Lecture 4 - Fundamentals

advertisement

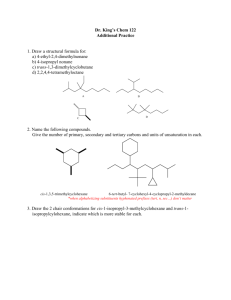

Lecture Chp-9&10 – Columns Lecture Goals Definitions for short columns Columns Analysis and Design of “Short” Columns General Information Column: Vertical Structural members Transmits axial compressive loads with or without moment transmit loads from the floor & roof to the foundation Analysis and Design of “Short” Columns General Information Column Types: 1. Tied 2. Spiral 3. Composite 4. Combination 5. Steel pipe Analysis and Design of “Short” Columns Tied Columns - 95% of all columns in buildings are tied Tie spacing h (except for seismic) tie support long bars (reduce buckling) ties provide negligible restraint to lateral expose of core Analysis and Design of “Short” Columns Spiral Columns Pitch = 1.375 in. to 3.375 in. spiral restrains lateral (Poisson’s effect) axial load delays failure (ductile) Analysis and Design of “Short” Columns Elastic Behavior An elastic analysis using the transformed section method would be: For concentrated load, P P fc Ac nAst f s nf c uniform stress over section n = Es / Ec Ac = concrete area As = steel area Analysis and Design of “Short” Columns Elastic Behavior The change in concrete strain with respect to time will effect the concrete and steel stresses as follows: Concrete stress Steel stress Analysis and Design of “Short” Columns Elastic Behavior An elastic analysis does not work, because creep and shrinkage affect the acting concrete compression strain as follows: Analysis and Design of “Short” Columns Elastic Behavior Concrete creeps and shrinks, therefore we can not calculate the stresses in the steel and concrete due to “acting” loads using an elastic analysis. Analysis and Design of “Short” Columns Elastic Behavior Therefore, we are not able to calculate the real stresses in the reinforced concrete column under acting loads over time. As a result, an “allowable stress” design procedure using an elastic analysis was found to be unacceptable. Reinforced concrete columns have been designed by a “strength” method since the 1940’s. Note: Creep and shrinkage do not affect the strength of the member. Behavior, Nominal Capacity and Design under Concentric Axial loads 1. Initial Behavior up to Nominal Load - Tied and spiral columns. Behavior, Nominal Capacity and Design under Concentric Axial loads Behavior, Nominal Capacity and Design under Concentric Axial loads P0 0.85 f c * Ag Ast f y Ast Let Ag = Gross Area = b*h Ast = area of long steel fc = concrete compressive strength fy = steel yield strength Factor due to less than ideal consolidation and curing conditions for column as compared to a cylinder. It is not related to Whitney’s stress block. Behavior, Nominal Capacity and Design under Concentric Axial loads 2. Maximum Nominal Capacity for Design Pn (max) Pn max rP0 r = Reduction factor to account for accidents/bending r = 0.80 ( tied ) r = 0.85 ( spiral ) ACI 10.3.6.3 Behavior, Nominal Capacity and Design under Concentric Axial loads 3. Reinforcement Requirements (Longitudinal Steel Ast) Let Ast g Ag - ACI Code 10.9.1 requires 0.01 g 0.08 Behavior, Nominal Capacity and Design under Concentric Axial loads 3. Reinforcement Requirements (Longitudinal Steel Ast) - Minimum # of Bars ACI Code 10.9.2 min. of 6 bars in circular arrangement w/min. spiral reinforcement. min. of 4 bars in rectangular arrangement min. of 3 bars in triangular ties Behavior, Nominal Capacity and Design under Concentric Axial loads 3. Reinforcement Requirements (Lateral Ties) ACI Code 7.10.5.1 size # 3 bar if longitudinal bar # 10 bar # 4 bar if longitudinal bar # 11 bar # 4 bar if longitudinal bars are bundled Behavior, Nominal Capacity and Design under Concentric Axial loads 3. Reinforcement Requirements (Lateral Ties) Vertical spacing: (ACI 7.10.5.2) s s s 16 db ( db for longitudinal bars ) 48 db ( db for tie bar ) least lateral dimension of column Behavior, Nominal Capacity and Design under Concentric Axial loads 3. Reinforcement Requirements (Lateral Ties) Arrangement Vertical spacing: (ACI 7.10.5.3) 1.) At least every other longitudinal bar shall have lateral support from the corner of a tie with an included angle 135o. 2.) No longitudinal bar shall be more than 6 in. clear on either side from “support” bar. Behavior, Nominal Capacity and Design under Concentric Axial loads Examples of lateral ties. Behavior, Nominal Capacity and Design under Concentric Axial loads Reinforcement Requirements (Spirals ) ACI Code 7.10.4 size 3/8 “ dia. (3/8” f smooth bar, #3 bar dll or wll wire) 1 in. clear spacing between spirals 3 in. ACI 7.10.4.3 Behavior, Nominal Capacity and Design under Concentric Axial loads Reinforcement Requirements (Spiral) Spiral Reinforcement Ratio, s Volume of Spiral 4 Asp s Volume of Core Dc s Asp Dc from : s 2 1 4 Dc s Behavior, Nominal Capacity and Design under Concentric Axial loads Reinforcement Requirements (Spiral) A f c g s 0.45 * 1 * ACI Eqn. 10-5 Ac f y where Asp cross - sectional area of spiral reinforcem ent Ac core area Dc2 4 Dc core diameter : outside edge to outside edge of spiral s spacing pitch of spiral steel (center to center) f y yield strength of spiral steel 60,000 psi Behavior, Nominal Capacity and Design under Concentric Axial loads 4. Design for Concentric Axial Loads (a) Load Combination Gravity: Pu 1.2 PDL 1.6 PLL Gravity + Wind: Pu 1.2 PDL 1.0 PLL 1.6 Pw and etc. Pu 0.9 PDL 1.3Pw Check for tension Behavior, Nominal Capacity and Design under Concentric Axial loads 4. Design for Concentric Axial Loads (b) General Strength Requirement f Pn Pu where, f = 0.65 for tied columns f = 0.7 for spiral columns Behavior, Nominal Capacity and Design under Concentric Axial loads 4. Design for Concentric Axial Loads (c) Expression for Design defined: Ast g Ag ACI Code 0.01 g 0.08 Behavior, Nominal Capacity and Design under Concentric Axial loads f Pn f r Ag 0.85 f c Ast f y 0.85 f c Pu concrete steel or f Pn f r Ag 0.85 f c g f y 0.85 f c Pu Behavior, Nominal Capacity and Design under Concentric Axial loads * when g is known or assumed: Ag Pu f r 0.85 f c g f y 0.85 f c * when Ag is known or assumed: Pu 1 Ag 0.85 f c Ast f y 0.85 fc fr Example: Design Tied Column for Concentric Axial Load Example: Design Tied Column for Concentric Axial Load Design tied column for concentric axial load Pdl = 150 k; Pll = 300 k; Pw = 50 k fc = 4500 psi fy = 60 ksi Design a square column aim for g = 0.03. Select longitudinal transverse reinforcement. Example: Design Tied Column for Concentric Axial Load Determine the loading Pu 1.2 Pdl 1.6 Pll 1.2 150 k 1.6 300 k 660 k Pu 1.2 Pdl 1.0 Pll 1.6 Pw 1.2 150 k 1.0 300 k 1.6 50 k 560 k Check the compression or tension in the column Pu 0.9 Pdl 1.3Pw 0.9 150 k 1.3 50 k 70 k Example: Design Tied Column for Concentric Axial Load For a square column r = 0.80 and f = 0.65 and = 0.03 Pu Ag f r 0.85f c g f y 0.85f c 660 k 0.85 4.5 ksi 0.65 0.8 ksi 4.5 0.85 ksi 60 0.03 230.4 in 2 Ag d 2 d 15.2 in. d 16 in. Example: Design Tied Column for Concentric Axial Load For a square column, As=Ag= 0.03(15.2 in.)2 =6.93 in2 Pu 1 Ast f r 0.85f c Ag f y 0.85fc 1 60 ksi 0.85 4.5 ksi 660 k 2 * 0.85 4.5 ksi 16 in 0.65 0.8 5.16 in 2 Use 8 #8 bars Ast = 8(0.79 in2) = 6.32 in2 Example: Design Tied Column for Concentric Axial Load Check P0 P0 0.85f c Ag Ast f y Ast 0.85 4.5 ksi 256 in 2 6.32 in 2 60 ksi 6.32 in 2 1334 k f Pn f rP0 0.65 0.81334 k 694 k > 660 k OK Example: Design Tied Column for Concentric Axial Load Use #3 ties compute the spacing s b # d b 2 cover dstirrup # bars 1 16 in. 3 1.0 in. 2 1.5 in. 0.375 in. 2 4.625 in. < 6 in. No cross-ties needed Example: Design Tied Column for Concentric Axial Load Stirrup design 16 in. 16d b 16 1.0 in. s 48dstirrup 48 0.375 in. 18 in. smaller b or d 16 in. governs governs Use #3 stirrups with 16 in. spacing in the column Behavior under Combined Bending and Axial Loads Usually moment is represented by axial load times eccentricity, i.e. Behavior under Combined Bending and Axial Loads Interaction Diagram Between Axial Load and Moment ( Failure Envelope ) Concrete crushes before steel yields Steel yields before concrete crushes Note: Any combination of P and M outside the envelope will cause failure. Behavior under Combined Bending and Axial Loads Axial Load and Moment Interaction Diagram – General Behavior under Combined Bending and Axial Loads Resultant Forces action at Centroid ( h/2 in this case ) Pn Cs1 Cc Ts2 compression is positive Moment about geometric center h h h a M n Cs1 * d1 Cc * Ts2 * d 2 2 2 2 2 Columns in Pure Tension Section is completely cracked (no concrete axial capacity) Uniform Strain y N Pn tension f y As i 1 i Columns Strength Reduction Factor, f (ACI Code 9.3.2) (a) Axial tension, and axial tension with flexure. f = 0.9 (b) Axial compression and axial compression with flexure. Members with spiral reinforcement confirming to 10.9.3 f 0.70 Other reinforced members f 0.65 Columns Except for low values of axial compression, f may be increased as follows: when f y 60,000 psi and reinforcement is symmetric and h d ds 0.70 h ds = distance from extreme tension fiber to centroid of tension reinforcement. Then f may be increased linearly to 0.9 as fPn decreases from 0.10fc Ag to zero. Column Columns Commentary: Other sections: f may be increased linearly to 0.9 as the strain s increase in the tension steel. fPb Design for Combined Bending and Axial Load (Short Column) Design - select cross-section and reinforcement to resist axial load and moment. Design for Combined Bending and Axial Load (Short Column) Column Types 1) Spiral Column - more efficient for e/h < 0.1, but forming and spiral expensive 2) Tied Column - Bars in four faces used when e/h < 0.2 and for biaxial bending General Procedure The interaction diagram for a column is constructed using a series of values for Pn and Mn. The plot shows the outside envelope of the problem. General Procedure for Construction of ID Compute P0 and determine maximum Pn in compression Select a “c” value (multiple values) Calculate the stress in the steel components. Calculate the forces in the steel and concrete,Cc, Cs1 and Ts. Determine Pn value. Compute the Mn about the center. Compute moment arm,e = Mn / Pn. General Procedure for Construction of ID Repeat with series of c values (10) to obtain a series of values. Obtain the maximum tension value. Plot Pn verse Mn. Determine fPn and fMn. Find the maximum compression level. Find the f will vary linearly from 0.65 to 0.9 for the strain values The tension component will be f = 0.9 Example: Axial Load vs. Moment Interaction Diagram Consider an square column (20 in x 20 in.) with 8 #10 ( = 0.0254) and fc = 4 ksi and fy = 60 ksi. Draw the interaction diagram. Example: Axial Load vs. Moment Interaction Diagram Given 8 # 10 (1.27 in2) and fc = 4 ksi and fy = 60 ksi Ast 8 1.27 in 2 10.16 in 2 Ag 20 in. 400 in 2 2 2 Ast 10.16 in 0.0254 2 Ag 400 in Example: Axial Load vs. Moment Interaction Diagram Given 8 # 10 (1.27 in2) and fc = 4 ksi and fy = 60 ksi P0 0.85 f c Ag Ast f y Ast 0.85 4 ksi 400 in 10.16 in 2 2 60 ksi 10.16 in 2 1935 k Pn rP0 0.8 1935 k 1548 k [ Point 1 ] Example: Axial Load vs. Moment Interaction Diagram Determine where the balance point, cb. Example: Axial Load vs. Moment Interaction Diagram Determine where the balance point, cb. Using similar triangles, where d = 20 in. – 2.5 in. = 17.5 in., one can find cb cb 17.5 in. 0.003 0.003 0.00207 0.003 cb 17.5 in. 0.003 0.00207 cb 10.36 in. Example: Axial Load vs. Moment Interaction Diagram Determine the strain of the steel cb 2.5 in. 10.36 in. 2.5 in. s1 cu 0.003 cb 10.36 in. 0.00228 cb 10 in. 10.36 in. 10 in. s2 cu 0.003 cb 10.36 in. 0.000104 Example: Axial Load vs. Moment Interaction Diagram Determine the stress in the steel fs1 Es s1 29000 ksi 0.00228 66 ksi 60 ksi compression fs2 Es s1 29000 ksi 0.000104 3.02 ksi compression Example: Axial Load vs. Moment Interaction Diagram Compute the forces in the column Cc 0.85 f cb 1c 0.85 4 ksi 20 in. 0.85 10.36 in. 598.8 k Cs1 As1 fs1 0.85 f c 3 1.27 in 2 60 ksi 0.85 4 ksi 215.6 k Cs2 2 1.27 in 2 3.02 ksi 0.85 4 ksi 0.97 k neglect Example: Axial Load vs. Moment Interaction Diagram Compute the forces in the column Ts As fs 3 1.27 in 2 60 ksi 228.6 k Pn Cc Cs1 Cs2 Ts 599.8 k 215.6 k 228.6 k 585.8 k Example: Axial Load vs. Moment Interaction Diagram Compute the moment about the center h h a h M Cc Cs1 d1 Ts d 3 2 2 2 2 20 in. 0.85 10.85 in. 599.8 k 2 2 20 in. 215.6 k 2.5 in. 2 20 in. 228.6 k 17.5 in. 2 6682.2 k-in 556.9 k-ft Example: Axial Load vs. Moment Interaction Diagram A single point from interaction diagram, (585.6 k, 556.9 k-ft). The eccentricity of the point is defined as M 6682.2 k-in e 11.41 in. P 585.8 k [ Point 2 ] Example: Axial Load vs. Moment Interaction Diagram Now select a series of additional points by selecting values of c. Select c = 17.5 in. Determine the strain of the steel. (c is at the location of the tension steel) c 2.5 in. 17.5 in. 2.5 in. s1 cu 0.003 c 17.5 in. 0.00257 fs1 74.5 ksi 60 ksi (compression) c 10 in. 17.5 in. 10 in. s2 cu 0.003 c 17.5 in. 0.00129 fs2 37.3 ksi (compression) Example: Axial Load vs. Moment Interaction Diagram Compute the forces in the column Cc 0.85 f cb 1c 0.85 4 ksi 20 in. 0.85 17.5 in. 1012 k Cs1 As1 fs1 0.85 f c 3 1.27 in 2 60 ksi 0.85 4 ksi 216 k Cs2 2 1.27 in 2 37.3 ksi 0.85 4 ksi 86 k Example: Axial Load vs. Moment Interaction Diagram Compute the forces in the column Ts As fs 3 1.27 in 2 0 ksi 0 k Pn 1012 k 216 k 86 k 1314 k Example: Axial Load vs. Moment Interaction Diagram Compute the moment about the center h a h M Cc Cs1 d1 2 2 2 20 in. 0.85 17.5 in. 1012 k 2 2 20 in. 216 k 2.5 in. 2 4213 k-in 351.1 k-ft Example: Axial Load vs. Moment Interaction Diagram A single point from interaction diagram, (1314 k, 351.1 k-ft). The eccentricity of the point is defined as M 4213 k-in e 3.2 in. P 1314 k [ Point 3 ] Example: Axial Load vs. Moment Interaction Diagram Select c = 6 in. Determine the strain of the steel, c =6 in. c 2.5 in. 6 in. 2.5 in. s1 cu 0.003 c 6 in. 0.00175 fs1 50.75 ksi (compression) c 10 in. 6 in. 10 in. s2 cu 0.003 c 6 in. 0.002 fs2 58 ksi (tension) c 17.5 in. 6 in. 17.5 in. s3 cu 0.003 c 6 in. 0.00575 fs3 60 ksi (tension) Example: Axial Load vs. Moment Interaction Diagram Compute the forces in the column Cc 0.85 f cb 1c 0.85 4 ksi 20 in. 0.85 6 in. 346.8 k Cs1 As1 fs1 0.85 f c 3 1.27 in 2 50.75 ksi 0.85 4 ksi 180.4 k C Cs2 2 1.27 in 2 58 ksi 147.3 k T Example: Axial Load vs. Moment Interaction Diagram Compute the forces in the column Ts As f s 3 1.27 in 2 60 ksi 228.6 k Pn 346.8 k 180.4 k 147.3 k 228.6 k 151.3 k Example: Axial Load vs. Moment Interaction Diagram Compute the moment about the center h h a h M Cc Cs1 d1 Ts d 3 2 2 2 2 0.85 6 in. 346.8 k 10 in. 2 180.4 k 10 in. 2.5 in. 228.6 k 17.5 in. 10 in. 5651 k-in 470.9 k-ft Example: Axial Load Vs. Moment Interaction Diagram A single point from interaction diagram, (151 k, 471 k-ft). The eccentricity of the point is defined as M 5651.2 k-in e 37.35 in. P 151.3 k [ Point 4 ] Example: Axial Load vs. Moment Interaction Diagram Select point of straight tension. The maximum tension in the column is Pn As f y 8 1.27 in 2 60 ksi 610 k [ Point 5 ] Example: Axial Load vs. Moment Interaction Diagram Point c (in) Pn Mn 1 - 1548 k 2 20 1515 k 253 k-ft 2 in 3 17.5 1314 k 351 k-ft 3.2 in 4 12.5 841 k 500 k-ft 7.13 in 5 10.36 585 k 556 k-ft 11.42 in 6 8.0 393 k 531 k-ft 16.20 in 7 6.0 151 k 471 k-ft 37.35 in 8 ~4.5 0k 395 k-ft infinity 9 0 -610 k 0 e 0 k-ft 0 Example: Axial Load vs. Moment Interaction Diagram Use a series of c values to obtain the Pn verses Mn. Column Analysis 2000 1500 P (k) 1000 500 0 0 100 200 300 -500 -1000 M (k-ft) 400 500 600 Example: Axial Load vs. Moment Interaction Diagram Max. compression Column Analysis 1200 1000 Location of the linearly varying f. 800 fPn (k) 600 Cb 400 200 0 -200 0 100 200 300 -400 Max. tension -600 -800 fMn (k-ft) 400 500