ASHE 7 07 Emerg Mgmt - the Healthcare Facilities Management

advertisement

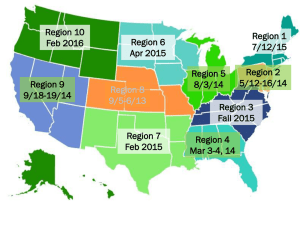

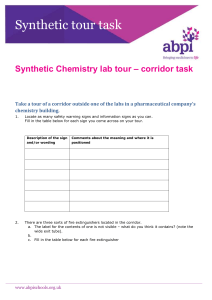

2012 THE HEALTHCARE ENVIRONMENT George Mills, Director Engineering Department The Joint Commission © Copyright, The Joint Commission UPDATE LS & EC RANKING IN TOP 10 IN 2011 EP 13 Corridor Clutter EP 9 & 5 & Rated Doors EP 2 Hazardous Areas All EP’s Fire Safety Testing 10. 31% LS.02.01.35 Sprinkler System Department of Engineering 2012 - 2 © Copyright, The Joint Commission 2. 56% LS.02.01.20 3. 52% LS.02.01.10 Penetrations 4. 45% LS.02.01.30 5. 40% EC.02.03.05 LS.02.01.20 (56%) of the means of egress. EP 13 Corridor Clutter Also scored EPs 16 – 22 Suites issues Equivalize > 5000 sq ft EP 1 Doors locked in means of egress Department of Engineering 2012 - 3 © Copyright, The Joint Commission The hospital maintains the integrity CORRIDOR STORAGE “If the corridor looks cluttered…it probably is” Corridor clutter is not a PFI issue Carts Allowed: Carts Isolation Carts Chemo Carts Based on a HITF the following carts are not allowed: Linen Hampers Latex Carts Anything in the egress corridor more than 30 minutes is storage Department of Engineering 2012 - 4 © Copyright, The Joint Commission Crash CORRIDOR STORAGE storage Less than or equal to 50sqft space Surge issue: based on policy patients may be treated in the egress corridor during surge conditions Goal is continuous compliance for patient safety NOT oscillating compliance Department of Engineering 2012 - 5 © Copyright, The Joint Commission Dead end corridors may be used for LS & EC RANKING IN TOP 10 IN 2011 EP 13 Corridor Clutter EP 9 & 5 & Rated Doors EP 2 Hazardous Areas All EP’s Fire Safety Testing 10. 31% LS.02.01.35 Sprinkler System Department of Engineering 2012 - 6 © Copyright, The Joint Commission 2. 56% LS.02.01.20 3. 52% LS.02.01.10 Penetrations 4. 45% LS.02.01.30 5. 40% EC.02.03.05 LS.02.01.10 (52%) Building and fire protection features are designed and maintained to minimize the effects of fire, smoke, and heat. 9 Penetrations EPs 5 – 7 Door issues EPs 1 & 2 Building Type issues EP 8 Duct issues Department of Engineering 2012 - 7 © Copyright, The Joint Commission EP LS & EC RANKING IN TOP 10 IN 2011 EP 13 Corridor Clutter EP 9 & 5 & Rated Doors EP 2 Hazardous Areas All EP’s Fire Safety Testing 10. 31% LS.02.01.35 Sprinkler System Department of Engineering 2012 - 8 © Copyright, The Joint Commission 2. 56% LS.02.01.20 3. 52% LS.02.01.10 Penetrations 4. 45% LS.02.01.30 5. 40% EC.02.03.05 LS.02.01.30 (45%) The hospital provides and maintains building features to protect individuals from the hazards of fire and smoke. 16 – 23 Smoke Barriers & Doors EP 2 Hazardous Areas Department of Engineering 2012 - 9 © Copyright, The Joint Commission EPs LS & EC RANKING IN TOP 10 IN 2011 EP 13 Corridor Clutter EP 9 & 5 & Rated Doors EP 2 Hazardous Areas All EP’s Fire Safety Testing 10. 31% LS.02.01.35 Sprinkler System Department of Engineering 2012 - 10 © Copyright, The Joint Commission 2. 56% LS.02.01.20 3. 52% LS.02.01.10 Penetrations 4. 45% LS.02.01.30 5. 40% EC.02.03.05 EC.02.03.05 (40%) The hospital maintains fire safety equipment and fire safety building features. of fire protection NOTE: #1 for Critical Access Hospitals Department of Engineering 2012 - 11 © Copyright, The Joint Commission Features LD.04.01.05 EP 4: WHAT TO DO WHEN THE DOCUMENTATION ISN’T THERE… as non-compliant Also score LD.04.01.05 EP 4 If the documentation becomes available later in the survey to the survey team, the team can: Consider removing the previous finding if documentation confirms the activity was completed as per the EP LD.04.01.05 EP 4 may also be removed during survey If the survey team would prefer not to evaluate the documentation the organization can submit clarification If the organization clarifies after survey: SIG Engineers will review and evaluate compliance LD.04.01.05 EP 4 remains Department of Engineering 2012 - 12 © Copyright, The Joint Commission During survey specific documentation is reviewed If the documentation is not available write the observation LS & EC RANKING IN TOP 10 IN 2011 EP 13 Corridor Clutter EP 9 & 5 & Rated Doors EP 2 Hazardous Areas All EP’s Fire Safety Testing 10. 31% LS.02.01.35 Sprinkler System Department of Engineering 2012 - 13 © Copyright, The Joint Commission 2. 56% LS.02.01.20 3. 52% LS.02.01.10 Penetrations 4. 45% LS.02.01.30 5. 42% EC.02.03.05 LS.02.01.35 EP 6 There are 18” or more of open NOTE: Perimeter wall and stack shelving may NFPA 25-1998, 2-2.1.1 Department of Engineering 2012 - 14 © Copyright, The Joint Commission space maintained below the sprinkler deflector to the top of storage. Perimeter Shelving 18” RULE Perimeter Shelving Ceiling 18” 18” Wall OK Wrong OK OK Department of Engineering 2012 - 15 © Copyright, The Joint Commission Wall LIFE SAFETY CODE SURVEYOR LSCS Background or Environment of Care based Prefer CHFM certification All HAP and CAH will be surveyed for a minimum of 2 days by a LSCS Greater than 1.5 million sq ft will be surveyed for a third day by the LSCS An additional day is added for every three buildings that are classified as healthcare Example: for a HAP organization with 2 million square feet of healthcare occupancy and 5 buildings classified as healthcare occupancy: the number of LSCS days would be 4 Department of Engineering 2012 - 16 © Copyright, The Joint Commission Facilities LIFE SAFETY CODE SURVEYOR Interfaces with survey team member(s) LSCS Survey Focus Safety Chapter EC.02.05.03 EC.02.05.07 EC.02.05.09 May conduct the EC Session May conduct the EM Session Other “Observations” May also survey LD.04.01.05 EP 4 Accountability LD.04.04.01 EP 2 Hi-Priority LD.01.03.01 EP 5 Resources Department of Engineering 2012 - 17 © Copyright, The Joint Commission Life WHAT TRIGGERS ITL (IMMEDIATE THREAT TO LIFE) system Significantly compromised sprinkler system Significantly compromised emergency power supply system Significantly compromised medical gas master panel Significantly compromised exits Other situations that place patients, staff or visitors at extreme danger Department of Engineering 2012 - 18 © Copyright, The Joint Commission Significantly compromised fire alarm WHAT TRIGGERS ITL (IMMEDIATE THREAT TO LIFE) CONT01 The Immediate Treat to Health or Safety has been successfully abated and verified through the direct observation or other determining method. Department of Engineering 2012 - 19 © Copyright, The Joint Commission PDA01 An Immediate Threat to Health or Safety exists for patients or the public within the hospital. AFS 10 IS RELATED TO THE SOC AND PFIS previously accepted PFIs (LS.01.01.01 EP 2) Failure to develop ILSM policy and implement appropriate ILSMs (LS.01.02.01 EP 3) Failure to manage previously accepted PFIs affects the Joint Commission Both organizations are aware of deficiencies that have been managed using the PFI process Department of Engineering 2012 - 20 © Copyright, The Joint Commission Failure to make sufficient progress on Resolution to a deficiency: Resolve it immediately Correct it within 45 days: Management process that documents the deficiency and actions to resolve ILSM must be considered Plan For Improvement located in the Statement of Conditions™ Corrected within 6 months of the Projected Completion Date ILSM must be considered Department of Engineering 2012 - 21 © Copyright, The Joint Commission DEFICIENCY RESOLUTION 45 DAY CORRECTIVE ACTION Documented Origination date Completion date Kept available for rolling 3 years Life Safety deficiencies Must not exceed 45 days Improvement (PFI) If originally a work order, close out as complete and generate the PFI Must be made available to the Joint Commission During survey to confirm management of the deficiency During CMS/Joint Commission validation process upon request Department of Engineering 2012 - 22 © Copyright, The Joint Commission If greater than 45 days create a Plan For HOW MANY OPEN PFIS ARE TOO MANY? organizations to self assess and create a Plan for Improvement The self disclosure has never defined how many is too many The ILSM process was created to allow both the organization and The Joint Commission to be aware of Life Safety Code deficiencies Failure to make progress on previously accepted PFIs, including failure to implement ILSMs results in Conditional Accreditation Department of Engineering 2012 - 23 © Copyright, The Joint Commission The PFI process was created to allow HOW MANY OPEN PFIS ARE TOO MANY? Survey Process: is no limit to the number of PFIs Evaluate both closed and currently open PFIs in the View All screen Spot check during building tour both some closed and open PFIs to evaluate how well the organization is managing the PFI process Evaluate the scope of PFI entries Are there life safety deficiencies Are they greater than maintenance items (i.e. screws missing from a door hinge) Department of Engineering 2012 - 24 © Copyright, The Joint Commission There STATEMENT OF CONDITIONS: PFI PFIs should be related to the LS Chapter clutter is not a legitimate PFI PFIs should provide specific information No blanket statements “…penetrations on 3rd floor” Specific references to Life Safety Drawings is acceptable 32 penetrations as identified on LS Drawing 3rd Floor, Center Tower dated 3/3/2010 Projected Completion Date is for all listed items (i.e. “32 penetrations”) Department of Engineering 2012 - 25 © Copyright, The Joint Commission Corridor TWO FORMS OF EQUIVALENCIES Fire Safety Evaluation System (FSES) process of calculating the features of life safety and deducting any deficiencies, with the outcome determining if the building is equivalized based on the FSES Traditional Equivalency A process of field verification identifying alternative methods of fire safety that off-set the identified deficiency Field verification from one of the following: Registered architect Fire Protection Engineer Local AHJ responsible for fire safety Department of Engineering 2012 - 26 © Copyright, The Joint Commission A HISTORY AUDIT TRAIL Engineers when considering extensions or other activities related to an organization Prior to surveying, the surveyor must preview the History Audit Trail to discover if equivalencies or other actions have occurred by SIG Engineers When surveying, brief but accurate information entered in the File Room is important Department of Engineering 2012 - 27 © Copyright, The Joint Commission The History Audit Trail is used by SIG George Mills, Director Department of Engineering The Joint Commission © Copyright, The Joint Commission 2012 LIFE SAFETY CODE NFPA 101-2012 1. Means of Egress Enhanced Patient lift & transport equipment may be stored in the Means of Egress, provided 5ft clear corridor width is maintained Fire plan addresses management of storage Accommodates current “equipment in use” Department of Engineering 2012 - 29 © Copyright, The Joint Commission NFPA 101-2012 Fixed seating permitted provided 6ft clear width < 50sqft with 10’ between groupings Groupings must be on same side of the egress corridor Department of Engineering 2012 - 30 © Copyright, The Joint Commission 2. 4. Cooking Facilities One cooking area may be open to the egress corridor per smoke compartment Any additional cooking areas must be in protected room similar to hazardous areas Provisions: No deep fat fryers Safety equipment to de-activate fuel supply Grease baffles installed No solid fuel (i.e. charcoal) Department of Engineering 2012 - 31 © Copyright, The Joint Commission NFPA 101-2012 CORRIDOR COOKING NFPA 101-2012 FIREPLACES patient sleeping rooms Section 18/19.5.2(2), (3) and (4) Allow the installation of direct vent gas fireplaces In smoke compartments containing patient sleeping rooms Installation of solid fuel burning fireplaces in areas other than patient sleeping areas Department of Engineering 2012 - 32 © Copyright, The Joint Commission 5. Fireplaces in smoke compartments with NFPA 101-2012 DECORATIONS Allow the use of Furnishings, Mattresses, and Decorations including Section 18/19.7.5 Allows the installation of combustible decorations on Walls Doors Ceilings LSC Section 18/19.7.5.6 Department of Engineering 2012 - 33 © Copyright, The Joint Commission 6. © Copyright, The Joint Commission GENERAL INTERPRETATIONS BUILDING MAINTENANCE PROGRAM (BMP) All EPs related to the original ten BMP items are ‘C’ categories © Copyright, The Joint Commission The BMP is no longer available to offset findings during survey, but is considered “best practice” GENERAL LIFE SAFETY INTERPRETATIONS placement: LS.02.01.29 EP 12 and NFPA 101 19.3.2.6 (6) states, The dispensers shall not be installed over or directly adjacent to an ignition source. The Joint Commission published information in 2006 defining “adjacent to” as no closer than 6inches, center of the dispenser to center of the ignition source Department of Engineering 2012 - 36 © Copyright, The Joint Commission Alcohol Based Hand Rub (ABHR) NFPA 101, 2012: 18/19.3.2.6. (8) Dispensers shall not be installed in the following locations: Above an ignition source for a horizontal distance of 1 in (25 mm) to each side of the ignition source. To the side of an ignition source within a 1 in. (25 mm) horizontal distance from the ignition source. Beneath an ignition source within a 1 in. (25 mm) vertical distance from the ignition source. Department of Engineering 2012 - 37 © Copyright, The Joint Commission GENERAL LIFE SAFETY INTERPRETATIONS FIRE & SMOKE DAMPER INSPECTIONS are by random sampling Confirm ILSM policy is implemented for any horizontal exits or egress enclosures that are compromised by inaccessible dampers Evaluate adequacy of damper accessibility plan Department of Engineering 2012 - 38 © Copyright, The Joint Commission Ensure inaccessible dampers truly EC.02.06.05 EP 1 recognize the Facilities Guidelines Institute (FGI) Guidelines for Design & Construction of Health Care Facilities ASHRAE 170 has been attached to the Guidelines Ventilation Table 20 – 60 % RH requirement of relative humidity in seven affected areas of the Surgical Environment, and one in Diagnostic & Treatment. NOTE CMS has not adopted this, but remains at 35 – 60%RH The established 60% upper range however should be maintained for issues such as mold growth. Department of Engineering 2012 - 39 © Copyright, The Joint Commission Effective 1/1/2011 the Joint Commission will RH% TREATMENT AREAS Class A Operating/Procedure room Class B and C operating rooms Operating/surgical cystoscopic rooms Delivery room (Caesarean) Treatment rooms Laser eye room Diagnostic & Treatment: Gastrointestinal Endoscopy Procedure Room Department of Engineering 2012 - 40 © Copyright, The Joint Commission Trauma room (crisis or shock) CENTRAL STERILE LAYOUT Physically separated soiled and clean work rooms Soiled Work Room: Work surface, sink, washer/sterilizer decontaminators Soiled room is not to have direct contact with the OR Clean assembly /work room Hand washing station Sufficient workspace and equipment Self-closing door or pass through is acceptable between soiled and clean work rooms Storage provisions for humidity, temperature, and ventilation Location of storage may be within the clean assembly/ workroom in a permanently designated space Guidelines for Design & Construction of Health Care Facilities FGI 2010 edition 3.7-5.1.2 - 3.7-5.1.2.3 Department of Engineering 2012 - 41 © Copyright, The Joint Commission ENDOSCOPY PROCESSING ROOM May be one room, dedicated to endoscopy equipment processing Sized as per amount of equipment processed Work flow from soiled to clean Clean should not be exposed to soiled • 3ft min clearance clean from soiled at all times • Droplet contamination is concern Work surface and sink Hand washing station Sufficient workspace, utilities and equipment Ventilation Negative air pressure to surrounding areas Minimum 10 ach (2 fresh, outside); direct exhaust NO requirements for temperature or humidity Guidelines for Design & Construction of Health Care Facilities FGI 2010 edition 3.9-5.1.1 - 3.9-5.1.1.2 Department of Engineering 2012 - 42 © Copyright, The Joint Commission ENDOSCOPY PROCESSING ROOM Storage May be a cabinet in the endoscopy processing room Cabinet must have doors Cabinet must be at least 3ft from potential droplet contamination • Consider route from processor to the cabinet • Route should not cross through soiled processing area Storage may be in a separate room Inventory of Scopes Recommended practice is to include scopes in the Medical Equipment Inventory Guidelines for Design & Construction of Health Care Facilities FGI 2010 edition 3.9-5.1.1 - 3.9-5.1.1.2 Department of Engineering 2012 - 43 © Copyright, The Joint Commission SCORING design Inability of the mechanical system to achieve required results EC.02.05.01 EP 4: Lack of written inspection, testing & maintaining frequencies Continuous monitoring by a building automation system (BAS) is acceptable Department of Engineering 2012 - 44 © Copyright, The Joint Commission EC.02.05.01 EP 1: Improper system SCORING to provide appropriate pressure relationships, air-exchange rates and filtration efficiencies Specific areas lack negative or positive pressures in relationship to adjacent areas • i.e. Endoscopy Processing Room should be negative to the egress corridor the correct number of air changes per hour Improper filtration • MERV = minimum efficiency reporting value Department of Engineering 2012 - 45 © Copyright, The Joint Commission EC.02.05.01 EP 6: Ventilation system is unable SCORING evaluate if further investigation needs to occur To perform the flutter test take a tissue and let it hang just off the floor near the bottom edge of a door If the tissue indicates incorrect air flow, stabilize the area by closing doors and windows, wait a few minutes and re-screen If the organization presents a Testing & Balancing report the following questions should be asked • when was the balancing done (seasonal issues) • are any specific requirements (such as keeping a door closed) needed to achieve satisfactory results If non-compliance is determined write a clear and specific finding Department of Engineering 2012 - 46 © Copyright, The Joint Commission Tissue test: only to be used as a pre-screening tool to SCORING Maintains ventilation, temperature and humidity levels suitable for care, treatment and services provided Ventilation: • i.e. doors held open by air pressure; odors Temperature: • Hot / Cold calls Humidity • Primary concern is for areas >60%RH − Mold growth is possible Department of Engineering 2012 - 47 © Copyright, The Joint Commission EC.02.06.01 EP 13 SCORING EC.02.05.05 EP’s 4 & 5 4: Infection Control systems are not maintained i.e. an isolation room that should be negative is positive EP 5: non-life support utility system components are not inspected, tested or maintained Improper number of air changes results in offensive odors in geriatric unit Department of Engineering 2012 - 48 © Copyright, The Joint Commission EP GENERAL LIFE SAFETY INTERPRETATIONS labels on the door and jambs Jambs prior to 1966 may not have a rating label Are ILSM in place where noncompliant door assemblies are found? Department of Engineering 2012 - 49 © Copyright, The Joint Commission Rated doors must have legible NON FLAMMABLE MEDICAL GAS VOLUME & STORAGE: SCORING Score EC.02.03.01 EP 1 …fire risk ‘E’ cylinders (<300ft³) per smoke compartment (22,500ft²) may be open to the egress corridor in a rack or appropriate holders Between 300 and 3000ft³ must be stored in a room that is limited construction with doors that can be locked “In use” verses “in storage” Properly secured to a gurney is considered “in use” Properly racked is “in storage” Empty are NOT considered part of the 12 in storage Empty and full must be stored (racked) separately Department of Engineering 2012 - 50 © Copyright, The Joint Commission 12 NFPA 99-2005 edition has additional language regarding O2 storage requirements, specifically: Storage of nonflammable gases: 9.4.1 > 3000 cubic feet 9.4.2 300 – 3000 cubic feet 9.4.3 0 - 300 cubic feet Other: 5.1.3.3.2 design and construction 5.1.3.3.3 ventilation of locations for manifolds 5.1.3.3.3.2 ventilation for motor driven equipment 5.1.3.3.3.3 ventilation for outdoors NOTE: CMS also recognizes 9.4.3 reference Department of Engineering 2012 - 51 © Copyright, The Joint Commission NON-FLAMMABLE GAS STORAGE: NFPA 99-2005 NON-FLAMMABLE MEDICAL GAS UNSAFE CONDITIONS: SCORING Score EC.02.06.01 …unsafe condition cylinders Laying on top a gurney mattress; leaning against the wall Free standing Comingling of full and empty cylinders Transfilling liquid oxygen Transfer of any gases from one cylinder to another in patient care areas of health care facilities is prohibited. Transfilling of liquid oxygen only in an area that is: • mechanically ventilated • sprinklered • ceramic or concrete flooring • separated with at least 1 hour construction from any patient care areas Department of Engineering 2012 - 52 © Copyright, The Joint Commission Unsecured TANK FARM maintains critical components of the piped medical gas systems. Tank Farm is included in this EP The bulk storage tank(s) and associated systems are critical components of the piped medical gas system Tanks above ground, not on roofs No electrical service above tanks 10’ Clear from vehicles & sidewalks 50’ from wood frame buildings • At least 1’-0” from other buildings • At least 10’ form any opening in wall of adjacent structures • Concrete pads at all spill points (3’ min) Permanent signage: OXYGEN – NO SMOKING – NO OPEN FLAMES Access controlled (i.e. locked) Department of Engineering 2012 - 53 © Copyright, The Joint Commission EC.02.05.09 EP 1 states the hospital tests, inspects and NFPA 110: EMERGENCY & STANDBY POWER SYSTEMS devices that have normal electrical power entering and leaving the ATS The power continues on to distribution panels When a ATS senses a disruption in power it sends a signal to the alternative power source seeking power This start circuit initiates the emergency generator starter The ATS is also equipped with a test switch to simulate the power disruption Recommended practice is to rotate which ATS initiates the start circuit to the emergency generator Department of Engineering 2012 - 54 © Copyright, The Joint Commission Automatic Transfer Switches (ATS) are self-acting Month, day year and initials of inspector as per NFPA 10-1998 EC.02.03.05 EP 15 4-3.4 Inspection Recordkeeping. 4-3.4.1 Personnel making inspections shall keep records of all fire extinguishers inspected, including those found to require corrective action. 4-3.4.2 At least monthly, the date the inspection was performed and the initials of the person performing the inspection shall be recorded. 4-3.4.3 Records shall be kept on a tag or label attached to the fire extinguisher, on an inspection checklist maintained on file, or in an electronic system (e.g., bar coding) that provides a permanent record. DO NOT COUNT DAYS, BUT ENSURE MONTHLY INSPECTION Department of Engineering 2012 - 55 © Copyright, The Joint Commission FIRE EXTINGUISHER: DATING GENERAL LIFE SAFETY INTERPRETATIONS Perimeter shelving and sprinkler provision: Are perimeter wall shelving that extends to the ceiling required to be fastened to the wall? NO Shelving is not required for storage There is no correlation between • Shelving • Clearance • The need to secure any shelving Department of Engineering 2012 - 56 © Copyright, The Joint Commission Firestop: Existing application is acceptable when It was installed in a manner consistent with original design specifications It is in acceptable condition currently If the firestop is cracking, etc, then it is to be removed and repaired using current technologies Department of Engineering 2012 - 57 © Copyright, The Joint Commission GENERAL LIFE SAFETY INTERPRETATIONS GENERAL LIFE SAFETY INTERPRETATIONS purposes is NOT an acceptable firestop in any fire or smoke barrier This product does have a UL label: for insulation properties Easily ignited Toxic gases may occur when burned NOTE: There are several acceptable fire stop products that expand when installed Department of Engineering 2012 - 58 © Copyright, The Joint Commission Expanding foam used for insulation Electrical Unlocked distribution panels in patient care areas Based on policy Consider risk assessment Score EC.02.01.06 EP 1 Open junction boxes Score at EC.02.03.01 EP 1 • Risk: arcing resulting in fire or loss of service Department of Engineering 2012 - 59 © Copyright, The Joint Commission GENERAL LIFE SAFETY INTERPRETATIONS Staff Safety EC.02.02.01 EP 3: Precautions & PPE EP 4: Spill procedures EPs 5 – 10: minimizes risk EC.04.01.01 EP 1: Monitoring & Reporting EPs 2 – 11: Specifics Manifests: EP 11 DOT training for those signing Department of Engineering 2012 - 60 © Copyright, The Joint Commission GENERAL LIFE SAFETY INTERPRETATIONS OUTDOOR SAFETY EC.02.01.01 EP 5 hospital maintains all grounds and equipment Grounds includes Sidewalks Parking lots Park ways Picnic and patio areas Play structures Department of Engineering 2012 - 61 © Copyright, The Joint Commission The OUTDOOR SAFETY EC.02.01.01 EP 5 hospital maintains all grounds and equipment Equipment includes Lawn maintenance equipment Snow removal equipment Maintenance equipment Paving Road repair Lighting Department of Engineering 2012 - 62 © Copyright, The Joint Commission The GENERAL LIFE SAFETY INTERPRETATIONS A stairwell may be allowed to be substituted as an “exit access corridor” Department of Engineering 2012 - 63 © Copyright, The Joint Commission Suite Exiting LS.02.01.20 EP 21 (18/19.2.5.1) Suites have access to an “exit access corridor” LS.02.01.20 EP 17(18/19.2.5.3) Suites must have at least two exits remote from one another SURGICAL SITE FIRES >50 million hospital & ASC surgeries 100 surgery fires per year 20 Serious 1 – 2 deaths Fire sites: 34% airway 28% head/face 38% other 74% occurred in oxygen enriched environment Department of Engineering 2012 - 64 © Copyright, The Joint Commission Estimated SURGICAL SITE FIRES Source: electrosurgical equipment 13% lasers Recommendations: Fire drills & Staff Education Review alarm procedures Review rescue techniques Review shut off locations Joint Commission response: Life Safety Code Surveyors gown and survey Department of Engineering 2012 - 65 © Copyright, The Joint Commission 68% CMS CONDITIONS OF PARTICIPATION 42 CFR 482.41 must maintain adequate facilities for its services 42 CFR 482.41(c)(2) Facilities, supplies and equipment must be maintained to ensure an acceptable level of safety and quality. The CMS Interpretive Guideline states “the hospital must monitor, test, calibrate and maintain equipment periodically in accordance with the manufacturer’s recommendation and Fed and State law.” Department of Engineering 2012 - 66 © Copyright, The Joint Commission Hospital BACKGROUND on 42 CFR 482.41(c)(2) 2009 hospital system implemented EQ56 CMS Regional Office stated that any risk or evidence based program conflicted with 42 CFR 482.41(c)(2) Other CMS Regional Offices accepted the Joint Commission processes The hospital system asked CMS why they were inconsistent with 42 CFR 482.41(c)(2) 1/2010 CMS instructed Joint Commission to comply with 42 CFR 482.41(c)(2) Department of Engineering 2012 - 67 © Copyright, The Joint Commission 2007 two hospitals cited by state agents based CMS RESPONSE CMS Deputy Director July 26, 2010 Department of Engineering 2012 - 68 © Copyright, The Joint Commission I am happy to inform you that the Joint Commission’s approach of utilizing a preventive maintenance schedule has been approved. Thank you for your cooperation and collaboration. S&C: 12-07-HOSPITAL PUBLISHED 12/11 Allows non-life support to adjust frequencies Restricts non-life support from adjusting FTE & other re-occurring costs ($4 – 10 Billion): Clinical Equipment: $2 – 5 Billion Facilities Equipment: $2 – 5 Billion New capital investment ($2 – 6 Billion): Clinical Equipment: $1 – 3 Billion Facilities Equipment: $1 – 3 Billion Department of Engineering 2012 - 69 © Copyright, The Joint Commission maintenance activities Restricts life support from frequencies and maintenance activity adjustments Restricts equipment maintenance methods Estimated financial impact to comply: 4/9/2012 DISCUSSION WITH CMS Ad Hoc team began to meet every Monday to create united response to CMS Provided council and resources Joint Commission leadership is supportive of discussing the issues with CMS Joint Commission met with CMS to discuss the S&C: 12-07 April 9, 2012 Restriction related to test equipment lifted Saving estimated as $2 – 6 Billion to healthcare Collaborative discussion with the conclusion research would be of benefit Research should be specific to reliability of the Joint Commission process in EC.02.04.01 Department of Engineering 2012 - 70 © Copyright, The Joint Commission Research Issues: How many organizations use the Joint Commission process? What guidance is used to modify frequency and maintenance activities? Have there been any adverse outcomes based on solely on this process If so, what? Self diagnostic equipment: How many devices with this feature? Department of Engineering 2012 - 71 © Copyright, The Joint Commission DISCUSSION, CONTINUED ACTION ITEMS AAMI & ASHE hosted Survey Monkeys webinars to review Joint Commission standards and make the field aware of the importance of the survey AAMI had 526 sites ASHE had 216 sites JCR had 794 sites Survey responses: AAMI had 1526 ASHE had 790 Department of Engineering 2012 - 72 © Copyright, The Joint Commission 5/18 AAMI, ASHE & JCR hosted free QUESTION 1 Range Percentages Responses <100 27.1 221 100 – 200 15.7 123 201 – 350 23.5 183 351 – 500 12.8 100 >500 20.9 162 Department of Engineering 2012 - 73 © Copyright, The Joint Commission How many acute care beds is your organization licensed or authorized for? QUESTION 2 Range Percentages Responses <500 20.1 158 500 – 1,000 19.1 150 1,000 – 2,500 22.8 180 2,500 – 5,000 17.4 135 >5,000 20.6 162 Department of Engineering 2012 - 74 © Copyright, The Joint Commission How many pieces of equipment are in your inventory? QUESTION 3 Percentages Responses Yes 90.9 714 No 9.1 70 Department of Engineering 2012 - 75 © Copyright, The Joint Commission Do you use the Joint Commission process identified in EC.02.05.01 EPs 2 – 4 (i.e. have an inventory based on risk and other criteria)? QUESTION 4 Percentage Responses Yes 92.7 728 No 7.3 57 Department of Engineering 2012 - 76 © Copyright, The Joint Commission Do you use the Joint Commission process identified in EC.02.05.01 EP 3 to establish maintenance activities (i.e. preventive maintenance procedure)? QUESTION 5 Percentage Responses Yes 90.9 711 No 9.1 71 Department of Engineering 2012 - 77 © Copyright, The Joint Commission Do you use the Joint Commission process identified in EC.02.05.01 EP 4 to establish maintenance frequencies? QUESTION 6 Percentage Responses Yes 1.0 8 No 99.0 782 Department of Engineering 2012 - 78 © Copyright, The Joint Commission Have you had any adverse outcomes (i.e. patient injuries or deaths) because you have modified the PM procedures or frequencies from the manufacturer’s recommendations, using the Joint Commission process identified in EC.02.05.01 EPs 2 – 4? None of the 12 that answered YES to question 6 had an adverse event 4 are not accredited by the Joint Commission 3 had comments that did not pertain to the topic 4 were pro-Joint Commission process comments 1 reported a bed brake failed to engage and a patient fell when leaning on the bed Department of Engineering 2012 - 79 © Copyright, The Joint Commission COMMENTS TO QUESTION 6 NEXT STEPS continued to actively help navigate this process AAMI, ASHE and Joint Commission will be meeting with CMS to review the research results Goal is to resolve the conflict with sound evidence provided by the research Department of Engineering 2012 - 80 © Copyright, The Joint Commission The Ad Hoc committee has © Copyright, The Joint Commission QUESTIONS? DEPARTMENT OF ENGINEERING 630 792 5900 George Mills, MBA, FASHE, CEM, CHFM, CHSP Director Michael Chisholm, CPE, CHFM Engineer John Maurer, CHFM, CHSP Engineer Bruce Boggan, MBA, CHFM Engineer Department of Engineering 2012 - 82 © Copyright, The Joint Commission Anne Guglielmo, CFPS, LEED, A.P., CHSP Engineer THE JOINT COMMISSION DISCLAIMER These slides are current as of 6/21/2012. The Joint Commission reserves the right to change the content of the information, as appropriate. These slides are only meant to be cue points, which These slides are copyrighted and may not be further used, shared or distributed without permission of the original presenter or The Joint Commission. Department of Engineering 2012 - 83 © Copyright, The Joint Commission were expounded upon verbally by the original presenter and are not meant to be comprehensive statements of standards interpretation or represent all the content of the presentation. Thus, care should be exercised in interpreting Joint Commission requirements based solely on the content of these slides. EYE WASH STATION FEDERAL REQUIREMENTS: OSHA recommendation to reduce the risk of injury from contact with caustic and corrosive materials in areas such as Power Plant Lab Placed so that the eyewash is within 10 seconds or 55 feet from where the corrosive chemicals is used Weekly flush until clear is required Annual inspection to ensure the system is fully functional Mixing valve recommended to achieve tepid Risk assess potential exposure to determine if cold water only would be acceptable Department of Engineering 2012 - 84 © Copyright, The Joint Commission Score Eye Wash issues at EC.02.02.01 EP 5 Risk assess location / application based on OSHA Medical services and first aid 1910.151(c) The eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use. Formaldehyde 1910.1048(i)(3) If there is any possibility that an employee's eyes may be splashed with solutions containing 0.1 percent or greater formaldehyde, the employer shall provide acceptable eyewash facilities within the immediate work area for emergency use. Battery charging and changing 1917.157(i) Facilities for flushing the eyes, body and work area with water shall be provided wherever electrolyte is handled, except that this requirement does not apply when employees are only checking battery electrolyte levels or adding water. Department of Engineering 2012 - 85 © Copyright, The Joint Commission EYE WASH STATION: RECOMMENDED LOCATIONS (I.E. OSHA) © Copyright, The Joint Commission Department of Engineering 2012 - 86