 – 25HP @ 208V ac 3 – 50HP @ 480V ac 30 – 100HP @ 208V ac 60 – 200HP @ 480V ac (frames B, C, D, E) (frames 4, 5, 6) (6) Programmable, 24VDC (6) Programmable, 24VDC (2) Programmable Form C (2) Programmable Form C (1) Non-Isolated (voltage or current) (1) Isolated, Bipolar (voltage or current) (2) Isolated, Bipolar (voltage or current) (1) 0-10VDC (1) Bipolar +/-10V or 4-20mA Hardware Features – Filtering • EMC Filtering – Supplied with all ratings – Internal Filter allows EN61800-3 Second Environment Levels to be met • Common Mode Filtering – Common mode cores supplied with all ratings – help attenuate common mode noise – Common mode capacitors supplied with all ratings – provide low impedance path World Class Motor Protection • Reflected Wave issues (also known as Standing Wave or transmission Line Effect) have been well documented in IGBT based drives • This phenomenon can cause significant voltage peaks at the motor that present the possibility for insulation breakdown • Rockwell Automation engineers have devoted years of research to develop industry-leading solutions for VTAC Drives – This has resulted in patented Software & Hardware features that protect motors with long motor leads – Each pulse is measured and controlled to avoid collisions with other reflected voltage pulses thus minimizing voltage amplification – These solutions are supported with hundreds of hours of lab tests! Hardware Features – Internal Bus Inductor • Provided with Every Rating: – 3% (min) 7.5 - 50HP @ 480V ac – 5% (min) 60 - 200HP @ 480Vac Current distortion (TDD) • Supplied in pos. & neg. leg • Reduces Harmonics • Helps with transient protection • Effective Impedance 0.45 0.4 0.35 0.3 TDD VTAC 9 Leading Competitor 0.25 0.2 0.15 0.1 0 10 20 30 40 50 60 Motor Frequency at rated load (Hz) THD VTAC 9 vs. Leading Competitor 120.00% Current Distortion (THD) – 5HP and larger @ 208V ac – 7.5HP and larger @ 480V ac TDD - VTAC 9 vs. Leading Competitor 100.00% 80.00% VTAC 9 60.00% Leading Competitor 40.00% 20.00% 0.00% 0 10 20 30 40 50 Motor Frequency at rated load (Hz) 60 70 Operator Keypad • • • • • • 5 Line LCD Keypad Removable Icon Based Programming Multi-Language Quick Start Feature Password Protectable Fault Pop Up FF-> Stopped Stopped Ready A Auto 0.00 Hz. - Fault - F05 Overvoltage Main Menu: Time Since Fault Diagnostics 1:10:07 Parameter Device Select Parameter Edit FF-> Stopped Stopped 0.00 Hz. Main Menu: Diagnostics Parameter Device Select Ready A Auto Operator Keypad Direction Indication Password Status Operating Status Menu, Programming Screen Auto / Hand Mode Status Alarm Annunciation Function Key Operation Operator Keypad Enter Key Configurable Function Keys Escape / Program Speed Control and Vertical Scroll Keys Enable Hand Reference Control Horizontal Scroll Keys Release Hand Reference Control Stop Key and Fault Reset Start Operation Keypad Icons Icons provide users a intuitive interface as well as a logical Main to Menu Icons method of grouping access drive functions and operations CSS QS Start-Up 1. Quickstart 2. Input Voltage 3. Motor Data 4. Motor Tests 5. Speed Limits 6. Ref Setup 7. Configure I/O 8. Done Parameters Control Source Select P Numbers Logic Control Ref Control Diagnostics Faults Alarms Reg Version OIM Version Status Info Display Language Monitor F Keys Drive ID Display Timeout Memory Device Select Password Reset Defaults Load from Drive Load to Drive Active User Set Start Up Icon provides access to Quick Start Utility that allows for fast, easy set-up involving seven parameter groups. Display Icon allows operators to configure the OIM for language, monitoring, function keys and other considerations. Parameter Icon provides quick access to drive and peripheral component parameters. Memory Icon allows operators to load and save different parameters sets into the OIM and, subsequently into the drive or to restore factory-set defaults. Device Select Icon allows operators to identify and select the drive or peripheral device from which to obtain data. Password Icon provides protection against modifications of all writable parameters by a unauthorized user and selects parameter access levels. Control Source Icon allows control and reference selection. Diagnostic Icon provides information on faults and alarms. Programming – File, Group, Element Monitor ************ Metering Drive Data Motor Control **************** Motor Data Torq Attributes Volts per Hertz Speed Command ********************* Spd Mode & Limits Speed References Discrete Speeds Speed trim Slip Comp Process PI Dynamic Control ********************* Ramp Rates Load Limits Stop/Brake Modes Restart Modes Power Loss Utility ***************** Reverse Config HIM Config MOP Config Drive Memory Diagnostics Faults Alarms Communication ******************* Comm Control Masks & Owners Data Links Inputs & Outputs ***************** Analog Inputs Analog Outputs Digital Inputs Digital Outputs Pulse I/O HVAC Features • Programmable Acceleration Time with S-Curve – Less mechanical stress on machinery and motors • Skip Frequencies – 3 “Critical Avoidance” operating points – No continuous operation at these points • Restart Modes – Line Loss – determines action after power is restored – Fault Conditions – Reset/Run allows certain faults to be automatically reset – Long Term Power Loss – Run on power-up • Sleep-Wake Mode – Drive starts when analog signal greater than user-specified level • PI Loop – Uses process feedback to compare against setpoint – Adjusts output Hz HVAC Features • Flying Start – Reconnect to a spinning motor • Shear Pin – Current limit adjustment for load and mechanical protection • Purge Input – Overrides stop signal across network • Intelligent Thermal Management – Carrier frequency reduction on overtemperature • Electronic Motor Overload – Based on programmed motor FLA – Class 10 protection Troubleshooting • Status LED – Flashing Green – Solid Green = Ready = Running – Flashing Yellow – Solid Yellow = Start Inhibits = Alarm Condition Exists – Flashing Red – Solid Red = Recoverable Fault = Non Recoverable Fault • Power LED • Viewable through the cover Troubleshooting • Alarms – User-Configurable: Alert operator of condition if left untreated, may lead to fault condition – Non-Configurable: Alert operator of condition caused by improper programming • Faults – Auto-Reset/Run: Auto Restart can be used to attempt to clear fault – Non-Resettable: Normally requires drive or motor repair – User-Configurable: Enabled or disabled to annunciate or ignore a fault F-> Faulted Aut o 0.00Hz. -- Fault-F06 Motor Stalled Main Menu: Time since fault Diagnostics 1:06:03 Parameter Device Select Drive Monitoring and Configuration Software • V*S Utilities Software • Windows Explorer look and feel – Left side tree view – Right side parameter list – HTML help • Parameter Upload / Download – Configure parameter settings – Monitor I/O activity – Compare Files • Monitor multiple drives when they’re on a communication network • Supported PC Operating Systems – Windows 95/98/2000/NT 3 Contactor Full Feature Bypass with Disconnect • Door interlock fused disconnect with Class J fuses – Some competitors offer disconnect switch which requires upstream short-circuit branch protection • 100,000 AIC rating for direct connection to high capacity power distribution lines – Some competitors offer circuit breaker which has AIC rating of 1420KA • 3 contactor bypass with Drive/DriveTest/Bypass modes – Allows troubleshooting/programming of drive while in bypass – Some competitors offer 2 contactor bypass which does not allow Drive to be electrically isolated should service be required • Bypass Control and Status Display provides quick visual indication of drive/bypass status through LED’s and schematic diagram • Class 20 motor overload protection in bypass circuit 3 Contactor Full Feature Bypass with Disconnect • Single customer terminal block for all field wiring • Dedicated Purge Input for connection to fire and life safety system • Switch for Hand/Off/Auto – Hand = Keypad – Off = Off – Auto = Communication port or terminal block • Remote activation of bypass 3 Contactor Full Feature Bypass with Disconnect 1 Bypass Control and Status Display 2 Bypass Control and Status Display Board 1 3 Drive Main Input Contactor 3 4 Drive Motor Output Contactor 5 Drive Bypass Contactor 2 6 Bypass Motor Overload Relay 4 5 6 7 115V AC Control Transformer 7 8 Field Control Wiring Terminal Block 9 Door Interlocked Main Input Disconnect 8 10 Main Input Disconnect Handle 10 9 Bypass Control and Status Display • Hand/Off/Auto Selector Switch • Drive/Drive Test/Bypass Selector Switch • Status LEDs – – – – – – Ready Interlock Open Drive Output Enable Purge Bypass Trip Bypass Run Bypass Components • Bypass Designs Utilize Rockwell Automation Industrial Components • Disconnect Switch (Bulletin 194R) – Meets OSHA Lockout/Tagout – 100KA Fault Withstand Rating • Contactors (Bulletin 100C) – Finger Safe – 3 Million manufactured per year – North American Market Leader for last 15 years (39% of market share) • Overload Relay (Bulletin 193) – Visible Trip Indication – Class 20 Overload Curve – Manual Reset with Test Button