Conceptual Design Requirements

advertisement

VIRGINIA POLYTECHNIC INSTITUTE AND STATE UNIVERSITY

2007 – 2008 International

Design Project

Effect of “designing in” airworthiness and

reliability on the development of a small,

unmanned, flight vehicle for the large event

surveillance mission.

Belle Bredehoft

Robert Briggs

Amanda Chou

Richard Duelley

Alex Kovacic

Jessica McNeilus

Philip Pesce

Dennis Preus

Megan Prince

Anthony Ricciardi

Michael Sherman

Erik Sunday

12/6/2007

Table of Contents

List of Variables .............................................................................................................................. 7

Introduction ..................................................................................................................................... 9

Conceptual Design Requirements ................................................................................................. 10

Comparator UAVs ........................................................................................................................ 10

Comparator UAV Configurations ............................................................................................. 11

Conventional Tractor ............................................................................................................. 11

Flying Wing ........................................................................................................................... 12

Pylon-Mounted Propeller ...................................................................................................... 12

Twin-Tail-boom Pusher ......................................................................................................... 12

Comparator UAV Review ......................................................................................................... 13

Conceptual Analysis ..................................................................................................................... 13

Initial Overall Conceptual Designs ............................................................................................... 14

Max Gross Takeoff Weight (MGTOW).................................................................................... 14

Wing Sizing and Placement ...................................................................................................... 14

Power Required and Endurance ................................................................................................ 15

Deployable Landing Gear System............................................................................................. 15

Landing Techniques .................................................................................................................. 15

General Geometry ..................................................................................................................... 16

Conventional Design ............................................................................................................. 16

Twin Tail-Boom .................................................................................................................... 17

Pylon Mount .......................................................................................................................... 17

Tail-Mounted Pusher ............................................................................................................. 18

Concept Comparison ..................................................................................................................... 18

Decision Matrix ............................................................................................................................ 19

Group A Decision Matrix .......................................................................................................... 19

Group B Decision Matrix .......................................................................................................... 21

Reliability...................................................................................................................................... 23

Final Group Concepts ................................................................................................................... 25

Group A Final Concept ............................................................................................................. 25

Constraint Analysis ................................................................................................................... 26

Sizing......................................................................................................................................... 27

Wing ...................................................................................................................................... 27

Fuselage ................................................................................................................................. 28

2

Tail ......................................................................................................................................... 28

Performance Analysis ............................................................................................................... 28

Stall ........................................................................................................................................ 28

Power Required – Straight and Level .................................................................................... 29

Power Required – Climb ....................................................................................................... 29

Engine – Power Available ..................................................................................................... 29

Endurance .............................................................................................................................. 30

Glide Range ........................................................................................................................... 31

Turn Rate ............................................................................................................................... 31

Group B Final Concept ................................................................................................................. 33

Constraint Analysis ................................................................................................................... 34

Airfoil Selection ........................................................................................................................ 35

Tail Sizing ................................................................................................................................. 36

Engine Selection, Power Requirements, and Endurance .......................................................... 37

Starters and Alternators ......................................................................................................... 39

Stability ..................................................................................................................................... 40

Reliability Analysis ................................................................................................................... 41

Final Values............................................................................................................................... 42

Loughborough University Design Process ................................................................................... 43

Downselection............................................................................................................................... 45

Final Concept ................................................................................................................................ 47

Constraint Analysis ................................................................................................................... 47

Wing Sizing ............................................................................................................................... 48

Tail Sizing ................................................................................................................................. 49

Performance Analysis ............................................................................................................... 49

Constraint Analysis ................................................................................................................... 52

Conclusion................................................................................................................................. 53

Appendix A – List of Equations ................................................................................................... 56

Appendix B – Initial Concept Drawings ....................................................................................... 58

Concept A1 ............................................................................................................................ 58

Concept A2 ............................................................................................................................ 59

Concept A3 ............................................................................................................................ 60

Concept A4 ............................................................................................................................ 61

Concept A5 ............................................................................................................................ 62

3

Concept B1 ............................................................................................................................ 63

Concept B2 ............................................................................................................................ 64

Concept B3 ............................................................................................................................ 65

Concept B4 ............................................................................................................................ 66

Concept B5 ............................................................................................................................ 67

Appendix C – Decision Matrix Group A ...................................................................................... 68

Appendix D – Decision Matrix, Group B ..................................................................................... 71

Appendix E – Constraint Analysis Script ..................................................................................... 73

Appendix F – Endurance Script .................................................................................................... 74

Appendix G – Power Script .......................................................................................................... 75

Appendix H – Constraint Analysis Script ..................................................................................... 76

4

Table of Figures

Figure 1. Arcturus T-16XL and EMIT Blue Horizon 2 ................................................................ 11

Figure 2. Boeing/Insitu ScanEagle ............................................................................................... 12

Figure 3. The Orca Light Sport Amphibian .................................................................................. 12

Figure 4. AAI Pioneer UAV and AAI RQ-7 Shadow 200 ........................................................... 12

Figure 5. Viking 300 ...................................................................................................................... 13

Figure 6. Average Sources of System Failures For U.S. Military UA Fleet (Based on 194,000

hours)6 ........................................................................................................................................... 23

Figure 7. Constraint Analysis ....................................................................................................... 27

Figure 8. Power Available Plot for Various Altitudes .................................................................. 30

Figure 9. New Conceptual Design ................................................................................................ 32

Figure 10. Exploded View of New Concept ................................................................................. 33

Figure 11. Final Concept – Group B ............................................................................................. 34

Figure 12. Constraint Analysis Curves for Final Concept ............................................................ 35

Figure 13. Cruise Speed and Stall Speed vs. Time ....................................................................... 38

Figure 14. Power Required Curve with 15hp Available ............................................................... 38

Figure 15. AVL Geometry Plot .................................................................................................... 40

Figure 16. LU Conventional Concept ........................................................................................... 43

Figure 17. LU Pylon-Mounted Engine Concept ........................................................................... 44

Figure 18. Constraint Analysis for New Conceptual Design ........................................................ 48

Figure 19. Power Curves............................................................................................................... 51

Figure 20. Constraint Analysis for New Conceptual Design ........................................................ 53

Figure 21. Final Concept Drawing................................................................................................ 54

Figure 22. Final Concept 3-View.................................................................................................. 55

Table of Tables

Table 1. Comparator UAV Review .............................................................................................. 13

Table 2. Concept Comparison....................................................................................................... 18

Table 3. Summarized Decision Matrix – Group A ....................................................................... 20

Table 4. Summarized Final Decision Matrix – Group B .............................................................. 22

Table 5. Initial Empennage Sizing Parameters ............................................................................. 28

Table 6. Stall Speed versus Altitude ............................................................................................. 29

Table 7. Endurance at Cruise (3,000 ft, 50 kts) ............................................................................ 31

Table 8. Glide Range and Glide Speed versus Absolute Altitude ................................................ 31

Table 9. Airfoil Comparison ......................................................................................................... 35

Table 10. Results of Airfoil Ratings ............................................................................................. 36

Table 11. Initial Empennage Sizing Parameters ........................................................................... 37

Table 12. Engine Specifications for Engine Comparison ............................................................. 38

Table 13. Engine Selection Decision Matrix ................................................................................ 39

Table 14. Final Values for Group B Concept ............................................................................... 42

Table 15. LU Conventional Concept Sizing ................................................................................. 43

Table 16. LU Pylon-Mounted Concept Sizing ............................................................................. 44

Table 17. LU Final Concepts Advantages and Disadvantages ..................................................... 45

Table 18. Assumptions for Constraint Analysis ........................................................................... 47

5

Table 19. Wing Sizing Parameters................................................................................................ 48

Table 20. Initial Empennage Sizing Parameters ........................................................................... 49

Table 21. Assumptions for Performance Analysis ....................................................................... 49

Table 22. Stall Speed at Various Altitudes ................................................................................... 52

Table 23. Assumptions for Constraint Analysis ........................................................................... 52

6

List of Variables

Variable

Description

Units

AR

Aspect ratio

[-]

b

Wing span

[ft]

c

Average chord length

[ft]

CD

Coefficient of drag

[-]

CD0

Coefficient of base drag

[-]

C DMD

Coefficient of drag at minimum drag

[-]

C DMP

Coefficient of drag at minimum power

[-]

Cht

horizontal tail volume coefficient

[-]

CL

Coefficient of lift

[-]

C Lmax

Maximum lift coefficient = 1.3

[-]

CL/CD

Lift to drag ratio

[-]

Maximum lift to drag ratio

[-]

Lift to drag ratio at minimum power

[-]

CLMD

Coefficient of lift at minimum drag

[-]

C LM P

Coefficient of lift at minimum power

[-]

Cm

Moment coefficient

[-]

Cvt

Vertical tail volume coefficient

[-]

D

Drag on aircraft

CL / CD max

CL / CD MP

[lbs]

dh/dt

Rate of climb at constant speed

dV/dt

change in velocity with time (ft/s2)

e

Oswald efficiency factor = 0.9

E

Endurance

g

Acceleration due to gravity

γp

Weight specific fuel consumption

h

Altitude

L

Lift on aircraft

[ft/sec]

[ft/s2]

[-]

[sec], [hr]

[ft/sec2]

[lbs/hp-hr]

[ft]

[lbs]

L/D

Lift to drag ratio

[-]

Lht

horizontal tail moment arm

[ft]

Lvt

vertical tail moment arm

[ft]

MGTOW

Maximum gross takeoff weight

[lbs]

n

Load factor

[-]

ηp

Propeller efficiency

[-]

P

Engine power

[ft-lbs/s], [hp]

Power available from engine

[ft-lbs/s], [hp]

Pavail

7

Preq

Power required from engine

[ft-lbs/s], [hp]

Q

Dynamic pressure

[lbs/ft2]

R

Range

[ft], [nm]

Gliding range

[ft], [nm]

Rglide

Ρ

Ambient air density

[sl/ft3]

S

Wing planform area

[ft2]

Horizontal stabilizer surface area

[ft2]

Sht

Svt

Vertical stabilizer surface area

T

Thrust from engine

T/W

(T/W)SL

V

[lbs]

Thrust to weight ratio

[-]

Thrust to weight ratio at straight and level flight

[-]

Aircraft velocity

[ft/sec]

VMD

Aircraft velocity at minimum drag

[ft/sec]

VMP

Aircraft velocity at minimum power required

[ft/sec]

Vstall

Aircraft velocity at stall

[ft/sec]

W

Weight of aircraft

[lbs]

W1

Maximum gross takeoff weight

[lbs]

W2

Empty weight

[lbs]

W/S

Wing loading

[lbs/ft2]

Wing loading at stall

[lbs/ft2]

(W/S)stall

8

Introduction

In the modern world of aerospace engineering, an increasing emphasis on safety,

performance, and reliability has driven aircraft designers to develop a variety of autonomous

vehicles. Uninhabited autonomous vehicles (UAVs) have a larger performance envelope, such

as increased maneuverability previously limited by the g-forces able to be withstood by humans.

Likewise, the vehicle’s size can be greatly reduced, improving both efficiency and cost. Being

able to predict the vehicle’s timely and consistent response to instructions, as well as the

possibility of system or structural failures, the overall reliability of the vehicle can be monitored.

The International Design Team in the Aerospace Engineering departments at Virginia

Tech and Loughborough University has been tasked with the development of a UAV whose

purpose is flying surveillance cover over a crowd of interest.

The task objectives and

requirements have been developed by Naval Air Systems Command (NAVAIR), the Patuxent

River Naval Air Station in Maryland. Part of NAVAIR’s request is to not only develop an aerial

vehicle that can accomplish the primary objective of surveillance, but also to study the impact of

design on aircraft reliability.

Specific emphasis is placed upon cost drivers for improved

reliability and at what point does increasing the cost no longer significantly improve the overall

integrity of the vehicle. From this analysis, a better understanding of UAV reliability can be

obtained.

To start off the design process, comparator UAVs were researched in order to investigate

what configurations of aircraft were used to fulfill mission requirements. Each university group

involved with the project was then divided up into conceptual design groups. Each Aerospace

Engineering student on the team developed an individual conceptual design which met as many

of the design requirements as possible. The Industrial Systems Engineer on each Virginia Tech

team then created and executed a decision making process as to which design from the five

conceptual designs would be used as the team design. The two team designs from Virginia Tech

were presented along with the designs from Loughborough University. A decision was made as

to which design would be used for the remainder of the project, after which, both university

groups will work together to fully develop this design.

NAVAIR will sponsor this design project throughout the next two years and the two

corresponding design phases. The first year will focus on the conceptual design of the vehicle,

9

whereas the second year will focus on the construction and flight testing of the UAV prototype.

The scope of this report is focused on the first year of the program, conceptual design.

Conceptual Design Requirements

The objective of this project is to design and conduct prototype development of a

remotely piloted UAV that has the following requirements:

Cruise speed of 50 kt (knots)

Top Speed of 70 kt

Range of 15 nm (nautical miles)

Minimum endurance of eight hours

Service ceiling of 10,000 ft at half fuel

Normal operational altitude of 3000 ft or 2000 ft above ground level (AGL)

Minimum turn rate of 6 degrees per second

Climb rate of at least 200 ft/min at sea level

Maximum Gross Takeoff Weight (MGTOW) of 300 lbs

Minimum payload of 30 lbs (45 lbs desired)

Payload power source of 10 watts

Noise levels below 50 dBA at 200 ft.

All weather operation with a 10 kt crosswind landing capability

Capable of rail catapult pneumatic launch

Landing within a 50 ft x 250 ft parking lot

Less than one flight failure per 100,000 hours of flight

Additionally, the vehicle must be capable of GPS based autonomous operations with

dynamic re-tasking from ground controllers. In the event of lost communications between the

vehicle and the ground station, the vehicle must be capable of autonomous flying to a

predetermined location in an attempt to restore communications. Likewise, the vehicle must be

capable of gliding to a predetermined point in the event of an engine-out condition.

Comparator UAVs

In order to start the design process, several comparator UAVs were investigated for their

similarity to mission requirements. Two groups of existing UAVs were found: those that fit the

10

weight requirement and those that fit the speed or endurance requirement. Once the comparator

aircraft were identified, they were split between the two groups and their configuration was

noted. The configurations included conventional tractor, flying wing, pylon-mounted engine,

and twin-tail-boom pusher. From these observations, conceptual designs could be modeled after

these aircraft configurations to fit all of the design requirements.

It is apparent that some of the vehicles more closely match some of the design

requirements than others. The performance values that are similar to the design requirements are

underlined in the table. For example, the T-16 matched the desired airspeeds, whereas its weight

and payload are too low. Likewise, the Shadow’s MGTOW and payload weight are close to

desired while its airspeed range is not. The Viking 300 is the comparator UAV that most

resembles the design requirements in almost every category: speed, weight, endurance, payload.

Comparator UAV Configurations

Conventional Tractor

Figure 1. Arcturus T-16XL1 and EMIT Blue Horizon 2

The Arcturus T-16XL and EMIT Blue Horizon 2 (Figure 1) are two versions of a single

configuration that fit different requirements. The T-16XL matches the maximum and cruise

speeds and exceeds the endurance specified for the project. However, it carries a lighter payload

and has a smaller maximum gross takeoff weight. Specific characteristics of the T-16XL that

stand out are that it is also rail-launched and can be landed conventionally. The Blue Horizon

carries a heavier payload, weighs slightly more than the MGTOW and has greater endurance

than required, but has a much faster cruise and maximum speed.

11

Flying Wing

Figure 2. Boeing/Insitu ScanEagle2

The ScanEagle (Figure 2) is the only flying wing configuration and fits only the speed

and endurance requirements. Like the T-16XL, this aircraft is underweight and carries a much

lighter payload than specified. Interesting characteristics of the ScanEagle, however, include its

capture method, which involves capturing a shock cord on a pole. This alternate landing method

was investigated as a possibility to be used with some of the conceptual designs.

Pylon-Mounted Propeller

Figure 3. The Orca Light Sport Amphibian

The Orca (Figure 3) is the only pylon-mounted engine configuration and does not fit any

of the requirements listed in Table 1. However, the Orca was used as a comparator aircraft due

to the investigation of noise reduction. For this reason, the propeller is mounted in a duct above

the aircraft.

Twin-Tail-boom Pusher

Figure 4. AAI Pioneer UAV3 and AAI RQ-7 Shadow 2004

12

Most of the comparator UAVs investigated were twin-tail-boom pushers. The Pioneer

and Shadow 200 (Figure 4) both fit the weight and payload requirements but fall a little short for

the endurance and cruise at a much higher speed than is necessary. The Viking300, however, fits

all of the requirements listed in Table 1, showing that it is possible to make an aircraft in this

configuration fit the mission specifications.

Figure 5. Viking 300

Comparator UAV Review

Table 1 compares the requirements of the comparator UAVs in order to show the

differences in performance and structural characteristics. Elements of the existing designs were

used to create five conceptual designs that would fit the requirements as shown.

Table 1. Comparator UAV Review

Maximum

Cruise

Airframe

Speed

Speed

(knots)

(knots)

Minimum

Endurance

(hours)

Span

(ft)

Engine

(hp)

MGTOW

(lbs)

Dry

Weight

(lbs)

Payload

(lbs)

Required

70

50

8

---

---

300

---

45

T-16XL

80

50

16

13

2.5

80

40

20

Pioneer

---

64

5

16

26

450

---

---

Shadow

118

90

4

12.8

38

327

---

50

ScanEagle

70

50

20

10

1.5

37.9

---

13.2

Viking 300

70

56

8-10

16.5

22.5

318

210

30

Orca

Blue

Horizon 2

---

100

3.5

---

---

1430

120

70

16

21.3

---

397

81.6

Conceptual Analysis

A preliminary performance calculation was done on each concept by using a series of

equations found in Introduction to Aerodynamics & Aircraft Performance.5 First, a preliminary

wing area was found using the weight and speed set by the requirements (see Equation 1, in

Appendix A) where CL and V are for cruise condition. The rest of the wing geometry was found

13

using a desired aspect ratio (anywhere from 5 to 10), structural concerns, and transportability

concerns. With this geometry, a power required for cruise was calculated using Equation 2 and

Equation 3 where CD0 and e are estimated from common values. By estimating the amount of

fuel, two endurance numbers were found. Equation 4 is for a constant altitude flight and

Equation 5 is for a constant velocity flight where ηp and γp are estimated from common engines

and propellers. The glide performance was evaluated using the lift to drag ratio (see Equation 6.)

After these numbers were found, the designs were then optimized using what was learned from

the preliminary calculations. For all designs, the wing area, wingspan, and overall weight were

reduced. This resulted in a lighter and smaller aircraft with much of the same endurance and

performance numbers.

Initial Overall Conceptual Designs

Initially ten concepts were made by each aerospace engineering student on the team. All

concepts are shown in Appendix B.

Max Gross Takeoff Weight (MGTOW)

The requirements given by NAVAIR stated that the MGTOW was 300 lbs. After an indepth weight and mission analysis, it was determined that the mission could be completed with a

lighter aircraft. Many of the proposed concepts were sized using a MGTOW up to 100 lbs lighter

than the proposed requirement. This was done to achieve a more transportable aircraft.

Two of the proposed designs did have a MGTOW of 300 lbs. This was to assume a

worst-case scenario. If the final aircraft weighed 300 lbs, the performance of the aircraft still met

the requirements, however, building a lighter aircraft only increases the performance.

Wing Sizing and Placement

Wing sizing for the initial concepts was done by assuming a CLcruise and computing the

required wing area. By using this as a guide the wing span and chord were chosen to optimize

between transportability and a favorable aspect ratio. The concepts vary in wing planform shape

since each design is a balance between these two constraints.

Some wings incorporated taper to achieve a more elliptical lift distribution. The problem

with adding taper is that the complex planform shape makes manufacturing the wing more

difficult. Most of the concepts utilize a high wing for the added roll stability and to avoid the

need for dihedral. A low wing might need dihedral to achieve adequate roll stability, and this

14

complicates manufacturing the wing as well. This design does, however, make loading payloads

from the top of the aircraft more difficult.

Power Required and Endurance

After the wing size was chosen, the power required for normal flight and the required 200

ft/min climb rate was calculated. The power required varied between the concepts due to

different wing areas and aspect ratios. Nevertheless, the power for cruise for most concepts fell

between 3 and 7 horsepower. Most of the designs utilize a 10-15 hp engine to facilitate a high

climb rate at higher altitudes. Using this information and engines available in this range, a

specific fuel consumption was estimated for each design. Endurance calculations showed that

most of the designs have endurance between eight and twelve hours, meeting the minimum

requirement given by NAVAIR.

Deployable Landing Gear System

Several of the proposed concepts utilized a deployable landing gear system. This system

was utilized to provide a possible camera payload with a clear field of view and reduce the

overall drag of the aircraft. However, this system does reduce the reliability of the aircraft. To

address this, a one-time deployable landing gear system was used. This system would not utilize

any hydraulics or pneumatics, but would be retracted manually on the ground. When the aircraft

is preparing to land, a servo will release a pin and the landing gear will deploy using gravity

and/or a spring mechanism. This system is less reliable than a fixed landing gear, but is more

reliable than a actuated retractable system.

Landing Techniques

One requirement given by NAVAIR was that the aircraft have the ability to land in a 250’

x 50’ “parking lot”. The proposed concepts addressed this issue in several different ways. Some

of the concepts utilized a tail hook that would capture a cable stretched across the landing area.

This design is simple, but requires more structure to support the load on the tail hook and

requires the ground crew to set up the capture system.

One concept utilized a variable pitch propeller to produce a reverse thrust on landing.

This system seems to prove adequate for stopping the vehicle and it does not require additional

structure. In spite of this, the mechanism needed to implement this idea is complicated and

possibly unreliable.

15

Another concept utilizes a constant braking system. The problem with a conventional

braking system is that it requires a mechanism to actuate the brakes. In the constant braking

system, the brakes are already closed when the aircraft lands, making the system very simple.

This places a lot of stress on the system, however, and the landing gear and might make the

aircraft hard to control after touchdown.

The last idea proposed to meet the landing requirement was a parachute system. The

parachute would be activated over the intended landing area and the aircraft would glide down.

The parachute system would call for a very small landing area, but brings in the concern of

packing the parachute before a flight. Thus, the parachute was deemed a good backup system,

but not to be used for the primary landing method.

General Geometry

Since all the proposed concepts were inspired by comparator UAVs, many of the

concepts were similar. The ten proposed concepts were placed into four groups.

Conventional Design

Two of the proposed concepts were conventional designs (Concept A4 and B3 in

Appendix B). Both designs incorporated a single piece fuselage, conventional tail, and single

tractor engine. This design has several benefits. Using a tractor engine reduces the noise

generated by the propulsion system and the engine can be placed near the CG of the aircraft. This

allows the payload weight to be changed without the concern of shifting the CG of the aircraft.

This also protects the expensive payload from a nose first crash but leaves the less expensive

engine to be damaged in a crash. The simple fuselage structure will make manufacturing the

aircraft easier.

The use of a tractor engine does have the problem with possible contamination of the

sensors by exhaust. In addition the safety of the ground crew decreases with this design, because

unlike the two tail-boom designs the propeller is not protected from the crew. Both convention

designs also use a tricycle gear for improved ground handling and less structural loads in the tail

section of the aircraft.

One of the conventional design concepts also utilized winglets. These were incorporated

to increase the spanwise efficiency of the wing and also provide some thrust from the wingtip

16

vortices. However, the incorporation of winglets increases the amount of structure needed in the

wing.

Twin Tail-Boom

Most of the proposed concepts (Concepts A1, A3, A5, B2, and B5 in Appendix B) have a

twin tail-boom design with a pusher engine located near the center of the aircraft between the

two booms. The twin tail-boom design has the benefit of protecting the propeller from foreign

objects. Also, the pusher design should address the issue with exhaust interfering with the sensor

payloads, but could be louder than a tractor system. One main concern with this design is the

more complex tail structure being a weak point of the aircraft. This design protects the engine for

a crash; however, the payload might need to be placed farther forward to balance the aircraft and

thus be susceptible to damage in a crash.

Three of the concepts of this design incorporate an inverted V-tail. This tail was chosen

due to the lightweight structure and the ease of integration with the twin tail-boom design. The

V-Tail also has a slightly lower interference drag than a conventional tail. The other two

concepts use H-Tails. One with the horizontal between the tail-booms, the other with the

horizontal on the top of the verticals. This design allows for multiple rudders increasing

reliability. The structure could be heavier than a conventional or inverted V-tail, especially in the

case where the horizontal is mounted to the vertical tails.

Pylon Mount

One proposed concept is a pylon-mounted engine design (Concept A2 in Appendix B). In

this design, the engine is mounted above the fuselage in a shroud. This design is beneficial

because of the noise reduction in having the fuselage and wing between the engine and the

ground. This design also protects the propeller from debris better than any of the proposed

concepts. Since the engine is separate of the fuselage, volume is made available that would have

otherwise been used by the engine. This design might have thrust line issues from having the

propeller far away from the vertical CG and the structure for this design is more complicated,

thus harder to manufacture.

For this design, a T-tail was chosen to avoid blanketing the horizontal tail by the wing in

high angle of attack situations. The T-tail is, however, a more complicated structure than a

conventional tail.

17

Tail-Mounted Pusher

Two of the proposed concepts have a conventional fuselage with the engine mounted in

the tail section of the aircraft. This design prevents the sensors from being affected by the engine

exhaust and places the engine far away from any electrical equipment, reducing damage or

interference from vibration. This design could be significantly louder than other designs because

of increased aerodynamic interference with the pusher propeller at the tail. The propeller is also

placed in a position that could easily be damaged on landing. Placing the engine in the tail also

increases the structure needed in the tail section of the aircraft and makes balancing the aircraft

more difficult.

Both of the designs of this type utilized Y-tails. The “V” part of the tail was chosen to

reduce the weight and drag of the tail. The vertical part of the Y-tail was incorporated because it

protects the propeller from a ground strike and adds the ability to have a redundant rudder for

yaw control.

Concept Comparison

Most of the concepts were comparable in size, differing only slightly in wingspan and

weight. As a result, the power required for cruise was roughly the same for each of the aircraft at

an average of about 3.5 hp. Other physical characteristics and performance of each concept are

compared in Table 2.

Table 2. Concept Comparison

Wing

Span (ft)

Wing

Area

(ft^2)

MGTOW

(lbs)

Empty

Weight

(lbs)

Endurance

(hr)

(L/D)max

Concept A1

20

55

300

230

10-14

16.03

Concept A2

20.6

85

250

228

8.55

13.29

Concept A3

19.3

53.6

300

225

9-11

15.7

Concept A4

12.7

20.2

132

67

8.5

11.5

Concept A5

20

65

205

160

8-10

18

Concept B1

20

74

175

140

10

10.63

Concept B2

15

45

175

150

8-9

10.23

Concept B3

16

50

200

150

16.7 - 17.7

10.36

Concept B4

15

45

175

150

8-9

10.23

Concept B5

16

40

200

160

9-10

11.6

18

Decision Matrix

To narrow down ten conceptual designs between the two groups into two concepts, each

group created a decision matrix consisting of key aspects to take into account that each particular

group deemed important for design. Both teams used a scale of 1 to 5 to score each concept,

with 1 being the worst, and 5 being the best. Each person within the teams then rated each

concept, including their own, based on the categories within each decision matrix. The process

for both teams is outlined within the following sections.

Group A Decision Matrix

To analyze the five conceptual designs from Group A, a decision matrix was created

consisting of key aspects to take into account (see a summarized version in Table 3 below).

There are eight main categories:

wing

performance

tail

payload

propulsion

fuselage

landing gear

overall design

The tail category includes both a division for the vertical stabilizer and a horizontal

stabilizer. The overall category is a general category designed to identify areas that are not

associated with a particular aspect of the vehicle, such as storage and portability. Each main

category has been divided into several sub-categories such as: reliability, structural implications,

or ease of manufacture.

In order to determine appropriate “scores” for the individual conceptual designs, several

steps were taken to assure a fair score. All sub-category weights add up to be 100 under each

main category. After each sub-category had been rated, the score was multiplied by the

respective weight to get a weighted score. These were then subtotaled for each main category

and then multiplied by the category weight. After each subtotal was multiplied by the category

weight, these scores were totaled for a total concept design score. The design with the highest

score was deemed to be the most appropriate choice to continue with. A table showing a

comparison of basic aircraft performance and parameters for each individual concept (see

Appendix C) was used to help make the ratings within the decision matrix. As can be seen,

concept design A1 “won” the decision matrix. However, the group decided to merge some of the

19

best components from each concept to come up with a new conceptual design to create an

optimal aircraft.

Wing

Table 3. Summarized Decision Matrix – Group A

Concept Designs

concept

concept

A3 score

A4 score

concept

A1 score

concept

A2 score

285.0

255.0

276.0

291.0

284.0

0.175

49.9

44.6

48.3

50.9

49.7

SUBTOTAL

330.0

289.5

313.0

350.0

304.0

16.5

14.5

15.7

17.5

15.2

336.0

277.0

330.0

347.0

308.0

0.05

16.8

13.9

16.5

17.4

15.4

SUBTOTAL

299.0

234.0

257.0

227.0

256.0

29.9

23.4

25.7

22.7

25.6

255.0

239.5

261.0

280.0

271.0

51.0

47.9

52.2

56.0

54.2

286.0

254.0

258.0

233.0

269.0

28.6

25.4

25.8

23.3

26.9

356.0

309.5

343.0

356.0

338.0

0.175

62.3

54.2

60.0

62.3

59.2

SUBTOTAL

330.0

300.0

380.0

260.0

360.0

0.05

16.5

15.0

19.0

13.0

18.0

SUBTOTAL

326.0

277.5

308.0

356.0

321.5

32.6

27.8

30.8

35.6

32.2

304.1

266.6

294.0

298.7

296.3

SUBTOTAL

CATEGORY

WEIGHT

concept

A5 score

Tail

Vertical Stabilizer

CATEGORY

WEIGHT

0.05

Horizontal Stabilizer

SUBTOTAL

Overall

Payload

Performance

Landing

Gear

Propulsion

Fuselage

CATEGORY

WEIGHT

CATEGORY

WEIGHT

0.1

SUBTOTAL

CATEGORY

WEIGHT

0.2

SUBTOTAL

CATEGORY

WEIGHT

0.1

SUBTOTAL

CATEGORY

WEIGHT

CATEGORY

WEIGHT

CATEGORY

WEIGHT

Total Score

0.1

20

Group B Decision Matrix

A decision matrix (Appendix D) was used to narrow down the initial five concepts from

Group B into one final concept. The categories of the decision matrix were as follows:

wing

conformity to requirements

tail

reliability

fuselage

human factors

propulsion

overall aircraft

This allowed for the option of not only one concept design to be selected, but a

combination of the concepts depending on the scoring in the categories. These categories were

weighted out of 1.0. Reliability was weighted the heaviest, at 0.3, because it is the main focus of

this design project. Conformity to requirements was the next highest weight to make sure that

the concepts fit all the requirements of the mission.

Listed in each category are the scored and weighted components. Most of these are

typical or self-explanatory concerns for each aircraft component. For instance, the wing and tail

both have aerodynamic efficiency, impact on stability/control, ease of manufacturing (also seen

in fuselage) and integration with fuselage. All categories, except reliability and human factor,

have some component that deals with weight. Some of the components specific to reliability

require further explanation. The glide component in the reliability category is a replacement for

the reliability of the propulsion system. This was done because none of the concepts have a

known propulsion system at this time. The propulsion system, however, is one of the main

concerns for reliability since it is the most likely place for failure. To overcome this hurdle, the

glide characteristics were analyzed to see how well the concept could glide to safety should the

propulsion system fail. The control surface (malfunction) component was used to evaluate how

the system would respond to a control actuator failure. These servos are another point of failure.

In the overall aircraft category, the transportability component is used to describe the ease of

moving the proposed concepts on the ground. The components in each section were weighted

out of a total of 1.0 based on their importance.

A summary of the final decision matrix is shown in Table 4. This matrix was examined

by the team to make sure there were no arguments and a final concept was selected.

21

Table 4. Summarized Final Decision Matrix – Group B

Wing

SUBTOTAL

CATEGORY

WEIGHT

0.1

concept

B2 score

concept

B5 score

3.5585

3.7

3.5145

3.6815

3.397

0.35585

0.37

0.35145

0.36815

0.3397

3.2675

3.9215

3.957

3.2745

3.7005

0.32675

0.39215

0.3957

0.32745

0.37005

3.312

3.7715

3.5175

3.4925

3.5445

0.3312

0.37715

0.35175

0.34925

0.35445

2.662

3.6425

4.261

3.3125

3.3745

0.2662

0.36425

0.4261

0.33125

0.33745

3.7625

3.505

3.7685

3.4495

3.4345

0.564375

0.3505

0.37685

0.34495

0.34345

3.899

3.491

3.824

3.59

3.504

1.1697

1.0473

1.1472

1.077

1.0512

3.865

4.515

4.325

3.955

4.805

0.19325

0.22575

0.21625

0.19775

0.24025

3.517

3.825

3.619

3.649

3.6065

0.3517

0.3825

0.3619

0.3649

0.36065

3.559025

3.5096

3.6272

3.3607

3.3972

Tail

SUBTOTAL

Concept Designs

concept

concept

B3 score

B4 score

concept

B1 score

Overall Aircraft Human Factor

Reliability

Conformity to

Requirements

Propulsion

Fuselage

CATEGORY

WEIGHT

0.1

SUBTOTAL

CATEGORY

WEIGHT

0.1

SUBTOTAL

CATEGORY

WEIGHT

0.1

SUBTOTAL

CATEGORY

WEIGHT

0.15

SUBTOTAL

CATEGORY

WEIGHT

0.3

SUBTOTAL

CATEGORY

WEIGHT

0.05

SUBTOTAL

CATEGORY

WEIGHT

TOTAL SCORE

0.1

22

Reliability

According to the Department of Defense UAS Roadmap6, reliability is the “core of …

reducing acquisition system cost and improving mission effectiveness for [UAV’s].” The

document goes on to state that reliability underlies the “affordability, availability, and

acceptance” of UAVs. In terms of affordability, an unmanned vehicle should be less expensive to

operate and maintain than a vehicle which is manned. By eliminating the cockpit, the average

savings in terms of weight ranges from 3,000 to 5,000 lbs. However, any further means to reduce

the costs and improve affordability tend to have a negative impact on the reliability of the

aircraft. Another aspect to carefully consider is the availability of the aircraft. By including

redundant systems in the vehicle, the reliability tends to increase, as does the cost.6

Clearly, reliability plays an essential role in designing an aircraft. By considering

dependability issues from the beginning stages of the design process, costs to correct faults can

be reduced. Important aspects to consider include the performance of the vehicle, the payload,

and propulsion methods. Uncontrollable conditions such as weather related problems, for

example icing or high winds, also pose a threat to the overall dependability of the system.

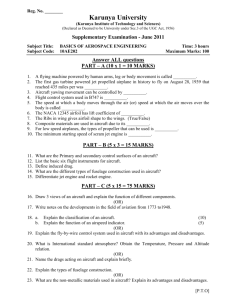

As can be seen in Figure 6, the number one source of failure in military unmanned

aircraft is related to the power and propulsion systems. Flight control, communication problems,

and human error are also listed as sources for system failures.

Figure 6. Average Sources of System Failures For U.S. Military UA Fleet (Based on 194,000 hours)6

During the design process careful attention must be paid to the maintenance procedures

for the aircraft. It would be beneficial to minimize the number of tools required for maintenance

and make sure these functions can be accessible from the ground (versus on a lift.) Also, the

material used for construction should be able to withstand corrosion. It is essential to create a

design which is “Jack-proof,” or simple enough that the average person would be able to

understand and use it.

With respect to overall aircraft structure, reliability considerations were taken into

account in each conceptual design. Aspects of each aircraft were designed based on vehicles

23

already in use. Taking the characteristics and reliability issues of past aircraft in account, aircraft

structure and form were designed to the desired specifications of each student.

The task of achieving the desired reliability of this aircraft is not an easy one. Aside from

specific concerns stated in each conceptual design, the considerations that must be taken into

account consist of the following:

engine reliability

navigation system (including autopilot and/or GPS)

servos for flight control

communication between the ground controllers and the aircraft

structural integrity of the aircraft

Once all of these considerations are accounted for, it must be realized that ultimately, the

reliability of the aircraft will be measured by the conformity to the proposed requirements of the

design.

Therefore, the performance of the aircraft will be the ultimate determinant of its

reliability.

There are many tools and statistical models available for use in this project. For example,

“time until failure” distributions are historically a great choice to use as models, especially for

electrical components. The general form of this distribution function can be seen in Equation 16.

This function analyzes the probability P that the working condition of the component is less-than

or equal-to time t.7 This is a very basic, fundamental summary of the distribution function that

can be modeled into a specific continuous distribution. From this summarized function, other

functions such as failure rate can be constructed given the same data. To find this distribution

for a component, a sample of data must be collected and analyzed to find the distribution that

best fits the data. The main concern with this type of modeling at this point is data gathering.

One way that data can be gathered is from the production company of each proposed

component of the aircraft. However, this is very unlikely to be obtainable considering the

confidentiality and probable lack of knowledge of the manufacturers of the component. A more

tangible but tedious task would be to experiment with the actual components enough to obtain a

reasonable sample of data to consider it for real results.

However practical it may seem to collect component data, this is an unlikely approach

considering construction of the aircraft will not occur this year. A more feasible approach is to

24

model a current, similar aircraft, or components based on historical events. This will allow the

team to obtain a “ballpark” measurement of the conceptual design’s components.

Final Group Concepts

Group A Final Concept

After the decision matrix results, the group came up with a design that would combine

the best of all the individual concepts and meet the design objectives, as seen in Figure 9. The

design consists of:

high wing

H-tail

shrouded pusher propeller

twin tail-booms

tricycle landing gear

The shroud around the propeller serves two purposes: increasing the efficiency of the

propeller and significantly reducing the noise level to meet the noise requirement. Placing the

motor at the aft of the fuselage decreases the likelihood of engine damage in a crash situation.

Likewise, exhaust from a rear-mounted engine will be deposited into the airflow downstream of

the payload sensors, thus avoiding any form of contamination on the payload. The engine of

choice for this aircraft is the Desert Aircraft DA-150, outputting 16.5 hp at maximum RPM.

This engine provides more power than necessary to meet the design speeds, cruising altitudes,

and climb rate, thus improving the safety margin for flight operations.

The engine fuel

consumption allows for an endurance of over 10 hours with only 25 lbs of fuel.

The payload will be located in the middle of the fuselage to protect it in a crash. Keeping

the most expensive parts of the aircraft away from the nose increases the reliability by avoiding

unnecessary maintenance and replacement costs. The payload sensors will be mounted on a

generic removable cartridge, allowing for easy exchange of payload for a variety of missions.

The high wing configuration was chosen to improve the roll stability of the aircraft, while

increasing the visibility of the payload. As mentioned above, the wing area was calculated to be

66 ft2 from constraint and performance equations to provide optimum performance at slow cruise

speeds. Likewise, an aspect ratio of about 7 was chosen to improve the wing’s ability to glide

without power and decrease its induced drag. This value was chosen such that the wing’s

25

dimensions would support the stresses during a pneumatic launch, obtain the best performances

during flight, and provide enough volume for the fuel needed. The wing was tapered to create

more of an elliptic lift distribution. A Clark Y airfoil was chosen for ease of construction due to

its flat lower surface, which also reduces the complexities of mounting it to the fuselage. The

Clark Y airfoil provides good performance characteristics in addition to its simplistic design.

The dual-boom mounted tail allows the mounting of the horizontal and vertical stabilizers

with an aft-mounted propulsion system. The two booms allow for an H-tail configuration,

providing increased reliability from multiple control surfaces. Additionally, the H-tail provides

adequate propeller clearance during ground operation.

A non-retractable tricycle landing gear system was chosen to decrease the risk of having

a mechanical malfunction. The main gear is placed behind the payload for increased sensor

visibility and propeller clearance. They also provide a wide enough base to reduce the risk of

wingtip strike during landing and rollout. The main gear is mounted to the fuselage to avoid

placing additional stresses and vibrations on the wing during ground operations. For landing and

stopping purposes, the main gear will utilize a constant applied breaking system. At touchdown,

the wheels will apply breaking forces for the aircraft to eliminate a separate break control

system. This increases reliability by reducing the number of systems.

For ease of ground transportation, the aircraft was designed to break apart and fit on the

roof of a truck. The wing breaks apart into three sections and fits together by sliding the wing

spars of adjacent sections into sleeves and then locking them with pins. The assembled wing

then locks into place on top of the fuselage. The dual booms and tail section slide into sleeves on

the aft side of the wing and lock in place with pins. This breakdown allows for any one damaged

component to be replaced without having to replace or repair the entire aircraft.

Constraint Analysis

Since maximum gross takeoff weight (MGTOW) is specified as 300 lbs in the

requirements, the necessary wing area can be determined (see Equation 1 in Appendix A.) To

move forward with the constraint analysis an Oswald efficiency factor of 0.9 and aspect ratio of

7 were assumed.

The values above are constant for all phases of flight except n,

according to the stage of the mission.

26

𝑑ℎ

𝑑𝑡

𝑑𝑉

, 𝑎𝑛𝑑 𝑑𝑡 will vary

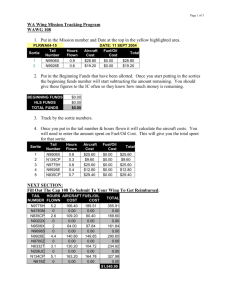

For Figure 7, landing, stall, climb, and turn rate are plotted. Straight and level flight is

omitted from these plots because

𝑇

𝑊

and

𝑊

𝑆

required for straight and level flight will always be

less demanding than those of other conditions.

Figure 7. Constraint Analysis

The optimum design point was chosen as the point that would allow the lowest possible

𝑙𝑏

wing area and thrust required. The wing loading at this design point is 4.475𝑓𝑡 2. At 300 lbs, this

demands a wing area of about 66 ft2. The

𝑇

𝑊

is about 0.11, resulting in a thrust required of 33

lbs at MGTOW.

Sizing

Wing

The aspect ratio for the design was chosen through careful analysis of the decision matrix

results from the five individual concepts. As the winning concept had an aspect ratio of 7.27, it

was deemed that with a MGTOW of 300 lbs, an aspect ratio of 7 would generate the best

performance results. This aspect ratio was verified through an iterative process between aircraft

27

performance and sizing. This fixed the wing area at 66 ft2, the span at 22 ft, and the mean

average chord at 3 ft. To create a more elliptic lift distribution, the wing also had a taper ratio of.

0.8

Fuselage

Using statistical equations for fuselage length developed by Raymer based on MGTOW,

the length can be calculated with Equation 15 from Appendix A. The variables A and C are

coefficients and Wo is the takeoff gross weight. Using a sailplane for estimation, A and C are

estimated to be 0.71 and 0.48 respectively, giving a fuselage length of 11 ft. To improve the

stability, the fuselage was lengthened by 1 ft to give the needed moment arm length.

Tail

To calculate the tail size, the moment arm and tail coefficients (cVT and cHT ), must be

estimated. Using typical values quoted by Raymer for a sailplane, cVT and cHT are approximated

as 0.50 and 0.03 respectively. The moment arm can be estimated at the conceptual design phase

as a percentage of the fuselage length. With the engine configuration of a pusher prop mounted

at the end of the fuselage, the tail arm is about 60% of the fuselage length, giving a moment arm

of 6.6 ft.8 The tail aspect ratio was chosen to be two thirds of the wing’s, giving an aspect ratio

of 4.67.9 The results of the initial sizing calculations are shown in Table 5.

Table 5. Initial Empennage Sizing Parameters

Horizontal Tail

Vertical Tail

Area

15.0 ft.²

6.6 ft.²

Span

8.37 ft.

5.55 ft.

Mean Chord

1.79 ft.

1.19 ft.

Volume Coefficient

0.50

0.03

Performance Analysis

Stall

The normal operating cruise speed of the vehicle is 50 kts at an altitude of 3000 ft.

Compared to other UAVs in the same weight category, this cruise speed is slow. One of the

design goals with this vehicle is to prevent the stall speed from occurring near the normal

operating cruise speed. By placing a large enough gap between the cruise speed and the stall

speed, the safety and reliability of the aircraft can be increased.

28

From the constraint analysis and sizing of the aircraft in the previous sections, the

planform area of the vehicle is 66 ft2 when operating at 300 lbs. Considering altitudes of 0,

3,000, and 10,000 ft above sea-level (ASL), the plane stalls at the following speeds:

Table 6. Stall Speed versus Altitude

Altitude above Sea-Level [ft]

Stall Speed (True airspeed) [kts]

0

32

3,000

34

10,000

37

At a cruising altitude of 3,000 ft, the buffer velocity is roughly 16 kts. The worst case

scenario for stall speed occurs at 10,000 ft but still provides a 13 kts buffer velocity.

Power Required – Straight and Level

Using Equation 2 from Appendix A, the power required to maintain straight and level flight

is found and can be plotted for different altitudes. In these calculations, it is assumed the aircraft

is operating at MGTOW; the altitudes range from sea-level to 10,000 ft. The following plot

depicts the power required curves for the different altitudes.

The plot reveals that a cruise speed of 50 kts would require slightly less than 3 hp to

maintain straight and level flight. The power required at cruise does not change much with

altitude; this is because the cruise speed is also the speed at which minimum drag occurs. A

cruise speed of 50 kts is thus optimal for maximum endurance.

Power Required – Climb

The power required to maintain a 200 ft/min climb rate can be calculated using Equation

11 from Appendix A, assuming constant velocity. The power required to climb at 50 kts at any

altitude is roughly 4.7 hp, while to climb at 70 kts at sea-level is roughly 7.4 hp (see Figure 8

below). The power required at climb is the maximum power required to climb condition in the

aircraft’s normal operating region.

Engine – Power Available

From the power required data, an engine can be chosen that meets the power

requirements. The assumed drag coefficient, 𝐶𝐷0 = 0.02, may be lower than the actual value, so it

is safer to choose an engine that outputs more power than calculated. In this case, the maximum

power needed comes from the maximum power required for climb at sea-level, 7.4 hp. One

29

ideal engine for this aircraft is the Desert Aircraft DA-150, outputting a total of 16.5 hp at 8,500

RPM. At 6,000 RPM, the engine uses 3.3 oz/min of fuel.

Extra power can be used to exceed the performance requirements, such as increasing

maximum speed or ceiling altitude. Plotting the power available (Equation 8 of Appendix A), on

top of the power required curves results in the Figure 8. It is important to point out that these

calculations assume the aircraft is operating at MGTOW for all altitude.

increasing

altitude

Power

Available

stall speed at 10000 ft

Climb

S&L

increasing

altitude

Figure 8. Power Available Plot for Various Altitudes

Clearly the power available at any point in flight (Figure 8) will be more than needed,

offering a little margin of power for safety. This plot shows that that ceiling altitude will be

greater than 10,000 ft at MGTOW.

Endurance

The endurance requirement for the aircraft is at least 8 hr. For the design cruise speed,

the aircraft is operating at minimum drag conditions. Assuming a propeller efficiency of P =

0.85, a specific fuel consumption of P = 3.6058e-007 1/ft, and a power output of 13 hp and

constant cruise, 19 lbs of fuel is needed to cruise at 3,000 ft for 8 hr (Equation 13 from Appendix

30

A). Table 7 shows the endurance obtained by increasing the amount of fuel available for a

normal cruise.

Table 7. Endurance at Cruise (3,000 ft, 50 kts)

Fuel [lbs]

Endurance [hr]

19

8.1

25

10.8

36

13.6

This table shows that for each additional gallon of fuel burned, the aircraft can stay aloft

for an additional 2.7 hr.

Glide Range

The glide range of the aircraft is determined using Equation 12 from Appendix A and is a

function of maximum lift-to-drag ratio as well as absolute altitude. Calculating the best glide

speed, as well as the glide range for various altitudes yields the following table:

Table 8. Glide Range and Glide Speed versus Absolute Altitude

Altitude [ft]

Glide Speed [kts]

Range [nm]

3,000

48

7.9

5,000

49

13.2

7,000

50.7

18.5

10,000

53

26.5

In the event of an engine failure, this table shows that the best glide speed to maintain is

roughly 50 kts for all altitudes. Calculating the range associated with each altitude shows that

around 6,000 ft above sea level, the aircraft would be able to glide the full 15 nm required

operational range. If an engine failure were to occur, the vehicle can glide a fair distance and, in

some cases, return to the point of departure. This gliding ability is one of the main reasons the

aircraft was designed with a higher aspect ratio.

Turn Rate

The required turn rate for this vehicle is 6 deg/sec. Using Equation 14 from Appendix A,

the load factor acting on the aircraft with this rate of turn is 1.04. The bank angle associated with

this rate of turn is 15.3°. With such a small increase in load factor for turning, the stall speed of

the aircraft increases no more than 1 kts.

31

Figure 9. New Conceptual Design

32

Figure 10. Exploded View of New Concept

Group B Final Concept

The final scores of each concept appeared to be so close, the group also decided it would

be best to combine the components of each proposed concept. Concept B3 started out with a

slightly higher score, so further evaluation was necessary to figure out why this was the best.

Most of the components were similar for each of the conceptual designs, except for the

placement of the propeller and tail configuration. Concept B3 did not seem to score much higher

than any other conceptual designs, except in the category of acoustics. Concept B3 had a tractor

propeller, so it had the potential for much quieter propulsions compared to the pusher

configuration used in all of the other concepts. After the decision to use a tractor propeller, the

rest of the concept was created.

In using a pusher propeller, the fuselage and tail of many of the concepts were

unconventional.

However, since the final concept uses a tractor propeller, a conventional

fuselage and wing configuration was used, much like the one depicted in Figure 11. Instead of

using the exact fuselage of Concept B3, the fuselage was made more streamlined in order to

33

produce more favorable aerodynamic qualities. Winglets were also eliminated from the original

conceptual design in order to reduce the structural loading on the wings.

Unlike any of the previous concepts introduced, an H-tail is used on this final concept for

transportability and added reliability. In order to make the vehicle more transportable, multiple

vertical stabilizers may be used in order to help in decreasing the necessary height of the tail.

Another major concern for the conventional tail is that if the rudder fails by getting stuck in one

position or fails to activate, the yaw control of the vehicle would essentially be eliminated. By

adding a second vertical stabilizer, the second rudder should be able to provide a small amount

of yaw control, should this occur. Figure 11 shows an isometric view of the final concept.

Figure 11. Final Concept – Group B

Constraint Analysis

After a concept was chosen a constraint analysis was performed on the aircraft. Using

Equation 17 the power loading required for several cases was found and plotted vs. wing

loading. The constraint analysis graph is shown in Figure 12.

34

Figure 12. Constraint Analysis Curves for Final Concept

It was then determined that the proposed wing loading of 4 is close to ideal. The power

loading of 0.075 is more than required and will provide enough power for higher drag flight

regimes, if needed.

Airfoil Selection

The goal of the airfoil selection was to choose one that would provide 200 lb. of lift with

the selected area of 50 ft2 and would minimize the total drag. Eight airfoils (Table 9) were

compared using Martin Hepperle’s JavaFoil program10 at a calculated Reynolds number of

2,000,000 to determine the needed information for the elimination process.

Table 9. Airfoil Comparison

Airfoil

Clmax

Cl0α

(L/D)max

Cm¼ c max

SD 7062

1.371

0.354

25.327

-0.101

NACA 4412

1.184

0.368

26.362

-0.118

NACA 4415

1.344

0.382

27.187

-0.128

SD7034

1.093

0.295

28.357

-0.083

S 2027

1.045

0.23

25.678

-0.077

NACA 4418

1.515

0.397

26.032

-0.142

Eppler 68

1.096

0.389

28.589

-0.137

NACA 2412

1.008

0.184

28.217

-0.065

35

The first phase of airfoil eliminations was based solely on the maximum lift coefficient of

the airfoil and a Clmax of 1.15 was determined to be the lower limit; thus the SD 7034, S 2027,

Eppler 68, and NACA 2412 were eliminated. The next phase of eliminations consisted of

selecting the three airfoils with the highest maximum lift coefficients thus the NACA 4412 was

eliminated. With only three airfoils left, the NACA 4415, SD 7062 and NACA 4418, several

more factors were introduced into the airfoil elimination process. The final factors for the airfoil

selection criterion were, in no particular order; maximum lift coefficient, lift coefficient at zero

angle of attack, manufacturability, maximum coefficient of moment about the quarter chord and

maximum lift over drag ratio.

It is important to look at the manufacturability of the airfoil section because

imperfections in manufacturing could reduce the overall reliability. Features of an airfoil that

could decrease its manufacturability score are excessive camber, thickness and hard to cut

angles. The maximum lift over drag ratio is a factor that provides a decent overall look at the

performance of the airfoil, a higher maximum lift over drag ratio is desirable. After setting these

criteria each airfoil was given a score and the results compared, see Table 10.

Table 10. Results of Airfoil Ratings

Weighting

NACA 4415

SD 7062

NACA 4418

Clmax

0.35

4

3

5

Cl0α

0.2

4

3

4

(L/D)max

0.1

5

3

4

Manufacturability

0.25

4

4

2

Total Score

1

4

3.35

3.65

The NACA 4415 was chosen as the airfoil to be used for the aircraft concept. This airfoil

will be used for the initial concept tail sizing and other factors to be determined later as

constraint analysis progresses.

Tail Sizing

The objective of the preliminary tail sizing was to obtain a rough estimate of the needed tail

size. The tail surfaces were initially sized using Raymer’s equations8: (See Equation 18 and

Equation 19 in Appendix A and note Svt is the area of both verticals.) With the wingspan and

mean chord already constrained at 16 ft. and 3 ft., respectively, only the volume coefficients, Cht

and Cvt, and the moment arm lengths, Lht and Lvt, needed to be defined. A recommendation in

36

Raymer indicated a horizontal volume coefficient of 0.7 is common; however 0.6 was used to

account for the endplate effect from the H-tail. A vertical tail volume coefficient of 0.04 was

chosen based on an average value for comparator aircraft found in Raymer.

This gave a horizontal tail area of 13.85 ft2. The tail aspect ratio was also selected as two

thirds that of the wing based on Stinton’s9 recommendation, effectively increasing the stall angle

of the horizontal tail above that of the wing. Using a 7° leading edge sweep on the horizontal the

span, root chord and tip chord were found. Using these numbers and the assumption that the

vertical tails are mounted to the tips of the horizontal with a chord equal to the tip chord of the

horizontal the dimensions of the verticals were found. A NACA 0012 was picked for both the

horizontal and vertical tails to allow volume for the required structure. The results of the initial

sizing calculations are shown in Table 11.

Table 11. Initial Empennage Sizing Parameters

Horizontal Tail

Vertical Tail (for one tail)

Area

13.85 ft.²

2.35 ft.²

Span

7 ft.

1.5 ft.

Root Chord

2.22 ft.

1.8 ft.

Mean Chord

2.01 ft.

1.6 ft.

Tip Chord

1.8 ft.

1.4 ft.

Moment Arm

6.5 ft.

6.8 ft.

Taper Angle

7°

15°

Volume Coefficient

0.6

0.04

Engine Selection, Power Requirements, and Endurance

The proposed concept design will cruise at an average speed of 56 knots with a power

required of 4 hp at cruise (Figure 13 and Figure 14). The proposed concept can easily achieve

the required 70 knot maximum speed. Figure 13 shows how the cruise speed will change as the

mission progresses while Figure 14 shows the power required for the aircraft to stay airborne.

37

Figure 13. Cruise Speed and Stall Speed vs. Time