Sydney Industry Electrical Safety Network Minutes of Meeting – 19

advertisement

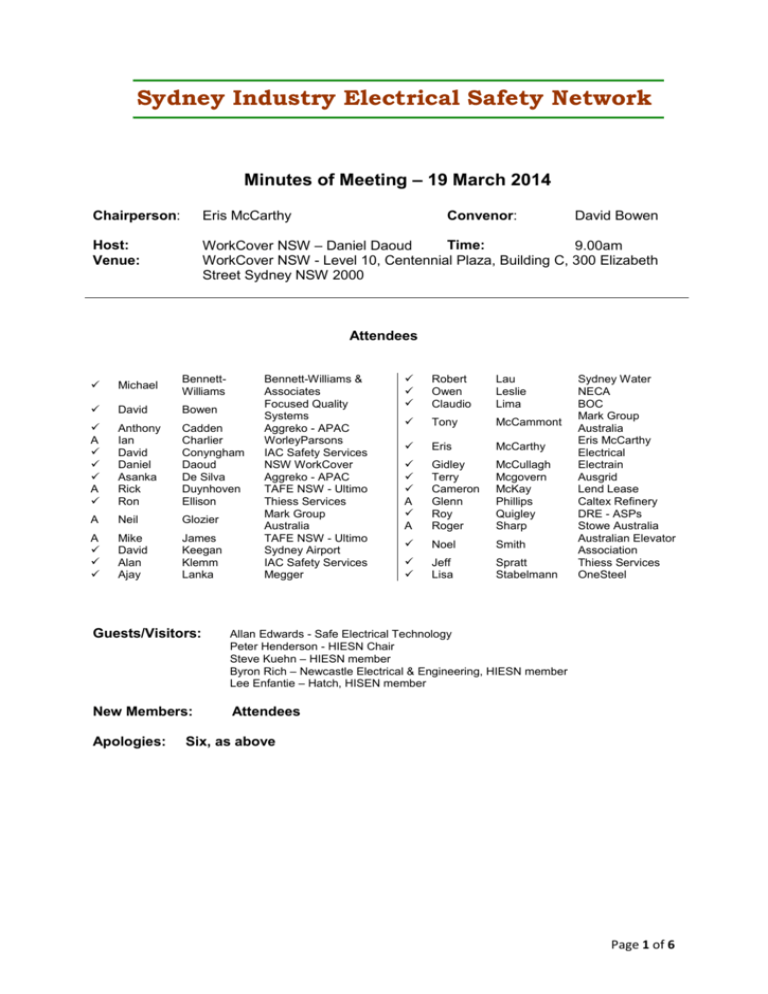

Sydney Industry Electrical Safety Network Minutes of Meeting – 19 March 2014 Chairperson: Eris McCarthy Convenor: Host: Venue: Time: WorkCover NSW – Daniel Daoud 9.00am WorkCover NSW - Level 10, Centennial Plaza, Building C, 300 Elizabeth Street Sydney NSW 2000 David Bowen Attendees Michael BennettWilliams David Bowen A A Anthony Ian David Daniel Asanka Rick Ron Cadden Charlier Conyngham Daoud De Silva Duynhoven Ellison A Neil Glozier A Mike David Alan Ajay James Keegan Klemm Lanka Bennett-Williams & Associates Focused Quality Systems Aggreko - APAC WorleyParsons IAC Safety Services NSW WorkCover Aggreko - APAC TAFE NSW - Ultimo Thiess Services Mark Group Australia TAFE NSW - Ultimo Sydney Airport IAC Safety Services Megger Robert Owen Claudio Lau Leslie Lima Tony McCammont Eris McCarthy A A Gidley Terry Cameron Glenn Roy Roger McCullagh Mcgovern McKay Phillips Quigley Sharp Noel Smith Jeff Lisa Spratt Stabelmann Guests/Visitors: Allan Edwards - Safe Electrical Technology Peter Henderson - HIESN Chair Steve Kuehn – HIESN member Byron Rich – Newcastle Electrical & Engineering, HIESN member Lee Enfantie – Hatch, HISEN member New Members: Attendees Apologies: Sydney Water NECA BOC Mark Group Australia Eris McCarthy Electrical Electrain Ausgrid Lend Lease Caltex Refinery DRE - ASPs Stowe Australia Australian Elevator Association Thiess Services OneSteel Six, as above Page 1 of 6 WELCOME The Chairman welcomed all attendees to the meeting and thanked the WorkCover for providing the venue for the inaugural meeting of the Sydney Industries Electrical Safety Network (SIESN). We have twenty seven participants including the technical speaker and a delegation of four members of the HIESN operating out of Newcastle/Hunter. It is pleasing to see a solid attendance and the diversity of industry represented. Impromptu well wishes from General Manager - NSW WorkCover John Watson (WorkCover GM) briefly joined the meeting. He welcomed the SIESN initiative and wished the network success. John spoke of some recent high profile incidents and of the change in role of WorkCover that has been in progress for the last ten years. The focus is on working collaboratively with industries to provide a safer work place. PRESENTATIONS Technical presentation Allan Edwards, Safe Electrical Technology described some of the different earthing systems and his general preference for IT earthing systems where both the active and neutral are isolated from ground. A single earth fault does not initiate a system failure or harm, but an earth fault on the other conductor may cause full fault current to flow. The initial earth fault can generally be detected by a voltage sensor, which in turn trips a two/four pole RCD. An RCD is ineffective in detecting the first fault on IT systems and likewise on MEN systems where a high impedance earth fault may occur (ie pulling less than 30mA). Such an earth fault will cause the frame voltage to rise and if that is detected, the signal can be used to trip the RCD. Typically a leakage voltage to frame is set to 43V, which is sufficiently high to overcome noise issues. The presentation stimulated considerable discussion. A one page summary is attached. Presentation from Chair of HIESN The Chair from the Hunter Industrial Electrical Safety Network (HIESN) welcomed the initiative to establish a Sydney network and provided a history to HIESN. HIESN started in July 1997 and have had over 40 organisations throughout that time attend. Positive outcomes from HIESN have included: Open sharing of incidents to help understand what had occurred and to prevent them occurring in other organisations; Discussion on technical and legislative items to develop common understanding and interpretation. This in turn helps reduce risk of contractors working across multiple organisations being non-compliant due to different interpretations; Development of required training outcomes which have been incorporated into TAFE training packages; Being recognised as an “industry body” to provide input into the review of electrical Australian/New Zealand Standards (AS/NZS 4836, 1674.2, 6010) Assisted WorkCover prepare a response to the Work Health and Safety Regulations. INCIDENTS Eris McCarthy Electrical One of the phases on a 3 phase socket-outlet remained live when switched. Product was a cheap look-alike import and will not have regulatory approval. Page 2 of 6 Learning: Buy from reputable wholesalers and only use approved and authentic electrical components and equipment. NSW WorkCover Audio technician was working on a home using a metallic cable snake (coat hanger) to snag an audio cable. He contacted a damaged cable with the conductors exposed resulting in an electric shock. Learning: Existing electrical wiring can deteriorate due to age or damage from rodents etc. Always use insulated hooks. Aggreko – APAC Temporary 1000kVA supply to a substation was installed. During pre-energisation checks it was found that the white phase was bolted to earth. Learning: Inspect and test as per AS3000 before energising. Sydney Water - Thiess Services Issues with high voltage equipment installed in the late 1970s not isolating all phases and it was only identified when the plant reported fluctuating/irregular voltages. Learning: Test for isolation before applying earthing leads and work. Consider preventative maintenance regime. Labelling error on two control panels in a pump station resulted in the incorrect equipment being isolated. This was identified during the isolation verification process (Test Before You Touch) and the site has been corrected. Learning: Labelling and schematics should be confirmed and marked up to as installed. “Test before you touch” is critical to electrical safety. BOC A fire in an electrical distribution board resulted in significant plant disruption. A 415V withdrawable ACB was found to have had damaged contact fingers, causing a hot spot. Bennett-Williams & Associates In an installation, the MEN point was installed on the supply transformer. The generator connection point had 4 pole isolators. When a temporary 2.5 MVA generator was brought to site, the neutral to earth was no longer connected resulting in a floating system. An electric shock was received by someone working in the installation. Learning: This fault should have been identified during AS3000 verification. Mark Group Australia Numerous discussions on solar installation issues. Failure of NHP CB on solar installation. Learning: Now using DC Isolator Can be an issue with polarisation of the breaker. Eris McCarthy Electrical Five cables in conduit from PV panels causing overheating/fire Learning: Conductors need to be de-rated. Megger The need for an external earth on HV testing equipment is not well understood. It results in the tester receiving an electric shock when disconnecting leads. Page 3 of 6 Testing capability is an important issue for safety. Test equipment should be checked for operation during testing and calibration frequencies considered. Typically we have 3-6 months in mining and in Queensland there is a general requirement for 12 monthly calibration. There was reference to AS/NZS3760, but no clear conclusion was drawn. Noted that much testing eg testing for energised, does not generally rely on precision. NECA Asbestos clean-up costs are not generally covered by public liability insurance. This can become an issue when material is inadvertently disturbed. Hatch Safety initiatives and safety culture in Australia are influencing safe work practices when our people are working overseas. Newcastle Electrical & Engineering An issue where a building was erected within 1 metre of an existing 750kVA transformer without appropriate fire protection for potentially flammable building materials. Under AS2067:2008 (and previous) the clearance should be 6 metres. It will likely be necessary to either move the building or use fire resistant enclosures / barriers to provide protection from fire arising from the substation. Noted that this fire hazard scenario of HV is not foreshadowed in the BCA. Ausgrid Illegal and unlicensed modifications to the domestic wiring led to two electric shocks at the one house. One issue was a member of the public wiring a light circuit. The other was a range hood unit being pushed up into the ceiling and severing a cable. Learning: Always a need to improve consumer / public awareness: turn power off when accessing the ceiling space because of exposed wiring and possible damage. Use qualified personnel. Minor electric shock during testing with test lamp when a second person (apprentice) was asked to assist. The apprentice touched the flying lead probe whilst trying to make effective contact with a water pipe. The current from a test lamp could typically be 100mA. Learning: The ICAM identified that the test leads were changed in procurement and not preferred, and the testing procedure when two people were required was not clear. OneSteel Recent review of electrical incidents indicated that 85% were not associated with electrical workers (ie other trades and operators) Noted that Ben Jones (OneSteel Hunter) has info on light switches and welding for nonelectrical personnel. GENERAL BUSINESS General observations on electrical compliance testing and verification was discussed A common observation in the electrical industry is that the testing of installations is one of the weaker skills in electricians. The inability for apprentices to perform testing until late in the apprenticeship was one contributing item discussed. Noted that Electrain have developed online training for AS3000 testing and IAC Safety Services have practical testing facilities. Another weakness discussed was the lack of understanding of fault loop impedance. Page 4 of 6 Peter Henderson advised of suitable presenter on testing and faultfinding from Henk VanVelze at Fluke, to be contacted. Owen Leslie mentioned the initiative by the UK Safety Council for Best Practice inspections of properties: UK Safety Council website - Reference not found. This is likely to be similar to AS3019:2007 Electrical installations—Periodic verification. AS3019 recommends inspections frequency of commercial properties each 4 years and residential 10 years and would also seem appropriate prior to property sale. It has three levels of detail starting at visual and ending with full AS3000 verifications, subject to findings. SIESN website Gidley McCullagh offered to initiate development of SIESN.com.au website. Plan is to build a record of meetings, presentations and electrical alerts. Steve Kuehn advised that The Electrical Product Recalls on http://www.recalls.gov.au/content/index.phtml/itemId/952814 go back till 1998 inclusive. 2014 MEETING SCHEDULE Date Venue Location 19 March 2014 NSW WorkCover Level 10, Centennial Plaza, Building C 300 Elizabeth Street Sydney NSW 2000 14 May IAC Safety Services Unit 1 39 – 41 Fourth Avenue Blacktown; or Unit 7 18 Third Avenue Blacktown - TBA 9 July Sydney Water 20 William Holmes Drive, Potts Hill 10 September 12 November Proposed future agenda items / Guest Speakers Subject Initiator Guest Speaker Schedule Status Earth integrity – mitigating the risk DB Allan Edwards 19 March 2014 Complete Arc Flash hazard review DB Brett Cleaves 14 May 2014 Scheduled ARC Flash testing of PPE DB Darren Jenkins 9 July 2014 Scheduled Electrical hazards in arc welding BR Testing and Faultfinding PH (Ausgrid) Byron Rich (Newcastle Electrical & Engineering) Henk VanVelze (Fluke Australia) Meeting Closed at 12.00 noon. Page 5 of 6 Photos of inaugural SIESN meeting, 19 March 2014 Peter Henderson presentation on HIESN achievements John Watson well-wishers for SIESN from NSW WorkCover Page 6 of 6